Académique Documents

Professionnel Documents

Culture Documents

Design of Base Raft: Title Conveyor Tunnel 1Bc-3

Transféré par

Uttam Kumar GhoshTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of Base Raft: Title Conveyor Tunnel 1Bc-3

Transféré par

Uttam Kumar GhoshDroits d'auteur :

Formats disponibles

SO NO.

8401

SHEET NO.

REV. NO. R-1

PREPARED SR

APPROVED SN

DOC. NO. DATE

DESIGN OF BASE RAFT

1.0 General Data

1.1 Factored moment

Direction X : Along transverse direction (span)

Direction Y : Along longitudinal direction

Along X

SPAN MOMENT

Load Combination 201 PL. No.-734

Maxm. Moment Mx = 38.92 kN-m/m

Design Moment, Mxd Mxd = 38.92 kN-m/m

SUPPORT MOMENT

Load Combination 202 PL. No.- 819

Maxm. Moment Mxd = 43.6 kN-m/m

Design Moment, Mxd Mxd = 43.60 kN-m/m

1.2 Section data

Depth of section D = 300 mm

Width of the section b = 1000 mm

1.3 Material Properties

Compressive strength of concrete fck = 25 N/mm

2

Yield strength of steel fy = 500 N/mm

2

2.0 Computation of steel requirement in X direction

SPAN MOMENT

Steel rebar dia. ft = 16 mm

Clear cover tension steel c1 = 40 mm

Effective cover c1e = 48 mm

Effective depth d = 252 mm

Mu/bd = 0.61 N/mm

2

per m. width

As per SP-16 Table-3 100 As/bd = 0.145

As = 365.63 mm

2

> Minm reqd. 0.12%

Spacing of 16 dia bars = 300 mm 360 mm

2

/ m

Area of provided steel As = 670 mm

2

100 As/bd = 0.27

SUPPORT MOMENT

Steel rebar dia. ft = 16 mm

Clear cover tension steel c1 = 40 mm

Effective cover c1e = 48 mm

Effective depth d = 252 mm

Mu/bd = 0.69 N/mm

2

per m.

4 MANGOE LANE, 7

TH

FLOOR,

KOLKATA 700 001., INDIA

PROJECT URANIUM ORE PROCESSING PLANT

THIS DOCUMENT IS MBES

PROPERTY AND MUST NOT BE

USED EXCEPT IN CONNECTION

WITH MBES WORK.

REPRODUCTION, USE OR 2-M009-DC-6-007

McNally Bharat

TITLE CONVEYOR TUNNEL 1BC-3 ENGINEERING COMPANY

LIMITED

=

As per SP-16 Table-3 100 As/bd = 0.163

As = 411.12 mm

2

> Minm reqd. 0.12%

Spacing of 16 dia bars = 300 mm 360 mm

2

/ m

Area of provided steel As = 670 mm

2

100 As/bd = 0.27

3.0 Computation of shear steel

Load Combination 202 PL. No.-820

Maxm. Shear at d distance from wall face SQX = 0.207 N/mm

2

Load Combination 202 PL. No.- 824

Maxm. Shear at d distance from wall face SQY = 0.008 N/mm

2

Design Shear tv = 0.207

0.21 N/mm

2

% steel provided at the section = 0.27

As per SP 16 Table:61/Table:19 IS456:2000

tc 0.370 N/mm

2

(SAFE)

ALONG X

SPAN MOMENT

Provide 16Y @ 300 c/c as main reinf

SUPPORT MOMENT

Provide 16Y @ 300 c/c as main reinf

ALONG Y

Provide 12Y @ 300 c/c as transv. reinf

CHECK FOR DEPTH:

Ref: Chart 23 SP-16 (IS-456)

Reinf. percentage prov. = 0.27

Ratio ( span/eff. depth) = 23

For span = 4 Eff. Depth = 174 mm

( required )

Hence depth provided ( 300 mm ) is OK.

Dia @ mm c/c Dia @ mm c/c

=

=

m

SO NO. 8401

SHEET NO.

REV. NO. R-1

PREPARED SR

APPROVED SN

DOC. NO. DATE

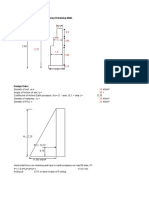

DESIGN OF TUNNEL WALL

`

1.0 General Data

1.1 Factored moment

Direction X : Along horizontal direction (span)

Direction Y : Along vertical direction

Along Y

SPAN MOMENT

Load Combination 203 PL. No.-653

Maxm. Moment My = 34.3 kN-m/m

Design Moment, Myd Myd = 34.30 kN-m/m

SUPPORT MOMENT

Load Combination 202 PL. No.- 422

Maxm. Moment Myd = 53.754 kN-m/m

Design Moment, Myd Myd = 53.75 kN-m/m

1.2 Section data

Depth of section D = 300 mm

Width of the section b = 1000 mm

1.3 Material Properties

Compressive strength of concrete fck = 25 N/mm

2

Yield strength of steel fy = 500 N/mm

2

McNally Bharat

TITLE CONVEYOR TUNNEL 1BC-3

ENGINEERING COMPANY LIMITED

4 MANGOE LANE, 7

TH

FLOOR,

KOLKATA 700 001., INDIA

PROJECT URANIUM ORE PROCESSING PLANT

THIS DOCUMENT IS MBES

PROPERTY AND MUST NOT BE USED

EXCEPT IN CONNECTION WITH

MBES WORK. REPRODUCTION, USE

OR DISCLOSURE OF THE CONTENTS

2-M009-DC-6-007

1.0M 59.88 KN/M2 59.88 + 9

3 M

Dia @ mm c/c Dia @ mm c/c Y Spacing Dia @ mm c/c Dia @ mm c/c

X

Y

WALL 300 THK

Z

2.0 Computation of steel requirement in Y direction

SPAN MOMENT

Steel rebar dia. ft = 16 mm

Clear cover tension steel c1 = 40 mm

Effective cover c1e = 48 mm

Effective depth d = 252 mm

Mu/bd = 0.54 N/mm

2

per m. width

As per SP-16 Table-3 100 As/bd = 0.128

As = 321.63 mm

2

< Minm reqd. 0.12%

Spacing of 16 dia bars = 300 mm 360 mm

2

/ m

Area of provided steel As = 670 mm

2

100 As/bd = 0.27

SUPPORT MOMENT

Steel rebar dia. ft = 16 mm

Clear cover tension steel c1 = 40 mm

Effective cover c1e = 48 mm

Effective depth d = 252 mm

Mu/bd = 0.85 N/mm

2

per m.

As per SP-16 Table-3 100 As/bd = 0.203

As = 510.59 mm

2

> Minm reqd. 0.12%

Spacing of 16 dia bars = 300 mm 360 mm

2

/ m

Area of provided steel As = 670 mm

2

100 As/bd = 0.27

3.0 Computation of shear steel

Load Combination 202 PL. No.-587

Maxm. Shear at d distance from wall face SQX = 0.018 N/mm

2

Load Combination 203 PL. No.- 708

Maxm. Shear at d distance from wall face SQY = 0.3 N/mm

2

Design Shear tv = 0.3

0.30 N/mm

2

% steel provided at the section = 0.27

As per SP 16 Table:61/Table:19 IS456:2000

tc 0.370 N/mm

2

(SAFE)

ALONG Y

SPAN MOMENT

Provide 16Y @ 300 c/c as main reinf

SUPPORT MOMENT

Provide 16Y @ 300 c/c as main reinf

ALONG X

Provide 12Y @ 300 c/c as transv. reinf

CHECK FOR DEPTH:

Depth provided is OK. Refer clarification given under Base Raft.

Dia @ mm c/c Dia @ mm c/c

=

=

=

SO NO. 8401

SHEET NO.

REV. NO. R-1

PREPARED SR

APPROVED SN

DOC. NO. DATE

DESIGN OF TOP SLAB

1.0 General Data

1.1 Factored moment

Direction X : Along transverse direction (span)

Direction Y : Along longitudinal direction

Along X

SPAN MOMENT

Load Combination 201 PL. No.-25

Maxm. Moment Mx = 47.3 kN-m/m

Design Moment, Mxd Mxd = 47.30 kN-m/m

SUPPORT MOMENT

Load Combination 202 PL. No.-15

Maxm. Moment Mxd = 44.33 kN-m/m

Design Moment, Mxd Mxd = 44.33 kN-m/m

1.2 Section data

Depth of section D = 300 mm

Width of the section b = 1000 mm

1.3 Material Properties

Compressive strength of concrete fck = 25 N/mm

2

Yield strength of steel fy = 500 N/mm

2

2.0 Computation of steel requirement in X direction

SPAN MOMENT

Steel rebar dia. ft = 16 mm

Clear cover tension steel c1 = 40 mm

Effective cover c1e = 48 mm

Effective depth d = 252 mm

Mu/bd = 0.74 N/mm

2

per m. width

McNally Bharat

TITLE CONVEYOR TUNNEL 1BC-3

ENGINEERING COMPANY

LIMITED

4 MANGOE LANE, 7

TH

FLOOR,

KOLKATA 700 001., INDIA

PROJECT URANIUM ORE PROCESSING PLANT

THIS DOCUMENT IS MBES

PROPERTY AND MUST NOT BE

USED EXCEPT IN CONNECTION

WITH MBES WORK.

REPRODUCTION, USE OR

2-M009-DC-6-007

As per SP-16 Table-3 100 As/bd = 0.178

As = 447.96 mm

2

> Minm reqd. 0.12%

Spacing of 16 dia bars = 300 mm 360 mm

2

/ m

Area of provided steel As = 670 mm

2

100 As/bd = 0.27

SUPPORT MOMENT

Steel rebar dia. ft = 16 mm

Clear cover tension steel c1 = 40 mm

Effective cover c1e = 48 mm

Effective depth d = 252 mm

Mu/bd = 0.70 N/mm

2

per m.

As per SP-16 Table-3 100 As/bd = 0.166

As = 418.36 mm

2

> Minm reqd. 0.12%

Spacing of 16 dia bars = 300 mm 360 mm

2

/ m

Area of provided steel As = 670 mm

2

100 As/bd = 0.27

3.0 Computation of shear steel

Load Combination 201 PL. No.-113

Maxm. Shear at d distance from wall face SQX = 0.265 N/mm

2

Load Combination 201 PL. No.- 119

Maxm. Shear at d distance from wall face SQY = 0.013 N/mm

2

Design Shear tv = 0.265

0.27 N/mm

2

% steel provided at the section = 0.27

As per SP 16 Table:61/Table:19 IS456:2000

tc 0.370 N/mm

2

(SAFE)

ALONG X

SPAN MOMENT

Provide 16Y @ 300 c/c as main reinf

SUPPORT MOMENT

Provide 16Y @ 300 c/c as main reinf

ALONG Y

Provide 12Y @ 300 c/c as transv. reinf

CHECK FOR DEPTH:

Depth provided is OK. Refer clarification given under Base Raft.

Dia @ mm c/c Dia @ mm c/c

=

=

=

Vous aimerez peut-être aussi

- SBC For B1a FillDocument11 pagesSBC For B1a FillAnonymous CQ4rbzLVEPas encore d'évaluation

- DWall Trench StabilityDocument4 pagesDWall Trench Stabilityvsnsfb100% (1)

- Pile Test 300diaDocument6 pagesPile Test 300diaTarkeshwar Lal SrivastavaPas encore d'évaluation

- Piled Raft FoundationsDocument79 pagesPiled Raft FoundationsVinod KumarPas encore d'évaluation

- Project - Park Hotel Location - PuneDocument7 pagesProject - Park Hotel Location - PunewaquarstrPas encore d'évaluation

- Masonry Retaining Wall - FinalDocument15 pagesMasonry Retaining Wall - Finalfarzi accoPas encore d'évaluation

- Filter Water TankDocument8 pagesFilter Water TankHemant Sonawadekar100% (1)

- Solution Shallow SETTLEMENT PDFDocument7 pagesSolution Shallow SETTLEMENT PDFRaja SyarifPas encore d'évaluation

- Wse Ibps CV DD 2Document146 pagesWse Ibps CV DD 2Lagnajit DasPas encore d'évaluation

- LiquefactionDocument5 pagesLiquefactionSantosh ZunjarPas encore d'évaluation

- 1 Ge DBR 7002 R0 20130614Document38 pages1 Ge DBR 7002 R0 20130614satoni12100% (1)

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignAnand.5Pas encore d'évaluation

- Tameer Consulting Associates: 0.52 RadiansDocument4 pagesTameer Consulting Associates: 0.52 RadiansAbhijit HazarikaPas encore d'évaluation

- Uplift CheckDocument2 pagesUplift CheckKTMOPas encore d'évaluation

- Well SinkingDocument153 pagesWell SinkingHari Krishna AaryanPas encore d'évaluation

- Jurutera Perunding Bersama SDN BHD Free Standing RC Retaining Wall Project Date Designed by Assumptions / PreamblesDocument34 pagesJurutera Perunding Bersama SDN BHD Free Standing RC Retaining Wall Project Date Designed by Assumptions / PreamblesKokKeiPas encore d'évaluation

- Crux Prestressing Pvt. LTD.: Pile DataDocument5 pagesCrux Prestressing Pvt. LTD.: Pile DataIlmtalabPas encore d'évaluation

- Eu 022Document10 pagesEu 022Khurshed Alam IndiaPas encore d'évaluation

- Deep Beam CheckDocument10 pagesDeep Beam CheckNikhil AgrawalPas encore d'évaluation

- Job Pile Design-450 (R1)Document3 pagesJob Pile Design-450 (R1)Kyle Foreman100% (1)

- SBC in Sand BH 4Document16 pagesSBC in Sand BH 4vishal kumarPas encore d'évaluation

- Soil+Surcharge From Adjacent Building On 20m RCC Pile Ø600mmDocument10 pagesSoil+Surcharge From Adjacent Building On 20m RCC Pile Ø600mmPrakash Singh RawalPas encore d'évaluation

- Oh - Tank - Foundation As Per Indian Standard CodeDocument7 pagesOh - Tank - Foundation As Per Indian Standard Codedsananda100% (1)

- Design of Ground Anchors For ClaysDocument1 pageDesign of Ground Anchors For ClaysMUHAMMAD ALIPas encore d'évaluation

- Analysis Sheet Pile 1Document7 pagesAnalysis Sheet Pile 1Azzam MahatmaPas encore d'évaluation

- Project: Client: Made by Date Location: Subject: Checked Revision Job NoDocument2 pagesProject: Client: Made by Date Location: Subject: Checked Revision Job NothaoPas encore d'évaluation

- Sump Design Chas 5.10.09Document22 pagesSump Design Chas 5.10.09battulas1953Pas encore d'évaluation

- Vikram Udyogpuri Limited, Ujjain, Madhya Pradesh SPML - Om Metals (JV)Document3 pagesVikram Udyogpuri Limited, Ujjain, Madhya Pradesh SPML - Om Metals (JV)arif_rubinPas encore d'évaluation

- Kentledge Design SpreadsheetDocument16 pagesKentledge Design Spreadsheethabibur Rahman Khan100% (1)

- Job Pile Design-450 (R1) PDFDocument2 pagesJob Pile Design-450 (R1) PDFprudencehpPas encore d'évaluation

- Beam Designation:-Member Number: - Load CombinationDocument2 pagesBeam Designation:-Member Number: - Load CombinationdhanarajPas encore d'évaluation

- Pre Cast Pile CapacityDocument19 pagesPre Cast Pile Capacityyogs_184Pas encore d'évaluation

- SHRT ColDocument3 pagesSHRT ColashokPas encore d'évaluation

- Project TitleDocument57 pagesProject Titlevishnumani3011Pas encore d'évaluation

- Footing DesignDocument37 pagesFooting DesignnaveenaeePas encore d'évaluation

- Soil Bearing (Axial) Capacity of Bored Pile: Design Data (Culvert No-07)Document4 pagesSoil Bearing (Axial) Capacity of Bored Pile: Design Data (Culvert No-07)Tanvir Shahrier Mahmud100% (1)

- Pile Length Calculation in Rock Is-14593 & IRC-78-1Document2 pagesPile Length Calculation in Rock Is-14593 & IRC-78-1Gouranga MunainPas encore d'évaluation

- SpreadsheetDocument7 pagesSpreadsheetChan Kin CheungPas encore d'évaluation

- Pile Capacity - FB - Mid PierDocument2 pagesPile Capacity - FB - Mid PierTriChandra MaharjanPas encore d'évaluation

- 07 DR. NAVEED Topic 6 Importance of Ductility in Structural Performance1Document69 pages07 DR. NAVEED Topic 6 Importance of Ductility in Structural Performance1Namrata ThapaPas encore d'évaluation

- Corbel Analysis Design 1.0Document19 pagesCorbel Analysis Design 1.0Eduardo Marques0% (1)

- Isolated Footing Design: Forces DetailsDocument7 pagesIsolated Footing Design: Forces DetailsMukhlish AkhatarPas encore d'évaluation

- V.A.S Design & Infra Consultants Pvt. LTDDocument13 pagesV.A.S Design & Infra Consultants Pvt. LTDPankaj SherwalPas encore d'évaluation

- L-TYPE RET WALL (WWW - Theengineeringcommunity.org) - 1Document46 pagesL-TYPE RET WALL (WWW - Theengineeringcommunity.org) - 1rymacPas encore d'évaluation

- 3 Pilecap DesignDocument6 pages3 Pilecap DesignUttam Kumar GhoshPas encore d'évaluation

- Stability Analysis of Plum WallDocument2 pagesStability Analysis of Plum WallShivendra KumarPas encore d'évaluation

- Design of Circular Walls-AnilDocument11 pagesDesign of Circular Walls-Anilnavneet3bawaPas encore d'évaluation

- Rock Anchor NDocument4 pagesRock Anchor NNitesh SinghPas encore d'évaluation

- Micro Pile DesignDocument3 pagesMicro Pile DesignPreethiPas encore d'évaluation

- Jack Well - Well FoundationDocument3 pagesJack Well - Well FoundationRamakanth PuttyPas encore d'évaluation

- Consolidation TestDocument8 pagesConsolidation TestSureshKumarPas encore d'évaluation

- FoundationDocument2 pagesFoundationikanyu79Pas encore d'évaluation

- Foundation DesignDocument24 pagesFoundation DesigneramitdhanukaPas encore d'évaluation

- Bore Pile DesignDocument2 pagesBore Pile DesignOng George SammyPas encore d'évaluation

- U Type Retaining WallDocument12 pagesU Type Retaining Wallharnishtanna212100% (2)

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document15 pagesLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110tttmm100% (1)

- Column DesignDocument68 pagesColumn DesignPiyush Tiwari100% (1)

- AK Consultant,: Design of R.C BeamDocument1 pageAK Consultant,: Design of R.C BeamVenkat BalajiPas encore d'évaluation

- Top Circular Slab DesignDocument3 pagesTop Circular Slab Designanshutomar791580% (5)

- Section 10 ExemptDocument2 pagesSection 10 ExemptUttam Kumar GhoshPas encore d'évaluation

- Q&A - Mughal DynastyDocument5 pagesQ&A - Mughal DynastyUttam Kumar GhoshPas encore d'évaluation

- Design of Concrete CorbelDocument2 pagesDesign of Concrete CorbelUttam Kumar GhoshPas encore d'évaluation

- Crane DesignDocument3 pagesCrane DesignUttam Kumar GhoshPas encore d'évaluation

- Design Parameters - Concrete Is 456Document5 pagesDesign Parameters - Concrete Is 456Uttam Kumar GhoshPas encore d'évaluation

- Period of TransitionDocument9 pagesPeriod of TransitionUttam Kumar GhoshPas encore d'évaluation

- SK-001 R0Document1 pageSK-001 R0Uttam Kumar GhoshPas encore d'évaluation

- Shear With TensionDocument1 pageShear With TensionUttam Kumar GhoshPas encore d'évaluation

- Wood and Armer MethodDocument1 pageWood and Armer MethodUttam Kumar GhoshPas encore d'évaluation

- Lap DevelopmentDocument4 pagesLap DevelopmentUttam Kumar GhoshPas encore d'évaluation

- Temperature Moment Calculation: H + K A +a +a KDocument2 pagesTemperature Moment Calculation: H + K A +a +a KUttam Kumar GhoshPas encore d'évaluation

- 1.5DL+1.5LL 1.5DL+1.5WLX+ 1.5DL+1.5WLX-1.5DL+1.5WLZ+ 1.5DL+1.5WLZ - 1.2DL+1.2LL+1.2WLX+ 1.2DL+1.2LL+1.2WLX - 1.2DL+1.2LL+1.2WLZ+ 1.2DL+1.2LL+1.2WLZDocument1 page1.5DL+1.5LL 1.5DL+1.5WLX+ 1.5DL+1.5WLX-1.5DL+1.5WLZ+ 1.5DL+1.5WLZ - 1.2DL+1.2LL+1.2WLX+ 1.2DL+1.2LL+1.2WLX - 1.2DL+1.2LL+1.2WLZ+ 1.2DL+1.2LL+1.2WLZUttam Kumar GhoshPas encore d'évaluation

- Thrust Block DesignDocument2 pagesThrust Block DesignUttam Kumar Ghosh100% (2)

- Is Steel SectionDocument38 pagesIs Steel SectionUttam Kumar GhoshPas encore d'évaluation

- Design of Concrete CorbelDocument2 pagesDesign of Concrete CorbelUttam Kumar GhoshPas encore d'évaluation

- Pile Load For 10 PilesDocument3 pagesPile Load For 10 PilesUttam Kumar GhoshPas encore d'évaluation

- Settlement - CalculationDocument2 pagesSettlement - CalculationUttam Kumar GhoshPas encore d'évaluation

- Bearing Capacity of Soil As Per IS-6403:1981: Input DataDocument1 pageBearing Capacity of Soil As Per IS-6403:1981: Input DataUttam Kumar GhoshPas encore d'évaluation

- Design Lined CanalsDocument2 pagesDesign Lined CanalsUttam Kumar GhoshPas encore d'évaluation

- Circular Hollow Concrete ColumnDocument3 pagesCircular Hollow Concrete ColumnUttam Kumar GhoshPas encore d'évaluation

- Steel Silo Quantity EstimationDocument4 pagesSteel Silo Quantity EstimationUttam Kumar Ghosh100% (1)

- For NB 300: Stress Diagram Is Drawn Only For Load Case-1Document7 pagesFor NB 300: Stress Diagram Is Drawn Only For Load Case-1Uttam Kumar GhoshPas encore d'évaluation

- For NB 300: Stress Diagram Is Drawn Only For Load Case-1Document7 pagesFor NB 300: Stress Diagram Is Drawn Only For Load Case-1Uttam Kumar GhoshPas encore d'évaluation

- Design of Unburned Clinker Silo Based On BS EN 1991-4:2006Document4 pagesDesign of Unburned Clinker Silo Based On BS EN 1991-4:2006Uttam Kumar GhoshPas encore d'évaluation

- Chimney FootingDocument3 pagesChimney FootingUttam Kumar GhoshPas encore d'évaluation

- Stair Wall JointDocument3 pagesStair Wall JointUttam Kumar GhoshPas encore d'évaluation

- Construction JointDocument3 pagesConstruction JointUttam Kumar GhoshPas encore d'évaluation

- 13C09-008-BBS-001 R0Document2 pages13C09-008-BBS-001 R0Uttam Kumar GhoshPas encore d'évaluation

- Stair Wall JointDocument3 pagesStair Wall JointUttam Kumar GhoshPas encore d'évaluation

- Base Mom ServiceDocument1 pageBase Mom ServiceUttam Kumar GhoshPas encore d'évaluation

- FastenersDocument46 pagesFastenerser_lalitgargPas encore d'évaluation

- Lined Split ClampDocument0 pageLined Split ClampSundar RamasamyPas encore d'évaluation

- Jagat Singh PurDocument6 pagesJagat Singh PurPrarthana MohapatraPas encore d'évaluation

- Ferrous and Nonferrous Alloys PDFDocument2 pagesFerrous and Nonferrous Alloys PDFRyan100% (1)

- SingaporeNon ConventionshipsDocument102 pagesSingaporeNon Conventionshipsmohdfirdausmokhtar100% (1)

- Ministry of Energy - Overview T&T Petroleum Post IndependenceDocument11 pagesMinistry of Energy - Overview T&T Petroleum Post Independenceronnysingh1Pas encore d'évaluation

- Annotations of The History of Curtain Walls in Industrial Buildings 1890 - 1920Document9 pagesAnnotations of The History of Curtain Walls in Industrial Buildings 1890 - 1920nachosollaPas encore d'évaluation

- Marine Superintendent - 2012Document2 pagesMarine Superintendent - 2012Muhammad IsalPas encore d'évaluation

- Aircraft at Pearl HarborDocument5 pagesAircraft at Pearl HarborRichard Lund100% (1)

- Material Requirements PlanningDocument40 pagesMaterial Requirements Planningazharama0% (1)

- ImportedfromGoogleNotebook MaterialScienceDocument97 pagesImportedfromGoogleNotebook MaterialScienceHarish PothepalliPas encore d'évaluation

- The Merchant Navy CareerDocument24 pagesThe Merchant Navy CareerMannMannPas encore d'évaluation

- A 1008 - A 1008M - 00 Qtewmdgtmda - PDFDocument7 pagesA 1008 - A 1008M - 00 Qtewmdgtmda - PDFTiến Lượng NguyễnPas encore d'évaluation

- Rehabilitacija - Okrugli Sto PrezentacijaDocument18 pagesRehabilitacija - Okrugli Sto PrezentacijajovzarePas encore d'évaluation

- Ports of India: Prepared byDocument23 pagesPorts of India: Prepared byvipulsenta3Pas encore d'évaluation

- Martin Catalog PDFDocument936 pagesMartin Catalog PDFFernando MedinaPas encore d'évaluation

- MPs Lesson PlanDocument2 pagesMPs Lesson PlanHareesha N GPas encore d'évaluation

- ABS - HSC - Navigation Bridge VisibilityDocument5 pagesABS - HSC - Navigation Bridge VisibilityDanilo ContrerasPas encore d'évaluation

- Abrasive Water Jet MachineDocument12 pagesAbrasive Water Jet MachineRav VenkateshPas encore d'évaluation

- Report On Importing To South AfricaDocument19 pagesReport On Importing To South AfricaNadine KadriPas encore d'évaluation

- Formulas and ConversionsDocument6 pagesFormulas and ConversionssubathraponniPas encore d'évaluation

- Content Uploads 109 200 37038 Aramex Comprehensive ProfileDocument10 pagesContent Uploads 109 200 37038 Aramex Comprehensive ProfileNoor AliPas encore d'évaluation

- Cause Inefficiency Bus Operation Flow at The Larkin Bus TerminalDocument61 pagesCause Inefficiency Bus Operation Flow at The Larkin Bus TerminalohferhanisabellaPas encore d'évaluation

- Al HelideckDocument8 pagesAl HelideckanandakoePas encore d'évaluation

- Self Compacting ConcreteDocument18 pagesSelf Compacting ConcreteKannan KandappanPas encore d'évaluation

- Astm d1785Document5 pagesAstm d1785Kehinde AdebayoPas encore d'évaluation

- AutomobileDocument7 pagesAutomobileankit807Pas encore d'évaluation

- Taig Lathe ManualDocument12 pagesTaig Lathe Manualspayt100% (1)

- RfiDocument5 pagesRfiPaul KwongPas encore d'évaluation

- ResumeDocument2 pagesResumeDeepak SharmaPas encore d'évaluation