Académique Documents

Professionnel Documents

Culture Documents

The 32 TT Fast-Erecting Crane.: Also On Crawler-Track Undercarriage

Transféré par

Amariei SebyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The 32 TT Fast-Erecting Crane.: Also On Crawler-Track Undercarriage

Transféré par

Amariei SebyDroits d'auteur :

Formats disponibles

The 32 TT fast-erecting

crane.

Also on crawler-track

undercarriage.

Multifunctional trolley

Automatic rail-gauge changeover

Automatic re-reeving

Double-reeved or double-quadruple-

reeved (optional extra)

Switch cabinet

Contactor control system

Hoist gear

3x pole-changing 11.0 kW

or with frequency converter

11.0 kW (optional extra)

EDC slewing gear

32 TT: standard feature 2.2 kW

32 TTR: standard feature 3.0 kW

Trolley travel

gear drive

2.6/3.5 kW

Operating support

Automatic locking

Control stand

(optional extra)

Crawler-track

undercarriage

Compact design

Low ground contact pressure

Excellent off-road mobility

Rapid relocation with full ballast

1

2

3

4

Multi-talented and supremely

economical.

With its innovative technology, the 32 TT fast-erecting crane with

double telescoping action redenes the performance standard in

its size category. The pioneering telescopic action represents a

major step forward. Such a varied range of tasks is unique. For

the operating company, this variety makes the 32 TT supremely

cost-effective.

For use on difcult terrain, this crane is also available on crawler

tracks as 32 TTR providing you with a wealth of benets on the

building site.

Powerful drives manu-

factured by Liebherr.

All drives are developed and

produced at the Liebherr

plant in Biberach. They have

been specially designed for crane use and

guarantee a long service life.

Unbelievably easy to erect.

The TT crane is not only compact to move

from site to site on the road, it can also be

erected extremely quickly. Its ingenious

erecting linkage lifts the crane on the sup-

port spindles automatically. One person can prepare the

TT crane for operation within about 30 minutes.

Adaptability means cost effectiveness.

Due to its combination of telescopic jib and

tower and the adaptability with several load

curves, the TT crane guarantees an exceptional

versatility. It can be adapted precisely to indi-

vidual operating situations as well as to the progress of work

on the construction site. With the crawler tracks of the 32 TTR,

rapid relocation from one site to another with full ballast causes

no problems.

Double telescoping action.

Both the tower and the jib of the 32 TT fast-

erecting crane can be extended and re-

tracted telescopically and varied in length

to suit every on-site operating situation.

2 3

1

Double

telescoping action.

Varying the length of the jib.

The jib of the 32 TT offers seven different jib lengths and can be positioned at two-metre

extension intervals to provide a xed working radius. This is possible both with the jib hori-

zontal or when it is raised to an angle. Working from the control panel, the jib is simply run

out to the desired length, using the trolley travel motor, and locked automatically.

Load moment to suit the task in hand.

Each of the jib length settings has its own load moment curve. As the jib is retracted step

by step, the usable load moment goes up each time by more than 10 %. In other words,

the telescopic jib matches load capacity to practical operating needs.

Load moment ranges:

30 mt - 57 mt

Variable hook height.

The TT cranes solid-wall tower also has a telescopic action. As the building progresses, the

tower can be extended upwards whether the jib is horizontal or raised at an angle - offering

three different height positions.

4 5

2

Obstructions are no problem for the 32 TT. Compact design, quick and easy movement.

The innovative 32 TT design principle makes this crane exceptionally versatile. For use on

difcult terrain, this crane is also available on crawler tracks as 32 TTR providing you with

a wealth of benets on the building site. The 32 TTR with crawler-track undercarriage is

noted for its outstanding mobility and therefore its exceptional economy. Soil pressure is

only 12 N/sq. cm in transport position and 21 N/sq. cm in service. Maximum travel speed

is 25 m/min with a drive rating of 22 kW.

With the tower retracted, this crane is ready for operation immediately after erecting.

The 32 TT standard crane equipped with its road axles can also be run into extremely

narrow gaps between buildings, with the tower either fully erected or half-erected. This

simplies work on the building site immensely and can save a lot of time in many

operating situations.

A single, versatile TT crane can handle a range of work

that would otherwise need several different types of

crane a denite economy bonus.

Adaptability means

cost effectiveness.

32 TTR on crawler-track undercarriage exibly used on the construction of a bridge.

6 7

3

Erecting is so simple.

The TT crane can be erected quickly and easily from the trans-

port position. The erecting linkage is operated conveniently from

the control panel, and the TT crane unfolds automatically.

The TT crane uses its erecting winch and two double guide arms

to reach the vertical position a completely new sequence of

erecting movements. When the tower is erected but not yet

extended telescopically the jib has already moved out to the

working position.

Unbelievably

easy to erect.

Complete and ready to operate.

After ballasting, the TT crane is complete and ready to op-

erate. The tower is locked to and released from the slew-

ing platform semi-automatically, using the Quick Connection

system. Only a wedge is used to secure the taper pins. The

inner tower is locked fully automatically to the outer tower.

An innovative ballasting technique.

The erecting winch gives the tower the generous ballasting

radius of up to 5 metres. The hoisting winch is then operat-

ed to place the ballasting slabs in position. The new semi-

automatic ballasting tongs and the equally new ballast slab

centring system set new standards in this area too.

The new ballasting tongs help to make ballasting far easier:

they are simply placed in position accurately and released

by hand the remainder of the process is automatic.

8 9

4

Hoisting and erecting winches.

The hoisting and erecting winches have separate drives. As an optional extra, a

hoist gear with frequency converter is available for continuous speed control be-

tween 0 and 50 m/min.

The EDC slewing gear.

The patented EDC slewing gear is another standard feature of the 32 TT crane.

Its electronic control system permits extremely sensitive, jolt-free slewing move-

ments. Continuously variable working speeds, electronic wind-load regulation, au-

tomatic damping to prevent load oscillation and peak moment limiting to prevent

excessive strain on the crane structure are further advantages of this well-proven

technology. Electronic monitoring allows the crane operator to reverse the slewing

gear by applying power in the opposite direction.

Trolley travel gear.

The trolley travel gear is equipped with a double pole-changing motor that not only

moves the trolley at speeds of either 20 or 40 metres/min but also extends and

retracts the jib.

Every detail carefully planned.

The multifunctional trolley.

The TTs multifunctional trolley changes gauge automatically as it passes from the heel section to the

outer section of the jib. Working from the control panel, the trolley is automatically halted if the jib is to be

telescopically extended. When the jib is at its new length, the crane operator locks it in position from the

control panel, after which the trolley is free to move again. Its as simple as that: when the trolley is halted,

the jib can be moved in or out; when the jib is halted, the trolley can be moved.

Powerful drive

systems.

Hoisting and erecting winches. EDC slewing gear. Trolley travel gear. Patented automatic rope re-reeving.

10 11

Liebherr-Werk Biberach GmbH

Postfach 1663, D-88396 Biberach an der Riss

+49 7351 41-0, Fax +49 7351 41-2225

www.liebherr.com, E-Mail: info.lbc@liebherr.com

Printed in Germany by MZA. LBC-626-04.07-3gb Subject to technical modications.

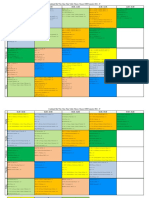

Performance overview.

Working radii

7 jib lengths:

18.0 m, 20.0 m, 22.0 m, 24.0 m,

26.0 m, 28.0 m, 30.0 m

Hook heights

14.5 m, 19.0 m, 24.0 m

20 raised

jib position

(optional extra)

Slewing radii

2.5 m, 2.75 m

Length for

road transport

16.7 m

Simple erecting

linkage

Patented ballasting

system

(optional extra)

Ballast

Self-centring (optional extra)

Semi-automatic ballasting tongs

Crane movement

in upright position

32 TT: on axles

32 TTR: on crawler tracks

Multifunctional trolley

Automatic rail-gauge changeover

Automatic re-reeving

Double-reeved or double-quadruple-

reeved (optional extra)

Switch cabinet

Contactor control system

Hoist gear

3x pole-changing 11.0 kW

or with frequency converter

11.0 kW (optional extra)

EDC slewing gear

32 TT: standard feature 2.2 kW

32 TTR: standard feature 3.0 kW

Trolley travel

gear drive

2.6/3.5 kW

Operating support

Automatic locking

Control stand

(optional extra)

Crawler-track

undercarriage

Compact design

Low ground contact pressure

Excellent off-road mobility

Rapid relocation with full ballast

This information is supplied without liability.

Vous aimerez peut-être aussi

- 40 T Crawler PDFDocument16 pages40 T Crawler PDFBharathyPas encore d'évaluation

- Macara Cu ContragreutatiDocument11 pagesMacara Cu ContragreutatiPaul VagrinPas encore d'évaluation

- KBK SistemiDocument28 pagesKBK SistemiGogy100% (1)

- 231 LTM 1500-8.1 PN 231.01.e12.2009 10586-0Document20 pages231 LTM 1500-8.1 PN 231.01.e12.2009 10586-0Adrian DaneaPas encore d'évaluation

- Liebherr LTM 1030-2.1 Mobile Crane - 30t - InformationDocument16 pagesLiebherr LTM 1030-2.1 Mobile Crane - 30t - InformationCallumWoodward100% (2)

- Manitou MRT Easy (EN)Document28 pagesManitou MRT Easy (EN)Manitou100% (1)

- Crawler Crane 1 PDFDocument12 pagesCrawler Crane 1 PDFagungPas encore d'évaluation

- GTC 700exDocument16 pagesGTC 700exMuhaiminPas encore d'évaluation

- Demag Bottom BlockDocument22 pagesDemag Bottom BlockGer Gut100% (1)

- Liebherr LTM 1040-2.1 Mobile Crane - 40t - InformationDocument16 pagesLiebherr LTM 1040-2.1 Mobile Crane - 40t - InformationCallumWoodward50% (2)

- MX-Utility 2011 enDocument6 pagesMX-Utility 2011 enKB0% (1)

- MT 3000 2 Offset VogeleDocument8 pagesMT 3000 2 Offset VogeleRobinson GuanemePas encore d'évaluation

- Eurobloc®: Electric Wire Rope Hoist For Load From 800 Up To 100.000 KGDocument8 pagesEurobloc®: Electric Wire Rope Hoist For Load From 800 Up To 100.000 KGf157839Pas encore d'évaluation

- 50 MT Crawler CraneDocument42 pages50 MT Crawler CraneramyaPas encore d'évaluation

- 360 Ton Liebherr LTM13001 SpecsDocument15 pages360 Ton Liebherr LTM13001 SpecsBqdcc6Pas encore d'évaluation

- Truss System NT - EN - Webb2011Document14 pagesTruss System NT - EN - Webb2011MAKRONPas encore d'évaluation

- RORUNNER System enDocument6 pagesRORUNNER System ennigelPas encore d'évaluation

- TK SeriesDocument4 pagesTK Seriescrys suryo prayogoPas encore d'évaluation

- Land Rig BrochureDocument9 pagesLand Rig Brochuresatya_dohare100% (1)

- Manitou MRT-X Easy (EN)Document28 pagesManitou MRT-X Easy (EN)Manitou67% (3)

- Rocker Shovel LoaderDocument7 pagesRocker Shovel LoaderDinesh dhakarPas encore d'évaluation

- Liebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFDocument8 pagesLiebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFJuan David Cabrera CardonaPas encore d'évaluation

- HTC-8670 - 70T CraneDocument40 pagesHTC-8670 - 70T CraneTaufik SinggihPas encore d'évaluation

- HTC-8670 70T PDFDocument40 pagesHTC-8670 70T PDFDian Ayu Angling SariPas encore d'évaluation

- Liebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0Document4 pagesLiebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0sheron100% (2)

- Wheel Load Design Calculation of Eot CraneDocument12 pagesWheel Load Design Calculation of Eot Craneram_babu_59100% (3)

- Tadano CranesDocument6 pagesTadano CranesvikrantparikhPas encore d'évaluation

- 456Document20 pages456Ovidiu RataPas encore d'évaluation

- Liebherr LTM 1090-4.1 Mobile Crane - 90t - InformationDocument18 pagesLiebherr LTM 1090-4.1 Mobile Crane - 90t - InformationCallumWoodward100% (2)

- 138 LTM 1150-5.1 PN 138.00.e06.2004Document5 pages138 LTM 1150-5.1 PN 138.00.e06.2004dsn_sarmaPas encore d'évaluation

- Gruas DemacDocument28 pagesGruas DemacJesus Perez0% (1)

- Precast ConcreteDocument6 pagesPrecast ConcreteMagdy BakryPas encore d'évaluation

- PQRS, T 28, TRTDocument138 pagesPQRS, T 28, TRTashokPas encore d'évaluation

- Hydraulic Crawler Crane: Standard ConfigurationDocument12 pagesHydraulic Crawler Crane: Standard Configurationmail_mulyadi5151Pas encore d'évaluation

- Sany SCC2500 SpecificationDocument21 pagesSany SCC2500 SpecificationDrajat Darmawan0% (1)

- Multipurpose Crane SystemDocument12 pagesMultipurpose Crane SystemPhu DoPas encore d'évaluation

- 07 Strand Jack Sedition 92834Document7 pages07 Strand Jack Sedition 92834vigobboPas encore d'évaluation

- Good Reasons To Swap From Trench Cutter To Hydraulic GrabDocument10 pagesGood Reasons To Swap From Trench Cutter To Hydraulic Grabrigaz6366Pas encore d'évaluation

- Stc300B Truck Crane 30 Tons Lifting CapacityDocument9 pagesStc300B Truck Crane 30 Tons Lifting CapacityLetácio OliveiraPas encore d'évaluation

- Pipe Handling EquipmentDocument4 pagesPipe Handling EquipmentJohn RongPas encore d'évaluation

- Pipelayer: Engine Weights Lift CapacityDocument16 pagesPipelayer: Engine Weights Lift CapacityEVCYPas encore d'évaluation

- Crane Control System For Crawler Cranes: Liccon 2Document12 pagesCrane Control System For Crawler Cranes: Liccon 2Krristiian RodrriguezzPas encore d'évaluation

- Pipelayer: Engine Engine (Continued)Document20 pagesPipelayer: Engine Engine (Continued)Daniel Marx ChillitupaPas encore d'évaluation

- CAT HighwallDocument16 pagesCAT HighwallJelena IvazPas encore d'évaluation

- 1078 Contmaster45tonnes 28 v4wDocument12 pages1078 Contmaster45tonnes 28 v4wJuan Manuel Hurtado Angulo0% (1)

- HydrospecDocument16 pagesHydrospecg665013Pas encore d'évaluation

- Compact Wheeled Excavators: Product RangeDocument16 pagesCompact Wheeled Excavators: Product Rangebalajiboss005Pas encore d'évaluation

- Repor T JobDocument2 pagesRepor T JobLiebherr67% (3)

- LIFTING DetailsDocument8 pagesLIFTING DetailsPSKUMAR2012Pas encore d'évaluation

- Demag DC-Com Chain HoistDocument4 pagesDemag DC-Com Chain Hoistmuhamedz100% (1)

- STC250Document9 pagesSTC250Abed Daher100% (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsD'EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsPas encore d'évaluation

- Scientific American Supplement, No. 312, December 24, 1881D'EverandScientific American Supplement, No. 312, December 24, 1881Pas encore d'évaluation

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheD'EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorD'EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorPas encore d'évaluation

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversD'EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversÉvaluation : 5 sur 5 étoiles5/5 (2)

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentD'EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- SDS Heat Sheets UpdateDocument15 pagesSDS Heat Sheets UpdateJeffrey ParentiPas encore d'évaluation

- Analysis of Delay Causes in Railway Passenger TransportationDocument8 pagesAnalysis of Delay Causes in Railway Passenger TransportationPABLO MAUROPas encore d'évaluation

- List of Irs SpecificationsDocument4 pagesList of Irs SpecificationsSambhav PoddarPas encore d'évaluation

- ARCH 1173: RSW: 01 Title: Wood Stairs Date Given: February 19, 2021 Due Date: February 25, 2021 ReferencesDocument7 pagesARCH 1173: RSW: 01 Title: Wood Stairs Date Given: February 19, 2021 Due Date: February 25, 2021 ReferencesJohn Nichole Hernandez DacanayPas encore d'évaluation

- Geosynthetics in Civil EngineeringDocument4 pagesGeosynthetics in Civil EngineeringJharolTQPas encore d'évaluation

- Federal Barge Lines CollectionDocument6 pagesFederal Barge Lines CollectionPaul BradeaPas encore d'évaluation

- Broadway Bridge Design Workshop PowerpointDocument47 pagesBroadway Bridge Design Workshop PowerpointMark ReinhardtPas encore d'évaluation

- Charland, M Technological NationalismDocument88 pagesCharland, M Technological Nationalismstephen_monteir4260Pas encore d'évaluation

- Easy Pinjaman Ekspress Repayment ScheduleDocument135 pagesEasy Pinjaman Ekspress Repayment ScheduleMazlan SayudinPas encore d'évaluation

- Control Relays M3FFR 1 ADocument1 pageControl Relays M3FFR 1 AamrPas encore d'évaluation

- The Largest Cities of CanadaDocument2 pagesThe Largest Cities of CanadaВалентина ВалентинаPas encore d'évaluation

- Life of Jay Gould, How He Made His Millions .. (1892)Document500 pagesLife of Jay Gould, How He Made His Millions .. (1892)Jello KokkustiPas encore d'évaluation

- JNPT Presentation NHAIDocument46 pagesJNPT Presentation NHAIAshish KohalePas encore d'évaluation

- Overseas Road Note 2Document49 pagesOverseas Road Note 2Iftikhar Kamran83% (6)

- Signalling in 25 KV Ac Electrified Section PDFDocument104 pagesSignalling in 25 KV Ac Electrified Section PDFpriyaranjan100% (1)

- Domestic Business Travel PolicyDocument14 pagesDomestic Business Travel PolicyPhani Kiran GurralaPas encore d'évaluation

- URE Product CatalogueDocument143 pagesURE Product CatalogueJuan Jaime Miranda Díaz100% (1)

- Your National Express eDocument1 pageYour National Express eAnkit JainPas encore d'évaluation

- Volvo V40 Price ListDocument7 pagesVolvo V40 Price Listdavid1064Pas encore d'évaluation

- Black Invention MythsDocument13 pagesBlack Invention MythsARTofATRPas encore d'évaluation

- Warsaw: December 2012 - January 2013Document67 pagesWarsaw: December 2012 - January 2013Sergio Castillejos MorenoPas encore d'évaluation

- Sea Freight in Logistics ManagementDocument111 pagesSea Freight in Logistics Managementnad_sh31100% (2)

- DPR - Volume II - Main Report - Part A (Version 2.1)Document292 pagesDPR - Volume II - Main Report - Part A (Version 2.1)Jobins JamesPas encore d'évaluation

- Final Draft Spec RDSO-2011-CG04 (Rev.1) Date 17.10.14 PDFDocument43 pagesFinal Draft Spec RDSO-2011-CG04 (Rev.1) Date 17.10.14 PDFAnkur GuptaPas encore d'évaluation

- Combined Slot Wise Time TableDocument2 pagesCombined Slot Wise Time TableSiddharth TiwariPas encore d'évaluation

- 06 Euro PlantDocument3 pages06 Euro Plantsimon_kunPas encore d'évaluation

- CIPET Inspection Call of OFB Tech 14.12.2022Document1 pageCIPET Inspection Call of OFB Tech 14.12.2022GNANA CHARAN GPas encore d'évaluation

- Design of Intersection-At Grade and Grade SeparatedDocument5 pagesDesign of Intersection-At Grade and Grade SeparatedEdmar TabinasPas encore d'évaluation

- Yearly Review of National Affairs 2017 in PDFDocument169 pagesYearly Review of National Affairs 2017 in PDFnagendraPas encore d'évaluation