Académique Documents

Professionnel Documents

Culture Documents

End Carriage DFW S E Assmebly

Transféré par

cutenganTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

End Carriage DFW S E Assmebly

Transféré par

cutenganDroits d'auteur :

Formats disponibles

290413 enGB 719 IS 845.

5

41238844.eps

214 276 44

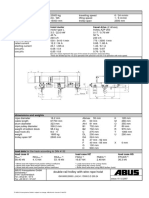

Assembly instructions

DRS 112, 125, 160, 200 wheel block system

2 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Contents

Further documents

Manufacturer Demag Cranes & Components GmbH

Drives

PO Box 67 58286 Wetter, Germany

Phone +49 (0)2335 92-0 Telefax +49 (0)2335 92-7676

Email: drives@demagcranes.com

www.drives.demagcranes.com

Original assembly instructions

General documents Order no.

DE EN FR ES

Brochures

Demag drives brochure 208 732 44 208 734 44 208 735 44 208 736 44

Demag wheel range brochure 208 722 44 208 724 44 208 725 44 208 726 44

Catalogues/technical data

Drive Designer Online www.demag-drivedesigner.com

Geared motors catalogue 203 150 44 203 151 44 203 152 44 203 153 44

DRS wheel block system 203 350 44 203 352 44 203 353 44 203 354 44

Demag DWS wheel set technical data 203 687 44 203 688 44 203 689 44 203 690 44

Geared travel motor catalogue Volume 3 Quick selection and gearbox limit torque DE / EN / FR 203 013 44

Geared travel motor catalogue Volume 3 Quick selection and gearbox limit torque IT / EN / ES 203 014 44 203 014 44

Assembly instructions

D 11 - D 41 helical gearbox assembly instructions 214 719 44 214 720 44 214 721 44 214 722 44

D 50 - D 90 helical gearbox assembly instructions 214 150 44 214 151 44 214 152 44 214 153 44

W 10 - W 100 angular gearbox assembly instructions 214 057 44 214 058 44 214 059 44 214 060 44

A 10 - A 90 offset gearbox assembly instructions 214 205 44 214 206 44 214 207 44 214 208 44

FG 06, FG 08, FG 10 gearbox assembly instructions 206 217 44 206 218 44 206 219 44 206 220 44

Motor assembly instructions Z motor range 214 227 44 214 228 44 214 229 44 214 230 44

KBA - KBF motor assembly instructions 214 317 44 214 318 44 214 319 44 214 320 44

Assembly instructions for brake accessories Z motor range 214 040 44 214 041 44 214 042 44 214 043 44

Assembly instructions/plug connection for KB and Z motor ranges 214 021 44 214 022 44 214 023 44 214 024 44

Encoders for Z motors, assembly instructions 214 371 44 214 372 44 214 373 44 214 374 44

DRS 112-200 wheel block system assembly instructions 214 275 44 214 276 44 214 277 44 214 278 44

DRS 250-500 wheel block system assembly instructions 214 326 44 214 327 44 214 328 44 214 329 44

DWS wheel set assembly instructions 214 132 44 214 133 44 214 134 44 214 135 44

0 Foreword 4

0.1 Copyright 4

0.2 After-sales service 4

0.3 Liability for defects 4

0.4 Limitations of liability 5

0.5 Denitions 5

1 Safety 6

1.1 Symbols 6

1.2 Intended use 6

1.3 Prohibited practices, improper use 6

1.3.1 Specication 6

1.3.2 Assembly 6

1.3.3 Environmental inuences 6

1.3.4 Maintenance 6

2 Brief technical description 7

2.1 Overview 7

2.2 Type designation key (example) for basic wheel blocks 8

2.3 Type plate 10

2.4 Paint nish 11

3 Receiving and storage 12

3.1 Checking goods on receiving 12

3.2 Transport 12

3.3 Storage 12

3.4 Weights 12

3 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4 Assembly and alignment 13

4.1 Travel wheel types 13

4.2 Assembly instructions 14

4.2.1 Top connection 14

4.2.1.1 Fitting universal shaft F for top connection 15

4.2.2 Side connection 16

4.2.2.1 Fitting universal shaft F for side connection 17

4.2.3 DRS 200 side connection with AD.50/WU.60 gearboxes 18

4.2.4 DRS 112 200 pin connection 20

4.2.5 DRS 200 pin connection with AD.50/WU.60 gearboxes 22

4.2.6 Fitting the wheel block 23

4.2.6.1 Axial retaining arrangement with track gauge adjustment 23

4.2.6.2 Pin set 24

4.2.6.3 Fitting pin connection (without welded plate) 25

4.2.6.4 Fitting pin connection (with welded plate) 25

4.2.6.5 Fitting universal shaft F for pin connection 26

4.2.6.6 Fitting pin connection with spacer plates for DRS 200 AD50/WU60 26

4.2.6.7 Fitting end connection with spacer plates 27

4.2.6.8 Fitting torque brackets for pin and end connection 27

4.2.6.9 Fitting torque brackets for pin and end connection

DRS 200 AD50/WU60 27

4.2.7 DRS 112 200 end connection 28

4.3 Manufacturing tolerances of crane runways 29

4.4 Alignment for top connection 30

5 Assembling drive elements 32

5.1 Torque brackets for individual and central drive units 32

5.1.1 A type offset gearboxes/W type angular gearboxes 32

5.1.2 A 50 type offset gearboxes 34

5.1.3 W 60 type angular gearboxes 35

5.2 Individual drive unit 36

5.2.1 A offset gearboxes 36

5.2.2 W angular gearboxes 36

5.3 Central drive unit 37

5.3.1 A offset gearboxes 37

5.3.2 W angular gearboxes 38

5.4 Central drive units with shaft protection 39

5.4.1 A 50 type offset gearboxes 39

5.4.2 W 60 type angular gearboxes 40

6 Fittings 41

6.1 Horizontal guide rollers 41

6.1.1 Fitting to wheel blocks 41

6.1.2 Fitting to steel superstructure 43

6.2 Buffer elements 44

6.2.1 DPZ cellular plastic buffers 44

6.2.2 DPG rubber buffers 44

7 Maintenance 46

7.1 Maintenance instructions 46

7.2 Travel wheel wear 47

7.2.1 Flange wear 47

7.2.2 Tread wear 47

7.2.3 Travel wheels of hardened design 47

7.3 Possible fault sources 47

8 Removing and tting travel wheels 48

EC manufacturer's declaration 51

4 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

0.3 Liability for defects

0 Foreword

You have purchased a Demag product. This equipment was manufactured in

accordance with state-of-the-art engineering principles.

These assembly instructions are designed to provide the operator with useful

instructions for safe and appropriate work on the product and to facilitate

maintenance.

Every individual given the task of transporting, installing, commissioning, operating,

maintaining and repairing our DRS wheel block system and additional equipment

must have read and understood

the assembly instructions

the safety regulations

the safety instructions in the individual chapters and sections.

The assembly instructions must be available to operating personnel at all times in

order to prevent operating errors and to ensure smooth and trouble-free operation

of our products.

These assembly instructions must be treated condentially. They should only be

used by authorised personnel. They may only be made available to third parties

with the written approval of Demag. All documents are protected within the sense

of copyright law.

No part of this documentation, in whole or in part, may be reproduced, distributed,

used or published in any way without specic prior consent. Infringements are an

offence resulting in obligatory compensatory damages.

All industrial rights reserved.

For technical information on Demag products and their systematic application,

please refer to one of our after-sales service centres, the relevant representative or

to our main ofce in Wetter.

See the details at the end of the assembly instruction for Drives contacts in

Germany, Austria and Switzerland.

These assembly instructions must be read carefully before installing and putting

the product into operation.

We assume no liability for any damage or malfunctions resulting from failure to

comply with the assembly instructions.

Any liability claims for defects must be made by quoting the order number

immediately on detecting the defect.

Any liability claims for defects are void in the event of:

inappropriate use,

faulty devices or equipment connected or attached to the product which are not

part of our scope of supplies and services,

use of non-genuine spare parts and accessories,

refurbishment or modication of the product unless approved by Demag in writ-

ing.

Wearing parts are not subject to liability for defects.

0.2 After-sales service

0.1 Copyright

5 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

All technical information, data and instructions for operation contained in these

assembly instructions were up to date on going to print and have been compiled

on the basis of our experience and to the best of our knowledge.

We reserve the right to incorporate technical modications within the scope of

further development of the wheel block system which is the subject of these

assembly instructions.

The information, illustrations and descriptions contained in these assembly

instructions are therefore only intended for information purposes.

The descriptions and illustrations contained in these assembly instructions do

not necessarily correspond to the scope of delivery or any subsequent spare part

delivery, either; the drawings and illustrations are not to scale.

Only documentation belonging to the actual order is valid.

We assume no liability for any defects, damage or malfunctions caused as a result

of operating errors, non-compliance with these assembly instructions or missing or

inappropriate repairs and maintenance.

We expressly point out that only genuine Demag spare parts and accessories

approved by us may be used. Accordingly, this also applies to other manufacturers'

parts supplied by us.

For safety reasons, the tting and use of spare parts or accessories which have

not been approved and unauthorised modication and conversion of the product

are not permitted and void any liability for damages resulting therefrom.

With the exclusion of any further claims, our liability for defects and liability

obligations for any defects pertaining to the products supplied or faults in the

documentation delivered or any negligence on our part are exclusively based on

the provisions of the original contract. Any further claims, in particular any and all

claims for damages, are excluded with the exception of legal claims in accordance

with product liability legislation.

Owner

Owners (employer, company) are dened as persons who own the product and

who use it appropriately or allow it to be operated by suitable persons.

Operating personnel

Operating personnel are dened as persons assigned by the owner of the product

to carry out special tasks such as installation, operation, setting-up, maintenance

including cleaning, fault elimination and transportation.

Specialist personnel

Specialist personnel are dened as persons assigned by the owner to carry out

specic tasks.

Qualied personnel

Qualied personnel are dened as persons who, owing to their technical train-

ing, knowledge and experience as well as knowledge of the relevant standards,

are able to assess the tasks given to them and identify potential hazards.

Trained person

Trained persons are dened as persons who have been instructed and trained

for the tasks assigned to them and on the possible hazards resulting from in-

correct handling and who have been informed about the required protective

devices, protective measures, relevant regulations, codes of practice, accident

prevention regulations and operating conditions and who have proven their

qualications.

Experienced technician

Experienced technicians are dened as persons, who, owing to their technical

training and experience, have sufcient knowledge of the product and are fa-

miliar with the relevant national industrial safety regulations, codes of practice,

accident prevention regulations, directives and generally accepted engineering

standards (e.g. EC Directives, German VDE and VBG regulations) enabling

them to judge the safe operating condition of the DRS wheel block system.

0.4 Limitations of liability

0.5 De nitions

6 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

1.3 Prohibited practises,

improper use

1.3.2 Assembly

1.3.3 Environmental inuences

1.3.1 Specication

1 Safety

1.1 Symbols

The following symbols and recommendations indicate potential safety hazards or

causes of damage:

Hazard warning

This symbol appears in the assembly instructions next to all instructions relating to

safety at work wherever a potential hazard to life and limb exists.

Follow these instructions at all times and be particularly careful and cautious.

Pass on safety instructions to all persons entrusted with working on the product

including the power supply.

In addition to the safety instructions, observe all general safety regulations and

codes of practise at all times.

Warning against dangerous electrical voltage

Contact with live parts (e.g. motors connected to the unit) can result in immediate

death. Protective covers (e.g. covers and enclosures) marked with this sign may

only be opened by qualied electricians. Before opening, all relevant operating,

control, feed or other voltages must be disconnected.

Operating hazard for the installation

This symbol in the assembly instructions indicates all warnings which, if not com-

plied with, may result in damage to the product, the installation or the goods to be

transported.

Demag DRS wheel blocks are complete travel units designed for moving loads

over a wide range of speeds in materials handling installations and general engi-

neering applications. They feature prepared connecting surfaces and are ready for

tting to support structures.

The relevant engineering guidelines must be observed when specifying the design.

See list of documents on page 2.

Under certain conditions, operation of the DRS wheel block system is prohibited as

this may result in malfunctions, equipment failure or hazard to life and limb, e.g. in

the case of:

Exceeding permissible loads

Exceeding the design service life

Occurrence of peak loads which were not considered in the design

Use of connecting elements not designed for use with the wheel block

Use of non-genuine Demag parts

Non-compliance with the assembly instructions

Tightening bolted connections without using a torque wrench

Incomplete assembly of connecting elements

Note: Safety measures must not be rendered inoperative or modied or used

contrary to the purposes for which they are intended.

Acidic, corrosive air as coolant

Explosion hazard atmospheres

Operation outside the permitted temperature range

Operation under prohibited ambient conditions

Note: Measures must be taken to ensure the travel wheels do not freeze up

under conditions of high humidity and low temperatures.

Exceeding the design service life

1.2 Intended use

1.3.4 Maintenance

7 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

2 Brief technical description

2.1 Overview

41621344.eps

The Demag DRS 112 to 200 wheel block system, suitable for loads up to

10,000 kg, is a concept designed to meet customer whishes.

The advantages of the system are:

Most favourable ground clearance conditions with Demag travel drives.

Robust aluminium housing with very good shape and position tolerances.

Variable basic design by tting various travel wheel materials and shapes.

Weather-resistant due to surface powder coating (RAL 7001, silver grey).

Special paint nish available on request. For further details on the paint nish,

see section 2.4.

Compensation of track gauge deviations of up to 8 mm possible.

Protected internal bearing arrangement.

Minimum maintenance due to bearings lubricated for life.

Travel wheel and bearings can be replaced thanks to bolted housing.

High installation availability since the housing does not necessarily need to be

removed to replace the travel wheel. Not having to realign the housing saves

time.

A damping element in the travel wheel reduces the load on the gearbox.

Sixth connection surface for tting (e.g. switching ags).

High-tensile bolted connections are dacromatised and therefore provided with

special surface protection.

The ange wear indicator facilitates preventive maintenance without any hazard

to the installation (see section 7.2).

41641055.eps

Residual ange indicator

Splined hub pro-

le to DIN 5480

8 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

2.2 Type designation key (example) for basic wheel blocks

DRS 112 A30 A 47 K H A10

Prepared for tting torque bracket

Gearbox:

A Offset gearboxes 10/20/30/40/50/

60/70/80/90

W Angular gearboxes 10/20/30/40/50/

60/70/80/90/100

X indicates: no gearbox considered

Guide roller arrangements, prepared for:

H Horizontal guide rollers, standard

X indicates: no guide rollers

Connection variants, prepared for:

K Top connection

W Side connection

B Pin connection

Travel wheel types

A GJS (GGG) with ange on both sides

B GJS (GGG) without ange

C Polyamide without ange, with larger diameter

D GJS (GGG) with ange on one side

E GJS (GGG) without ange, with larger diameter

F Hydropur without ange, with larger diameter

S Special travel wheel

Travel wheel tread b

1

:

for types A and D: see section 4.1

for types B, C, E, F: 0 indicated

Basic type

A. . Driven wheel block, for torque bracket tting and

indication of hub proles

MA . . Wheel block also driven and indication of the shaft

prole diameter

NA . . Non-driven wheel block

Size 112, 125, 160, 200

Demag wheel block system

9 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Travel carriage with 4 wheel blocks and a central drive unit

41239655.eps

1 DRS125-NA-A-47-K-X-X

2 DRS125-NA-A-47-K-X-X

3 DRS125-A35-A-47-K-X-A20

4 DRS125-MA35-A-47-K-X-X

Travel carriage with 4 wheel blocks and 2 individual drives

1 DRS125-NA-A-47-K-X-X

2 DRS125-NA-A-47-K-X-X

3 DRS125-A47-A-47-K-X-A20

4 DRS125-A47-A-47-K-X-A20

41641155.eps

Example for using the type designation key

1

2

3

4

1

2

4

3

10 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Example

Serial number

Order number/ASN number

Type code

41239044.eps

Serial number

Order number/ASN number

Type code

41239144.eps

2.3 Type plate

A type plate is applied to each of the end faces of DRS wheel blocks to identify the

unit for possible spare part orders.

The type plate may be covered by buffer or guide roller assemblies on one side

depending on the design of the wheel block. In this case, the information can

be read off the second type plate or relevant ttings can be relatively easily

disassembled.

A blank type plate form can be found below which you can use for your

documentation. Fill in the data of the wheel blocks used in your installation.

41239344.eps

Type plates are applied to both end

faces

11 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

2.4 Paint nish

DRS 112 to 200

Standard

The aluminium wheel block housings are provided with a weather-resistant powder

coating in RAL 7001 (silver grey) with a minimum thickness of 90 m before

leaving the factory.

Continuous coating quality is ensured by our works standard for wheel block

housings (ident. no. 012 326 99).

Special paint nish

For special paint nishes, wheel blocks can be supplied with a dual component

PUR nish coat at the request of the customer.

If the paint nish is to be applied by the customer, attention must be paid to

works standard for special paint nish on powder-coated wheel block surfaces

(ident-no. 012 328 99).

Acid-resistant paint nish

The surfaces of wheel blocks with a powder-coated nish may be used in environ-

ments with acid vapours without any treatment. Alternatively, a dual component

acid protection paint nish may be applied to appropriately pre-treated housings.

Wheel blocks must also be tted with ball bearings featuring double lip seals.

The gap between the housing and the cover is sealed with an acid-proof varnish.

12 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

3 Receiving and storage

3.1 Checking goods on

receiving

The scope of delivery is specied in the shipping papers.

Check the delivery immediately on receipt to ensure that it is complete and

examine it for any damage caused in transit.

Do not make any changes to the goods and packing material. Do not use the

goods yet.

Report any damage to the forwarding agent and request the required papers as

listed below.

Then contact the supplier.

Do not return the damaged goods until this is agreed with the supplier.

Observe local regulations and requirements for transport outside Germany.

The wheel block is supplied made up into one unit. Additional equipment may be

supplied in separate packing.

The wheel block is packed depending on the transport method and its size. Unless

otherwise agreed in the purchase contract, the packaging corresponds to the pack-

aging guidelines of Demag Cranes & Components GmbH.

Symbols used on the packing

3.3 Storage

Handle wheel block units with utmost care to avoid damage caused by careless

loading and unloading, for example.

Wheel blocks must be stored in dry places which are not subject to extreme tem-

perature uctuations, e.g. on a wooden support.

Unpacked wheel blocks must not be stacked on top of each other.

Note: Do not damage the paint nish.

Mechanical (scratches), chemical (acid, alkaline) or thermal (sparks,

welding beads, heat) damage will result in corrosion and failure of the

exterior protection.

3.2 Transport

Protect from heat Keep dry Fragile Top

Top-heavy No hooks Attach sling here Centre of gravity

412 83944 - 41284644.eps

3.4 Weights

DRS wheel block size Max. weight in kg

112 8,1

125 11,5

160 20,1

200 41,6

13 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Travel wheel type A B C

Flange-guided travel wheel

Spheroidal-graphite cast iron

Travel wheel without ange

Spheroidal-graphite cast iron

Travel wheel without ange

Polyamide

Size

Max. wheel

load

2)

d1

1)

-0,2

d2 b1

max

b2 s

Max. wheel

load

2)

d1

1)

-0,2

b2

Max. wheel

load

2)

d4

1)

b2

t mm mm mm mm mm t mm mm t mm mm

DRS 112 2,75 112 132 60 80 10 2,75 112 80 0,75 130 80

DRS 125 5,0 125 150 60 80 10 5,0 125 80 1,0 140 80

DRS 160 7,0 160 188 65 89 12 7,0 160 89 1,7 180 90

DRS 200 10,0 200 230 65 101 18 10,0 200 101 2,7 225 102

Travel wheel type D E F

Travel wheel with one ange

Spheroidal-graphite cast iron

Travel wheel without ange

Spheroidal-graphite cast iron

Travel wheel without ange

Hydropur

Size

Max. wheel

load

2)

d1

1)

-0,2

d2 b2

b1

2

s

Max. wheel

load

2)

d3

1)

-0,2

b2

Max. wheel

load

2)

d4

1)

b2

t mm mm mm mm mm t mm mm t mm mm

DRS 112 2,75 112 132 80 30 10 2,75 126 80 0,59 130 68

DRS 125 5,0 125 150 80 30 10 5,0 145 80 0,79 140 68

DRS 160 7,0 160 188 89 32,5 12 7,0 183 89 1,18 180 75

DRS 200 10,0 200 230 101 32,5 18 10,0 226 101 1,7 225 86

4.1 Travel wheel types

Standard DRS112 DRS200 designs

41618744.eps 41618844.eps 41618944.eps

41619044.eps 41619144.eps 41619244.eps

d

3

b2

4 Assembly and alignment

1)

Travel wheel diameter

2)

Max. wheel load in group of mechanisms 1Bm, 40 m/min, 40 C

14 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.2 Assembly instructions

4.2.1 Top connection

Lock nut

Zinc-ake coated

threaded pin

grade: 10.9

42092344.eps

x

Holes to accommodate

optional aligning pins

Sliding nut

DRS wheel

block size

Order no. Dimensions in mm

a2 a3 a4 a17 d5 d12 d13 l1 l2 l3

1)

min-max min-max

112 75362044 145 70 45

+ 4

7

45 M12 14

14,5

65 18,5-19 8-25

125 75362044 170 86 55

+ 4

7

55 M12 14 65 22,5-23 8-25

160 75252044 220 118 55

+ 3

5

55 M16 18 75 24,5-25 15-25

200 75252044 275 175 65

+ 3

5

65 M16 18 75 28,5-29 15-25

1)

Part no. includes: threaded pins and lock nuts

T

h

r

e

a

d

d

e

p

t

h

Fig. 1

Bore hole

arrangement

15 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

L3

L2

L1

D

2

D

1

4.2.1.1 Fitting universal shaft F for

top connection

41757644.eps 41757744.eps

Tools

Torque wrench, ring type, hexagon socket screw key, hexagon-socket offset screw

key

Preparation

Drill bore holes in connecting structure according to bore hole pattern (see page

14, g. 1.)

The bore holes to accommodate the eccentric aligning arrangement are only

required in connection with the aligning device, part no. 752 100 44 (see section

4.4 "Alignment").

Assembly

Screw the threaded pins by hand into the sliding nuts already tted in the

factory until they stop, and then screw them back out by a quarter of a turn.

Fit and tighten the locknuts by hand (counter by holding the threaded pin). Then

position and align the wheel block (see section 4.4 Alignment).

Counter the threaded pins (by holding in place using the hexagon socket at

the end of the pin) and tighten the locknuts with the corresponding tightening

torque.

Tightening torque DRS 112/125 = 130 Nm

DRS 160/200 = 330 Nm

After tting, close all unused through holes with the plastic plugs included in the

supply.

Fitting universal shaft F

Fit grooved ball bearing (5) onto drive shaft (1) and secure in the axial direction

using retaining ring (8).

Fit the pre-completed shaft in bearing seat (3) and secure using retaining ring

(7).

Then assemble entire shaft unit with connecting plate (2) and secure using

retaining ring (6). (Compensate axial play with shims (9/10)).

Remove lock nut (11) of the housing/cover connection.

Centre the drive shaft unit on the wheel block using two split sleeves (4) and

bolt together as a unit using the wheel block housing bolts.

Finally counter the drive shaft unit with locknuts (11).

Tightening torque DRS 112/125 = 36 Nm

DRS 160/200 = 72 Nm

DRS

wheel

block

size

Dimensions in mm

D1 D2 L1 L2 L3

f8

112 45

90

182 74 36

125 55 195 78

38

160 65

120

235 85

200 75 305 95 53

Wheel block in basic design A30/112 - A35/125 - A45/160 - A50/200

16 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

1 Split pin tted in wheel block in the factory

2 Flanged washer

3 Washer

4 Hexagon bolt

5 Lock nut

41619544.eps

4.2.2 Side connection

d14

l1

c3 c4

d8

a5

d9

a6

h

4a

7

a

8

C

C

C -C

42092044.eps

Bore hole arrangement

Wheel centre

MA/NA

A

1

) Part no. includes: collared sleeve and dacromatised bolted fastening parts

2)

Torque bracket for pin connection

DRS wheel

block size

Order no. Dimensions in mm

a5 a6 a7 a8 c3 c4 d8 d9 d14 h4 l1

1)

0,1 0,1 0,1 0,1 min-max D9 min-max

112 75362244 145 145 30 40 20-23 10,4 10,5 18,5 50 47 12-15

125 75222244 175 175 20 40 24,5-27,5 12 13 21 60 53,5 15-18

160 75252244 220 220 25 55 35,5-41,5 14,5 16,5 30

80

70 14-20

200 75302244 275 275 35 75 38,5-43,5 19 20,5 35 90 20-25

(only for drive on connecting plate side)

Drive on wheel block side (W1)

Drive on connecting plate side

(W2) (wheel block only in MA

basic design)

2)

17 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

L3

L2

L1

D

2

D

1

Tools

Torque wrench

Assembly

When the hexagon bolts are tightened, the split sleeves tted in the upper

part of the wheel block are pulled into the mounting plate of the steel support

structure by the ange washers. The bevel on the split pins must face towards

the connecting structure.

Then t two further hexagon bolts to the lower part of the wheel block with

washers on both sides.

Tightening torque DRS 112 = 55 Nm,

DRS 125 = 95 Nm

DRS 160 = 230 Nm

DRS 200 = 450 Nm

After tting, close all unused through holes with the plastic plugs included in the

supply.

4.2.2.1 Fitting universal shaft F for

side connection

41757944.eps 41757844.eps

DRS

wheel

block

size

Dimensions in mm

D1 D2 L1 L2 L3

f8

112 45

90

182 74 36

125 55 195 78

38

160 65

120

235 85

200 75 305 95 53

Fitting universal shaft F

Note

For DRS125 units, the protruding housing/cover bolted connection must be

replaced with the enclosed shorter cheese head screws with hexagon nuts.

Fit grooved ball bearing (5) onto drive shaft (1) and secure in the axial direction

using retaining ring (8).

Fit the pre-completed shaft in bearing seat (3) and secure using retaining ring

(7).

Then assemble entire shaft unit with connecting plate (2) and secure using

retaining ring (6). (Compensate axial play with shims (9/10)).

Remove both upper lock nuts from the wheel block.

Push the drive shaft unit onto both upper hexagon bolts.

Finally secure the drive shaft unit in place using the two adapter nuts (4) and

the bolt retaining arrangement included in the supply;

Tightening torque DRS 112 = 55 Nm

DRS 125 = 95 Nm

DRS 160 = 230 Nm

DRS 200 = 450 Nm

18 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.2.3 DRS 200 side connection with AD. 50/WU. 60 gearboxes

d14

d8

a5

d9

a6

a

7

a

8

C - C

c6

l1

c5

c3 c4 C

C

42092146.eps

Bore hole arrangement of the

connecting structure

MA/A

A

1)

Part no. includes: pins, spacer sleeve, retaining elements and zinc-ake coated bolted fastening parts

2)

Part no. includes: collared sleeves, adapter sleeves, retaining elements and zinc-ake coated bolted fastening parts

(only for drive on connecting plate side)

Drive on wheel block side (W1)

DRS wheel

block size

Order no. Dimensions in mm

a5 a6 a7 a8 c3 c4 c5 c6 d8 d9 d14 h4 l1

0,1 0,1 0,1 0,1 min-max min-max H13 min-max

200

MA/NA 75302244

1)

275 275 35 75

38,5-43,5

19

38,5-43,5

33 20,5 35 D9 80 90 20-25

A 75302644

2

) 39-44 33-38

19 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

41833644.eps

1 Split sleeve tted in wheel block in the factory

2 Component parts included in the torque bracket set

3 Retaining ring

4 Shim

5 Supporting washer

6 Hexagon socket screw

7 Adapter sleeve

8 Flanged washer

9 Hexagon bolt

10 Washer

11 Washer

12 Lock nut

Tools

Torque wrench

Assembly

When the hexagon bolts are tightened, the split sleeves tted in the upper

part of the wheel block are pulled into the mounting plate of the steel support

structure by the ange washers. The bevel on the split pins must face towards

the connecting structure.

Then t two further hexagon bolts to the lower part of the wheel block with

washers on both sides.

Tightening torque DRS 200 = 450 Nm

After tting, close all unused through holes with the plastic plugs included in the

supply.

20 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.2.4 DRS 112 200 pin connection

42278544.eps

42278644.eps

Drive side Non-driven side

42279344.eps 42279044.eps

Bore hole arrangement

Hollow prole section to DIN 59410/59411

1)

See section 4.2.6.1 for use of threaded pins or spacer elements.

41752544.eps

Wheel centre

Wheel centre

Wheel centre

1)

1)

Bore hole template

for side with welded

plate

Welded plate Superstructure

1

)

1)

1

)

(without tolerance)

Assembly bore hole

for central drive

arrangement

DRS wheel block

size

Dimensions in mm

a4 a5 a7 a8 a9 a10 a11 a12 a13 a14 a15 a16

1)

0,05 0,1

1)

0,1 0,1 0,1 0,1 0,1 0,1

112 148 145 52 40 64 10 50 60 79 93

125 162 175 60 40 72 41 10 58,5 68,5 92 77,5 108

160 206 220 70 55 90 56 12 75 90 110 97,5 135

200 266 275 90 75 118 70 10 105 115 140 120 168

21 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

42278744.eps

42279144.eps 42279244.eps

Without welded plate With welded plate:

suitable for aligning pin sets (L) or bolting

MA./MW torque brackets.

See section 4.2.6.3 for welded plate

1)

See section 4.2.6.1 for use of threaded pins or spacer elements.

2)

Check l

1

dimension, see section 4.2.6.2 Pin set

3)

See section 4.2.6.2 Pin set

1)

3) 3)

See section 4.2.6.3 for welded plate

Dimensions in mm

DRS wheel

block size

a18 c1 d9 d10 d14 d15 d16 l1

2)

l2 Hollow prole section to DIN

3)

D9/h8

1)

min max min a19 a20

75 96 18,5 20 50 M10 M8

119,5 127,5

8 200 x 120 x 8 24 47 112

129,2 137,2

74 98 21 23 60 M10 M8

119,0 127,0

8 200 x 120 x 8 24 54 125

128,2 140,2

86 110 30 32 80 M12 M10

138,0 150,0

10 260 x 140 x 10 30 70 160

150,2 160,2

103 130 35 38 80 M12 M10

170,0 182,0

10 260 x 180 x 10 30 90 200

182,2 194,2

22 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.2.5 Pin connection B

DRS 200 with AD.50/WU.60 gearboxes

42091846.eps

Wheel centre

Note: See section 4.2.6.1 for tting spacer elements

1

) Check l

1

dimension, see section 4.2.6.2 Pin set

2)

See section 4.2.6.2 Pin set

2)

Pin connection B

A

Without welded plate With welded plate

Wheel centre

A

Pin connection B

Bore hole template for A Bore hole template for A (welded plate side)

DRS wheel

block size

Dimensions in mm

a5 a7 a8 a18 a19 a20 c1 d9 d10 d14 l1

1)

l2

0,05 D9 max min

200 275 90 75 108,5 127 168 130 35 38 80 194 10

23 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

The track gauge can be changed using interchangeable spacer plates. Standard

assignments and maximum adjustment are shown in the table.

The spacer plates must be secured during transport to prevent them from being

lost.

Spacer plate

Spacer plates

Supporting

washer (play

compensated by

means of shims)

Pin

Retaining ring

The zinc-ake coated threaded pins are used to align the alignable pin connection

and then to secure the wheel block in the axial direction.

41758944.eps

1) Part no. includes per DRS: 4 threaded pins and 4 lock nuts

2) DRS 200 with AD50/WU60 gearbox only possible with spacer plates, see page 27

Spacer plates

Threaded pins

1 Pin

2 Threaded pin

3 Lock nut

4 Retaining ring

5 Supporting washer

6 Shim

7 Spacer plate

Adjusting the track gauge with

threaded pin and lock nut

Adjusting the track gauge with spacer

plates

41758844.eps

DRS Set part

no.

1)

Threaded pin grade:

45 H

Nut (3) tightening

torque

112 / 125 752 147 44 M10 x 40 60 Nm

160 / 200 2) 752 148 44 M12 x 50 104 Nm

Dimensions in mm Set per DRS consisting of

DRS Order no. l

max

b

max

Max. adjusting range Number and thickness

112 752 139 44 111 7,5 7 2 x 2mm + 2 x 3mm + 2 x 5mm

125 752 140 44 114 8 7,5 2 x 2mm + 2 x 3mm + 2 x 5mm

160 752 141 44 130 10 9,5 3 x 2mm + 2 x 3mm + 2 x 5mm

200 752 142 44 162 16 15,5 4 x 2mm + 2 x 3mm + 4 x 5mm

41758744.eps

4.2.6 Fitting the wheel block

4.2.6.1 Axial retaining arrangement

with track gauge adjustment

Not included in scope of supply

42275744.eps

24 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.2.6.2 Pin set

41751344.eps

Pin set for DRS 200 with AD50/WU60 gearbox

41752644.eps

1)

Pin set for the driven type.

Wheel

block

Order no. Type Weight Materials Surface

protection

Dimensions in mm

DRS DIN EN 10083

dD9 /

h8

l

l1 Washers

Shaft

retaining

rings

4x DIN 471

Size kg min. max. 1 2 2,5 3 3,5

112

753 737 44 S 00,6 42CrMo4+QT

Pin surface

zinc-

ake-

coated

18,5

143,5 119,5 127,5

4 8 18 x 1,5

753 738 44 L 00,7 36NiCrMo16+QT 153 129,2 137,2

125

752 337 44 S 00,8 42CrMo4+QT

21

143,5 119,0 127

4

8

20 x 1,75

752 338 44 L 00,9 36NiCrMo16+QT 161 128,2 140,2 12

160

752 637 44 S 02,0 42CrMo4+QT

30

168 138,0 150

4

12

30 x 2

752 638 44 L 02,1 42CrMo4+QT 178 150,2 160,2 10

200

753 137 44 S 03,2 42CrMo4+QT

35

202 170,0 182

4 12 35 x 2,5

753 138 44 L 03,4 42CrMo4+QT 214 182,2 194,2

DRS wheel

block size

Order no.

Type

Weight Materials Surface protection Dimensions in mm

DIN EN 10083

d

D9 / h8

D l

l1 Washers

Shaft retain-

ing rings

2x DIN 471

kg min. max. 1 2

200

752 947 44

1)

L 03,9 42CrMo4+QT Pin surface zinc-ake coated 35 40 235,5 170 194

2 x dia.

40

2 x dia.

35

24 x dia.

35

dia. 35 x 2,5

dia. 40 x 2,5

25 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Tools

Torque wrench, hexagon socket key

Preparation

Drill holes (bore holes must be free of paint) in the connecting structure (hollow

prole section or similar) according to the above bore hole pattern taking the basic

types (NA, A, MA) into consideration.

4.2.6.3 Fitting pin connection (without welded plate)

Fit the wheel block into the prepared hollow prole section and connect with the pin.

Fit the retaining rings and supporting washers included in the supply to secure

against axial movement and to secure the connecting pin in position free of play.

Adjusting the track gauge with threaded pin and lock nut:

(Not possible for DRS 200 with AD50/WU60)

Turn threaded pins (2) into the hollow prole above the pin. Counter threaded

pins (2) and secure with lock nuts (3).

Tightening torque for M8 = 36 Nm, M10 = 65 Nm.

Adjusting the track gauge with spacer plates

Fit distance elements (7).

Fit the geared motor (with torque bracket tted as described in section 5) by bolting

the complete drive to the hollow prole section using the retaining bolts included in

the supply.

4.2.6.4 Fitting pin connection (with welded plate)

Fit the wheel block into the prepared hollow prole section and connect with the

pin.

Place welding plate onto the correspondingly drilled side.

Fit the retaining rings and supporting washers included in the supply to secure

against axial movement and to secure the connecting pin in position free of play.

Align the wheel block.

Secure welding plate by tacking and then weld following welding instructions

(g. 1).

Adjusting the track gauge with threaded pin and lock nut:

(Not possible for DRS 200 with AD50/WU60, see page 27)

Turn threaded pins (2) into the hollow prole above the pin. Counter threaded

pins (2) and secure with lock nuts (3).

Tightening torque for M8 = 36 Nm, M10 = 65 Nm.

Adjusting the track gauge with spacer plates

Fit distance elements (7).

Welding instructions for welding

plate

Weld seam thickness a: DRS 112/125 = 3 mm

DRS 160/200 = 4 mm

41759144.eps Fig. 1

1 Pin

2 Threaded pin

3 Lock nut

4 Retaining ring

5 Supporting washer

6 Shim

7 Spacer plate

Adjusting the track gauge with

threaded pin and lock nut

Adjusting the track gauge with spacer

plates

41758844.eps 41758744.eps

26 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.2.6.6 Fitting pin connection with

spacer plates for

DRS 200 AD50/WU60

41759044.eps

Assembly

Place the wheel block in the completed hollow prole.

Variant with welded plate:

Place the welding plate on the correspondingly drilled side and secure, using

pins. Align the wheel block. Secure welding plate by tacking and then weld fol-

lowing welding instructions (see page 25, g. 1).

Variant without welded plate:

Secure using pins

Fit retaining rings and supporting washers to secure the pin in the axial direction

and secure it in position with little play on the non-driven side (small pin diam-

eter).

Fit distance plates

Fit the geared motor (with torque bracket tted as in section 5) on the large pin

diameter and then t retaining rings and supporting washers.

4.2.6.5 Fitting universal shaft F for

pin connection

L5

L4

L2

L1

D

2

D

1

41758144.eps

41758044.eps

Fitting universal shaft F

Fit grooved ball bearing (5) onto drive shaft (1) and secure in the axial direction

using retaining ring (8).

Fit the pre-completed shaft in bearing seat (3) and secure using retaining ring

(7).

Then assemble entire shaft unit with connecting plate (2) and secure using

retaining ring (6). (Compensate axial play with shims (9/10)).

Remove retaining rings (13), supporting washers (12) and lock nuts (11) from

the existing pin connection.

Push drive shaft unit onto the two pins.

Then t supporting washers (12) and retaining rings (13) again.

Fit lock nuts (11).

DRS

wheel

block

size

Dimensions in mm

D1 D2 L1 L2 L4 L5

f8 max

112 45

90

182 74

12

127

125 55 195 78 130

160 65

120

235 85

12

148

200 75 305 95 182

27 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Assembly

Weld end connection to the existing structure according to welding instructions

on page 28.

Fit wheel block in end connection and secure using pins.

For the driven variant: place the welding plate on the corresponding side and

weld according to welding instructions (see page 25, g. 1).

Fit retaining rings and supporting washers to secure the pin in the axial direction

and secure it in position with little play.

Fit distance elements (7).

Fitting end connection with spacer plates for DRS 200-AD50/WU60, see section

4.2.6.6.

41644555.eps

4.2.6.7 Fitting end connection with

spacer plates

41759744.eps

4.2.6.8 Fitting torque brackets for

pin and end connection for

DRS 112 200

Tightening torque

see section 5.1

Fit the geared motor (with torque bracket tted as described in section 5) by bolting

the complete drive to the welded-on plate using the enclosed locking screws (1) for

DRS 112/200.

Fit the geared motor (with torque bracket tted as described in section 5)

on the large pin diameter. Then t retaining rings and supporting washers.

41850444.eps

4.2.6.9 Fitting torque brackets for

pin and end connection for

DRS 200 AD50/WU60

1

28 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

41756744.eps

Not included in scope of supply

Bore hole template for alignable end connection and axial securing arrangement with threaded pins (by the customer)

41681444.eps

DRS wheel block size

Dimensions in mm

a4 a6 a9 d10 d15

112 148 145 64 20

M 10

125 162 175 72 23

160 206 220 90 32

M 12

200 266 275 118 38

Side with

welded plate

drilled by the customer

4.2.7 DRS 112 200 end connection

End connection dimensions

DRS

wheel

block

size

Order no. Dimensions in mm Options

a5 a6 a7 a8 a16 d9 d14 b1 b2 h l t1 t2 w1 w2 w3

Welded

plate

Pin set Spacer

plate set

1) 1) 1)

112

A

753 714 44 145 7 45 40 93 18,5 50 30 111 150 223 8 7 3 4 4

753 829 44 753 738 44

752 139 44

NA/MA 753 737 44

125

A

752 314 44 175 8 54 40 110 21,0 60 40 111 200 265 8 8 3 4 4

752 429 44 752 338 44

752 140 44

NA/MA 752 337 44

160

A

752 614 44 220 10 70 55 140 30,0 80 50 129 250 330 8 10 4 4 5

752 729 44 752 638 44

752 141 44

NA/MA 752 637 44

200

A

753 114 44 275 10 90 75 170 35,0 80 50 154 300 395 8 10 4 4 5

753 229 44 753 138 44

752 142 44

NA/MA 753 137 44

1)

After aligning and tacking, rst weld on the inside and then the outside.

Welded connections to tolerance class DIN 13920 BF assessment group DIN EN 5817 C

29 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.3 Manufacturing tolerances of

crane runways

S

m

i

n

S

S

m

a

x

41409444.eps

-

B

-

B

+

B

2000

2000

2

0

0

0

b

b

b

41409544.eps

2

0

0

0

-

C

+

C

2000

2000

c

c

c

41409644.eps

s

E

+

E

41409744.eps

Source: VDI 3576 Recommendation: Tolerance class 2

41760144.eps

Example for end connection with drive

Tolerance Crane runways

Designation Diagram Tolerance class 1 Tolerance class 2 Tolerance class 3

Tolerance A

of track gauge dimension s of

crane rails with reference to the

rail centre and crane runway

length

S

max

= s + A S

min

= s - A

for s 16 m:

A = 3 mm

for s > 16 m:

A = [3 + 0,25 (s - 16)]

A in mm

use s in m

for s 16 m:

A = 5 mm

for s > 16 m:

A = [5 + 0,25 (s - 16)]

A in mm

use s in m

for s 16 m:

A = 8 mm

for s > 16 m:

A = [8 + 0,25 (s - 16)]

A in mm

use s in m

Tolerance B

of the lateral straightness of the

rail head with reference to the

crane runway length.

Tolerance b

of the lateral straightness with

reference to 2000 mm measured

length (sample length) at any side

of the rail head

Position of a rail seen in plan

B = 5 mm

b = 1 mm

B = 10 mm

b = 1 mm

B = 20 mm

b = 2 mm

Tolerance C

of straightness with reference to

the height of the crane rail centre

and crane rail length

Tolerance c

of the lateral straightness with

reference to 2000 mm measured

length (sample length) at any side

of the crane runway

Position of a rail seen in elevation (longitu-

dinal slope)

C = 5 mm

c = 1 mm

C = 10 mm

c = 2 mm

C = 20 mm

c = 4 mm

Tolerance E

of the height with reference to

perpendicular measuring points at

every point of the crane runway

Position of runway in relation to one

another in elevation (transverse slope)

E = 0,5 x s

in mm

use s in mm

E

max

= 5 mm

E = 1 x s

in mm

use s in mm

E

max

= 10 mm

E = 2 x s

in mm

use s in mm

E

max

= 20 mm

30 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

4.4 Alignment for top

connection

Installation set

41620744.tif

41642655.eps

Wheel blocks must be precisely

aligned to prevent bearing damage

and, therefore, premature travel wheel

wear.

Make up the frame (frame assem-

blies) or the support superstructure

and roughly align them with the DRS

mounting positions.

Example for aligning a travel car-

riage.

A laser measuring device is available

for aligning.

Order no.: 752 100 44

Assembly instructions 214 825 44 for

alignment are included in the case.

41621255.eps

Alignment

Fast and optimum alignment of

wheel blocks using the Demag

alignment device with sliding nuts

and prepared connection openings

in the wheel block housing.

Only well aligned wheels reduce

wear to a minimum. Achievable

accuracy with measuring device:

1,6 .

Sliding nut arrangement, used for

alignment, offers a lateral align-

ment path of 3 mm.

31 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

42000444.eps

The values given in the diagram are sufcient for normal applications.

Further information on tolerances is given in the relevant standards and guidelines.

DIN 7168 General tolerances (clearance tolerances) Lengths and angles

DIN 8570 Clearance tolerances for welded constructions, Sheet 1 Dimensions for lengths and angles, Sheet 3 Shape and

position

VDI 3571 Manufacturing tolerances for bridge cranes

VDI 3576 Rails for crane installations, rail connections, rail mountings, tolerances

a in mm

0

,

5

a

(

m

m

)

Individual drive unit 2,5

Central drive unit 1,6

N 2 mm central drive unit

6 mm individual drive unit

L

2

m

m

f

o

r

L

1

0

m

32 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

5.1 Torque brackets for individual and

central drive units

5.1.1 A type offset gearboxes/W type angular gearboxes

5 Assembling drive elements

Step 1:

Fit the torque bracket to the geared motor

Examples:

Offset gearbox

Angular gearbox

Before the torque bracket is installed and depending on

the mounting position of the gearbox, check whether the

mounting bolts for step 2 (if covered by the gearbox) need

to be inserted in the corresponding bore holes of the torque

bracket before the torque bracket is attached to the gear-

box.

Tightening torques

All bolts are coated with a micro-encapsulated layer and must only be used once.

Step 1 4 bolts

T

o

r

q

u

e

b

r

a

c

k

e

t

a.) Hexagonal socket bolts with packing plate

b.) Locking bolt

Offset gearbox

MA112-1 23 Nm a.) M8x35

MA125-1 23 Nm a.) M8x35

MA125-2 20 Nm b.) M10x20

MA160-1 23 Nm a.) M8x35

MA160-2 20 Nm b.) M10x20

MA200-1 20 Nm b.) M10x20

Angular gearbox

MW112-1 42 Nm b.) M8x25

MW125-1 42 Nm b.) M8x25

MW125-2 85 Nm b.) M10x30

MW160-1 85 Nm b.) M10x35

MW160-2 130 Nm b.) M12x35

MW200-1 85 Nm b.) M10x35

MW200-2 130 Nm b.) M12x35

MW200-3 330 Nm b.) M16x35

b.)

a.)

42754544.eps

b.)

42754644.eps

42754744.eps

33 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

Step 2:

Fit the geared motor with torque bracket to the wheel block or connecting structure

Examples:

1)

After tightening the nuts, check the bolted connections of the wheel block

Step 2 4 or 6 nuts/bolts

T

o

r

q

u

e

b

r

a

c

k

e

t

Connected direct to the driven wheel block with

lock nuts

Connected to the connecting structure with locking

bolts

Offset gearbox

M8 / 35 Nm M8x20 / 35 Nm

M10 / 65 Nm M10x25 / 75 Nm

for angular gearbox

M8 / 35 Nm M8x20 / 35 Nm

M10 / 65 Nm M10x25 / 75 Nm

M10 / 85 Nm

1)

M10x25 / 85 Nm

Tightening torques

All bolts are coated with a micro-encapsulated layer and must only be used once.

Lock nut

Connecting structure

Locking bolt

42754844.eps

42755044.eps

42755144.eps

34 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

5.1.2 A 50 type offset gearboxes Fitting for top, side and pin connection arrangements

MA200-2 torque bracket connection

42115144.eps

42115244.eps

1 Offset gearbox

2 Torque bracket

3 Locking bolt

1 Offset gearbox

4 Pin (adapter sleeve for side

connection)

5 Polyamide collared sleeve

6 Polyamide washer

7 Supporting washer (40 x 58 x 2,5), note

outside diameter of 58 mm

8 Supporting washer

9 Retaining ring

10 Shim

11 Shim

12 Retaining ring

1 2 3

1 5 4 10 8 12

4

6 7

11

9 6 7

11

9

10 8 12

Assembly

Remove corrosion protection and paint from contact surface of gearbox and torque bracket.

Fit torque bracket (2) to gearbox (1) using locking bolts (3) included in the supply.

Assembly

Insert pin (4) into wheel block and secure against axial movement with supporting washers (8), shims (10) and retaining

ring (12).

Place polyamide collared sleeves (5) and drive unit (1) onto pin (4).

Fit polyamide washer (6), supporting washer (7), shim (11) and retaining ring (9) in the sequence indicated.

Tightening torque 130 Nm

Size Torque bracket Locking screw (3)

Wheel block Gearbox Quantity Dimensions

DRS 200 AD 50 MA200-2 8 M12x25

35 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

5.1.3 W 60 type angular gearboxes Fitting for top, side and pin connection arrangements

MW200-4 torque bracket connection

42116744.eps

1 Angular gearbox

2 Torque bracket

3 Locking bolts

Assembly

Remove corrosion protection and paint from contact surface of gearbox and torque bracket.

Fit torque bracket (2) to gearbox (1) using locking bolts (3) included in the supply.

42116644.eps

Assembly

Insert pin (4) into wheel block.

Place polyamide collared sleeves (5) and drive unit (1) onto pin (4).

Fit polyamide washer (6), supporting washer (7), shim (11) and retaining ring (9) in the sequence indicated.

Secure pin (4) against axial displacement with supporting washers (8), shims (10) and retaining ring (12) on the second

side.

1 2 3

4 5

1

6 7

11

9 9

11

7 6 4 10

8

12 10

8

12

1 Angular gearbox

4 Pin (adapter sleeve for side connec-

tion)

5 Polyamide collared sleeve

6 Polyamide washer

7 Supporting washer (40 x 58 x 2,5), note

outside diameter of 58 mm

8 Supporting washer

9 Retaining ring

10 Shim

11 Shim

12 Retaining ring

Tightening torque 130 Nm

Size Torque bracket Locking screw (3)

Wheel block Gearbox Quantity Dimensions

DRS 200 WU 60 MW200-4 8 M12x25

36 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

5.2 Individual drive unit

Journal shaft on one side with involute splines

41807044.eps

5.2.2 W angular gearboxes

41807355.eps

Clean drive shaft before tting, check splined prole section and lubricate with grease (Klber

Staburags NBU12 Alltemp or Fuchs Gleitmo WSP5040).

Assembly

Connect travel drive (2) with wheel block (1) as described in section 5.1.

Assembly

Connect travel drive (2) with wheel block (1) as described in section 5.1.

1 2

After tting a W 50 angular gearbox, check the bolted

connections of the wheel block for the correct tightening

torque (72 Nm).

5.2.1 A offset gearboxes

Clean drive shaft before tting, check splined prole section and lubricate with

grease (Klber Staburags NBU12 Alltemp or Fuchs Gleitmo WSP5040).

37 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

5.3 Central drive unit

41806944.eps

41807144.eps

Assembly

Connect travel drive (2) with wheel block (1) as described in section 5.1.

J ournal drive shaft arrangements do not need to be secured against axial displacement. Hollow drive shaft arrange-

ments (12) must be secured against axial displacement by tting retaining rings (8/9) and supporting washers (7/13) as

well as spacer ring (10) included in the supply.

Insert split sleeve (5) into connector (4).

Slide connector (4) onto drive shaft (11/12).

Insert central drive shaft (6) into wheel block (3).

Place spacer rings (10) onto central drive shaft (6) and push the shaft into the connector until it stops against the split

sleeve.

Determine the quantity of spacer rings (10) required until the retaining ring groove is reached.

Secure central drive shaft (6) against axial displacement by tting retaining ring (9).

Drive arrangement: Hollow shaft with solid shaft

8 7 10

13 9

12

11 5 4 6 9 10

Drive arrangement: Journal shaft on both sides with involute splines

5.3.1 A offset gearboxes

41833844.eps

10

7

8

9

13

12

Clean drive shaft before tting, check splined prole section and lubricate with grease (Klber

Staburags NBU12 Alltemp or Fuchs Gleitmo WSP5040).

38 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

5.3.2 W angular gearboxes

41807255.eps

41807444.eps

Drive arrangement: Hollow shaft with solid shaft

Assembly

Connect travel drive (2) with wheel block (1) as described in section 5.1.

J ournal drive shaft arrangements do not need to be secured against axial displacement. Hollow drive shaft arrange-

ments (12) must be secured against axial displacement by tting retaining rings (8/9) and supporting washers (7/13) as

well as spacer ring (10) included in the supply.

Insert split sleeve (5) into connector (4).

Slide connector (4) onto drive shaft (11/12).

Insert central drive shaft (6) into wheel block (3).

Place spacer rings (10) onto central drive shaft (6) and push the shaft into the connector until it stops against the split

sleeve.

Determine the quantity of spacer rings (10) required until the retaining ring groove is reached.

Secure central drive shaft (6) against axial displacement by tting retaining ring (9).

7 10 2 12 13 9 8

11 5 4 6 9 10

2 3

1

After tting a W 50 angular gearbox, check the bolted connections of the wheel block for the

correct tightening torque (72 Nm).

Drive arrangement: Journal shaft on both sides with involute splines

41833944.eps

10

7

8

12

13

9

Clean drive shaft before tting, check splined prole section and lubricate with grease (Klber

Staburags NBU12 Alltemp or Fuchs Gleitmo WSP5040).

39 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

11 5 4 6 9 10

14 15

3

2

1

5.4 Central drive units with shaft protection

5.4.1 A offset gearboxes

42065846.eps

41833844.eps

Assembly of central drive unit with shaft protection

Connect travel drive (2) with wheel block (1) as described in section 5.1. J ournal drive shaft arrangements do not need

to be secured against axial displacement. Hollow drive shaft arrangements (12) must be secured against axial displace-

ment by tting retaining rings (8/9) and supporting washers (7/13) as well as spacer ring (10) included in the supply.

Insert split sleeve (5) into connector (4).

Slide connector (4) onto drive shaft (11/12) and determine distance L1.

Cut shaft protection tube (14) to length L1 +10%.

Remove connector (4) again and slide on tube (14).

Insert central drive shaft into wheel block (3) and slide connector (4) back onto the shaft (11/12).

Place spacer rings (10) onto central drive shaft (6) and push the shaft into the connector until it stops against the split

sleeve. Determine the quantity of spacer rings (10) required until the retaining ring groove is reached.

Determine distance L2 and cut shaft protection tube (15) to length L2 +10%.

Push through central drive shaft (6) in the direction of wheel block (3) and slide on cut shaft protection tube (15) over the shaft.

Slide back central drive shaft (6) until stop is reached in connector (4) and secure against axial displacement by tting

spacer rings (10) and retaining ring (9).

Drive arrangement: Hollow shaft with solid shaft

8 7 10

13 9

12

Drive arrangement: Journal shaft on both sides with involute splines

10

7

8

9

13

12

41807144.eps

Clean drive shaft before tting, check splined prole section and lubricate with grease (e.g.

Klber Staburags NBU12 Alltemp or Fuchs Gleitmo WSP5040).

42753044.eps

Dimensions L1 and L2 for the length

of the shaft protection tubes

40 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

11 5 4 6 9 10

2 3

1

14 15

5.4.2 W angular gearboxes

42065946.eps

41807444.eps

Drive arrangement: Hollow shaft with solid shaft

7 10 2 12 13 9 8

Drive arrangement: Journal shaft on both sides with involute splines

Assembly of central drive unit with shaft protection

Connect travel drive (2) with wheel block (1) as described in section 5.1. J ournal drive shaft arrangements do not need

to be secured against axial displacement. Hollow drive shaft arrangements (12) must be secured against axial displace-

ment by tting retaining rings (8/9) and supporting washers (7/13) as well as spacer ring (10) included in the supply.

Insert split sleeve (5) into connector (4).

Slide connector (4) onto drive shaft (11/12) and determine distance L1.

Cut shaft protection tube (14) to length L1 +10%.

Remove connector (4) again and slide on tube (14).

Insert central drive shaft into wheel block (3) and slide connector (4) back onto the shaft (11/12).

Place spacer rings (10) onto central drive shaft (6) and push the shaft into the connector until it stops against the split

sleeve. Determine the quantity of spacer rings (10) required until the retaining ring groove is reached.

Determine distance L2 and cut shaft protection tube (15) to length L2 +10%.

Push through central drive shaft (6) in the direction of wheel block (3) and slide on cut shaft protection tube (15) over the shaft.

Slide back central drive shaft (6) until stop is reached in connector (4) and secure against axial displacement by tting

spacer rings (10) and retaining ring (9).

41833944.eps

10

7

8

12

13

9

Clean drive shaft before tting, check splined prole section and lubricate with grease (e.g.

Klber Staburags NBU12 Alltemp or Fuchs Gleitmo WSP5040).

42753044.eps

Dimensions L1 and L2 for the length

of the shaft protection tubes

41 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

6 Fittings

Permissible horizontal load: no more than 15 % of the wheel load.

The guide roller arrangement as a solo component can transmit at least 20 % of

the permissible wheel load.

Ordering information:

If a guide roller arrangement is specied in the type key when ordering a single

wheel block, this is prepared for tting before leaving the factory.

Exception: DRS 200 with top connection

The permissible horizontal force is limited to 10 % of the permissible wheel load.

DRS 112 200 with travel wheel type E

The permissible horizontal force is limited to 12 % of the permissible wheel load.

Rails with sloping head ank surfaces must not be used.

6.1 Horizontal guide rollers

DRS 112 200

6.1.1 Fitting to wheel blocks

42015744.eps

k =Rail width

DRS 112 125 160 DRS 200

41641644.eps

s s

DRS

wheel

block

size

Tightening

torques

Dimensions in mm

in Nm

Locking bolt

1 2 3 s

min

s

max

a a7 b

min

b

max

b1 d h h1 h2 l l1 l3 m n

112 130 1 5 80,5 4,5 30 70 20,6 52 126,5 38,2 76 180 5 60 125 24,5

125 130 1 5 88 4,5 30 70 20,6 62 143 50 95,5 192 5 60 140 25,4

160 330 130 1 5 109 7,5 30 80 23,8 72 162 65 93,5 230 6 72 173,5 29

200 330 130 1 5 133 8 40 90 27 80 174 75 92 250 6 80 210 33

42 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

41641944.eps

Assembly

Fit the washer with the wide slot facing downwards on the raised guide to pre-

vent turning.

Fit the pins with the at-sided heads in the slot to prevent turning.

Fit guide rollers to wheel block as shown above and tighten by hand.

Tighten locking bolts (2/3) to specied tightening torque (see table).

Adjust roller distance dimension s and align the guide rollers with the rail.

Tighten locking bolts (1) with specied torque (see table).

Fitting for wheel block not prepared before leaving the factory

If a wheel block is tted with a roller guide arrangement at a later date, the follow-

ing additional measures must be carried out:

Drill bore holes on cover side to diameter d4 and depth a8 and t split sleeves

with slot facing upwards .

Subsequently t two threaded inserts into the end face.

41641844.eps

DRS wheel block

size

Travel wheel type

a

mm

Order no. Retrotting set part no.

Horizontal guide roller

assembly

1)

Fitted to wheel block

2)

Fitted to connecting structure

1)

112

B 81 753 610 44 753 611 44 753 610 44

E 87 753 710 44 753 711 44 753 710 44

125

B 88 752 210 44 752 211 44 752 210 44

E 98 752 310 44 752 311 44 752 310 44

160

B 109 752 510 44 752 511 44 752 510 44

E 119 752 610 44 752 611 44 752 610 44

200

B 133 753 010 44 753 011 44 753 010 44

E 145 753 110 44 752 111 44 753 110 44

1) Part no. includes roller guide arrangement and bolted fastening parts

2) Part no. includes roller guide arrangement, threaded sleeves and roll pins

Split sleeve (slot

facing upwards)

Locking bolt 1

Locking bolt 3

Locking bolt 2

Threaded insert

Washer

Pin

Size

Locking bolt tightening torques

Dimensions in mm

1 2 3 s

min

s

max

a8 d4

DRS 112 130 Nm 1 5 35 13

DRS 125 130 Nm 1 5 35 18

DRS 160 330 Nm 130 Nm 1 5 40 23

DRS 200 330 Nm 130 Nm 1 5 45 28

d

4

a8

Rz63

s k s

43 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

6.1.2 Fitting to steel superstructure

Permissible horizontal load: no more than 20% of the wheel load

41679055.eps 41679155.eps

Drill out holes for split sleeves to d

5

H12

after tting.

Size

Dimensions in mm

a a1 a2 a3 a4 a5 a6 a9 a10 a11 d1 d2 d3 d5

DRS 112 40 48 22 40 76 102 13 6 12,5 8

DRS 125 50 56 20,5 38,5 95 113 13 6 12,5 8

DRS 160 54 58 26 49,5 93,5 148,5 13 8 16,5 10

DRS 200 62 22 62 28 54 92 157 16 132 36 13 10 16,5 12

d2

d

1

a

6

a

5

a2

a

d

2

d

3

a

4

a

3

a

6

a

1

0

a

5

d

3

d

1

d

2

a

9

a

3

a

1

1

a

4

a

a1

44 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

41642444.eps

Screw threaded pin (2) into buffer

(1) until maximum I2 dimension is

reached.

Screw buffer into threaded insert in

wheel block.

6.2 Buffer elements

6.2.1 DPZ cellular plastic buffers

Possible tting arrangement to end of DRS 112 200 wheel blocks without horizontal guide roller arrangement

41671244.eps

DPZ cellular plastic buffers

DRS wheel

block size

Buffer

Dimensions in mm

no guide rollers with guide rollers

d1 d2 l1 l2 Threaded pins (2)

112

125

160

200

DPZ 070 70 65 70 26 M12 x 30 M12 x 55

DPZ 100 100 95 100 26 M12 x 30 M12 x 55

DPZ 130 130 122 120 26 M12 x 30 M12 x 55

DPZ 160 160 155 150 40 M12 x 30 M12 x 55

41671744.eps

DPG rubber buffers

6.2.2 DPG rubber buffers

DRS wheel

block size

Buffer

Dimensions in mm

no guide rollers with guide rollers

d1 d2 l1 l2 Threaded pin (2)

112

125 160

200

DPG 063 063 56 067 26 M12 x 30 M12 x 55

DPG 080 080 71 084 26 M12 x 30 M12 x 55

DPG 100 100 90 105 26 M12 x 30 M12 x 55

45 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

41642555.eps

To ensure uniform buffer impact with

a horizontal guide roller arrangement

tted to only one wheel block, two

shims, type E2 must be tted between

the buffer and wheel block on the

opposite side.

41642244.eps

41642344.eps

2 3 E1 1

Remove the locking bolt and

screw threaded pin (2) up to max.

dimension l4 into the tapped insert in

the wheel block.

Tighten locknut (3) and counter with

threaded pin using hexagon socket.

(Tightening torque 130 Nm).

Fit shim, type E1, with the ribs facing

the wheel block side and screw the

buffer onto the threaded pin.

2xE2 1xE1

s

2

s

2s

1

End stop

1) Only one type E2 shim required.

Fig. 11

Possible tting arrangement to end of DRS 112 200 wheel blocks with horizontal guide roller arrangement

(gs. 11 12)

Fig. 12

DRS 112 200

Guide roller tting including

distance elements

DRS wheel

block size

Buffer

l4

mm

112 / 125

DPZ 070

11 0,5

DPZ 100

160 / 200

DPZ 070

14 0,5

DPZ 100

DPZ 130

DPZ 160

Buffer Shim

E1 E2

s1 s2

DPG 63 / DPZ 70 14 10

DPG 80 / DPZ 100 20 12,5

DPZ 130 / DPG 100 25 16

DPZ 160

1)

15 21

46 2

1

4

2

7

6

4

4

_

e

n

_

2

9

0

4

1

3

7 Maintenance

7.1 Maintenance

instructions

DRS wheel block

Owing to their design, DRS wheel blocks are maintenance free.

ZNA - ZBA - ZBF motors

See assembly instructions ident no. 214 228 44