Académique Documents

Professionnel Documents

Culture Documents

Kodak Impresora Placas Dryview 8900 - r3 - Service Manual

Transféré par

manolozamoraDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kodak Impresora Placas Dryview 8900 - r3 - Service Manual

Transféré par

manolozamoraDroits d'auteur :

Formats disponibles

EASTMAN KODAK COMPANY, 2005 HEALTH GROUP

Confidential

Restricted

Information

{Adjust/Replace}{Production}{Health Group}{ExternalAndInternal} Publication No. 8F1621

15JUL05

ADJUSTMENTS AND REPLACEMENTS

for the

Kodak DryView 8900 LASER IMAGER RELEASE 3

Service Code: 4878

Important

Qualified service personnel must do these procedures.

H199_0500AC

ADJUSTMENTS AND REPLACEMENTS

15JUL05

8F1621

Page

2 of 186

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodaks negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

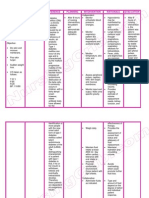

Description Page

Table of Contents

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PROCESSOR - Temperature of DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PROCESSOR - BRUSHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PROCESSOR - PHOTODETECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PROCESSOR - DIVERTER AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IMAGING AY - ENCODER READHEAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

IMAGING AY - MAGNET WAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

IMAGING AY - Index Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

IMAGING AY - Film Skew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

+5 V DC POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

LOCAL PANEL - Calibration of the TOUCH SCREEN. . . . . . . . . . . . . . . . . . . . . 39

FILM FEED ROLLER DRIVE AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DICOM RASTER ENGINE (DRE) COMPUTER and COVER. . . . . . . . . . . . . . . . . 44

DRE COMPUTER - HARD DRIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DRE COMPUTER - DVD DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

DRE COMPUTER - POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DRE COMPUTER - FANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

EXPOSURE BRIDGE AY (EBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ROLLBACK MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

ROLLBACK CARTRIDGE PRESENCE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . 57

ROLLBACK HOME SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ROLLBACK OPEN SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

ROLLBACK MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

ROLLBACK ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

RF TAG ANTENNA BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

ADJUSTMENTS AND REPLACEMENTS

15JUL05

8F1621

Page

3 of 186

RF TAG READER BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PICKUP AND FEED MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

FILM FEED ROLLER DRIVE AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

FILM FEED HEEL AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

HEEL PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

FEED ROLLER OPEN SENSOR and FILM AT FEED SENSOR . . . . . . . . . . . . . 73

PICKUP HOME SENSOR and CUPS ENGAGED SENSOR . . . . . . . . . . . . . . . . . 74

FILM OUT SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

FEED ROLLER CLOSE MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

FILM FEED DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

FILM FEED MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

PICKUP MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

VACUUM VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

VACUUM PUMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

SUCTION CUPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

CARTRIDGE CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

VERTICAL TRANSPORT MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

FILM AT PROCESSOR SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

VERTICAL TRANSPORT UP and DOWN MOTORS . . . . . . . . . . . . . . . . . . . . . . . 91

VERTICAL TRANSPORT BELTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

PROCESSOR - ENTRANCE GUIDE AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

PROCESSOR - ENTRANCE GUIDE FRAME. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

PROCESSOR - VERTICAL DRUM GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

PROCESSOR - DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

PROCESSOR - DRUM DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

PROCESSOR - MOTOR DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

PROCESSOR - COOLING FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

PROCESSOR - UPPER FAZ TRAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

PROCESSOR - LOWER FAZ TRAP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

PROCESSOR - DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PROCESSOR - BRUSH AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PROCESSOR - PHOTODETECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

PROCESSOR CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

DENSITOMETER LIGHT SOURCE BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

FILM AT DENSITOMETER SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

DENSITOMETER BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

SORTER TRAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

TURNAROUND AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

EXIT PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

SORTER AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

SORTER - DRIVE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

SORTER - STEPPER DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

ADJUSTMENTS AND REPLACEMENTS

15JUL05

8F1621

Page

4 of 186

SORTER - TORQUE ACTUATORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

SORTER - EMITTER BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

SORTER - DETECTOR BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

SORTER CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

IMAGING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

PLATEN FILM TRANSPORT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

PLATEN SWEEP MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

PLATEN FEED MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

PLATEN LOAD MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

PLATEN CENTERING MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

PLATEN FILM CENTERING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

PLATEN LOAD HOME SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

FILM AT PLATEN SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

PLATEN CENTERING HOME SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

PLATEN SWEEP HOME SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

START OF PAGE SENSOR BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

TRANSLATION HOME and TRANSLATION LIMIT SENSORS. . . . . . . . . . . . . . . 148

MAGNET WAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

OPTICS ELECTRONICS AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

OPTICS AND CARRIAGE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

POWER MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

BACK DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

ELECTRONICS PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

DRAWER PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

SIDE PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

DRAWER LATCH AY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

DOOR LATCH AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

LOCAL PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

DUCT FILTER DOOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Additional Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Making a Configuration Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Restoring Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Upgrading the DRE with a New Version of the System Software - Ghosting 174

Upgrading the Software Applications for the MCS MASTER CPU BOARD and the

MICRO BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Upgrading the Microcontroller Application when a New MICRO BOARD is

Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

5 of 186

Section 1: Adjustments

PROCESSOR - Temperature of DRUM

Adjustment Specification

Prerequisites:

None

To Check:

Important

The TEMPERATURE METER AND PROBE must receive calibration together once a year.

1. Send the METER, PROBE, and a CALIBRATION FORM to:

National Calibration and Testing Laboratories

5960 Madison Avenue West

Minneapolis, MN 55427

The calibration time is approximately one week.

Purpose: To set the correct temperature for the DRUM.

Specification: The temperature is between 123.6 - 124.4C (254.5 - 256F).

Special Tools: TEMPERATURE METER AND PROBE TL-5574

BLOCK for PROBE 78-8064-5583-4

LAPTOP COMPUTER with Microsoft INTERNET EXPLORER

5.5 or higher

SERVICE TOOL

CROSSOVER CABLE TL-5568

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

6 of 186

Caution

Dangerous Voltage

1 Energize the IMAGER.

2 Allow the equipment to reach the

Ready mode.

3 Prepare the METER.

a Install the BLOCK on the PROBE

137 mm (5 3/8 in.) from the

PROBE SENSOR.

b Clean the PROBE with alcohol.

c Set the METER to display in C.

4 Set the SERVICE SWITCH in the

service position.

F C

METER

BLOCK

PROBE SENSOR

PROBE

137 mm (5 3/8 in.)

H199_1525GA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

7 of 186

5 Release the front and back LATCHES.

Caution

The DRUM and ROLLERS are hot.

6 Lift the COVER.

7 Insert the PROBE at the center of the

DRUM.

Note

The METER must be at room temperature

during the check.

8 Lower the COVER.

9 Close the front and back LATCHES.

10 Pull on the PROBE to check that the

PROBE SENSOR is directly under a

ROLLER.

11 Allow the indication on the METER to

be stable.

12 Record the temperature.

13 Release the LATCHES.

14 Lift the COVER.

15 Move the PROBE to the back of the DRUM.

16 Lower the COVER.

17 Close the front LATCH.

18 Do steps Step 10 through Step 12 again.

19 Release the front LATCH.

20 Lift the COVER.

ROLLERS

center

back

back LATCH

PROBE

DRUM

front

front LATCH

to METER

COVER

PROBE SENSOR

H199_1526GA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

8 of 186

21 Move the PROBE to the front of the DRUM.

22 Lower the COVER.

23 Close the back LATCH.

24 Do Step 10 through Step 12 again.

25 Check that all 3 temperatures are 123.6 - 124.4C (254.5 - 256F).

To Adjust:

1 Open the LOWER RIGHT FRONT

DOOR.

2 Connect the LAPTOP COMPUTER to

the RJ-45 CONNECTOR at the front of

the IMAGER.

Note

The CONNECTOR is located below the AIR

FILTER COVER.

3 Energize the LAPTOP COMPUTER.

4 Connect the SERVICE TOOL through

SecureLink.

5 From the Service menu, select

Configuration>MCS>Processor.

H199_0734AC

H199_0734ACB

RJ-45 CONNECTOR

AIR FILTER COVER

FRONT DOOR

LOWER RIGHT

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

9 of 186

6 Click [Modify].

7 In the Measured Temperature windows, type the 3 measured temperatures.

Important

The Current offsets windows indicate the offsets between the Current Temperature value

in the PROCESSOR MICRO and the Measured Temperature value.

8 Click [Save].

9 Close the Processor Temperature Configuration window.

10 Allow approximately 10 minutes for the temperatures to be stable.

11 Check that all 3 temperatures are 123.6 - 124.4C (254.5 - 256F).

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

10 of 186

PROCESSOR - BRUSHES

Adjustment Specification

Prerequisites:

None

To Check:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

3 Remove:

3 SCREWS

top and bottom COVERS

4 Check:

5 BRUSHES are aligned vertically with the 5 SLIP RINGS.

Surface of each BRUSH touches the surface of the adjacent SLIP RING.

Purpose: To align the BRUSHES with the SLIP RINGS.

Specification: The 5 BRUSHES are aligned vertically with the 5 SLIP

RINGS.

The surface of each BRUSH touches the surface of the

adjacent SLIP RING.

Special Tools: None

top COVER

bottom COVER

BRUSHES

3 SCREWS

SLIP RINGS

H199_1527AA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

11 of 186

To Adjust:

1 Loosen the 2 SCREWS.

2 Align the BRUSHES vertically with the

SLIP RINGS.

3 Manually rotate the DRUM backward

and forward to seat the SLIP RINGS

horizontally on the curved surfaces of

the BRUSHES.

4 Tighten the 2 SCREWS.

5 Check:

5 BRUSHES are aligned vertically

with the 5 SLIP RINGS.

Surface of each BRUSH touches the

surface of the adjacent SLIP RING.

Postrequisites:

1 If the power wires to the BRUSH are disconnected and connected before this adjustment,

check the circuits with the SERVICE TOOL. Select Diagnostics>MCS>General>Heater

Wiring. See DIAGNOSTICS 8E5983:

BRUSH

DRUM

SLIP RING

2 SCREWS

H199_1528GA

Section Procedure

Using the Diagnostics PROCESSOR HEATER Wiring

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

12 of 186

PROCESSOR - PHOTODETECTOR

Adjustment Specification

Prerequisites:

None

To Check:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

3 Remove:

3 SCREWS

top and bottom COVERS

Purpose: To align the horizontal and vertical position of the

PHOTODETECTOR with the LEDs on the ROTATING

PROCESSOR BOARD (RPB).

Specification: The HOLDER is 10 mm (0.39 in.) from the surface of the

RPB.

The distance between the bottom of the HOLDER and the

bottom of the BRACKET is 46 mm (1.8 in.).

Special Tools: METRIC RULER with mm increments

top COVER

bottom COVER

3 SCREWS

H199_1529AA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

13 of 186

4 Use a METRIC RULER to check that

the distance between the front surface

of the HOLDER and the RPB is 10 mm

(0.39 in.).

5 Check that the distance between the

bottom of the HOLDER and the bottom

of the BRACKET is 46 mm (1.8 in.).

To Adjust:

1 Adjust the distance between the

HOLDER and the RPB.

a Loosen the SCREW on the bottom

of the BRACKET.

b Move the BRACKET forward or

backward to set the distance

between the HOLDER and the

RPB to 10 mm (0.39 in.).

c Tighten the SCREW.

H199_1530AA

RPB 10 mm

(0.39 in.)

HOLDER

BRACKET

46 mm

(1.8 in.)

H199_1531AA

RPB

SCREW

BRACKET

2 SCREWS

HOLDER

10 mm

(0.39 in.)

46 mm

(1.8 in.)

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

14 of 186

2 Adjust the position of the HOLDER vertically.

a Loosen the 2 SCREWS.

b Align the HOLDER vertically until the distance between the bottom of the HOLDER

and BRACKET is 46 mm (1.8 in.).

c Tighten the 2 SCREWS.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

15 of 186

PROCESSOR - DIVERTER AY

Adjustment Specification

Prerequisites:

None

To Check:

1 Remove the UPPER FAZ TRAP. See

PROCESSOR - UPPER FAZ TRAP.

2 Check that the SCREW at each end of

the DIVERTER is at the bottom of the

SLOT.

Purpose: To adjust the position of the DIVERTER AY with the position of

the DRUM.

Specification: The 2 SCREWS for the DIVERTER AY is at the bottom of the

SLOTS.

Special Tools: None

H199_0745GC

DIVERTER AY

SLOT

SCREW

DIVERTER

H199_0745GCA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

16 of 186

To Adjust:

1 Loosen the 2 SCREWS.

2 Move the DIVERTER up until the 2

SCREWS are at the bottom of the 2

SLOTS.

3 Tighten the 2 SCREWS.

Postrequisites:

None

H199_0745GC

H199_0745GCB

DIVERTER

2 SCREWS

2 SLOTS

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

17 of 186

IMAGING AY - ENCODER READHEAD

Adjustment Specification

Prerequisites:

None

To Check:

Checking with the SERVICE TOOL

1 Connect the LAPTOP COMPUTER to the IMAGER with a CROSSOVER CABLE.

2 Set the SERVICE SWITCH in the service position.

3 Use SecureLink and the Service WebLink to open the SERVICE TOOL.

4 Select Diagnostics>MCS>Optics.

5 On the MCS Optics Diagnostics screen, select Test Readhead Alignment.

Purpose: To align the ENCODER READHEAD with the ENCODER

SCALE.

Specification: In the SERVICE TOOL, the outputs of the READHEAD is 700

- 1800 mV. The high end of this specification is

recommended.

On the VOLTMETER, the output of the READHEAD is 270 -

655 mV. The high end of this specification is recommended.

Special Tools: LAPTOP COMPUTER with Microsoft INTERNET EXPLORER

5.5 or higher

SERVICE TOOL

CROSSOVER CABLE TL-5568

READHEAD ALIGNMENT TOOL TL-5715

READHEAD SETTING SHIM with ADAPTER TL-5711

VOLTMETER

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

18 of 186

6 Click [Run].

Note

The test runs for approximately 80 seconds then displays Status and a summary. A Status

of Pass indicates only that the test has completed and has no relationship to the feedback

values.

7 Check that the 4 measured outputs of the READHEAD is 700 - 1800 mV. The high end

of this specification is recommended.

Note

The LINEAR MOTOR CONTROLLER BOARD does not operate approximately below 450

mV and above 2000 mV.

The READHEAD values decrease approximately 100 mV peak-to-peak from temperature

conditions.

Debris on the ENCODER SCALE drops the values of the feedback.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

19 of 186

Checking with the VOLTMETER

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

2 Extend the IMAGING AY.

3 Position the CARRIAGE between the left and right side of the RAILS.

4 Disconnect the READHEAD CABLE from J104 on the LINEAR MOTOR CONTROLLER

BOARD.

5 Connect:

READHEAD CABLE to the READHEAD ALIGNMENT TOOL

READHEAD ALIGNMENT TOOL into a 120 V AC OUTLET with the ADAPTER

Note

If 120 V AC wall power is not available, the READHEAD ALIGNMENT TOOL can operate

from internal BATTERIES.

VOLTMETER

LINEAR MOTOR

CONTROLLER BOARD

J104

CARRIAGE

POWER

SWITCH

READHEAD

ALIGNMENT TOOL

with ADAPTER

READHEAD

CABLE

H199_1509BA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

20 of 186

6 Set the POWER SWITCH on the READHEAD ALIGNMENT TOOL to ON.

7 Connect a VOLTMETER to the READHEAD ALIGNMENT TOOL.

Important

The CARRIAGE must be in motion to actuate the READHEAD.

8 Slowly move the CARRIAGE forward and backward the full length of the RAILS.

Note

If the room lights are down, you will be able to see the light from the LED in the READHEAD.

A green LED indicates that the READHEAD has an output that is close to normal, but might

or might not be within specification. A red LED indicates a weak output.

9 With the CARRIAGE in motion, observe the VOLTMETER.

READHEAD

ALIGHNMENT TOOL

AC POWER

VOLTMETER

CARRIAGE

READHEAD

RAILS

H199_1532BA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

21 of 186

10 Record the minimum and maximum voltages for reference. The specification for the

output of the READHEAD is 270 - 655 mV. The high end of this specification is

recommended.

Note

Because the indication on the VOLTMETER is a ground-to-peak reading for the Kodak

REMOTE MANAGEMENT SERVICES, the reading will be lower than the indications from the

SERVICE TOOL. The SERVICE TOOL displays peak-to-peak mV AC.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

22 of 186

To Adjust:

Aligning the READHEAD on the ROLL AXIS

Important

This procedure applies only if the 2 SCREWS for the RAIL with the ENCODER SCALE

include SPHERICAL WASHERS. With no SPHERICAL WASHERS, you must skip this

procedure and advance to Adjusting the Offset Gap and Aligning the READHEAD on

the PITCH AXIS.

1 Loosen the 2 SCREWS that fasten the

RAIL to allow rotation of the RAIL.

Important

The output of the READHEAD is changed

by small motions.

2 With the CARRIAGE in motion:

a Slowly rotate the RAIL to obtain an

output from the VOLTMETER that

is 270 - 655 mV. The high end of

this specification is recommended.

b Adjust until the output remains at

the high end of this specification, if

possible, for the full length of the

RAILS forward and backward.

3 Tighten the 2 SCREWS.

H199_1533AA

2 SCREWS

SPHERICAL

WASHERS

CARRIAGE

READHEAD

RAIL

ENCODER

SCALE

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

23 of 186

4 Does the output remain within the value identified in the Specification?

Adjusting the Offset Gap and Aligning the READHEAD on the PITCH AXIS

1 Remove the OPTICS ELECTRONICS

AY.

2 Loosen the Offset/Pitch SCREWS.

Yes No

No other adjustment is necessary. a. Remove the SPHERICAL WASHERS and

tighten the 2 SCREWS on the ends of the RAIL

in order to align the RAIL with the ENCODER

SCALE.

b. Advance to Adjusting the Offset Gap and

Aligning the READHEAD on the PITCH AXIS.

OPTICS

ELECTRONICS AY

READHEAD

BRACKET

"Offset/Pitch"

SCREWS

H199_1510AA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

24 of 186

3 Insert the READHEAD SETTING SHIM

between the READHEAD and the

ENCODER SCALE.

Note

If your hands are large, you might have to

remove the PLATEN FILM TRANSPORT to

do this adjustment.

4 Position the top of the READHEAD

SETTING SHIM approximately level

with the top of the ENCODER SCALE.

Important

The output of the READHEAD is changed

by small changes in position of the

READHEAD.

5 Press the READHEAD against the

SETTING SHIM.

6 Apply pressure on both ends of the READHEAD BRACKET to align the READHEAD with

the ENCODER SCALE.

7 At the same time, apply pressure on the CARRIAGE to keep the 2 VEE-BEARINGS

seated on the RAILS

8 Tighten the Offset/Pitch SCREWS, checking that the READHEAD does not move.

9 Remove the SETTING SHIM.

CARRIAGE

READHEAD

READHEAD

BRACKET

READHEAD

SETTINGS

SHIM

ENCODER

SCALE

RAIL

READHEAD

BRACKET

RAIL

"Offset/Pitch" SCREWS

Side View

End VIew

2 VEE

BEARINGS

"Offset/Pitch" SCREWS

H199_1534CA

2 VEE

BEARINGS

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

25 of 186

10 If the SPHERICAL WASHERS were removed in Step 4, install the WASHERS and do the

Aligning the READHEAD on the ROLL AXIS.

11 Do Checking with the VOLTMETER:

If the minimum and maximum are within 270 - 655 mV, advance to Step 12.

If the minimum output is below 270 - 655 mV:

Again Adjusting the Offset Gap and Aligning the READHEAD on the PITCH

AXIS to reach the recommended values.

If after some adjustments, you cannot reach the recommended values, adjust

Pitch to the highest output possible, then do the Roll adjustment if necessary.

Note

If after some Roll and Pitch adjustments, the READHEAD output is not within the values of

the Specification, the READHEAD is malfunctioning.

12 Disconnect:

VOLTMETER

READHEAD ALIGNMENT TOOL

13 Install:

OPTICS ELECTRONICS AY

IMAGING AY

14 Do Checking with the SERVICE TOOL.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

26 of 186

IMAGING AY - MAGNET WAY

Adjustment Specification

Prerequisites:

None

To Check:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

2 Extend the IMAGING AY.

3 Check that the 4 SCREWS are tight.

4 Move the CARRIAGE to the front of the

IMAGING AY.

5 Insert the 2 FORCER SPACERS into

the MAGNET WAY between the top of

the LINEAR TRANSLATION MOTOR

and the 2 MAGNETS.

6 If the FORCER SPACERS do not set

correctly, do the adjustment.

7 Move the CARRIAGE to the back of the

IMAGING AY.

8 Do Step 5 through Step 6 again.

Purpose: To align the MAGNET WAY with the LINEAR TRANSLATION

MOTOR.

Specification: The LINEAR TRANSLATION MOTOR moves freely from end to

end in the MAGNET WAY.

Special Tools: 2 FORCER SPACERS TL-5710

0.6 mm (0.0256 in.)

minimum

2 FORCER SPACERS

2 MAGNETS

MAGNET WAY

LINEAR TRANSLATION

MOTOR

4 SCREWS

IMAGING

AY

Front

Back

MAGNET WAY

CARRIAGE

H199_1535GA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

27 of 186

9 Check that the LINEAR TRANSLATION MOTOR moves freely from end to end in the

MAGNET WAY.

To Adjust:

1 Partially loosen the 4 SCREWS.

2 Move the CARRIAGE to the front.

3 Insert the 2 FORCER SPACERS into

the MAGNET WAY between the top of

the LINEAR TRANSLATION MOTOR

and the 2 MAGNETS.

4 Loosely tighten the front SCREWS.

5 Move the CARRIAGE to the back.

6 Insert the FORCER SPACERS. See

Step 3.

7 Loosely tighten the back 2 SCREWS.

8 Move the CARRIAGE to the front.

9 Insert the FORCER SPACERS.

10 Fully tighten the front 2 SCREWS.

11 Move the CARRIAGE to the back.

12 Insert the 2 FORCER SPACERS.

13 Fully tighten the back SCREWS.

14 Move the CARRIAGE fully forward and backward until the LINEAR TRANSLATION

MOTOR moves freely from end to end on the MAGNET WAY.

Postrequisites:

None

0.6 mm (0.0256 in.)

minimum

2 FORCER SPACERS

2 MAGNETS

MAGNET WAY

LINEAR TRANSLATION

MOTOR

4 SCREWS

IMAGING

AY

Front

Back

MAGNET WAY

CARRIAGE

H199_1535GA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

28 of 186

IMAGING AY - Index Delay

Adjustment Specification

Prerequisites:

None

To Check:

1 Connect the LAPTOP COMPUTER to the IMAGER with the CROSSOVER CABLE.

2 Use SecureLink and the Service WebLink to open the SERVICE TOOL.

3 Select Configuration>MCS>Optics.

4 Click [Test Print] to run a Ball test print.

Purpose: To adjust Start of Page timing after a SPINNER MOTOR

replacement.

Specification: A 0.5 mm (0.02 in.) gray area is on the leading edge of the film.

Special Tools: LAPTOP COMPUTER with Microsoft INTERNET EXPLORER

V 5.5 or higher

SERVICE TOOL

CROSSOVER CABLE TL5568

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

29 of 186

5 Check that the gray area on the leading edge is 0.5 mm (0.02 in.), with no transparent

area appearing.

Note

If no gray or transparent area appears, scanning started before the laser beam hit the film.

If the area is too large, and both gray and transparent areas are visible, the image will

extend beyond the other end of the film.

scan direction

scan direction

index delay too small index delay too large

Leading

edge of

FILM in

IMAGER

start of page start of page

0.5 mm(0.02 in.) wide gray area

H199_1511BA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

30 of 186

To Adjust:

1 Observe the number of pixels displayed in the Index Delay (pixels) window.

Note

This number indicates the number of pixels set to obtain the gray area:

If the gray area on the test print is too narrow, the number of pixels must be increased.

If the area is too wide, the number of pixels must be decreased.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

31 of 186

2 To:

Postrequisites:

None

Decrease the area on the test print, do: Increase the area on the test print, do:

a. On the test print, measure the width of

the gray area in mm.

b. Multiply the measured distance by 25

to obtain the pixel width of the area.

25 pixels equals 1 mm (0.04 in.).

c. Subtract the measured pixel width

from the displayed Index Delay

(pixels) number in the window.

d. Click [Modify].

e. Type the number determined in Step c

into the window.

f. Click [Save].

Note

If the index delay is too small, it might not be

visible on the film. You will have to increase it by

increments until it is visible.

a. Click [Modify] and increase the number in the

Index Delay (pixels) window by 50. This will

increase the gray area by 2 mm (0.08 in.).

b. Click [Save].

c. Click [Test Print] and check the index delay

area again.

d. Do Step a through Step c until a 0.5 mm

(0.02 in.) gray area appears on the leading

edge of the film.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

32 of 186

IMAGING AY - Film Skew

Adjustment Specification

Prerequisites:

None

To Check:

1 Run a SMPTE test print.

2 Check that the image skew on the

leading edge of the film is no more than

1 mm (0.038 in.).

Purpose: To adjust the position of the right CENTERING FINGER to

prevent image skew on the film.

Specification: Image skew on the leading edge of the film is no more than 1

mm (0.038 in.).

When film is moved to the center of the PLATEN:

both CENTERING FINGERS touch the film

all 5 PLATEN FINGERS touch the film

Special Tools: None

image skew

H

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

33 of 186

3 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

4 Extend the IMAGING AY.

5 Rotate the large GEAR to move the REGISTRATION BAR to the front position.

6 Lift one of the 5 FINGER CARRIAGES on the back of the PLATEN TRANSPORT to

allow film to move through the PLATEN TRANSPORT.

PLATEN TRANSPORT

ROLLER

KNOB

GEAR

bottom ROLLERS

REGISTRATION

BAR

front

5 FINGER

CARRIAGES

H199_1536BA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

34 of 186

7 Use the ROLLER KNOB to load a sheet

of 14 x 17 in. film into the PLATEN

TRANSPORT.

8 Rotate the ROLLER KNOB until the film

is below the bottom ROLLERS.

9 Press down on one of the 5 FINGER

CARRIAGES to allow the PLATEN

FINGERS to engage the film.

10 Use a FLASHLIGHT to check that the

edge of the film is in contact with all 5

PLATEN FINGERS.

11 If necessary, move the film until it

touches all 5 PLATEN FINGERS.

12 Move the LINK until one CENTERING

FINGER touches the film.

13 Check that both the right and left

CENTERING FINGERS are touching

the film.

14 Move the LINK until the CENTERING

FINGERS move the film approximately

12 mm (1/2 in.) toward the IMAGER.

15 Check that the film touches all 5

PLATEN FINGERS and both

CENTERING FINGERS.

H199_1537GA

LINK

CENTERING FINGERS

5 PLATEN FINGERS

CENTERING

FINGER

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

35 of 186

To Adjust:

1 Loosen the 2 NUTS on the right

BRACKET.

2 Check that the film touches all 5

PLATEN FINGERS.

3 Move the LINK until the right and left

CENTERING FINGERS touch the edge

of the film.

4 Tighten the 2 NUTS.

5 Move the LINK until the CENTERING

FINGERS move the film toward the

IMAGER approximately 12 mm (1/2 in.).

6 Check:

5 PLATEN FINGERS touch the film

right and left CENTERING

FINGERS touch the film

7 If the specifications are not obtained,

do:

a Step 1 and Step 2.

b Use the LINK to move the right

CENTERING FINGER forward or

backward a minimum distance.

c Tighten the 2 NUTS.

5 PLATEN FINGERS

left CENTERING

FINGER

right CENTERING

FINGER

2 NUTS

LINK

right

BRACKET

H199_1538GA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

36 of 186

8 Run a SMPTE test print.

9 Check that the image skew is not more

than 1 mm (0.038 in.) at the leading

edge. Adjust again in 1 mm (0.038 in.)

increments:

10 After you complete the adjustment, lift

one of the FINGER CARRIAGES to

disengage the PLATEN FINGERS from

the film.

11 Rotate the ROLLER KNOB to remove

the film from the PLATEN TRANSPORT.

Postrequisites:

None

image skew

If the skew is at the top

of the film:

If the skew is at the

bottom of the film:

Move the right

CENTERING

FINGER back.

Move the right

CENTERING

FINGER forward.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

37 of 186

+5 V DC POWER SUPPLY

Adjustment Specification

Prerequisites:

None

To Check:

1 Check that the system is in ready

mode.

2 Open the BACK DOOR.

3 Loosen the SCREW.

4 Remove the ELECTRONICS PANEL.

5 Connect the VOLTMETER to the +5 V

test point and one of the GND test

points on the EBA BOARD.

6 Check that the voltage is +5.0 to +5.1 V

DC.

7 Leave the VOLTMETER connected if an

adjustment is necessary.

Purpose: To adjust the output of the +5 V DC SUPPLY

Specification: The voltage measured at the + 5 V test point on the EBA

BOARD is +5.0 to +5.1 V DC.

Special Tools: VOLTMETER

J23

J13

H199_1539GA

+5 V DC

POWER

SUPPLY

SCREW

ELECTRONICS

PANEL

+5 V test point

EBA BOARD

GND

USB

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

38 of 186

To Adjust:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

Important

Do not disconnect any other internal

CABLES from the POWER MODULE.

3 Move the POWER MODULE

approximately 15 cm (6 in.) outside the

IMAGER for access to the +5 V DC

POWER SUPPLY. See the removal

procedure in POWER MODULE.

4 Connect the POWER CORD.

5 Apply power to the IMAGER.

6 Allow 5 minutes for the SUPPLIES to be stable.

7 Rotate the +5 V DC ADJUSTMENT to obtain a +5.0 to +5.1 V DC indication on the

VOLTMETER.

Postrequisites:

None

POWER

MODULE

+5 V DC

POWER

SUPPLY

+5 V DC

ADJUSTMENT

H199_1513BA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

39 of 186

LOCAL PANEL - Calibration of the TOUCH SCREEN

Adjustment Specification

Prerequisites:

None

To Check:

You cannot check this adjustment.

To Adjust:

Important

Do this adjustment if:

New system software is installed.

A new LOCAL PANEL is installed.

1 On the Status screen of the LOCAL PANEL, touch [Menu]. On the Main Menu, touch

[Service].

2 Type:

99 in the Enter Passcode window

987654 in the Enter Passcode window

3 Touch [OK].

Purpose: To align the cursor positions on the TOUCH SCREEN to the

graphics on the LOCAL PANEL.

Specification: The cursor moves to your finger in the 7 test areas on the

TOUCH SCREEN.

Special Tools: STYLUS.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

40 of 186

4 On the Service screen, touch [Calibrate Touch Screen].

Note

The Calibration Target screen displays.

5 Use the STYLUS to touch the TARGET at the center.

Note

A screen displays with a 1/2 TARGET at the top right edge.

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

41 of 186

6 Use the STYLUS to touch the center of the 1/2 TARGET.

7 When the TARGETS display in new areas, touch each at the center until all 7 are

completed.

8 When the message Touch the screen to see if the cursor moves to your finger....

displays, touch the screen in the 7 test areas.

9 Check that the cursor moves to your finger in the 7 test areas on the TOUCH SCREEN.

10 If the cursor operates:

Postrequisites:

None

Correct Not Correct

a. Touch [Yes] to leave the calibration.

b. On the TSHARC Properties

screen, touch [Cancel].

Touch [No] to do the calibration

again.

1

2

3

4

6

5

7

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

42 of 186

FILM FEED ROLLER DRIVE AY

Adjustment Specification

Prerequisites:

None

To Check:

1 Check the alignment of the IDLER

ROLLER and DRIVE ROLLER.

a Rotate the DRIVE SHAFT in both

directions at the DRIVE GEAR.

b Check that the contact of the

IDLER ROLLER and DRIVE

ROLLER is parallel.

Purpose: To align the IDLER ROLLER with the DRIVE ROLLER.

Specification: The contact of the IDLER ROLLER and DRIVE ROLLER is

parallel.

Special Tools: None

DRIVE ROLLER

IDLER ROLLER DRIVE GEARS

DRIVE SHAFT

H199_1540AA

ADJUSTMENTS AND REPLACEMENTS Adjustments

15JUL05

8F1621

Page

43 of 186

To Adjust:

1 Adjust the FILM FEED ROLLER DRIVE

AY.

a Rotate the DRIVE SHAFT until the

2 DOWEL PINS in the 2 DRIVE

GEARS are horizontal.

b Remove the 2 E-RINGS from the 2

DRIVE GEARS.

c Move the 2 DRIVE GEARS

approximately 13 mm (0.5 in.)

toward the center of the DRIVE

SHAFT.

d Lift up on the IDLER ROLLER to

make it tight with the DRIVE

ROLLER.

e Carefully move the 2 DRIVE

GEARS, one at a time, toward the

2 IDLER GEARS until the GEARS

align at the horizontal position of

the DOWEL PIN.

f Install the 2 E-RINGS.

2 Check that the contact of the IDLER

ROLLER and DRIVE ROLLER is

parallel.

Postrequisites:

None

FILM FEED ROLLER DRIVE AY

IDLER ROLLER 2 DRIVE GEARS

DRIVE ROLLER 2 IDLER GEARS

2 IDLER GEARS 2 DRIVE GEARS

2 E-RINGS DRIVE SHAFT 2 DOWEL PINS

H199_1541GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

44 of 186

Section 2: Replacements

DICOM RASTER ENGINE (DRE) COMPUTER and COVER

Prerequisites:

None

To Remove:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

3 Open the BACK DOOR.

4 Loosen the SCREW.

5 Remove the ELECTRONICS PANEL.

DRE COMPUTER

SCREW

ELECTRONICS PANEL

H199_1621AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

45 of 186

6 Disconnect:

120 V AC from the UPS

LOCAL PANEL power/speaker

Customer network

USB to the EBA

LOCAL PANEL data

COM 2 to the EBA

PS/2 to the LOCAL PANEL

7 Remove the SCREW.

8 Pull the DRE COMPUTER toward you.

9 Remove:

3 SCREWS

COVER

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

COM 2 to EBA

PS/2 to LOCAL PANEL

LOCAL PANEL DATA

USB TO EBA

LOCAL PANEL

CUSTOMER NETWORK

120 V AC

from UPS

SCREW

3 SCREWS

COVER

H199_1620GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

46 of 186

DRE COMPUTER - HARD DRIVE

Prerequisites:

1 Remove the DICOM RASTER ENGINE (DRE) COMPUTER and COVER.

To Remove:

Possible damage from electrostatic discharge.

ESD

1 Remove the 4 SCREWS.

2 Disconnect the 2 CABLE

CONNECTORS.

3 Remove the HARD DRIVE.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Load the new version of the system software for the DRE on the HARD DRIVE. See

Upgrading the DRE with a New Version of the System Software - Ghosting.

2 Restore the system configuration. See Making a Configuration Backup.

2 CABLE CONNECTORS

4 SCREWS

HARD DRIVE

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

47 of 186

DRE COMPUTER - DVD DRIVE

Prerequisites:

1 Remove the DICOM RASTER ENGINE (DRE) COMPUTER and COVER.

To Remove:

Possible damage from electrostatic discharge.

ESD

1 Disconnect:

2 CABLE CONNECTORS ON THE

HARD DRIVE

2 CABLE CONNECTORS ON THE

DVD DRIVE

2 Remove:

4 SCREWS from the bottom of the

DRE COMPUTER

4 SCREWS on the two sides

DVD DRIVE

2 CABLE CONNECTORS

HARD DRIVE

2 CABLE CONNECTORS

DVD DRIVE

4 SCREWS

4 SCREWS

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

48 of 186

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

49 of 186

DRE COMPUTER - POWER SUPPLY

Prerequisites:

1 Remove:

DICOM RASTER ENGINE (DRE) COMPUTER and COVER

To Remove:

Possible damage from electrostatic discharge.

ESD

1 Disconnect:

2 CABLE CONNECTORS on the

HARD DRIVE

2 CABLE CONNECTORS on the

DVD DRIVE

MOTHERBOARD POWER CABLE

2 Remove:

2 SCREWS on the back of the

ENCLOSURE

One SCREW inside the

ENCLOSURE

POWER SUPPLY

2 CABLE CONNECTORS

HARD DRIVE 2 CABLE CONNECTORS

DVD DRIVE

MOTHERBOARD

POWER CABLE

ENCLOSURE

SCREW

2 SCREWS

POWER SUPPLY

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

50 of 186

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

51 of 186

DRE COMPUTER - FANS

Prerequisites:

1 Remove the DICOM RASTER ENGINE (DRE) COMPUTER and COVER.

To Remove:

Possible damage from electrostatic discharge.

ESD

1 Disconnect the 2 FAN CABLES.

2 Remove:

4 SCREWS for each FAN

2 FANS

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

2 FAN CABLES

4 SCREWS

CABLE

2 FANS

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

52 of 186

EXPOSURE BRIDGE AY (EBA)

Prerequisites:

None

To Remove:

Important

The EBA AY includes the MCS MASTER CPU BOARD and the EBA BOARD.

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

USB

H199_1543BA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

53 of 186

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

3 Open the BACK DOOR.

4 Remove the VERTICAL DUCT.

a. Remove the ELECTRONICS

PANEL.

b. Disconnect the FAZ HOSE from the

VERTICAL DUCT.

c. Remove the 2 SCREWS.

d. Disconnect the VERTICAL DUCT

from the PLENUM COUPLING.

5 Disconnect CABLES from:

J1 - J7

J9 - J19

J21 - J23

6 Remove the 7 SCREWS.

7 Pull the EBA from the 2 corner PINS.

To Install:

1 Reverse the steps in the removal procedure.

2 Upgrade the software in the new MCS MASTER CPU BOARD. See Upgrading the

Software Applications for the MCS MASTER CPU BOARD and the MICRO BOARDS.

CABLES

7 SCREWS

2 corner

PINS

EBA BOARD

FAZ

HOSE

DUCT

2 SCREWS

VERTICAL

PLENUM

COUPLING

H199_1596GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

54 of 186

3 Upgrade the software in the new EBA BOARD and all other MICROCONTROLLERS on

the I2C bus that do not have compatible software. See Upgrading the

Microcontroller Application when a New MICRO BOARD is Installed.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

55 of 186

ROLLBACK MODULE

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 ROLLBACK

MODULES.

1 Use the LOCAL PANEL to open the

DRAWER.

2 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Important

Most parts of the ROLLBACK MODULE can

be installed with the DRAWER opened,

without removing the DRAWER and

ROLLBACK MODULE.

3 If necessary, remove the DRAWER

together with the ROLLBACK MODULE,

by pulling the DRAWER from the

IMAGER on the SLIDES.

SLIDE

BEARINGS

SLIDE

DRAWER

TRACK

ROLLBACK

MODULE

FILM

CARTRIDGE

H199_1544AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

56 of 186

To Install:

Caution

When you install the DRAWER on the SLIDES, you must check that the SLIDES are

aligned correctly with the TRACKS.

To prevent damage to the SLIDE BEARINGS, the SLIDES must be horizontal when

inserted into the TRACKS.

1 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

57 of 186

ROLLBACK CARTRIDGE PRESENCE SENSOR

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 ROLLBACK

MODULES.

1 Use the LOCAL PANEL to open the

DRAWER.

2 Move the ROLLBACK ROLLER to the

top of the TRAY.

3 Remove the SCREW.

Caution

Use caution not to damage the SENSOR.

4 Disconnect the CONNECTOR.

5 Remove the SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

H199_1545AA

ROLLBACK

ROLLER

SCREW

SENSOR

CONNECTOR

TRAY

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

58 of 186

ROLLBACK HOME SENSOR

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 ROLLBACK

MODULES.

1 Use the LOCAL PANEL to open the

DRAWER.

2 Place the ROLLBACK ROLLER on top

of the TRAY.

3 Remove the SENSOR SCREW.

Caution

Use caution not to damage the SENSOR.

4 Disconnect the CONNECTOR.

5 Remove the SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

SENSOR

SCREW

ROLLBACK

ROLLER

TRAY

CONNECTOR

H199_1546AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

59 of 186

ROLLBACK OPEN SENSOR

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 ROLLBACK

MODULES.

1 Use the LOCAL PANEL to open the

DRAWER.

2 Remove:

SCREW

COVER

SENSOR SCREW

3 Disconnect the CONNECTOR.

4 Remove the SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

H199_1547GA

SCREW

COVER

SENSOR

CONNECTOR

SCREW

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

60 of 186

ROLLBACK MOTOR

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 ROLLBACK MODULES.

1 Use the LOCAL PANEL to open the DRAWER.

2 De-energize the IMAGER. Touch:

power icon

[Shut Down]

3 Move the ROLLBACK ROLLER to approximately the center of the TRAY.

4 Remove the 2 SCREWS.

5 Cut the CABLE TIE.

6 Disconnect the CONNECTOR.

ROLLBACK

MOTOR

SHAFT

E-RING

MOUNTING

PLATE

ROLLBACK

ROLLER

TRAY

2 SCREWS

GEAR

CONNECTOR

DOWEL PIN

CABLE TIE

H199_1548BA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

61 of 186

7 Remove:

E-RING from the SHAFT

GEAR

DOWEL PIN

To Install:

1 Before you install the 2 SCREWS, rotate the ROLLBACK MOTOR on the MOUNTING

PLATE until:

GEARS align

ROLLBACK MOTOR is flat against the MOUNTING PLATE

2 Install a new CABLE TIE around the ROLLBACK MOTOR, next to the CONNECTOR.

3 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

62 of 186

ROLLBACK ROLLER

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 ROLLBACK MODULES.

1 Use the LOCAL PANEL to open the DRAWER.

2 Move the ROLLBACK ROLLER to approximately the center of the TRAY.

H199_1549HA

BEARING

GEAR

ROLLBACK

ROLLER

SPRING

ROLLBACK

ROLLER

FRONT

LINK

KNOB

E-RING

ACTUATOR

KNOB

ROLLBACK

ROLLER

DRAWER

front

back

TRAY

FLAG

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

63 of 186

3 From the front of the DRAWER, remove:

E-RING

KNOB

ACTUATOR GUARD

FRONT LINK

SPRING

Caution

You must hold the BEARING, GEAR, and FLAG at the back end of the TRAY to prevent the

items from falling.

4 From the front of the DRAWER, remove the ROLLBACK ROLLER from the BEARING,

GEAR, and FLAG on the back end.

To Install:

Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

64 of 186

RF TAG ANTENNA BOARD

Prerequisites:

1 Remove the ROLLBACK MODULE.

To Remove:

Important

This procedure applies to all 3 ROLLBACK

MODULES.

1 Rotate the ROLLBACK MODULE and

DRAWER bottom up.

2 Place the ROLLBACK MODULE and

DRAWER on a stable surface.

3 Remove the 4 NUTS.

4 Disconnect the RF TAG ANTENNA

BOARD from the CONNECTOR.

To Install:

1 Reverse the steps in the removal procedure

Postrequisites:

None

ROLLBACK

MODULE

and DRAWER

CONNECTOR

4 NUTS

RF TAG ANTENNA BOARD

H199_1550AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

65 of 186

RF TAG READER BOARD

Prerequisites:

None

To Remove:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

3 Open the BACK DOOR.

4 Remove:

4 CONNECTOR PLUGS

2 SCREWS

RF TAG READER BOARD

To Install:

1 Reverse the steps in the removal procedure.

2 Energize the IMAGER.

3 If a 20-156 error occurs, indicating the software is not compatible, upgrade the software

in the new RF TAG READER BOARD. See Upgrading the Microcontroller

Application when a New MICRO BOARD is Installed.

Postrequisites:

None

H199_1551AA

2 SCREWS

RF TAG READER

BOARD

4 CONNECTOR PLUGS

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

66 of 186

PICKUP AND FEED MODULE

Prerequisites:

None

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Important

The PICKUP AND FEED MODULE must be

in the up position before you engage the

SHIPPING LOCK.

2 Engage the SHIPPING LOCK.

a Loosen the LOCK SCREW.

b Move the SHIPPING LOCK fully to

the left.

c Tighten the LOCK SCREW.

LOCK SCREW

SHIPPING LOCK

PICKUP AND FEED MODULE

H199_1552AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

67 of 186

3 At the front of the IMAGER, remove the

2 SCREWS.

4 Pull the PICKUP AND FEED MODULE

from the IMAGER.

5 Set the MODULE, with the bottom up,

on a stable surface.

To Install:

1 Reverse the steps in the removal procedure.

Caution

To prevent damage, the SHIPPING LOCK must be disengaged before you apply power.

2 Disengage the SHIPPING LOCK.

a Loosen the LOCK SCREW.

b Move the SHIPPING LOCK fully to the right.

c Tighten the LOCK SCREW.

Postrequisites:

None

H199_1553AA

2 SCREWS

PICKUP AND FEED

MODULE

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

68 of 186

FILM FEED ROLLER DRIVE AY

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Remove the 3 NUTS from each end of

the FILM FEED ROLLER DRIVE AY.

Important

Do not do Step 2 for access to other parts.

2 If necessary, cut the CABLE TIE.

3 Disconnect the CONNECTOR.

4 Remove the FILM FEED ROLLER

DRIVE AY.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

1 Adjust the FILM FEED ROLLER DRIVE AY.

CONNECTOR

CABLE TIE

3 NUTS

3 NUTS

FILM FEED ROLLER

DRIVE AY

H199_1554GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

69 of 186

FILM FEED HEEL AY

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

1 Disengage the SHIPPING LOCK to allow the HEEL AY to move to the up position.

2 Remove:

E-RING

PIVOT PULLEY PIN

3 Disconnect the DRIVE CABLE from the HEEL AY.

4 Use the SPRING HOOK TL-5712 to disconnect the 2 HEEL SPRINGS.

H199_1555BA

PIVOT PULLEY

PIN

2 HEEL

SHAFTS

4 E-RINGS

PICKUP FRAME

2 HEEL SPRINGS

HEEL AY

DRIVE CABLE

SHIPPING LOCK

E-RING

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

70 of 186

5 Disconnect the HEEL AY from the PICKUP FRAME. Remove:

4 E-RINGS

2 HEEL SHAFTS

6 Rotate the HEEL AY to locate other components.

Note

Normally the HEEL AY is disconnected not for replacement, but to provide access to other

components.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

71 of 186

HEEL PADS

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Place the HEEL AY in the up position.

Caution

Use caution not to damage the SENSOR.

2 Carefully remove the 3 HEEL PADS.

3 Use ALCOHOL WIPES to clean the old

adhesive from the 3 HEELS.

4 Check that all the old adhesive is

removed.

Note

If the new PADS do not adhere correctly,

operation problems can result.

To Install:

1 Remove the layer of paper from the adhesive surface of the new HEEL PAD.

2 Apply one edge of the HEEL PAD to the HEEL AY.

H199_1556GA

HEEL AY

SENSOR

3 HEEL PADS

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

72 of 186

Caution

Do not to leave any air bubbles between the PAD and the HEEL AY.

3 Press the adhesive surface to the HEEL AY from one side to the other.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

73 of 186

FEED ROLLER OPEN SENSOR and FILM AT FEED SENSOR

Prerequisites:

1 Remove:

PICKUP AND FEED MODULE

FILM FEED ROLLER DRIVE AY

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 For either SENSOR:

a. Remove the SCREW.

b. Disconnect the CONNECTOR from

the SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

Do the alignment for the FILM FEED ROLLER DRIVE AY.

FEED ROLLER

OPEN SENSOR

SCREW SCREW

FILM AT FEED

SENSOR

CONNECTORS

H199_1557GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

74 of 186

PICKUP HOME SENSOR and CUPS ENGAGED SENSOR

Prerequisites:

1 Remove:

PICKUP AND FEED MODULE

FILM FEED HEEL AY

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 For either SENSOR:

a. Remove the SCREW.

b. Disconnect the CONNECTOR from

the SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

SCREW

PICKUP

SENSOR

SCREW

CUPS

ENGAGED

SENSOR

CONNECTOR

H199_1558AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

75 of 186

FILM OUT SENSOR

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Remove the SCREW.

2 Disconnect the CONNECTOR from the

FILM OUT SENSOR.

3 Remove the FILM OUT SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

FILM OUT SENSOR

SCREW

CONNECTOR

H199_1559AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

76 of 186

FEED ROLLER CLOSE MOTOR

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Disconnect the CONNECTOR.

2 Remove:

4 SCREWS

FEED ROLLER CLOSE MOTOR

with the GEAR

2 SCREWS

MOUNTING PLATE

3 Remove from the FEED ROLLER

CLOSE MOTOR:

E-RING

GEAR

DOWEL PIN

To Install:

1 Install on the SHAFT of the new FEED ROLLER CLOSE MOTOR:

DOWEL PIN

GEAR

E-RING

H199_1560GA

MOUNTING PLATE

FEED ROLLER

CLOSE MOTOR

CONNECTOR

2 SCREWS

4 SCREWS

E-RING

GEAR

DOWEL PIN

SHAFT

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

77 of 186

2 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

78 of 186

FILM FEED DRIVE BELT

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Remove:

SCREW

IDLER SHAFT

PULLEY

4 SCREWS

2 Move the MOTOR and PULLEY

approximately 13 mm (0.5 in.).

3 Remove the DRIVE BELT.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

DRIVE

BELT

SCREW

PULLEY

IDLER

SHAFT

4 SCREWS

MOTOR

H199_1561GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

79 of 186

FILM FEED MOTOR

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Remove the BELT TENSIONER.

2 Disconnect the CONNECTOR from the

FILM FEED MOTOR.

3 Remove:

E-RING from the end of the SHAFT

4 SCREWS - T20, Torx

FILM FEED MOTOR

GEAR

E-RING

To Install:

1 Install on the SHAFT:

GEAR

E-RING

2 Reverse the steps in the removal procedure.

Postrequisites:

None

FILM FEED

MOTOR

E-RING

BELT

TENSIONER

4 SCREWS

GEAR

E-RING

CONNECTOR

SHAFT

H199_1562GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

80 of 186

PICKUP MOTOR

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Engage the SHIPPING LOCK.

2 Move the DRIVER PULLEY forward to

loosen the DRIVE CABLE.

3 Remove:

DRIVE CABLE

E-RING

DRIVER PULLEY

4 Disconnect the CONNECTOR for the

PICKUP MOTOR.

5 Remove the 4 NUTS.

6 Lift the PICKUP MOTOR and

BRACKET up.

7 Remove the 4 SCREWS to release the

PICKUP MOTOR.

4 SCREWS

4 NUTS

PICKUP

MOTOR

DRIVE CABLE

CONNECTOR

DRIVE CABLE

SHIPPING LOCK

E-RING

DRIVER PULLEY

BRACKET

H199_1563GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

81 of 186

To Install:

Important

Before you install the PICKUP AND FEED MODULE in the IMAGER, you must check that the

DRIVE CABLE is installed correctly.

1 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

82 of 186

VACUUM VALVE

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Disconnect:

VACUUM HOSE

CONNECTOR

2 Remove:

2 NUTS

VACUUM VALVE

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

H199_1564GA

2 NUTS

VACUUM

VALVE

CONNECTOR

VACUUM HOSE

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

83 of 186

VACUUM PUMP

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Disconnect:

VACUUM HOSE

CONNECTOR

2 Remove:

NUT from the LOOP CLAMP

VACUUM PUMP and adhesive

FOAM PAD

To Install:

1 Use ISOPROPYL ALCOHOL and a WIPE to clean the adhesive from the VACUUM

PUMP installation area.

2 Place the LOOP CLAMP on the PUMP.

3 Align the PUMP with FOAM PAD on the BASE.

4 Place the ends of the LOOP CLAMP on the BOLT to set the correct area for installation.

5 Remove the COVER from the FOAM PAD.

VACUM PUMP

NUT

LOOP CLAMP

FOAM PAD

COVER

BOLT

CONNECTOR

VACUUM HOSE

H199_1565GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

84 of 186

6 With the PUMP and FOAM PAD on the installation area, press down to adhere the

FOAM PAD and PUMP to the BASE.

7 Install:

NUT for the LOOP CLAMP

CONNECTOR

VACUUM HOSE on the PUMP

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

85 of 186

SUCTION CUPS

Prerequisites:

1 Remove the PICKUP AND FEED MODULE.

To Remove:

Important

This procedure applies to all 3 PICKUP

AND FEED MODULES.

1 Rotate the SUCTION CUP

counterclockwise.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

H199_1

4 SUCTION CUPS

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

86 of 186

CARTRIDGE CONTROL BOARD

Prerequisites:

None

To Remove:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage.

2 Disconnect the POWER CORD.

3 Open the BACK DOOR.

4 Disconnect CABLES from:

J100 - J102

J200 - J202

J300 - J302

5 Remove:

8 SCREWS

CARTRIDGE CONTROL BOARD

To Install:

1 Reverse the steps in the removal procedure.

2 Energize the IMAGER.

8 SCREWS

CARTRIDGE CONTROL

BOARD

H199_1567AA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

87 of 186

3 If a 20-156 error occurs, indicating the software is not compatible, upgrade the software

in the new CARTRIDGE CONTROL BOARD. See Upgrading the Microcontroller

Application when a New MICRO BOARD is Installed.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

88 of 186

VERTICAL TRANSPORT MODULE

Prerequisites:

None

To Remove:

1 De-energize the IMAGER. Touch:

power icon

[Shut Down]

Caution

Dangerous Voltage

2 Disconnect the POWER CORD.

3 Open the left FRONT DOOR.

4 From the front of the IMAGER, remove

the SCREW.

5 Pull the VERTICAL TRANSPORT

MODULE forward approximately 12 mm

(0.5 in.)

6 Move the VERTICAL TRANSPORT

MODULE left to disengage it from the

LOCKING PIN on the top right.

H199_1568CA

VERTICAL TRANSPORT

MODULE

UPPER

FRAME

SCREW

LOCKING PIN

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

89 of 186

Caution

To prevent damage to the lower part of the VERTICAL TRANSPORT MODULE, you must lift

and move the top of the MODULE through the UPPER FRAME when you remove it.

7 Pull the VERTICAL TRANSPORT MODULE forward to remove it from the IMAGER.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

90 of 186

FILM AT PROCESSOR SENSOR

Prerequisites:

1 Remove the VERTICAL TRANSPORT MODULE.

To Remove:

1 If necessary, loosen the 2 GUIDE

SCREWS to allow access to the

SENSOR SCREW.

2 Remove the SENSOR SCREW.

Caution

Use caution not to damage the ACTUATOR

FLAG of the PROCESSOR SENSOR.

3 Disconnect the CONNECTOR.

4 Remove the PROCESSOR SENSOR.

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

CONNECTOR

PROCESSOR

SENSOR

SENSOR

SCREW

ACTUATOR

FLAG

2 GUIDE

SCREWS

H199_1569GA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

91 of 186

VERTICAL TRANSPORT UP and DOWN MOTORS

Prerequisites:

1 Remove the VERTICAL TRANSPORT MODULE.

To Remove:

1 Disconnect the POWER CORD.

2 For either MOTOR, do:

a Loosen the TENSIONER.

b Remove the BELT.

c Disconnect the CONNECTOR to

the MOTOR.

d Remove:

3 SCREWS

E-RING

PULLEY

MOTOR

To Install:

1 Reverse the steps in the removal procedure.

Postrequisites:

None

TENSIONER

BELT

CONNECTOR

3 SCREWS

MOTOR

PULLEY

E-RING

CONNECTOR

3 SCREWS

TENSIONER

H199_1570CA

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

92 of 186

VERTICAL TRANSPORT BELTS

Prerequisites:

1 Remove the VERTICAL TRANSPORT MODULE.

To Remove:

1 Disconnect the POWER CORD.

2 If the BELT has a TENSIONER, do:

a Loosen the M4 SCREW.

b Rotate the TENSIONER to loosen

the tension and tighten the M4

SCREW.

3 Remove the BELTS:

M4 SCREW

TENSIONER

C

PULLEY

2 E-RINGS

BELT

D

A

E

B

F

G

H

H199_1571CA

BELT Action

A a. Remove:

2 E-RINGS

both PULLEYS

B a. Remove:

BELT A

lower E-RING

lower PULLEY

C a. Remove BELT A.

b. Loosen the TENSIONER.

D a. Remove:

2 E-RINGS

both PULLEYS

ADJUSTMENTS AND REPLACEMENTS Replacements

15JUL05

8F1621

Page

93 of 186

To Install:

1 Reverse the steps in the removal procedure.

2 When installing the BELTS, do: