Académique Documents

Professionnel Documents

Culture Documents

Thermal Analysis of Lead-Free Solder

Transféré par

capela135Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thermal Analysis of Lead-Free Solder

Transféré par

capela135Droits d'auteur :

Formats disponibles

- 1 -

N0. MAY.2003

Yutaka Ichimura

Application Engineering Section

Thermal Analysis of Lead-free Solder

1. Introduction

As the switch from tin-lead solders continues, various tin-based alloys are being adopted as

lead-free solders based on a balance of various properties. While melting temperature, oxidization,

mechanical characteristics, costs and other elements are part of the evaluation, investigating

thermal characteristics is important when setting the actual process conditions.

In this brief, various thermal analysis methods are used to measure lead-free solders

1)

.

2. Measurements

Four lead-free solders were used as measurement samples. Their alloy composition by weight

is as follows.

a. Sn 97% - Cu 3%

b. Sn 97% - Bi 3%

c. Sn 97% - Ag 3%

d. Sn 89% - Zn 8% - Bi 3%

The following instruments were used for measurements.

DSC6200 Differential Scanning Calorimeter

DSC6100 High Sensitivity Differential Scanning Calorimeter

TG/DTA6200 Thermogravimetry / Differential Thermal Analyzer

TMA/SS6100 Thermomechanical Analyzer

3. Result

Figure 1 shows the DSC results for the three samples with 3% of Cu, Ag or Bi added to Sn and

the Sn 89% - Zn 8% - Bi 3% sample. Comparing the two-component samples shows that the 3%

Ag sample had the lowest melting temperature peak. Furthermore, all samples were nearly

eutectic compositionally and no shoulder peaks were observed in this measurement condition.

Figure 2 shows the results for the Sn 97% - Ag 3% sample measured at the low heating rates.

Lower heating rates improve DSC curve resolution and shoulder peaks were observed here that

were not seen in the 10C/min condition. The eutectic composition of Sn-Ag alloys is an Ag

content of 3.5%. Since this measurement sample is close to eutectic, it is difficult to observe

shoulder peaks. The final temperature of a shoulder peak is the temperature at which the solder

completely melts. These results show that the work temperature of near-eutectic samples can be

investigated by measuring at low heating rates.

- 2 -

Figure 1 DSC Results for Lead-Free Solders

a. Sn97%-Cu3%, b. Sn97%-Bi 3%

c. Sn97%-Ag3%, d. Sn89%-Zn8%-Bi 3%

Unit : DSC6200

Sample weight : 20mg

Heating rate : 10C/ min

Temp. /

.

.

.

.

.

.

.

.

D

S

C

/

m

W

a

b

c

d

Figure 2 DSC Results for S 97%-Ag3% at Low Heating Rates

0.1C/min, 0.2C/min

0.5C/min, 1.0C/min

Unit : DSC6100

Sample weight : 20mg

.

.

.

.

.

.

.

D

S

C

/

m

W

Temp. /

.

.

.

.

- 3 -

Figure 4 TMA Results for Lead-Free Solders

a. Sn97%-Cu3%, b. Sn97%-Bi 3%

c. Sn97%-Ag3%, d. Sn89%-Zn8%-Bi 3%

Sample length : 20mm

Heating rate : 5C/ min

.

.

.

.

.

Temp. /

T

M

A

/

.

a

b

c

d

50~150C

(1/C)

a : 21. 4410

- 6

b : 19. 2610

- 6

c : 20. 1110

- 6

d : 22. 8710

- 6

Figure 3 TG/DTA Results for Lead-Free Solders

a. Sn97%-Cu3%, b. Sn97%-Bi 3%

c. Sn97%-Ag3%

Sample weight : 10mg

Heating rate : 5C/ min

D

T

A

/

V

T

G

/

.

.

.

.

.

.

.

Temp. /

.

.

.

.

.

.

.

.

.

.

a

b

c

a

b

c

- 4 -

Figure 3 shows the TG/DTA results for the three samples of Sn alloys with 3% of Cu, Ag or Bi.

In this condition, powder samples were heated in air. All DTA curves showed endothermic peaks

caused by melting and the TG curves showed weight increases starting from near the melting

temperatures. In particular, the DTA curve for the Sn 97% - Cu 3% sample showed endothermic

peak before melting and this sample had the largest weight increase, indicating that it oxidizes

more easily than other samples. These results show that TG/DTA is effective in investigating the

relation of work temperatures and oxidization reactions.

Figure 4 shows the TMA results for the lead-free solders. All samples showed thermal

expansion as the temperature increased. The average linear expansion coefficient (1/C) was

calculated for the 50C to 150C range for all samples. The results show that the Zn-Bi sample

had the highest expansion rate. It is important to be aware of variations in the thermal expansion

rate of solders and joint material, as this may cause stress when temperatures change. These

results show that TMA can accurately evaluate the thermal expansion of solders.

4. Summary

This brief introduced examples of the thermal analysis of four lead-free solders.

The thermal analysis methods introduced here can evaluate various thermal characteristics of

solders, including liquid phase temperatures, oxidization reactions and thermal expansion rates,

which are important in the research, development, and quality management of lead-free solders.

Reference

1) T. Nakamura, Y. Ichimura, K. Oshiro and R. Kinoshita, The 37th Japanese Conference on

Calorimetry and Thermal Analysis, p98 (2001)

Vous aimerez peut-être aussi

- AER423 Lab - Thermal Conductivity and Contact ResistanceDocument10 pagesAER423 Lab - Thermal Conductivity and Contact ResistanceHassanKhanPas encore d'évaluation

- Differential Scanning Calorimetry (DSC)Document96 pagesDifferential Scanning Calorimetry (DSC)Rajesh DwivediPas encore d'évaluation

- Determination of Manganese in Steel by Flame Atomic Absorption SpectrosDocument7 pagesDetermination of Manganese in Steel by Flame Atomic Absorption Spectrossexycassie100% (1)

- M4M13 SING - PHYS182.finalreportDocument3 pagesM4M13 SING - PHYS182.finalreportNicholas Bonn SingPas encore d'évaluation

- Bing Coal Analysis, EnglishDocument6 pagesBing Coal Analysis, EnglishHazem Diab100% (1)

- The Standard Coal Analysis: M M M WDocument6 pagesThe Standard Coal Analysis: M M M WHazem Diab100% (1)

- Proximate Analysis of CoalDocument30 pagesProximate Analysis of Coalvince coPas encore d'évaluation

- Calculate The Weight Loss of Aluminum in A 0.5 M Sodium Sulphate Solution As Per NACE-TM-0169/ASTM G31Document22 pagesCalculate The Weight Loss of Aluminum in A 0.5 M Sodium Sulphate Solution As Per NACE-TM-0169/ASTM G31Farwa NaeemPas encore d'évaluation

- Outokumpu Corrosion Management News Acom 3 2014Document11 pagesOutokumpu Corrosion Management News Acom 3 2014Joshua WalkerPas encore d'évaluation

- Shellsol A150 ND q7497 Eu 18042016Document3 pagesShellsol A150 ND q7497 Eu 18042016sizmaruPas encore d'évaluation

- Tugas 3 Tribologi Bagus Setiyo Aji 19103011031Document13 pagesTugas 3 Tribologi Bagus Setiyo Aji 19103011031Teknik MesinBagus Setiyo AjiPas encore d'évaluation

- Qualitative - Analysis - Class 12thDocument3 pagesQualitative - Analysis - Class 12thAnuj YadavPas encore d'évaluation

- Shellsol T q7412 PDFDocument3 pagesShellsol T q7412 PDFmePas encore d'évaluation

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaPas encore d'évaluation

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresPas encore d'évaluation

- Shellsol T q7412 AmDocument3 pagesShellsol T q7412 AmRagavendra Prabu GovindarajuPas encore d'évaluation

- Determination of Molar Volume and Universal Gas ConstantDocument4 pagesDetermination of Molar Volume and Universal Gas ConstantChester James PeñarubiaPas encore d'évaluation

- Datasheet KetonesmibkasiapacificDocument3 pagesDatasheet Ketonesmibkasiapacificnitin birajdarPas encore d'évaluation

- March 7 Homework Solutions: Mechanical Engineering 375 Heat TransferDocument5 pagesMarch 7 Homework Solutions: Mechanical Engineering 375 Heat TransferFadelPrawiraErwinPas encore d'évaluation

- Compression Properties of Lead-Bismuth: Y. Dai, F. Barbagallo, F. GroeschelDocument4 pagesCompression Properties of Lead-Bismuth: Y. Dai, F. Barbagallo, F. GroeschelRadu CristianPas encore d'évaluation

- Methodology: Table 3.1. Enthalpy and Entropy of Magnesium, Calcium and Iron (II) CarbonatesDocument8 pagesMethodology: Table 3.1. Enthalpy and Entropy of Magnesium, Calcium and Iron (II) Carbonatesnomore891Pas encore d'évaluation

- Heat and MassDocument5 pagesHeat and MassagooPas encore d'évaluation

- The Effect of Prior Tempering On Cryogenic Treatment To Reduce Retained AusteniteDocument10 pagesThe Effect of Prior Tempering On Cryogenic Treatment To Reduce Retained AusteniteMinh Nam BùiPas encore d'évaluation

- Sample ComputationDocument4 pagesSample ComputationTetsuya OkazakiPas encore d'évaluation

- DSC Calculation of Specific HeatDocument4 pagesDSC Calculation of Specific HeatSteel BeingPas encore d'évaluation

- Cobalt Replacement 1Document7 pagesCobalt Replacement 1Avinash BalakrishnanPas encore d'évaluation

- Tech Rep 4-2011 Copper Zirkonium AlloysDocument14 pagesTech Rep 4-2011 Copper Zirkonium AlloysBahadır UysalPas encore d'évaluation

- Determination of Manganese in Steel by Visible SpectrosDocument6 pagesDetermination of Manganese in Steel by Visible SpectrossexycassiePas encore d'évaluation

- Quench Sensitivity Al AlloysDocument31 pagesQuench Sensitivity Al AlloysCatalin Marian Vartosu-TomaPas encore d'évaluation

- Nam-2001-Numerical and Experimental Studies of 3-Dimensional Thermoforming ProcessDocument9 pagesNam-2001-Numerical and Experimental Studies of 3-Dimensional Thermoforming ProcessTim OpatzPas encore d'évaluation

- PTG Chapter 3 Asal ChemistryDocument15 pagesPTG Chapter 3 Asal ChemistryKai GeePas encore d'évaluation

- Isopentane Shell ChemicalsDocument3 pagesIsopentane Shell Chemicalsazrim02Pas encore d'évaluation

- Lab Report GCDocument8 pagesLab Report GCAyish MataPas encore d'évaluation

- Application TA 011eDocument4 pagesApplication TA 011ePedro Romel Nascimento HerbayPas encore d'évaluation

- Particle Size Dependence of Coal Volatile Matter Is There A Non-Maceral-Related EffectDocument4 pagesParticle Size Dependence of Coal Volatile Matter Is There A Non-Maceral-Related EffectAbdul Aziz AmmarPas encore d'évaluation

- Karakteristik Tembaga TemperaturDocument12 pagesKarakteristik Tembaga TemperaturdharmantoPas encore d'évaluation

- Thermal Expansion of SpinelsDocument6 pagesThermal Expansion of SpinelsRichardPas encore d'évaluation

- IJREI - Analysis of Calorimetric Measurement Bismuth and Tin SystemDocument5 pagesIJREI - Analysis of Calorimetric Measurement Bismuth and Tin SystemIjrei JournalPas encore d'évaluation

- Icsoba-45, 391-400, 2016Document10 pagesIcsoba-45, 391-400, 2016Debashis DashPas encore d'évaluation

- Thermal Analysis TechniquesDocument34 pagesThermal Analysis TechniquesMujahid AmeenPas encore d'évaluation

- Nadia Hamzawy Mohamed - Nadia PaperDocument7 pagesNadia Hamzawy Mohamed - Nadia PaperchatgptuseregyptPas encore d'évaluation

- Thermal PropertiesDocument13 pagesThermal Propertiesoreaby05Pas encore d'évaluation

- Dissolved Gas Analysis of Thermal Faults in Transformer Liquids Simulated Using Immersed Heating MethodDocument10 pagesDissolved Gas Analysis of Thermal Faults in Transformer Liquids Simulated Using Immersed Heating MethodilhamPas encore d'évaluation

- Cai2006 Schlenk LineDocument4 pagesCai2006 Schlenk LineAnge NeiraPas encore d'évaluation

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- Siemens 1 GTX 100 TurbineDocument16 pagesSiemens 1 GTX 100 TurbinejparmarPas encore d'évaluation

- ASTM E1354 ReportDocument6 pagesASTM E1354 ReportMinhaj AliPas encore d'évaluation

- Accepted Manuscript: Materials LettersDocument10 pagesAccepted Manuscript: Materials Letterswahy027Pas encore d'évaluation

- Soal Coulson Richardson Page 696-706 (STHE Design)Document11 pagesSoal Coulson Richardson Page 696-706 (STHE Design)Glen gaylandPas encore d'évaluation

- Enthlapy Lab 2Document8 pagesEnthlapy Lab 2Judy FaourPas encore d'évaluation

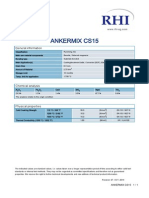

- Ankermix Cs15 Stahl Flow Control Iso enDocument1 pageAnkermix Cs15 Stahl Flow Control Iso enthinhbntPas encore d'évaluation

- Temperature: The Working RangeDocument10 pagesTemperature: The Working RangeZied HazemPas encore d'évaluation

- 1 s2.0 S0921509397004917 MainDocument5 pages1 s2.0 S0921509397004917 MainMehtap KuzuPas encore d'évaluation

- Incineration of Styrene-Butadiene Rubber: The Influence of Heating Rate and Oxygen Content On Gas Products FormationDocument14 pagesIncineration of Styrene-Butadiene Rubber: The Influence of Heating Rate and Oxygen Content On Gas Products FormationPhilip ShihPas encore d'évaluation

- Methyl Ethyl Ketone: Shell ChemicalsDocument3 pagesMethyl Ethyl Ketone: Shell ChemicalssyamlokPas encore d'évaluation

- Optimal Heat Transfer Calculation and Balancing For Gas Sweetening Process A Case StudyDocument9 pagesOptimal Heat Transfer Calculation and Balancing For Gas Sweetening Process A Case Studylutfi awnPas encore d'évaluation

- MTR - HT# 52154Document1 pageMTR - HT# 52154ColinPas encore d'évaluation

- Process Intensification for Sustainable Energy ConversionD'EverandProcess Intensification for Sustainable Energy ConversionPas encore d'évaluation

- The Origin and Development of English NovelDocument16 pagesThe Origin and Development of English NovelFaisal JahangeerPas encore d'évaluation

- Surviving Hetzers G13Document42 pagesSurviving Hetzers G13Mercedes Gomez Martinez100% (2)

- Occult Final DraftDocument142 pagesOccult Final DraftAlquimista AncestralPas encore d'évaluation

- (Mr. Nigel West, Oleg Tsarev) TRIPLEX Secrets Fro (B-Ok - Xyz)Document377 pages(Mr. Nigel West, Oleg Tsarev) TRIPLEX Secrets Fro (B-Ok - Xyz)conbePas encore d'évaluation

- Adv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023Document18 pagesAdv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023senorislamPas encore d'évaluation

- Hudson Legal CV Interview GuideDocument16 pagesHudson Legal CV Interview GuideDanielMead100% (1)

- Achieving Rapid Internationalization of Sub Saharan Africa - 2020 - Journal of BDocument11 pagesAchieving Rapid Internationalization of Sub Saharan Africa - 2020 - Journal of BErnaPas encore d'évaluation

- Small Hydro Power Plants ALSTOMDocument20 pagesSmall Hydro Power Plants ALSTOMuzairmughalPas encore d'évaluation

- Merger and Acquisition Review 2012Document2 pagesMerger and Acquisition Review 2012Putri Rizky DwisumartiPas encore d'évaluation

- Organizational Behavior: L. Jeff Seaton, Phd. Murray State UniversityDocument15 pagesOrganizational Behavior: L. Jeff Seaton, Phd. Murray State UniversitySatish ChandraPas encore d'évaluation

- ICargo Mobility QantasDocument4 pagesICargo Mobility QantasViswateja KrottapalliPas encore d'évaluation

- A#2 8612 SehrishDocument16 pagesA#2 8612 SehrishMehvish raniPas encore d'évaluation

- Executive Summary: College of EngineeringDocument17 pagesExecutive Summary: College of Engineeringjoel c. herreraPas encore d'évaluation

- Pierre Bonnard: La Revue BlancheDocument2 pagesPierre Bonnard: La Revue BlancheHdjsPas encore d'évaluation

- Excursion Parent Consent Form - 2021 VSSECDocument8 pagesExcursion Parent Consent Form - 2021 VSSECFelix LePas encore d'évaluation

- Admin Law ReviewerDocument5 pagesAdmin Law ReviewerNirvana Time Sulivan Estiva100% (1)

- Memorandum of Inderstanding Ups and GoldcoastDocument3 pagesMemorandum of Inderstanding Ups and Goldcoastred_21Pas encore d'évaluation

- Chap 2 Human Resource Strategy and PerformanceDocument35 pagesChap 2 Human Resource Strategy and PerformanceĐinh HiệpPas encore d'évaluation

- Slavfile: in This IssueDocument34 pagesSlavfile: in This IssueNora FavorovPas encore d'évaluation

- Case Report On Salford Estates (No. 2) Limited V AltoMart LimitedDocument2 pagesCase Report On Salford Estates (No. 2) Limited V AltoMart LimitedIqbal MohammedPas encore d'évaluation

- Online MDP Program VIIIDocument6 pagesOnline MDP Program VIIIAmiya KumarPas encore d'évaluation

- Land Laws (MOHD AQIB SF)Document18 pagesLand Laws (MOHD AQIB SF)Mohd AqibPas encore d'évaluation

- ReinsuranceDocument142 pagesReinsuranceabhishek pathakPas encore d'évaluation

- Deed of Assignment: Test All Results Data andDocument3 pagesDeed of Assignment: Test All Results Data andkumag2Pas encore d'évaluation

- Authors & Abstract Guideline V-ASMIUA 2020Document8 pagesAuthors & Abstract Guideline V-ASMIUA 2020tiopanPas encore d'évaluation

- Journey Toward OnenessDocument2 pagesJourney Toward Onenesswiziqsairam100% (2)

- 240 Marilag v. MartinezDocument21 pages240 Marilag v. Martinezdos2reqjPas encore d'évaluation

- La Bugal BLaan Tribal Association Inc. vs. RamosDocument62 pagesLa Bugal BLaan Tribal Association Inc. vs. RamosAKnownKneeMouseePas encore d'évaluation

- Linking Social Science Theories/Models To EducationDocument2 pagesLinking Social Science Theories/Models To EducationAlexa GandioncoPas encore d'évaluation

- ZodiacDocument6 pagesZodiacapi-26172340Pas encore d'évaluation