Académique Documents

Professionnel Documents

Culture Documents

Adaptive Fault Diagnosis Algorithm For Controller Area Network

Transféré par

anmol6237Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Adaptive Fault Diagnosis Algorithm For Controller Area Network

Transféré par

anmol6237Droits d'auteur :

Formats disponibles

IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 61, NO.

10, OCTOBER 2014 5527

Adaptive Fault Diagnosis Algorithm for

Controller Area Network

Supriya Kelkar, Member, IEEE, and Raj Kamal, Member, IEEE

AbstractA controller area network (CAN)-based distributed

system may develop faults at run-time. These faults need to be

detected and diagnosed. This paper proposes a new algorithm

named adaptive fault diagnosis algorithm for CAN (AFDCAN). It

is designed for low-cost resource-constrained distributed embed-

ded systems. The proposed algorithm detects all faulty nodes on

the CAN. It allows new node entry and reentry of repaired faulty

nodes during a diagnostic cycle. AFDCAN is found to provide

high fault tolerance and to ensure reliable communication. It uses

single-channel communication deploying the bus-based standard

CAN protocol. A hardware implementation of the proposed algo-

rithm has been used to obtain the results. The results show that the

proposed algorithm diagnoses all faults in the system. Analysis of

the proposed algorithm proves that the algorithm uses a denite

and bounded number of testing rounds and messages to complete

one diagnostic cycle.

Index TermsAdaptive algorithms, automotive applications,

controller area network (CAN) protocol, distributed networks,

distributed systems, fault diagnosis, real-time systems.

I. INTRODUCTION

D

IFFERENT techniques are used to handle faults in a

distributed network. Faults in the network may be due

to node failures or connection failures. Faults at nodes can

arise due to failures in the processor, in the memory, or in the

inputoutput hardware interfaces. The faults in the network can

be at the physical layer, data link layer, application layer, or

network management level [1].

Controller area network (CAN) protocol is widely used in

real-time industrial and automotive applications. There are

many other proprietary as well as standard serial protocols used

for automotive multiplexing [2], [3]. CAN handles the errors

efciently at the node level. Error connement depends upon

the behavior of the node when the node is in one of the three

states, namely, active state, passive state, or bus-off state [4].

The connement of faults is a part of the CAN protocol [4].

However, along with capabilities of fault diagnosis and fault

connement at node level, CAN-based distributed embedded

Manuscript received April 6, 2013; revised July 22, 2013 and September 8,

2013; accepted November 14, 2013. Date of publication January 2, 2014; date

of current version May 2, 2014. This work was supported by the Cummins Col-

lege of Engineering for Women, Pune, India, and the Institute of Engineering

and Technology, Devi Ahilya University, Indore, India.

S. Kelkar is with the Computer Engineering Department, Cummins College

of Engineering for Women, Pune 411052, India (e-mail: supriya.kelkar@

cumminscollege.in).

R. Kamal is with the School of Computer Science and Information Tech-

nology, Devi Ahilya University, Indore 452017, India (e-mail: dr_rajkamal@

hotmail.com).

Color versions of one or more of the gures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identier 10.1109/TIE.2013.2297296

systems need a robust fault diagnosis algorithm at network

level. This is to assure a reliable communication to achieve

expected functioning of the system. Reliability can be achieved

by providing redundancy at node level or at channel level [5]

[7]. However, this additional use of hardware increases the

cost. In a distributed embedded system, every node needs to

have knowledge about other nodes in the system. In case of

master-slave conguration, the functions are distributed among

different nodes. Every node in the system in such a situation

should be able to detect the faulty nodes in the system and

should relay this information on the network. There will be a

considerable rise in the number of diagnostic messages if every

node tries to detect the health of all other nodes. This, in turn,

increases the bus-load and slows down the communication.

There is a high probability of denial of bus access to low-

priority messages due to the increase in bus-load.

Authors address these issues and propose adaptive fault diag-

nosis algorithm for CAN (AFDCAN). Every node in AFDCAN

tests other nodes until it detects a rst fault-free node. Thus, a

node in AFDCAN does not test all other nodes in the system.

All of the fault-free nodes together detect the faulty nodes in the

system. This reduces the number of diagnostic messages on the

bus. Thus, the system diagnostic function is distributed among

the nodes. Also, redundancy in terms of extra nodes or channels

is not required [5][7].

II. EARLIER WORK AND MOTIVATION FOR THE

PRESENT WORK

CAN is a single-channel protocol [4]. It does not support

redundant bus for communication among different nodes in the

network [5]. Considerable literature is available for CAN to

achieve redundancy at channel or media level [5], [6] and at

node level [6]. Redundancy at media and node levels is a desired

feature for fault handling in safety-critical applications. Time

triggered-CAN (TT-CAN) supports channel redundancy with

the use of additional hardware [7], [8]. Time triggered protocol

supports node and channel duplication for real-time control

systems such as automotive applications [9]. An active star

topology called CANcentrate has been proposed for providing

a solution to communication failures in CAN-based systems

[10], [11]. CANcentrate uses an active hub to connect the CAN-

based nodes and prevents propagation of errors from one port

to others. However, CANcentrate requires additional hardware,

which itself may become faulty.

Automotive applications such as steer-by-wire are driven by

actuators [12]. The faulty actuators need to be switched off

within a short time span to avoid unwanted system behavior.

0278-0046 2014 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.

5528 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 61, NO. 10, OCTOBER 2014

Time-constrained failure diagnosis uses a subset of the total

number of processors in the system to test an actuator indepen-

dently [12]. The individual test results are exchanged among

these processors, and the fault-free processors correctly identify

the actuator fault. Here, more processors are required for testing

[12]. Another approach for diagnosing faults in automotive

applications is based on condensed diagnosis instead of global

diagnosis [13]. Condensed diagnosis includes diagnostic in-

formation of components, inputs, and signals for a unit or an

agent along with a scalar variable representing removed com-

ponents. Using condensed local diagnosis of different agents,

the condensed global diagnosis of the system can be computed.

Arogeti et al. [14] have proposed a new fault detection and

isolation technique for an electrohydraulic steering system of

an electric vehicle. They have proposed a hybrid bond graph

modeling technique and have derived the global analytical

redundancy relations [14]. Vong et al. [15] have proposed a new

framework for simultaneous-fault diagnosis. They have used

pairwise probabilistic multilevel classication based on time-

dependent patterns and have applied the framework to diagnose

automotive engine-ignition systems. The effects of faults on

the estimation of schedulability and reliability are illustrated

in [16]. Authors have applied the outcome of the analysis on

a distributed antilock breaking system of an automotive [16].

Networked control systems (NCSs) are used in applica-

tions such as automotive, manufacturing processes, etc. [17].

Jiang et al. have considered the Takagi-Sugeno fuzzy model

for the NCSs and have proposed H

lter design with respect

to transfer delays and packet loss [17]. Yang et al. [18] have

modeled the NCSs as nonlinear switched systems and have

addressed the problem of system stabilization. Their results

have been applied to multiagent systems with leader-follower

structure, especially when the follower agent may not cooperate

with the leader and run away from a target or a goal [18].

Data-driven approach is used for fault diagnosis in automo-

tive domain, in manufacturing systems, and in process control

applications. Faults are detected and isolated using a multivari-

ate statistical technique, namely, principle component analysis

(PCA) and pattern classier techniques such as support vector

machines, probabilistic neural network, and K-nearest neighbor

[19]. PCA and independent component analysis (ICA) are used

together to detect the faults in operating parameter identiers

which are collected through various sensors and diagnostic

routines situated in the electronic control units (ECUs) [20].

ICA is better suited than PCA for fault detection in automo-

tive applications. ICA is more effective for automotive subsys-

tem data of non-Gaussian nature [21]. Although PCA is used

for fault isolation, it is not well suited for task discrimination

[22], [23]. PCA shows limited discrimination or classication

when data for both normal operation and fault operation are

available [23]. Among correspondence analysis (CA) and PCA,

better results are observed with the former [22], [24].

Kelkar and Kamal conclude that these data-driven methods

are useful in cases where the system is multivariate and the data

set available for fault detection is very large. Techniques for

multivariate statistical analysis such as PCA tend to reduce the

number of variables in a data set, thus limiting the dimensions

of the data. Statistical techniques such as PCA, ICA, and CA

TABLE I

COMPARISON OF DISTRIBUTED ALGORITHMS

are applied on normal or fault diagnosis data acquired through

data loggers. Analyses using these techniques are carried out

outside the actual control units or systems.

A number of algorithms have been suggested in the area

of fault diagnosis in distributed networks. Table I shows the

comparison of some of these algorithms [25][27]. Distributed

system-level diagnosis algorithm for arbitrary networks such

as point-to-point, broadcast, or combination of both has been

proposed [28]. Here, a fault-free node is made responsible to

get tested by another fault-free node. The tests are conducted

periodically, and the node transmits diagnostic information to

all of its neighbors about detection of a new node or a repaired

faulty node. This information is received simultaneously by all

of the neighbors. A hierarchical adaptive distributed system-

level diagnosis algorithm (Hi-ADSD) uses clusters containing

nodes, where the number of nodes in a cluster is always a

power of two [29]. Here, a node can get tested by more than

one node, and tests are conducted asynchronously. The number

of test rounds required for Hi-ADSD [29] is less than that for

adaptive DSD [27]. There is also an improvement in diagnosis

latency [29].

Comparison-based model is another approach for fault di-

agnosis in multiprocessor systems. In this model, redundant

tasks are executed at two processors, and the outcomes of the

tasks are sent to a central observer which, in turn, compares the

outcomes to nd the faulty processor [30], [31]. The processors

themselves compare the outcomes of the tasks executed by

two other processors instead of the central observer [32]. In

generalized comparison model (GCM), the comparison is done

by one of the two processors being tested [33].

The outcomes are also sent to the central observer, even

though the processors themselves perform the comparison [32],

[33]. The outcomes of the tasks executed by two processors are

also sent to all other processors in the broadcast comparison

KELKAR AND KAMAL: ADAPTIVE FAULT DIAGNOSIS ALGORITHM FOR CONTROLLER AREA NETWORK 5529

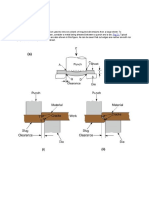

Fig. 1. System under consideration for fault diagnosis.

model [34]. Articial neural network (ANN) based GCM

model employs backpropagation neural networks to diagnose

the faults in multiprocessor or multicomputer systems [35].

These ANN-based techniques require considerable memory

and processing power.

SAE J1939 protocol uses CAN bus at physical layer. This

protocol is widely used in automotive applications and also

supports extensive diagnostic features. SAE J1979 is the SAE

guideline for On-Board-Diagnostics-II (OBD-II) [36]. Specic

online and ofine diagnostic features for different categories of

automotive are available in SAE documents.

While working with distributed embedded systems, authors

felt a need to incorporate an effective fault detection technique

in these systems. For example, in the process control applica-

tions, some nodes or microcontroller-based systems may fail

during operation. Such information of failed nodes needs to be

known to all other nodes in the network. For this purpose, the

methodologies used in distributed computer systems [25][29]

have been found suitable. These methods have been used for

hybrid or star networks where fault detection algorithms are

mostly adaptive and parallel.

The adaptive algorithm does not use a xed testing scheme

but adapts to the current fault situation in the system, and the

nodes are tested accordingly. In distributed computer systems,

diagnostic tests are carried out by different nodes simulta-

neously and hence are termed as parallel. A fault detection

method using parallel diagnostic tests would have been stressful

to the distributed embedded systems which use bus topology.

Hence, in this paper, the authors have proposed an adaptive

sequential algorithm for fault detection in bus-based distributed

embedded systems, named as AFDCAN. It is an adaptive fault

detection algorithm, which resides inside the nodes along with

the applications and detects faults in the system as and when

they occur.

AFDCAN uses distributed network approach for detecting

faults. AFDCAN is designed for CAN-based embedded dis-

tributed networks which specically use bus topology. This

algorithm needs comparatively less memory, and the number

of messages required for a diagnostic cycle is optimized.

AFDCAN can be adapted for other automotive protocols such

as local interconnect network and SAE J1939 with a few

modications. In the present work, focus is on nding the faulty

nodes in the network and, in turn, informing the statuses of

faulty nodes to all of the healthy nodes. As mentioned earlier,

different approaches have been used for fault diagnosis in

CAN-based systems. These approaches include additional use

of hardware in case of CANcentrate [10], specic domains like

automotive using SAE J1979 [36], time-constrained fault diag-

nosis [12], condensed diagnosis [13], generic distributed mul-

ticomputer systems [25][29], etc. To the best of the authors

knowledge, specically in the CAN protocol, fault detection

techniques for a bus topology have not been proposed earlier.

The remainder of this paper is organized as follows.

Section III proposes the new AFDCAN algorithm. Section IV

provides its modeling and analysis. Section V proposes fur-

ther modications to AFDCAN. Comparison of AFDCAN

with other distributed diagnosis algorithms is presented in

Section VI. Section VII presents important experimental results

for different fault cases when implemented using the hard-

ware. This is followed by Section VIII giving the conclusion.

The mathematical representation of the AFDCAN algorithm is

presented in the Appendix.

III. AFDCAN

A. System Details, Assumptions, and Fault Model

for AFDCAN

AFDCAN algorithm uses single bidirectional channel and

bus-based CAN topology. Let V be the set containing n number

of nodes in the system, where N

1

is the rst node, N

2

is the

second node, etc. Then

V = {N

1

, N

2

, N

3

, N

4

, . . . , N

n

} . (1)

The following assumptions are considered for fault condi-

tions in AFDCAN.

1) The node is assumed faulty when it stops functioning.

2) There can be one or more faulty nodes in the system,

where faults are bounded.

3) The number of faulty nodes in the system is bounded

by (n 2), where n is the total number of nodes in the

system.

4) A node can become faulty any time during the diagnostic

cycle. This fault condition of the node may be temporary

or permanent.

5) Fluctuations or changes in the status of a node are not

detected during the same diagnostic cycle if that node has

already been tested. However, the change in status of that

node will be detected in the next diagnostic cycle.

6) Every node is tested by only one other node in a diagnos-

tic cycle.

Fig. 1 shows a generic system utilizing the AFDCAN algo-

rithm for fault diagnosis. AFDCAN uses the following fault

model for the CAN network. The fault model denes the

outcome of the test, i.e., response from the fault-free node or

from the faulty node when the test message is sent by another

fault-free node.

5530 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 61, NO. 10, OCTOBER 2014

Fig. 2. Format of the buffer at every node.

Fig. 3. Test/result/second result/broadcast frame.

Let t(n

i

, n

j

) be the test performed by node n

i

on node n

j

.

Then, result R

e

of t(n

i

, n

j

) will be

R

e

= 0, if n

i

is fault free and n

j

is faulty;

R

e

= 1, if both n

i

and n

j

are fault free;

n

i

cannot test n

j

and evaluate n

j

as fault free if n

i

itself is faulty.

In the present algorithm, the faulty node stops functioning,

and therefore, it is unable to communicate with the other nodes.

B. Details of the AFDCAN Algorithm

A node continues to diagnose until it nds a fault-free

node. This approach is similar to the adaptive DSD algorithm

proposed for distributed systems [27].

Each node is assigned a unique node identication (NID).

Each node maintains a buffer (NBUFF) containing n number of

elds, where n is the total number of nodes in the system. The

NBUFF of each node consists of individual elds containing

node ID and state for all of the nodes in the system. The state

indicates whether the node is faulty, is fault free, or is in an

undened state. Fig. 2 shows NBUFF of a node in a system

containing ve nodes. A fault-free node in the network initiates

the AFDCAN algorithm by sending the test frame.

The format for different types of frames used in AFDCAN is

shown in Fig. 3. There are 8 B in the CAN data frame allocated

to data eld. Fig. 3 shows these 8 B and their use in AFDCAN.

A node can be a tester which tests the other nodes or it can

be a testee which gets tested by any one fault-free node. While

sending the test frame, the NID of the tester becomes the source

node identication (SID), and the NIDof the testee becomes the

destination node identication (DID).

Any node that does not receive a test frame as a testee within

a specic time becomes the tester and initiates the diagnosis

process. The testee receives the test frame if it is not faulty.

It marks the tester as fault free in its buffer. Also, it updates

its buffer with the diagnostic information of all of the nodes

preceding the tester. This status information is available in

the test frame sent by the tester. Then, the testee will send

the result frame to the tester. After receiving the result frame

from the testee within timeout, the tester reads the diagnostic

information fromthe result frame. As read fromthe result frame

sent by the testee, the tester updates its buffer, marking its own

status as fault free. Also, the tester marks the testee as fault free

in its buffer. This communication is called test round between

two nodes. This is shown in Fig. 4.

The aforementioned test rounds continue until the last node

in the system is tested. The last fault-free node sends the second

result frame to the earlier fault-free node after all of the test

rounds are completed. After the reception of second result

frame, the (m 1)th fault-free node transmits the broadcast

frame to all of the nodes, which contains the complete diagnosis

report of the network. Here, m n, with n being the total

number of nodes in the system and mth node being the last

fault-free node in the system. This is the end of one diagnostic

cycle as shown in Fig. 4. These diagnostic cycles are periodic

in nature.

In Fig. 5, as discussed earlier, the test round will be

completed between N

1

and N

2

, N

2

and N

3

, and N

3

and N

4

.

However, when N

4

sends the test frame to N

5

, node N

5

, being

faulty, does not respond and thus does not send the result frame

to N

4

. Therefore, N

4

marks N

5

as faulty in its buffer and then

sends the second result frame to N

3

. Now, N

3

will update its

buffer for the nal result and will send the broadcast frame to all

of the nodes so that all of the fault-free nodes will update their

buffers with the complete diagnostic information of the system.

This is the reason why the second result frame is transmitted in

the AFDCAN algorithm.

C. Entry of New Nodes and Reentry of Faulty Nodes

After Repairs

AFDCAN supports new node entry and its participation in

the fault diagnostic cycle.

When a new node is powered up, it needs to listen to the

bus. The new node sends the new node entry frame after the

detection of a result frame on the bus. All of the nodes which are

part of the diagnostic cycle receive the new node entry frame.

These nodes recognize the arrival of the new node and allocate

a eld in their buffer for this node. The allocated eld in the

buffer is then updated with the node ID and state of the new

node. Thus, the new node starts participating from the next

diagnostic cycle.

Fig. 6 shows the format of the entry frame for a new node.

Faulty nodes can also reenter the network and participate in

the diagnostic cycle after they are repaired. A faulty node can

join the current or ongoing diagnostic cycle if its tester has not

yet sent the test frame to it. Otherwise, it starts participating

from the next diagnostic cycle. The number of faulty nodes is

bounded by (n 2).

In the Appendix, Section A presents the algorithm for a test

round between the tester and the testee, Section B presents the

algorithms for different timeout conditions, and the algorithm

for the new node entry is presented in Section C.

IV. MODELING AND ANALYSIS OF THE AFDCAN

ALGORITHM

The system considered by AFDCAN is represented by a

directed multigraph G, where G = (V, E) consists of a set V

KELKAR AND KAMAL: ADAPTIVE FAULT DIAGNOSIS ALGORITHM FOR CONTROLLER AREA NETWORK 5531

Fig. 4. Complete diagnostic cycle when all of the nodes are fault free.

Fig. 5. Complete diagnostic cycle when node N

5

is faulty.

Fig. 6. Entry frame for a new node.

of vertices, a set E of edges, and a function f from E to

{(u, v)|u, vCV }. The edges e

1

and e

2

are multiple edges if

f(e

1

) = f(e

2

)[37].

In the graph, the vertices represent the nodes, and the

edges represent the communication paths. These communica-

tion paths are unidirectional. Fig. 7 is the graphical representa-

tion of the systemunder consideration for a case where there are

no faulty nodes. T represents the test frame sent by the node,

R, the result frame sent by the node, 2R, the second result

frame sent by the node, and B, the broadcast frame sent by

the node. It may be noted that these edges are directed outward

from the nodes.

Consider nodes N

3

and N

4

shown in Fig. 7. As there are

two edges, namely, result and broadcast, directed from N

4

to N

3

, one can say that (N

4

, N

3

) is an edge of G(V, E),

with f(e

1

) = f(e

2

) = (N

4

, N

3

). Similarly, for nodes N

4

and

N

5

, it can be proved that (N

5

, N

4

) is an edge of G(V, E),

with f(e

1

) = f(e

2

) = (N

5

, N

4

). Thus, it is proved that Fig. 7

represents a multigraph. Fig. 8 represents the multigraph of the

system with fault condition.

The system under consideration has been proved to be a

planar graph for all fault conditions with (n 2) as bounded

Fig. 7. System with no faulty node.

Fig. 8. System with node N

2

faulty.

condition for faulty nodes. That means that the system with ve

nodes is a planar graph with the maximum allowed number of

faulty nodes being three.

5532 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 61, NO. 10, OCTOBER 2014

Fig. 9. Adjacency matrix for out-degree of nodes, when node N

2

is faulty.

The following discussion provides the proofs for a lemma

and two theorems.

Lemma: There is a directed path from any fault-free node to

any other fault-free node. This leads to following theorems.

Theorem 1: The number of test rounds for one complete

diagnostic cycle is denite and bounded.

Theorem 2: The number of diagnostic messages required for

a complete diagnostic cycle is denite and bounded.

The proofs for the aforementioned lemma and theorems are

given in Section IV-(A)(C), respectively.

A. Proof for the Lemma

Fig. 9 shows the adjacency matrix N for out-degree of nodes

N

1

, N

2

, N

3

, N

4

, and N

5

. N represents the case where node N

2

is faulty as shown in Fig. 8.

In an adjacency matrix N

N =[a

ij

] then

a

ij

=1, if there is an edge from N

i

to N

j

, i, j =1, 2 . . . 5

a

ij

=0 otherwise [37].

For Fig. 8, when a

ij

= 0, no directed path exists from i to j,

and when a

ij

= 1, a directed path exists.

The rows of the adjacency matrix represent nodes N

1

, N

2

,

N

3

, N

4

, and N

5

, respectively. In the adjacency matrix shown

in Fig. 9, where the elements having values of 1 indicate that a

directed path exists and 2 indicate that more than one path exist

between the nodes. When all of the elements in ith row are zero,

N

i

th node is faulty. The second row (row N

2

) of Fig. 9 contains

all zeros indicating N

2

being a faulty node. The following are

some of the observations regarding the fault conditions in the

system after analyzing the adjacency matrix (Fig. 9).

1) If a particular row contains all of the elements as zero, the

corresponding node is a faulty node.

2) The elements above the main diagonal of the adjacency

matrix provide the information about the directed path

between all of the fault-free nodes of the system.

B. Proof for Theorem 1

One test round in AFDCAN consists of two messages be-

tween any two fault-free nodes. They are the test message and

the result message.

With n being the total number of nodes in the system, the

number of test rounds t

R

will be (n 1) for the fault-free

system.

If there are f number of faulty nodes in the system, then

t

R

= n 1 f. (2)

There is an additional result message sent from mth fault-

free node to (m 1)th fault-free node, where m n and m

is the last fault-free node in the system with f faulty nodes.

This constitutes half of t

R

. Also, (m 1)th fault-free node

broadcasts the result which contains the complete diagnosis

report of the network.

For the fault-free system, the number of broadcasting mes-

sages will constitute {(n 1)/2} test rounds, where (n 1)

is the total number of broadcasted messages from (m 1)th

fault-free node. Also, there are test messages sent to f faulty

nodes, where these nodes do not respond and thus do not com-

plete the test round. This constitutes {(n 2)/2} test rounds,

where (n 2) is the maximum number of faulty nodes. Thus,

there is a need to consider all of the aforementioned additional

communication edges as part of the diagnostic cycle. These

communication edges will also contribute to (2).

Let c

e

be the total of aforementioned additional communi-

cation edges. Also, t

R

is called as t

RPair

, which represents

the total number of pairs of messages inclusive of all of the

communication edges for a single diagnostic cycle in a system.

The maximum number of pairs of messages in one complete

diagnostic cycle of the system is represented by t

RPair(max)

.

Therefore

t

RPair(max)

= n 1 f + c

e

(3)

where

c

e

=

n 1

2

+

1

2

+

n 2

2

and c

e

= Total of all of the additional communication edges as

described previously.

Therefore

t

RPair(max)

= 2n f 2. (4)

Consider the system consisting of ve nodes, with three

nodes detected as faulty. In this case, as per (4), there will be

maximum ve pairs of messages (t

RPair(max)

) in one complete

diagnostic cycle. Equation (4) satises all of the 26 fault

conditions for the system with ve nodes.

C. Proof for Theorem 2

Let t

m

be the total number of test messages sent, r, the total

number of result messages sent, and (n 1), the total number

of broadcasted messages.

Then, the total number of messages (m

s

) in one complete

diagnostic cycle is

m

s

= t

m

+ r + (n 1). (5)

If there are f number of faulty nodes in the system, then

r = n f. (6)

Therefore

m

s

= t

m

+ 2n f 1. (7)

Equation (7) provides the exact number of messages required

for one complete diagnostic cycle for the fault-free or fault

KELKAR AND KAMAL: ADAPTIVE FAULT DIAGNOSIS ALGORITHM FOR CONTROLLER AREA NETWORK 5533

Fig. 10. Arrow diagram for the system with nodes N

1

and N

3

faulty.

condition of the system. The value of m

s

can also be obtained

from the arrow diagram. The arrow diagram shown in Fig. 10

represents the condition where nodes N

1

and N

3

are faulty.

The in-degree d

in

(G) gives the exact number of messages for a

complete diagnostic cycle. For the system with ve nodes, the

values of m

s

can be obtained for all of the 26 fault conditions

using arrow diagrams similar to Fig. 10.

Let m

smax

be the upper bound for the number of messages

in one complete diagnostic cycle. It is known from earlier

discussion that

t

m

(n 1). (8)

Thus, by adding (2n f 1) on both sides of (8), we get

m

smax

= 3n f 2. (9)

Thus, the total number of messages in one complete diagnos-

tic cycle is bounded and also denite.

V. PROPOSED MODIFICATIONS IN AFDCAN

The diagnostic cycle in AFDCAN is periodic, and the algo-

rithm checks each and every node during the diagnostic cycle.

A node is tested again even if it is detected as faulty in the

earlier cycle. This technique increases the time required for

the completion of a diagnostic cycle, as the earlier node waits

for the response from the next faulty node until timeout. A

solution to this additional latency would be in avoiding the

testing of the faulty nodes in the next diagnostic cycles. A

fault-free node can check its buffer to identify faulty nodes, if

any, for the currently completed diagnostic cycle. During the

next diagnostic cycle, a fault-free node can avoid testing these

faulty nodes. Thus, the diagnostic time can be reduced. This

will improve the performance of AFDCAN. In such a case, the

faulty node after repair can enter into the diagnostic cycle by

sending the entry frame for the repaired faulty node.

The entry frame for the repaired faulty node will contain SID

specifying the node ID, DID as zero, and frame type equal to

0101. The entry frame for the repaired faulty node will be

similar to the entry frame for the new node (Fig. 6) but with

the frame type bits as 0101. Also, the buffer writing at every

node can be avoided if the current fault status of a tested node

is the same as that found in the buffer.

Presently, the number of faulty nodes in the system is

bounded by (n 2). This bound can be made equal to (n 1)

with minor changes in the algorithm. Thus, AFDCAN can

operate even if there is only one fault-free node in the system.

TABLE II

COMPARISON OF DISTRIBUTED FAULT DIAGNOSIS ALGORITHMS

VI. COMPARISON OF AFDCAN WITH OTHER

FAULT DIAGNOSIS ALGORITHMS FOR

DISTRIBUTED NETWORKS

The AFDCAN algorithm is based on the CAN protocol.

In this section, the authors compare AFDCAN with other

algorithms [25][29] for fault diagnosis in distributed networks.

These algorithms [25][29] are discussed in Section II.

AFDCAN is a fault diagnosis algorithm for distributed em-

bedded systems, whereas the algorithms in [25][29] have been

implemented on Ethernet-based distributed computer systems.

AFDCAN is an adaptive fault diagnosis algorithm, and the al-

gorithms in [25][29] also are of adaptive type. The algorithms

in [25][29] are executed in parallel by the computer systems,

whereas the tests in AFDCAN are executed sequentially. How-

ever, in AFDCAN, the transmission of the nal result to all of

the nodes is done at the same time, which means in parallel.

The fault model used in AFDCAN is asymmetric as dis-

cussed in Section III-A. Presently, in AFDCAN, the faulty node

does not respond to the test message sent by the other node and

does not understand the nal result. This is because AFDCAN

considers the faulty node as ceased to function, as in the fail-

stop model discussed in [28]. The fault model is symmetric [27]

for algorithms described in [25][27], and [29]. A comparison

of AFDCAN and other algorithms is presented in Table II.

VII. RESULTS AND DISCUSSIONS

A. System With Five Nodes

The AFDCAN algorithm has been implemented using ve

embedded hardware units based on Renesas M16C/6N group

microcontroller [38]. The baud rate used for CAN data transfer

is 125 kb/s. All 26 conditions for fault diagnosis of the system

containing ve nodes are considered and veried. Figs. 11

and 12 show two fault conditions detected by AFDCAN. The

marked area in each of these gures indicates one complete

5534 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 61, NO. 10, OCTOBER 2014

Fig. 11. All of the nodes are fault-free.

Fig. 12. Nodes N

2

, N

3

, and N

4

are faulty.

diagnostic cycle. Lines 1 and 2 of the marked areas show one

test round between two nodes. The different cases which make

up 26 conditions for fault diagnosis in the system with ve

nodes are as follows: 1) no faulty node in the system; 2) one

faulty node in the system; 3) two faulty nodes in the system;

and 4) three faulty nodes in the system.

The bus activity is captured using Vector CANalyzer, and the

results have been veried.

B. Entry of New Nodes and Reentry of Faulty Nodes

Entry of new node and reentry of repaired faulty nodes

are also veried experimentally for AFDCAN as shown in

Figs. 1316. The system with four nodes N

1

, N

2

, N

3

, and N

4

is considered. Node N

5

is used to test the entry of a new node.

Fig. 13. New node N

5

entry.

Fig. 14. New node N

5

is part of the diagnostic cycle.

Fig. 13 shows the entry of N

5

, and Fig. 14 shows N

5

becoming

part of the diagnostic cycle. Node N

5

is considered as a faulty

node for testing the reentry of the repaired faulty node. N

5

is

powered off to indicate the fault condition (Fig. 15), and later,

N

5

is powered on again to indicate the reentry in the system

(Fig. 16).

C. Diagnostic Cycle Time of AFDCAN

AFDCAN is executed on the hardware as explained earlier in

Section VII-A at 125-kb/s baud rate, with all of the ve nodes

being fault free. The bus activity of the complete diagnostic

cycle captured on CAN bus is shown in Fig. 11 as marked area.

The time taken for completion of one diagnostic cycle of Fig. 11

is 560 ms.

KELKAR AND KAMAL: ADAPTIVE FAULT DIAGNOSIS ALGORITHM FOR CONTROLLER AREA NETWORK 5535

Fig. 15. Faulty node N

5

is powered off.

Fig. 16. Faulty node N

5

reenters the diagnostic cycle after repair.

Authors have further improved this diagnostic cycle time

without affecting the AFDCAN algorithm with the same baud

rate. The improved diagnostic cycle time for completion of one

diagnostic cycle is 526 ms, as shown in the marked area of

Fig. 17.

When the AFDCAN algorithm is executed at 500-kb/s baud

rate, the diagnostic cycle time is found to be 526 ms. This

diagnostic cycle time is the same as when AFDCAN is exe-

cuted at 125 kb/s. As mentioned earlier, while implementing

AFDCAN, authors have made use of the local timer module

of the microcontroller at every node. In order to achieve syn-

chronization between all of the nodes in the 26 fault conditions,

it was required to provide a time window for checking the re-

ception of different AFDCAN frames at every node. Therefore,

the diagnostic cycle time depends on the timer at every node

and is not affected by the baud rate of the CAN bus.

Fig. 17. Improved diagnostic cycle time when all of the ve nodes are fault

free.

D. Support for Large Number of Nodes in AFDCAN

The CAN data frame has 64 b (8 B) of data eld along

with other elds. Data eld is used for sending information

on the CAN bus. Out of 8 B of data eld, 2 B are required

for specifying SID and DID, respectively (Fig. 3). Also, 4 b

are required for specifying frame type (Fig. 3). Therefore, the

remaining 44 b can be used for holding diagnostic data of the

nodes present in the system. Two bits per node are required to

represent the state of the node (Fig. 3) in AFDCAN. Hence,

AFDCAN supports 22 nodes in the system, including entries

of new nodes. Thus, a large number of nodes can be part

of the fault diagnosis system. This feature is useful for both

automotive and industrial applications.

VIII. CONCLUSION

The AFDCAN algorithm uses a denite number of test

rounds and sends a denite number of messages to nd the fault

conditions in the CAN-based distributed embedded system.

Therefore, AFDCAN uses a denite bandwidth, based on total

number of nodes in the system. The number of test rounds

and the number of messages decrease with the increase in the

number of faulty nodes.

AFDCAN also supports the entry of new nodes and reentry

of repaired faulty nodes, as demonstrated in Section VII-B. The

failure of the response is detected by the testee or tester with

the help of timeout.

Thus, AFDCAN uses denite time for fault diagnosis of the

system. The improved diagnostic cycle time of AFDCAN is

526 ms, when all of the ve nodes are fault free.

Looking further, synchronization of timings at different

nodes in the system is required for better performance of the

AFDCAN. Also, the time taken by AFDCAN diagnostic cycle

can be reduced by implementing the primary message generator

[6]. The improvements proposed in Section V may also be

considered.

5536 IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS, VOL. 61, NO. 10, OCTOBER 2014

TT-CAN is a higher layer protocol above the standard CAN.

Standard CAN messages are sent in TT-CAN [7]. These mes-

sages are transmitted at a specic time slot, and thus, they

do not compete with other CAN messages for bus access.

Communication schedules of all CAN nodes are synchronized

by TT-CAN for a network. By designing the schedules of dif-

ferent CAN nodes for different AFDCAN diagnostic messages,

AFDCAN may be adopted for TT-CAN.

AFDCAN may become part of CAN-based automotive net-

works. In automotive, both periodic and aperiodic messages

may appear on the CAN bus. It is essential to meet the trans-

mission deadline for each message. The AFDCAN messages

need to be scheduled carefully in such a way that they do not

interfere in the existing schedules of message transfers at every

node. This will ensure the real-time transfer and safety aspects

of CAN messages in automotive.

In automotive, the CAN messages are sent or received by

nodes or ECUs of CAN network. These messages are given

priority with the help of the identier present in the CAN data

frame. For a CAN message, the lower the identier, the higher

is the priority assigned. As far as AFDCAN is concerned, the

priority of the diagnostic messages is decided based on the

priority of the existing periodic and aperiodic messages. While

allocating identiers to the diagnostic messages for AFDCAN,

the transmission deadlines of the periodic and aperiodic mes-

sages need to be considered.

The collective diagnostic information of all of the nodes in

AFDCAN is available with any fault-free node in the system.

The corrective action can be taken, or the faults can be reported

depending on the severity of the problem. Thus, the use of

AFDCAN gives a new proposition for network diagnosis in

applications such as automotive and industrial automation.

APPENDIX

A. Algorithm to Find First the Fault-Free Node by the Tester

1) Initialization;

2) Make test frame, TFRM.

TFRM = {NID} {DID} {Tbit}

n

j=1

{TBUFF

1,j

}

where,

n

j=1

{TBUFF

1,j

} =

n

j=2k

{NBUFF

1,j

} k = 1, 2 . . . n.

3) Send TFRM to testee.

4) Wait until timeout.

5) If result frame is received within timeout, then, read the

received frame in RFRM.

a. If frame type bits found in RFRM indicate R bits

(0001) then, modify node buffer as follows:

n

j=2k

{NBUFF

1,j

} =

j=l+m

{RFRM

1,j

} where,

k=1, 2 . . . n, m=1, 2 . . .(n1), l ={|SID|+|DID|+2}.

b. Mark testee as fault-free, NBUFF

1,2DID

= 1.

c. Exit.

6) If result frame is not received by tester from testee within

timeout, increment faulty node counter by one.

7) Check for destination ID eld (DID) for following condi-

tions:

a. DID less than n;

b. DID equal to n.

8) If condition (7.a) is true, then,

a. NBUFF

1,2DID

= 0 and make DID = DID + 1.

b. TFRM={NID}{DID}{Tbit}

n

j=1

{TBUFF

1,j

}

where,

n

j=1

{TBUFF

1,j

} =

n

j=2k

{NBUFF

1,j

}

where, k = 1, 2 . . . n.

c. Send TFRM to testee and exit.

9) If condition (7.b) is true, then,

RFRM={NID}{DID}{2Rbit}

n

j=1

{TBUFF

1,j

},

where DID is the NID of the earlier fault-free node and

n

j=1

{TBUFF

1,j

} =

n

j=2k

{NBUFF

1,j

}

where, k = 1, 2 . . . n.

10) RFRM is 2nd result frame. Send it to the earlier fault-free

node.

B. Algorithm for the Following Timeout Conditions in

AFDCAN

1) Algorithm for steps to be taken when test frame sent from

the tester is not received by the testee, within timeout.

a. Update node buffer as:

2(NID1)

j=2k

{NBUFF

1,j

}=0, where, k=1, 2 . . .(NID1).

b. Increment faulty node counter by one.

c. Send test frame to next node.

2) Second result frame not received by tester or broadcast

frame not received by the node.

a. j = 2k, {NBUFF

1,j

} = u, where, u = 2

d

indicating

undened state of the node and k = 1, 2 . . . n.

b. Start new diagnostic cycle.

C. Algorithm for Sending the New Node Entry Frame to All of

the Nodes in the System

(Refer to Fig. 6)

1) TFRM = {NID} {0} {NERbit}.

2) Send TFRM to all of the nodes in the system after sensing

a result frame on the bus.

REFERENCES

[1] L. Cauffriez, J. Ciccotelli, B. Conrardc, and M. Bayartc, Design of

intelligent distributed control systems: A dependability point of view,

Reliab. Eng. Syst. Safety, vol. 84, pp. 1932, 2004.

[2] S. Kelkar and R. Kamal, Control area network based quotient remainder

compression-algorithm for automotive applications, in Proc. 38th Annu.

IEEE IECON, Montreal, QC, Canada, Oct. 2012, pp. 30303036.

[3] S. Kelkar and R. Kamal, Comparison and analysis of quotient remain-

der compression algorithms for automotives, in Proc. IEEE INDICON,

Kochi, India, Dec. 2012, pp. 802807.

[4] Robert Bosch GmbH, Ver. 2.0 Controller Area Network (CAN)Protocol

Specication 1991, Robert Bosch GmbH, Ver. 2.0.

[5] M. J. Short and M. J. Pont, Fault-tolerant time-triggered communication

using CAN, IEEE Trans. Ind. Informat., vol. 3, no. 2, pp. 131142,

May 2007.

[6] J. R. Pimentel and J. A. Fonseca, FlexCAN: A exible architecture for

highly dependable embedded applications, in Proc. 3rd Int. Workshop

Real-Time Netw., Italy, 2004. [Online]. Available: http://paws.kettering.

edu//~jpimente/excan/FlexCAN-architecture.pdf

[7] T. Fuhrer, B. Muller, W. Dieterie, F. Hartwich, R. Hugel, and H. Weiler,

Time triggered communication on CAN, in Proc. 7th Int. CAN

Conf., Amsterdam, Netherlands, 2000. [Online]. Available: http://www.

bosch-semiconductors.de/media/pdf_1/canliteratur/cia2000paper_1.pdf

[8] Muller, T. Fuhrer, F. Hartwich, R. Hugel, and H. Weiler, Fault tol-

erant TTCAN networks, in Proc. 8th Int. CAN Conf., Las Vegas,

NV, USA, 2002. [Online]. Available: http://www.bosch-semiconductors.

de/media/pdf_1/canliteratur/fault_tolerant_ttcan.pdf

KELKAR AND KAMAL: ADAPTIVE FAULT DIAGNOSIS ALGORITHM FOR CONTROLLER AREA NETWORK 5537

[9] H. Kopetz and G. Grnsteidl, TTP-A protocol for fault-tolerant real-time

systems, Computer, vol. 27, no. 1, pp. 1423, Jan. 1994.

[10] B. Manuel, P. Julin, N. Guillermo, and A. Lus, An active star topology

for improving fault connement in CAN networks, IEEE Trans. Ind.

Informat., vol. 2, no. 2, pp. 7885, May 2006.

[11] M. Barranco, J. Proenza, and L. Almeida, Quantitative comparison of

the error-containment capabilities of a bus and a star topology in CAN

networks, IEEE Trans. Ind. Electron., vol. 58, no. 3, pp. 802813,

Mar. 2011.

[12] N. Kandasamy, J. P. Hayes, and B. T. Murray, Time-constrained failure

diagnosis in distributed embedded systems: application to actuator diag-

nosis, IEEE Trans. Parallel Distrib. Syst., vol. 16, no. 3, pp. 258270,

Mar. 2005.

[13] J. Biteus, E. Frisk, and M. Nyberg, Distributed diagnosis using a con-

densed representation of diagnoses with application to an automotive

vehicle, IEEE Trans. Syst., Man, Cybern. A, Syst. Humans, vol. 41, no. 6,

pp. 12621267, Nov. 2011.

[14] S. A. Arogeti, D. Wang, C. B. Low, and M. Yu, Fault detection isolation

and estimation in a vehicle steering systems, IEEE Trans. Ind. Electron.,

vol. 59, no. 12, pp. 48104820, Dec. 2012.

[15] C. M. Vong, P. K. Wong, and W. F. Ip, Anewframework of simultaneous-

fault diagnosis using pairwise probabilistic multi-label classication for

time-dependent patterns, IEEE Trans. Ind. Electron., vol. 60, no. 8,

pp. 33723385, Aug. 2013.

[16] H. A. Hansson, T. Nolte, C. Norstrom, and S. Punnekkat, Integrating

reliability and timing analysis of CAN-based systems, IEEE Trans. Ind.

Electron., vol. 49, no. 6, pp. 12401250, Dec. 2002.

[17] B. Jiang, Z. Mao, and P. Shi, H

-lter design for a class of networked

control systems via T-S fuzzy-model approach, IEEE Trans. Fuzzy Syst.,

vol. 18, no. 1, pp. 201208, Feb. 2010.

[18] H. Yang, B. Jiang, V. Cocquempot, and H. Zhang, Stabilization of

switched nonlinear systems with all unstable modes: Applications to

multi-agent systems, IEEE Trans. Autom. Control, vol. 56, no. 9,

pp. 22302235, Sep. 2011.

[19] K. Choi, J. Luo, K. Pattipati, S. M. Namburu, L. Qiao, and S. Chigusa,

Data reduction techniques for intelligent fault diagnosis in automotive

systems, in Proc. IEEE Int. Conf. Autotestcon, Sep. 2006, pp. 6672.

[20] A. Routray, A. Rajguru, and S. Singh, Data reduction and clustering

techniques for fault detection diagnosis in automotives, in Proc. 6th

Annu. Conf. Autom. Sci. Eng., Toronto, ON, Canada, 2010, pp. 326331.

[21] N. Das, A. Routray, and P. K. Dash, ICA methods for blind source

separation of instantaneous mixtures: A case study, Neural Inf. Process

Lett. Rev., vol. 11, no. 11, pp. 225246, Nov. 2007.

[22] K. P. Detroja, R. D. Gudi, S. C. Patwardhan, and K. Roy, Fault detec-

tion and isolation using correspondence analysis, Ind. Eng. Chem. Res.,

vol. 45, no. 1, pp. 223235, 2006.

[23] K. P. Detroja, R. D. Gudi, and S. C. Patwardhan, Data reduction algo-

rithm based on principle of distributional equivalence for fault diagnosis,

Control Eng. Practice, vol. 20, no. 10, pp. 10331041, Oct. 2012.

[24] S. Pusha, R. D. Gudi, and S. Noronha, Polar classication with corre-

spondence analysis for fault isolation, J. Process Control, vol. 19, no. 4,

pp. 656663, Apr. 2009.

[25] S. H. Hosseini, J. G. Kuhl, and S. M. Reddy, A diagnosis algorithm for

distributed computing systems with dynamic failure and repair, IEEE

Trans. Comput., vol. 33, no. 3, pp. 223233, Mar. 1984.

[26] A. Bagchi and S. L. Hakimi, An optimal algorithmfor distributed system-

level diagnosis, in Proc. 21st IEEE Int. Symp. Fault-Tolerant Comput.,

Montreal, QC, Canada, 1991, pp. 214221.

[27] R. P. Bianchini and R. W. Buskens, Implementation of on-line distributed

system-level diagnosis theory, IEEE Trans. Comput., vol. 41, no. 5,

pp. 616626, May 1992.

[28] S. Rangarajan, A. T. Dahbura, and E. A. Ziegler, A distributed system-

level diagnosis algorithm for arbitrary network topologies, IEEE Trans.

Comput., vol. 44, no. 2, pp. 312334, Feb. 1995.

[29] E. P. Duarte and T. Nanya, A hierarchical adaptive distributed

system-level diagnosis algorithm, IEEE Trans. Comput., vol. 47, no. 1,

pp. 3445, Jan. 1998.

[30] M. Malek, A comparison connection assignment for diagnosis of mul-

tiprocessor systems, in Proc. 7th Int. Symp. Comput. Architect., 1980,

pp. 3135.

[31] K. Chwa and S. Hakimi, Schemes for fault tolerant computing: A com-

parison of modularly redundant and t-diagnosable systems, Inf. Control,

vol. 49, no. 3, pp. 212238, Jun. 1981.

[32] J. Maeng and M. Malek, A comparison connection assignment for

self-diagnosis of multiprocessor systems, in Proc. 11th Int. Symp.

Fault-Tolerant Comput., 1981, pp. 173175.

[33] A. Sengupta and A. Dahbura, On self-diagnosable multiprocessor sys-

tems: Diagnosis by the comparison approach, IEEE Trans. Comput.,

vol. 41, no. 11, pp. 13861395, Nov. 1992.

[34] M. Blough and H. Brown, The broadcast comparison model for on-line

fault-diagnosis in multicomputer systems: Theory and implementation,

IEEE Trans. Comput., vol. 48, no. 5, pp. 470493, May 1999.

[35] E. Mourad and A. Nayak, Comparison-based system-level fault diag-

nosis: A neural network approach, IEEE Trans. Parallel Distrib. Syst.,

vol. 23, no. 6, pp. 10471059, Jun. 2012.

[36] C. A. Lupini, Vehicle Multiplex Communication-Serial Data Networking

Applied to Vehicular Engineering. Warrendale, PA, USA: SAE, 2004.

[37] K. H. Rosen, Discrete Mathematics and its Application, 5th ed.

New York, NY, USA: McGraw-Hill, 1988.

[38] Renesas M16C/6N Group Hardware manual, Oct. 2005.

Supriya Kelkar (M02) received the Bachelors

degree in electronics and communication engineer-

ing from Karnataka University, Karnataka, India, in

1989, and the Masters degree in electronics and

telecommunication engineering from Pune Univer-

sity, Pune, India, in 1999. She received the Ph.D.

degree in the area of automotive multiplex systems

from the Institute of Engineering and Technology,

Devi Ahilya University, Indore, India, in 2014.

She was a Research and Development Engineer

for electronics systems with Chromatography and

Instruments Company, Vadodara, India, for three years. She is currently an

Associate Professor with the Computer Engineering Department, Cummins

College of Engineering for Women, Pune. Her research interests include

fault diagnosis in distributed real-time systems, data compression algorithms

for automotive distributed systems, and real-time networks for industrial and

automotive applications, such as controller area networks.

Dr. Kelkar is a member of the IEEE Vehicular Technology Society.

Raj Kamal (M07) received the Doctoral degree

in the area of physics from the Indian Institute of

Technology, New Delhi, India, in 1972.

He has over 40 years of experience in research,

has published over 125 research papers, and has

taught physics, electronics, computer science, and

information technology. He carried out postdoctoral

research at Uppsala University, Uppsala, Sweden, in

19781979 and 1984. He is currently a Professor

with the School of Computer Science and Infor-

mation Technology, Devi Ahilya University, Indore,

India. He is widely recognized for his research and engineering books:

Embedded Systems (McGraw-Hill), Computer Architecture (a Schaum Se-

ries Adaptation by McGraw-Hill), Microcontrollers (Pearson Education), and

Mobile Computing (Oxford University Press).

Dr. Kamal is a member of the IEEE Computer Society.

Vous aimerez peut-être aussi

- Vehicle Detection SystemDocument4 pagesVehicle Detection SystemHrudhay LuckyPas encore d'évaluation

- Paper 59-Marine Engine Room Alarm Monitoring SystemDocument9 pagesPaper 59-Marine Engine Room Alarm Monitoring Systemthomas1313Pas encore d'évaluation

- Major Project Sunny - DocxhiiiDocument52 pagesMajor Project Sunny - Docxhiiisiddumudavath93Pas encore d'évaluation

- Checkpoint and Restart For Distributed Components in XCAT3Document8 pagesCheckpoint and Restart For Distributed Components in XCAT3xico107Pas encore d'évaluation

- Design and Evaluation of Hybrid Fault-Detection SystemsDocument12 pagesDesign and Evaluation of Hybrid Fault-Detection SystemsAbdrazag MohPas encore d'évaluation

- T.L Fault DetectionDocument9 pagesT.L Fault DetectionRanjith KumarPas encore d'évaluation

- J1939Document30 pagesJ1939Mohammed100% (1)

- Aodv Protocol ThesisDocument4 pagesAodv Protocol ThesisSarah MariePas encore d'évaluation

- A Simple Real Time Fault Signature Monit PDFDocument12 pagesA Simple Real Time Fault Signature Monit PDFfares noureddinePas encore d'évaluation

- Energy Management in Wireless Sensor NetworksD'EverandEnergy Management in Wireless Sensor NetworksÉvaluation : 4 sur 5 étoiles4/5 (1)

- DEWA Automation PaperDocument27 pagesDEWA Automation PaperBruce CoxPas encore d'évaluation

- Novel Wireless Sensors Network Routing Approach For Industrial Process ControlDocument8 pagesNovel Wireless Sensors Network Routing Approach For Industrial Process ControlwafaPas encore d'évaluation

- Referensi 4Document15 pagesReferensi 4Anonymous ugAY1fsF0aPas encore d'évaluation

- Delay-Aware Medium Access Schemes For WSN-Based Partial Discharge MeasurementDocument13 pagesDelay-Aware Medium Access Schemes For WSN-Based Partial Discharge MeasurementjeevithaPas encore d'évaluation

- 8-Bit UART With BIST and Hamming Code Feature Using Verilog ModuleDocument5 pages8-Bit UART With BIST and Hamming Code Feature Using Verilog ModuleAbhishek SinghPas encore d'évaluation

- Thesis On Vehicular Ad Hoc NetworkDocument8 pagesThesis On Vehicular Ad Hoc Networkanaespinalpaterson100% (2)

- Clinic: A Service-Oriented Approach For Fault Tolerance in Wireless Sensor NetworksDocument7 pagesClinic: A Service-Oriented Approach For Fault Tolerance in Wireless Sensor Networks- -Pas encore d'évaluation

- Overcoming Computational Errors in Sensing Platforms Through Embedded Machine-Learning KernelsDocument12 pagesOvercoming Computational Errors in Sensing Platforms Through Embedded Machine-Learning KernelsctorreshhPas encore d'évaluation

- Review Paper On Vehicle Diagnosis With Electronic Control UnitDocument7 pagesReview Paper On Vehicle Diagnosis With Electronic Control UnitInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Ijcs 2016 0301002 PDFDocument3 pagesIjcs 2016 0301002 PDFeditorinchiefijcsPas encore d'évaluation

- An Algorithm For Fault Node Recovery of Wireless Sensor NetworkDocument4 pagesAn Algorithm For Fault Node Recovery of Wireless Sensor NetworkInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- TS4 6 ArtificialNeuralNetworkBasedFaultDocument6 pagesTS4 6 ArtificialNeuralNetworkBasedFaultSubhankar BosePas encore d'évaluation

- 2020 Data Driven Feature Extraction For Analog Circuit Fault Diagnosis Using 1D Convolutional Neural NetworkDocument11 pages2020 Data Driven Feature Extraction For Analog Circuit Fault Diagnosis Using 1D Convolutional Neural NetworkimadldnPas encore d'évaluation

- The Effects of Active Queue Management On Web PerformanceDocument12 pagesThe Effects of Active Queue Management On Web Performanceharini1opPas encore d'évaluation

- Fault Detection and Isolation in Robotic Manipulator Via Hybrid Neural NetworksDocument12 pagesFault Detection and Isolation in Robotic Manipulator Via Hybrid Neural Networksnick4namePas encore d'évaluation

- VinayKumarV MRaghavaCharyulu 129 PDFDocument7 pagesVinayKumarV MRaghavaCharyulu 129 PDFUpendra VaddePas encore d'évaluation

- Deep PCA Based Real-Time Incipient Fault Detection and Diagnosis Methodology For Electrical Drive in High-Speed TrainsDocument12 pagesDeep PCA Based Real-Time Incipient Fault Detection and Diagnosis Methodology For Electrical Drive in High-Speed TrainsDr.Suresh Chavhan -IIITKPas encore d'évaluation

- Cjme 2014 03 475Document8 pagesCjme 2014 03 475HASSANE HOTAITPas encore d'évaluation

- Annual Reviews in Control: Dominique Sauter, Mohamed Amine Sid, Samir Aberkane, Didier MaquinDocument12 pagesAnnual Reviews in Control: Dominique Sauter, Mohamed Amine Sid, Samir Aberkane, Didier MaquinsidaminePas encore d'évaluation

- Fault Diagnosis in MLIDocument8 pagesFault Diagnosis in MLIGp NAYAGRAH ELECTRICALPas encore d'évaluation

- Kwp2000 and UDS Difference - Automotive BasicsDocument5 pagesKwp2000 and UDS Difference - Automotive Basicstfone1Pas encore d'évaluation

- Simulation-Based Fault-Tolerant Multiprocessors SystemDocument10 pagesSimulation-Based Fault-Tolerant Multiprocessors SystemTELKOMNIKAPas encore d'évaluation

- Fuzzy Logic Approach For Fault Diagnosis of Three Phase Transmission LineDocument5 pagesFuzzy Logic Approach For Fault Diagnosis of Three Phase Transmission LineJournal 4 ResearchPas encore d'évaluation

- Reliable Composite Fault Diagnosis of Hydraulic Systems Based On LinearDocument15 pagesReliable Composite Fault Diagnosis of Hydraulic Systems Based On LinearAhmad luthfi asrorPas encore d'évaluation

- Internet of ThingsDocument20 pagesInternet of ThingsKonark JainPas encore d'évaluation

- Analysis of Different Routing Protocols For Wireless Dense NetworkDocument3 pagesAnalysis of Different Routing Protocols For Wireless Dense Networkعلي الورفليPas encore d'évaluation

- An Intelligent Data-Driven Model To Secure Intra - Vehicle Communications Based On Machine LearningDocument8 pagesAn Intelligent Data-Driven Model To Secure Intra - Vehicle Communications Based On Machine LearningIJRASETPublicationsPas encore d'évaluation

- Intelligent Decision Based Route Selection and Maintenance Approach Using AOMDV in VANETDocument9 pagesIntelligent Decision Based Route Selection and Maintenance Approach Using AOMDV in VANETIJRASETPublicationsPas encore d'évaluation

- Parameter Value Optimization of Ad-Hoc On Demand Multipath Distance Vector Routing Using Particle Swarm OptimizationDocument8 pagesParameter Value Optimization of Ad-Hoc On Demand Multipath Distance Vector Routing Using Particle Swarm Optimizationfitriani SaputriPas encore d'évaluation

- Analysis of Communication Protocols For Smart MeteringDocument9 pagesAnalysis of Communication Protocols For Smart Meteringedmuarizt7078Pas encore d'évaluation

- SDSFLF: Fault Localization Framework For Optical Communication Using Software Digital Switching NetworkDocument12 pagesSDSFLF: Fault Localization Framework For Optical Communication Using Software Digital Switching NetworkIJRES teamPas encore d'évaluation

- Kezunovic Cigre2005Document11 pagesKezunovic Cigre2005pvenky_kkdPas encore d'évaluation

- Documents The Effects of Active Queue Management On Web PerformanceDocument12 pagesDocuments The Effects of Active Queue Management On Web Performanceeyes_dragonPas encore d'évaluation

- Abstract: Due To Significant Advances in Wireless Modulation Technologies, Some MAC Standards Such As 802.11aDocument6 pagesAbstract: Due To Significant Advances in Wireless Modulation Technologies, Some MAC Standards Such As 802.11aVidvek InfoTechPas encore d'évaluation

- Design and Evaluation of Hybrid Fault-Detection SystemsDocument12 pagesDesign and Evaluation of Hybrid Fault-Detection SystemsVishnu_SairamPas encore d'évaluation

- WCET-AwarePartialControl-FlowCheckingfor Resource-ConstrainedReal-Time EmbeddedSystemsDocument10 pagesWCET-AwarePartialControl-FlowCheckingfor Resource-ConstrainedReal-Time EmbeddedSystemsanmol6237Pas encore d'évaluation

- Distributed Fault Detection of Wireless Sensor Networks: Jinran Chen, Shubha Kher, and Arun SomaniDocument7 pagesDistributed Fault Detection of Wireless Sensor Networks: Jinran Chen, Shubha Kher, and Arun SomaniBalaji SrikanthPas encore d'évaluation

- WAMS Webinar by Prof Soman and Mr. Gopal Gajjar, IIT Mumbai, 7th August 2013Document3 pagesWAMS Webinar by Prof Soman and Mr. Gopal Gajjar, IIT Mumbai, 7th August 2013s_banerjeePas encore d'évaluation

- Instruction Set Extension of A RiscV Based SoC For Driver Drowsiness DetectionDocument12 pagesInstruction Set Extension of A RiscV Based SoC For Driver Drowsiness Detection1066357565Pas encore d'évaluation

- With Electronic Control Unit", Rucha Pupala, India. It IsDocument7 pagesWith Electronic Control Unit", Rucha Pupala, India. It IsSai DatlaPas encore d'évaluation

- Approximate Arithmetic Circuit Design For Error Resilient ApplicationsDocument16 pagesApproximate Arithmetic Circuit Design For Error Resilient ApplicationsAnonymous e4UpOQEPPas encore d'évaluation

- Sensors: Clustering and Flow Conservation Monitoring Tool For Software Defined NetworksDocument23 pagesSensors: Clustering and Flow Conservation Monitoring Tool For Software Defined NetworksAngel Nicolas Arotoma PraviaPas encore d'évaluation

- Final Paper - Advance ConceptDocument5 pagesFinal Paper - Advance ConcepthafizgPas encore d'évaluation

- Xiong 2016Document2 pagesXiong 2016VengadeshPas encore d'évaluation

- Unsupervised Electric Motor Fault DetectDocument11 pagesUnsupervised Electric Motor Fault DetectVictor SeguraPas encore d'évaluation

- Error Control BorelliDocument6 pagesError Control BorelliwhirryPas encore d'évaluation

- SDN: Management and Orchestration Considerations: White PaperDocument13 pagesSDN: Management and Orchestration Considerations: White PaperTaha AlhatmiPas encore d'évaluation

- General Development of Multiplexing: Section 6Document16 pagesGeneral Development of Multiplexing: Section 6Sco JoPas encore d'évaluation

- Fault-Injection and Dependability Benchmarking For Grid Computing MiddlewareDocument10 pagesFault-Injection and Dependability Benchmarking For Grid Computing MiddlewareMustafamna Al SalamPas encore d'évaluation

- Intelligent Transportation SystemDocument13 pagesIntelligent Transportation SystemZION LIFEPas encore d'évaluation

- HW Starter Manual March HresolutionDocument23 pagesHW Starter Manual March HresolutionCharan KumarPas encore d'évaluation

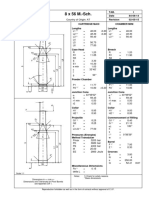

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDocument1 pageSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237Pas encore d'évaluation

- Industrial EnclosuresDocument56 pagesIndustrial Enclosuresanmol6237Pas encore d'évaluation

- Kaz Tech Damping Calculation SeminarDocument99 pagesKaz Tech Damping Calculation SeminarManu PantPas encore d'évaluation

- Design and Fabrication of Automated Manual Gear Transmission in Motor BikesDocument57 pagesDesign and Fabrication of Automated Manual Gear Transmission in Motor Bikesanmol6237Pas encore d'évaluation

- Clients ListDocument4 pagesClients Listanmol6237Pas encore d'évaluation

- RGB Color TableDocument5 pagesRGB Color Tableanmol6237Pas encore d'évaluation

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDocument2 pagesSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237Pas encore d'évaluation

- Nissan Walkin ChennaiDocument2 pagesNissan Walkin Chennaianmol6237Pas encore d'évaluation

- Introduction To HM PDFDocument37 pagesIntroduction To HM PDFanmol6237Pas encore d'évaluation

- Nissan Walkin ChennaiDocument2 pagesNissan Walkin Chennaianmol6237Pas encore d'évaluation

- Train Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD PassengerDocument1 pageTrain Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD Passengeranmol6237Pas encore d'évaluation

- Creo2 Adv PrimerDocument174 pagesCreo2 Adv PrimerAmit JhaPas encore d'évaluation

- Press Tool Cutting ForceDocument1 pagePress Tool Cutting Forceanmol6237Pas encore d'évaluation

- M Tech Project List 2015 NewDocument5 pagesM Tech Project List 2015 Newanmol6237Pas encore d'évaluation

- Nissan Walkin ChennaiDocument2 pagesNissan Walkin Chennaianmol6237Pas encore d'évaluation

- Nissan Walkin Chennai 1Document2 pagesNissan Walkin Chennai 1anmol6237Pas encore d'évaluation

- GD AdvantagesDocument1 pageGD Advantagesanmol6237Pas encore d'évaluation

- Tool Design TerminologyDocument5 pagesTool Design Terminologyanmol6237Pas encore d'évaluation

- Train Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD PassengerDocument1 pageTrain Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD Passengeranmol6237Pas encore d'évaluation

- SHEARINGDocument6 pagesSHEARINGanmol6237Pas encore d'évaluation

- GDDocument2 pagesGDanmol6237Pas encore d'évaluation

- Gate Syllabus For Mech EnggDocument4 pagesGate Syllabus For Mech Engganmol6237Pas encore d'évaluation

- Term - 1 - Class - X Communicative English - 2010Document27 pagesTerm - 1 - Class - X Communicative English - 2010Nitin GargPas encore d'évaluation

- Ceed Model Question PaperDocument21 pagesCeed Model Question PaperSatvender SinghPas encore d'évaluation

- E2SEM1MT2TD06102012Document3 pagesE2SEM1MT2TD06102012anmol6237Pas encore d'évaluation

- Notification SSC Junior Notification-SSC-Junior-Engineer-Posts - Pdfengineer PostsDocument36 pagesNotification SSC Junior Notification-SSC-Junior-Engineer-Posts - Pdfengineer PostsVikas GoyalPas encore d'évaluation

- Ansys Training Book.Document15 pagesAnsys Training Book.Sarath Babu SPas encore d'évaluation

- More Than 100 Keyboard Shortcuts Must ReadDocument3 pagesMore Than 100 Keyboard Shortcuts Must ReadChenna Keshav100% (1)

- Intro To CFD ProblemDocument1 pageIntro To CFD ProblemlinoPas encore d'évaluation

- HDO OpeationsDocument28 pagesHDO OpeationsAtif NadeemPas encore d'évaluation

- Ferobide Applications Brochure English v1 22Document8 pagesFerobide Applications Brochure English v1 22Thiago FurtadoPas encore d'évaluation

- Lesson Plan For DemoDocument9 pagesLesson Plan For DemoJulius LabadisosPas encore d'évaluation

- BV DoshiDocument6 pagesBV DoshiNimPas encore d'évaluation

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 pagesDHA - Jebel Ali Emergency Centre + RevisedJam EsPas encore d'évaluation

- Ticket: Fare DetailDocument1 pageTicket: Fare DetailSajal NahaPas encore d'évaluation

- Celula de CargaDocument2 pagesCelula de CargaDavid PaezPas encore d'évaluation

- Worked Solution Paper5 A LevelDocument8 pagesWorked Solution Paper5 A LevelBhoosan AncharazPas encore d'évaluation

- Learning Competency PDFDocument1 pageLearning Competency PDFLEOMAR PEUGALPas encore d'évaluation

- Fashion DatasetDocument2 644 pagesFashion DatasetBhawesh DeepakPas encore d'évaluation

- Rdramirez Aota 2018 Poster For PortfolioDocument1 pageRdramirez Aota 2018 Poster For Portfolioapi-437843157Pas encore d'évaluation

- Standard BMW PDFDocument19 pagesStandard BMW PDFIna IoanaPas encore d'évaluation

- Reference GuideDocument88 pagesReference GuideAnonymous Qm0zbNk100% (1)

- Eje Delantero Fxl14 (1) .6Document2 pagesEje Delantero Fxl14 (1) .6Lenny VirgoPas encore d'évaluation

- Sociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadDocument44 pagesSociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadJohn Blackburn100% (20)

- The Intel 8086 / 8088/ 80186 / 80286 / 80386 / 80486 Jump InstructionsDocument3 pagesThe Intel 8086 / 8088/ 80186 / 80286 / 80386 / 80486 Jump InstructionsalexiouconPas encore d'évaluation

- Writ Petition 21992 of 2019 FinalDocument22 pagesWrit Petition 21992 of 2019 FinalNANDANI kumariPas encore d'évaluation

- Law of AttractionDocument2 pagesLaw of AttractionKate SummersPas encore d'évaluation

- Req Equip Material Devlopment Power SectorDocument57 pagesReq Equip Material Devlopment Power Sectorayadav_196953Pas encore d'évaluation

- Addendum ESIA Oct 2019Document246 pagesAddendum ESIA Oct 2019melkamuPas encore d'évaluation

- 8 X 56 M.-SCH.: Country of Origin: ATDocument1 page8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimPas encore d'évaluation

- TB 60 Repair Parts PDFDocument282 pagesTB 60 Repair Parts PDFvatasa100% (2)

- CandyDocument24 pagesCandySjdb FjfbPas encore d'évaluation

- Abas Drug Study Nicu PDFDocument4 pagesAbas Drug Study Nicu PDFAlexander Miguel M. AbasPas encore d'évaluation

- Exclusive GA MCQs For IBPS Clerk MainDocument136 pagesExclusive GA MCQs For IBPS Clerk MainAnkit MauryaPas encore d'évaluation

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocument7 pagesSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0Pas encore d'évaluation

- Entrepreneurship - PPTX Version 1 - Copy (Autosaved) (Autosaved) (Autosaved) (Autosaved)Document211 pagesEntrepreneurship - PPTX Version 1 - Copy (Autosaved) (Autosaved) (Autosaved) (Autosaved)Leona Alicpala67% (3)

- Acer Globalisation ProcessDocument10 pagesAcer Globalisation ProcesscrosstheevilPas encore d'évaluation

- VRARAIDocument12 pagesVRARAIraquel mallannnaoPas encore d'évaluation

- Febrile Neutropenia GuidelineDocument8 pagesFebrile Neutropenia GuidelineAslesa Wangpathi PagehgiriPas encore d'évaluation