Académique Documents

Professionnel Documents

Culture Documents

Preliminary Design of The Hybrid Air-Launching Rocket For Nanosat

Transféré par

Nabetse070 évaluation0% ont trouvé ce document utile (0 vote)

96 vues6 pagesAir-launching is an effective method that can launch the 'Nanosat' for low launching cost. A supersonic air launching rocket with total weight of 830. Kg, the payload weight of 3. Kg and the propulsion system length of 5. M has been designed.

Description originale:

Titre original

Preliminary Design of the Hybrid Air-launching Rocket for Nanosat

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAir-launching is an effective method that can launch the 'Nanosat' for low launching cost. A supersonic air launching rocket with total weight of 830. Kg, the payload weight of 3. Kg and the propulsion system length of 5. M has been designed.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

96 vues6 pagesPreliminary Design of The Hybrid Air-Launching Rocket For Nanosat

Transféré par

Nabetse07Air-launching is an effective method that can launch the 'Nanosat' for low launching cost. A supersonic air launching rocket with total weight of 830. Kg, the payload weight of 3. Kg and the propulsion system length of 5. M has been designed.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

Preliminary Design of the Hybrid Air-launching Rocket for Nanosat

Jae-Woo Lee, Kyung-Ho Noh and Yung-Hwan Byun

Department Aerospace Information Engineering, Konkuk University, Korea

Bong-Kyo Park

Hanwha Corporation

jwlee@konkuk.ac.kr

Abstract

Air-Launching is an effective method that can

launch the 'Nanosat' for low launching cost. In this

study, the preliminary design of the air-launching

micro rocket was performed. Mission and trajectory

optimization was performed and the propulsion system

was designed based on the mission design. A

supersonic air launching rocket with total weight of

830.95 kg, the payload weight of 3.56 kg and the

propulsion system length of 5.89 m has been designed.

1. Introduction

Recently, the demand for the small satellites is

growing and many countries which hold advanced

technology in the space launcher development,

concentrate on the development of the rockets for the

small satellites. For the development of very small

satellites, less than 10 kg of weight, the space

technology which applies the MEMS(Micro-Electro

Mechanical Systems) is necessary[1, 2].

Very small satellites can be classified into two

categories; Nano-satellites, which weigh around 1 -

10kg, and pico-satellites, which weigh around 0.1 -

1kg[3]. Several nanosats have been developed till now:

the QQW1 of 4 kg weight, the ODERACS series

satellites of 5 kg weight, and 3 kg satellites like the

SPUTNIK-40 and the TUBSAT-N[1]. Nanosat is

regarded as the future-oriented new technology which

can overcome the limits of the small and micro

satellites. Key factors when designing or selecting a

launch vehicle are the launch cost and the launch

capacity, i.e. the weight of the satellite to be carried.

Because the launch cost per unit mass will grow as the

weight of the satellite become smaller, either several

nanosats must be launched together or, the nanosat

launched with the large satellite. Hence the launching

time and the operation of the satellite are limited.

Therefore, new launching method can launch the

nanosat individually with low launching cost. 'air-

launching' can be a solution.

By implementing air-launching, there would be no

restrictions on the launch sites, the launch angle and

the launch direction. This can be a very strong point

especially to the countries where the satellite launching

is very difficult owing to the geographical reasons, like

Korea. Moreover, "air-launch" is a very economical

way of launching satellites compared with the ground-

launch, because it can utilize the high initial launching

speed from the mother plane, and the improved thrust

efficiency resulted from low dynamic pressure and big

nozzle expansion ratio at high altitude[4, 5].

Among the air-launching rocket system developed

until now, there are NOTS and Cabel. NOTS, the first

air-launching rocket, was launched by a Douglas F-4D

Skyray airplane. As the vehicle was designed for

maximum simplicity, it featured no moving parts. All

launches apparently failed, most due to structural

failures. The first and third orbital attempts could have

possibly orbited their payloads, as tracking stations

picked up signals, which could have originated from

the payload. After 10 launches the program was

discontinued and a improved vehicle, called Caleb,

was developed[6]. The Pegasus and the Burlak are

more recent air-launchers. In the M-3S II User Guide,

ISAS of Japan also announced its intention to develop

air-launching rockets for the small satellite using M-V

rocket[7].

Pegasus is a small commercial launch vehicle

developed by Orbital Science Corporation. It is a three-

stage, solid-propellant, inertially guided, all-composite

winged space booster. The Pegasus has been carried

aloft by a specially modified Lockheed L-1011 carrier

aircraft to level flight launch conditions of

approximately 11.9 km altitude and Mach number of

0.8. Pegasus follows a nearly vacuum optimized lifting

ascent trajectory to orbit, carrying 275 kg payloads to

480 km polar orbits as well as proportional payloads to

Fifth International Conference on Computational Science and Applications

0-7695-2945-3/07 $25.00 2007 IEEE

DOI 10.1109/ICCSA.2007.16

290

Fifth International Conference on Computational Science and Applications

0-7695-2945-3/07 $25.00 2007 IEEE

DOI 10.1109/ICCSA.2007.16

290

Fifth International Conference on Computational Science and Applications

0-7695-2945-3/07 $25.00 2007 IEEE

DOI 10.1109/ICCSA.2007.16

290

other altitudes and inclinations or suborbital

trajectories[8].

Burlak, a Russian Pegasus, uses a liquid propellant

and is launched at 13.5km with a supersonic speed,

M=1.7 from the Tu-160 bomber[5]. As the launching

speed from the mother plane increases, the weight and

launch cost can be reduced, therefore the

supersonically launching Burlak is more advantageous

than the Pegasus, launched at subsonic speed. Various

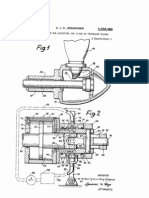

air-launchers are shown at Fig. 1.

Figure 1. Air-launching rockets

In this study, the design process of the three-stage

air-launching rocket system shall be defined first, and

the mission design, the conceptual and preliminary

design and system optimization will be performed.

2. Air-Launching Rocket Design Process

For the air-launching rocket design, like the aircraft

design, many technical areas like aerodynamics,

propulsion analysis are involved from the concept

exploration stage, hence an integrated design

consideration among all the related engineering fields

is crucial to acquire the best design solution with given

constraints in order to reduce the design changes or

resulting development cost.

When developing a system, with which many

engineering disciplines are highly coupled like rocket

system design, the classical separate single discipline

design approach is difficult to apply, because most

design variables are coupled with many engineering

phenomena. To resolve the problems which occur

during the design optimization procedure,

Multidisciplinary Design Optimization (MDO)

techniques, which can handle complex engineering

problems with many design variables and constraints

from various technical disciplines, are required[9].

Figure 2. Air-launching rocket design process

With given design requirements, rocket mission is

defined first. Then the propulsion system including the

rocket motor, the oxidizer feeding system, and the

fuel/oxidizer control system is designed. Through

stability and control analysis and aerodynamic

analysis, the wing and tails are designed. Subsystem

are defined and designed. The material properties of

the major structural components and subsystems are

defined hence, approximate weight of the rocket

system is estimated. The optimized design can not be

obtained at one design cycle, several design iterations

are required. The rocket design process is shown at

Fig. 2.

In this study, the mission design, the trajectory

design and optimization, propulsion system design,

wing design, and the subsystem design will be

performed.

3. Design of the Hybrid Air-launching

Rocket for nanosat

3.1. Mission Design and Optimization

The mission design process of the air-launching

rocket system can be divided into several parts. Based

on the given design conditions and mission

291 291 291

requirements, the characteristics of the propulsion and

basic aerodynamic parameters are determined. The

required velocity to launch the payload to the pre-

specified orbit, the mass ratio of each stage, and the

structural coefficient are estimated. From the simple

empirical equations, the total required velocity of the

launcher is calculated by considering the gravity, the

drag, and the thrust loss. The required total velocity is

distributed to each stage in order to have the minimum

total weight. From the trajectory analysis and

optimization, a mission profile which can minimize the

total rocket weight, is derived. This process is repeated

until the design constraints are all satisfied.

For the air-launching rocket design study, F-4E,

which has the best weapon load capacity in ROK Air

Force inventory, is selected as the mother plane. The

lowest possible latitude location while not going

through the main land of Japan, must be selected as the

air-launching site, in order to maximize the earth

rotation effect. The mother plane will take off at the

Jeju airport (the longitude 12629 42 , the latitude

of 3330 29 ), and the launching location is the

longitude 125, the latitude of 30(Refer Fig. 3). The

total mission radius is approximately 682 km.

For the mission analysis of the mother plane, the

mission profile is divided into 16 mission segments

and the "MISS V 2.01"[10], a general aircraft mission

analysis program, is utilized. Total required fuel

weight is 12000 lb, 4670 lb less than the maximum

fuel weight of the F-4E. Therefore, it is demonstrated

that the flight mission of the mother plane to the launch

location is possible.

Launch location

Figure 3. Air-launching location

From the variables determined so far, the total

required velocity to launch the rocket to the specified

orbit is calculated using the empirical equations. Drag

is influenced only on the first stage, and the velocity

loss due to the atmospheric pressure is neglected,

considering the low atmospheric pressure and high

thrust-to-weight ratio during the second and third

stages. In addition, velocity gain from the rotation of

the earth, and the air-launching initial velocity gain are

included in the determination of the total required

velocity of the launcher. The obtained required

velocity is 8966 m/s. The total velocity is distributed to

each stage of the rocket in order to minimize the rocket

weight. Table 1 shows the result.

Table 1. Velocity distribution

Stage Structure(kg) Propellant(kg) Payload(kg) Total(kg)

3rd 2.95 10.45 3.5 16.90

2nd 16.69 62.77 17.43 96.36

Fairing 10.0

1st 152.15 572.36 106.36 830.87

3.2. Trajectory Optimization

The trajectory analysis and optimization code is

developed using the simple equations of motion, which

were derived by assuming the rocket as a point mass

and the earth as a perfect sphere[11]. To simulated the

lift produced from the wing at first stage of the rocket

the aerodynamic model[12] of Pegasus launcher is

implemented.

By using the performance parameters determined

during the initial sizing stage, following optimization

problem is formulated for the mission and trajectory

design and optimization.

The main title (on the first page) should begin 1-3/8

inches (3.49 cm) from the top edge of the page,

centered, and in Times 14-point, boldface type.

Capitalize the first letter of nouns, pronouns, verbs,

adjectives, and adverbs; do not capitalize articles,

coordinate conjunctions, or prepositions (unless the

title begins with such a word). Leave two 12-point

blank lines after the title.

Maximize payload mass

Subject to perigee altitude = 200 km

perigee velocity = 8,127 m/sec

flight path angle at perigee = 0 deg

Design variables: angle of attacks (14 design

variables)

Mission design and trajectory optimization is

performed to maximize the payload mass, while

satisfying the given mission requirements. For the

numerical optimization SQP of IMSL are employed.

Figures 4 and 5 show the optimization history. Total

292 292 292

rocket weight is 830.9 kg and the payload weight is

3.56 kg.

objective

-0.600

-0.550

-0.500

-0.450

-0.400

-0.350

-0.300

0 5 10 15 20 25 30 35 40

Iterationnumber

O

b

j

e

c

t

i

v

e

Figure 4. Objective function history

-0.150

-0.100

-0.050

0.000

0.050

0.100

0.150

0.200

0.250

0 5 10 15 20 25 30 35 40

x1 x2 x3 x4 x5 x6 x7

Figure 5. Design variable history

1st Stage Ignition

t=5sec

h=11,882m

v=763.8m/sec

1st Stage Burnout

t=60sec

h=57,890m

v=3528.9m/sec

2nd Stage Ignition

t=90sec

h=89,568m

v=3433.7m/sec

Payload Fairing

Seperation

t=155sec

h=149,822m

v=5705.9m/sec

3rd Stage Ignition

t=214sec

h=191,421m

v=5637.8m/sec

2nd Stage Burnout

t=124sec

h=121,731m

v=5752.0m/sec

2nd Stage

Seperaton

t=184sec

h=172,209m

v=5669.3m/sec

3rd Stage

Burnout & Orbital

Insertion

t=241sec

h=200,138m

v=8126.1m/sec

t=0sec

h=12,000m

v=787.0m/sec

Figure 6. Optimized mission profile

3.3. Propulsion system Design

3.3.1. 1

st

Stage Hybrid Motor Design

The hybrid rocket engine, which uses a solid fuel

and a liquid oxidizer, has in- remediate characteristics

between the solid fuel and liquid propellant rocket

engines. The popular combination of the fuel and the

oxidizer is HTPB and LOX. Studies on the HTPB +

H2O2, and PE/N2O + LOX combinations are going

on. The concept of the hybrid propulsion system is

described at Fig. 7. The liquid oxidizer is pumped into

the combustion chamber by the compressed gas. The

valve located between the liquid oxidizer tank and the

combustion chamber can supply, shut off and control

the flow of the oxidizer, hence the ignition,

extinguishments, and thrust control of the rocket can

be possible. Specific impulse of the hybrid engines is

290 -350 sec, in-between the specific impulses of the

solid and liquid propellant rockets[13].

Figure 7. Concept of the hybrid rocket

propulsion system[14]

Based on the optimized trajectory of the rocket, first

stage hybrid rocket engine is designed [15]. Figure 8

shows the grain shape of the rocket fuel.

Figure 8. Grain geometry

Figure 9 shows the propulsion system configuration

including the motor case and the liquid oxidizer tank.

The weight of the major subsystems obtained from

the empirical equations, is summarized at Table 2.

Table 2. Mass of 1

st

stage main components

Component

Motor

case

Oxidizer

tank

Nozzle

& TVC

Structural

supports

Mass(kg) 46.99 60.76 49.88 15.76

293 293 293

Figure 9. 1st Stage hybrid propulsion system

Second and Third Stage Solid Motor Design

The grain shapes and components design of the second

and third stages of the solid motor are shown at Figs.

10 and 11.

Figure 10. 2

nd

Stage solid motor

Figure 11. 3

rd

Stage solid motor

3.3.4. Wing Design

From the trajectory analysis, the maximum lift is

estimated. The wing is design to produce the maximum

required lift by considering the safety factor of 1.15.

The design wing geometry is as follows, Wing

area=3.81 m

2

; Root chord=2.47 m; Span=2.808 m.

Figure 12. Wing profile

3.3.5. Attitude Control System

The basic hardware components of the attitude

control system of the space launcher are the inertial

measuring unit (IMU), the on-board computer, and the

driving actuator which can produce the required

control moments.

In this study, the electro-magnetic actuator is used

for the first stage fin control, and the thrust vector

control is implemented for the second stage. For the

third stage the thrust control using the spin motor is

used. Figure 13 shows the schematic attitude control

system of current study.

F- 4E Phantom

IMU

Flight Computer

- Navigation Calculation

- Guidance Calculation

-Auto Pilot

-Flight Sequencing

Air- Launching Rocket

IMU

(LN- 200S)

1st Stage FinActuator

(EMA)

2nd Stage Thrust

Vector Control

3rd Stage Spin Motor

(Thruster)

Attitude, Velocity, Positon

Deflection

Angle

Deflection

Angle

Command

V

Figure 13. Attitude control system

3.3.6. Digital Mockup Development

Digital mockup is fabricated using the CATIA V.

5.8. Figure 14 shows the part of the digital mockup of

the rocket.

294 294 294

Figure 14. Digital mockup using the CATIA

4. Conclusion and Future Works

In this study, the preliminary design of the air-

launching micro rocket was performed. Mission and

trajectory optimization was performed and the

propulsion system was designed based on the mission

design. Total rocket weight was 830.95 kg, the payload

weight was 3.56 kg. The designed propulsion system

length is 5.89 m, hence the total rocket length will not

exceed 7 m when considering the fairing length.

Therefore, the designed rocket can be installed to the

F-4E. Based on the current study, stability and control,

and subsystem design will be performed. Moreover the

system design by implementing the multidisciplinary

design and optimization (MDO) techniques will be

performed.

Acknowledgement

This study was supported by fundamental research

progress (No. R01-2006-000-107400-0) of the KOSEF

(Korea Science and Engineering Foundation) and

BK21(Brain Korea) program.

References

[1] H. C. Bang and H. C. Park, "Status and Future

Outlook on Nano-Pico Satellites Development",

Journal of The Korean Society Aeronautical and Space

Sciences, Vol. 28, No. 5, Aug. 2000.

[2] Birk, R. J., Tompkins, J. M., and Burns, G. S.,

"Commercial Remote Sensing Small Satellite

Feasibility Study", Proceedings of SPIE-The

International Society for Optical Engineering, Vol.

1495, pp. 2-5, 1991.

[3] http://www.ee.surrey.ac.uk/nano

[4] Chul Park, "Prospects for Launch System

Development in Korea," The First International

Aerospace Technomart, Oct. 1996, pp. 79-104.

[5] J-W. Lee, J. Y. Hwang, "The Conceptual Design of

Air-Launching Micro Space Launcher, Mirinae-1,"

Journal of Korean Society for Aeronautical and Space

Sciences, Vol. 29, No. 2, March, 2001.

[6] http://www.astronautix.com/lvs/nots.htm

[7] http://www.rocketry.com/mwade

[8] Steven J. Isakowitz, Joseph P. Hopkins Jr., and

Joshua B. Hopkins, International Reference Guide to

Space Launch Systems, 3rd Ed. AIAA, 1999, pp.267-

280.

[9] Sobiezczanski-Sobieski, J., and Haftka, R. T.,

"Multidisciplinary Aerospace Design Optimization:

Survey of Recent Developments ", AIAA-96-0711,

34th Aero. Sci. Meeting, Jan. 1996.

[10] Jack D. Mattingly, William H. Heiser, Daniel H.

Daley, Aircraft Engine Design, AIAA Education

Series, 1987.

[11] W. R. Roh, Y. D Kim, S. R. Lee H. J. Kim,

"Trajectory Optimization of KOMPSAT Launch

Vehicle Using Nonlinear Programming", Journal of

Korean Society for Aeronautical and Space Sciences,

Vol. 28, No. 1, Feb. 2001, pp.106-114.

[12] Michael R. Mendenhall, Daniel J. Lesieutre,

Steven C. Caruso, Marnix F. E. Dillenius, Gary D.

Kuhn, "Aerodynamics Design of Pegasus: Concept to

Flight with Computational Fluid Dynamics," Journal

of Spacecraft and Rockets, Vol. 31, No. 6, November-

December, 1994, pp.1007-1015.

[13] W. J. Larson, Space Propulsion Analysis and

Design, MacGraw-Hill, Inc., 1995.

[14] http://www.isd.net/anowicki/SPBI101.HTM

[15] S. T. Kwon, C. J. Lee, "Design of Air Launched

Rocket System Using Hybrid Motor", Proceedings of

the KSAS Spring Annual Meeting, Apr. 2002, pp 293-

296.

295 295 295

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Titan 34B 34D Users Guide 1982 04Document144 pagesTitan 34B 34D Users Guide 1982 04Charlie BarberPas encore d'évaluation

- Spacecraft StructuresDocument40 pagesSpacecraft Structuressorinake123100% (1)

- JEGTP 2003 Vol 125 N4 PDFDocument233 pagesJEGTP 2003 Vol 125 N4 PDFAquila777Pas encore d'évaluation

- Model Rocketry ProjectsDocument14 pagesModel Rocketry ProjectsAviation/Space History LibraryPas encore d'évaluation

- Two Stage To Orbit PHD Thesis Hank 2006fullDocument254 pagesTwo Stage To Orbit PHD Thesis Hank 2006fullnumaidecatPas encore d'évaluation

- Oxygen Turbopump Design for Dual Expander Cycle Rocket Engine ThesisDocument84 pagesOxygen Turbopump Design for Dual Expander Cycle Rocket Engine ThesisNecdet DemiralpPas encore d'évaluation

- Rocket PropulsionDocument61 pagesRocket PropulsionAcsah Beth AbjPas encore d'évaluation

- Hydraulics International Air Driven Gas Booster Pumps Data Sheet PDFDocument16 pagesHydraulics International Air Driven Gas Booster Pumps Data Sheet PDFGiana KoesoemahPas encore d'évaluation

- Hanson e Martin (2002) - Low Capital Revamp Increases Vacuum Gas Oil YieldDocument8 pagesHanson e Martin (2002) - Low Capital Revamp Increases Vacuum Gas Oil Yieldvazzoleralex6884Pas encore d'évaluation

- Mastering Physics - Mek2 - Assignment 1Document11 pagesMastering Physics - Mek2 - Assignment 1rexc483% (6)

- ReaccionesDocument1 pageReaccionesNabetse07Pas encore d'évaluation

- EQEDITOR Use the Equation EditorDocument11 pagesEQEDITOR Use the Equation EditorpanchopanzaPas encore d'évaluation

- Analysis of Regenerative Cooling in Liquid Propellant Rocket EnginesDocument100 pagesAnalysis of Regenerative Cooling in Liquid Propellant Rocket EnginesValentin HuePas encore d'évaluation

- Analysis of Regenerative Cooling in Liquid Propellant Rocket EnginesDocument100 pagesAnalysis of Regenerative Cooling in Liquid Propellant Rocket EnginesValentin HuePas encore d'évaluation

- Us 3228480Document9 pagesUs 3228480Nabetse07Pas encore d'évaluation

- ICEM CFD Tutorial Parallel PlatesDocument23 pagesICEM CFD Tutorial Parallel PlatesNabetse07Pas encore d'évaluation

- Us 3228480Document9 pagesUs 3228480Nabetse07Pas encore d'évaluation

- Ansys Icem CFD 12.1Document2 pagesAnsys Icem CFD 12.1Nabetse07Pas encore d'évaluation

- Gas gun dynamics: Understanding complex designs through mechanics and thermodynamicsDocument11 pagesGas gun dynamics: Understanding complex designs through mechanics and thermodynamicsGülden ÇİMENPas encore d'évaluation

- AssignmentDocument2 pagesAssignmentHumera khanPas encore d'évaluation

- Class 9 Science Chapter 9 Revision NotesDocument8 pagesClass 9 Science Chapter 9 Revision NotesANUJ KALRA100% (1)

- A258926 PDFDocument372 pagesA258926 PDFEsteban LoboPas encore d'évaluation

- RuntechTURBO EngDocument20 pagesRuntechTURBO Engvemanreddy29Pas encore d'évaluation

- Rocket Vehicle Dynamics - Orbital Mechanics For Engg Students Curtis HDDocument31 pagesRocket Vehicle Dynamics - Orbital Mechanics For Engg Students Curtis HDIshaq Khan IK100% (1)

- Aircom VST 225 260 - 1st - 2 16Document2 pagesAircom VST 225 260 - 1st - 2 16Rodolfo RamirezPas encore d'évaluation

- FAI PravilnikDocument61 pagesFAI PravilnikMarjan IvanovskiPas encore d'évaluation

- Design & Modification of Homogenizer MachineDocument47 pagesDesign & Modification of Homogenizer MachineWest Sales FPSPas encore d'évaluation

- LPG Characterization and Production Quantification For Oil and Gas ReservoirsDocument9 pagesLPG Characterization and Production Quantification For Oil and Gas Reservoirsdumi-dumiPas encore d'évaluation

- Multi-stage incubators and hatchers advance eggs efficientlyDocument7 pagesMulti-stage incubators and hatchers advance eggs efficientlyJon BrostitoPas encore d'évaluation

- Launching of Satellites: Expendable Launch VehiclesDocument4 pagesLaunching of Satellites: Expendable Launch VehiclesHARIPRASATH ECEPas encore d'évaluation

- Modeling, Simulation and Optimization of Complex Processes HPSC 2018Document402 pagesModeling, Simulation and Optimization of Complex Processes HPSC 2018María Fernanda Rojas FajardoPas encore d'évaluation

- Staging OF Rockets and MissilesDocument14 pagesStaging OF Rockets and MissilesSurekha GurijalaPas encore d'évaluation

- Mission Analysis and Simulation: Optimal RocketsDocument10 pagesMission Analysis and Simulation: Optimal Rocketsa320neoPas encore d'évaluation

- Oakton High School - CDR - ReportDocument76 pagesOakton High School - CDR - Reportapi-482725014Pas encore d'évaluation

- Antec Machine AuditDocument8 pagesAntec Machine AuditDivyanshu Garodia100% (1)

- Space Station Expedition 17Document72 pagesSpace Station Expedition 17Aviation/Space History LibraryPas encore d'évaluation

- N2O4/MMH Thruster DesignDocument10 pagesN2O4/MMH Thruster DesignjuniormirandaPas encore d'évaluation

- (9F) Exergy Analysis of R1234ze (Z) As MGN Temperature Heat Pump Woeking Fluid With Multi-Stage CompressionDocument10 pages(9F) Exergy Analysis of R1234ze (Z) As MGN Temperature Heat Pump Woeking Fluid With Multi-Stage CompressionDaniel DimaPas encore d'évaluation