Académique Documents

Professionnel Documents

Culture Documents

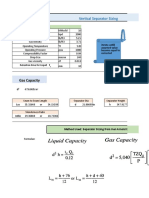

Default Separator Calculation

Transféré par

zamijakaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Default Separator Calculation

Transféré par

zamijakaDroits d'auteur :

Formats disponibles

Design Condition :

25 MMSCFD

3000 BPD

800 psig

80

o

F

3.4 lb/ft

3

51.5 lb/ft

3

35 Refer to Hysis

Vertical

10 ft See Table C.1

30 %

3 ft

0.18 See Table C.1

0.68 ft/s

4.552 ft

3

/s Refer to Hysis

6.72 ft

2

2.93 ft = 35.1 inches

40 inches = 3.3 ft

1 minute See Table C.1.7

26.17 ft

3

= 4.66 barrel

6711.09 BPD

3.3 ft OKE

10 ft OKE

3

10 ft See Table C.1

30 %

3 ft

0.35 See Table C.1

1.32 ft/s

4.552 ft

3

/s Refer to Hysis

3.46 ft

2

2.10 ft = 25.2 inches

30 inches = 2.5 ft

1 minute See Table C.1.7

14.72 ft

3

= 2.62 barrel

3774.99 BPD

Liquid volume =

Minimum ID of separator =

Use =

Retention time =

Va =

Actual gas flow rate =

Minimum gas flow area =

Shell height =

Liquid height =

for K =

Liquid volume (excluding

Liquid capacity of the

API gravity =

Liquid height =

[Range 2.5~6 refer to Shell Standard -

Kepatutan Bentuk]

H =

(H/D) =

Liquid capacity of the

separator =

ID =

Use =

Retention time =

Liquid volume (excluding

bottom head) =

Minimum gas flow area =

SEPARATOR SIZING

Minimum ID of separator =

Va =

Actual gas flow rate =

Assume :

Shell height =

Liquid volume =

Gas flow rate =

Oil flow rate =

Operating pressure =

Operating temperature =

for K =

Gas density =

Oil density =

Separator type =

2.5 ft OKE

10 ft OKE

4

0.35

In case there is no data due to

absences of vendor recommendation

use K =

Refer to page 97 Oilfield processing

Volume 2 : Crude Oil, Francis S.

Manning

(H/D) = [Range 2.5~6 refer to Shell Standard -

Kepatutan Bentuk]

H =

ID =

Design Condition :

60 MMSCFD

39.8 lb/s Refer to Hysis

0.012 cP

500 psig

100

o

F

2.07 lb/ft

3

31.2 lb/ft

3

Horizontal

No

32.2 ft/s

150 micron = 0.00049213 ft

4741.31 Formula 7-3

1.4 Fiq 7-3

0.461 ft/s Formula 7-1

19.23 ft

3

/s

3.50 ft = 42 inch

15.19 ft Formula 7-12

4.34 Normally 2 < (H/ID) < 4

4.00 ft 48 inch

13.29 ft Formula 7-12

3.32 Normally 2 < (H/ID) < 4

4.50 ft 54 inch

11.81 ft Formula 7-12

2.62 Normally 2 < (H/ID) < 4

5.00 ft 60 inch

10.63 ft Formula 7-12

2.13 Normally 2 < (H/ID) < 4

Design Condition :

60 MMSCFD

39.8 lb/s Refer to Hysis

0.012 cP

500 psig

100

o

F

2.07 lb/ft

3

31.2 lb/ft

3

Vertical

No

32.2 ft/s

0.461 ft/s Formula 7-1

Gravitational acceleration =

Demister =

Vt = (terminal velocity)

Vessel length : H =

(H/ID) =

Gas viscosity =

Separator type =

Gas flow =

Assume diameter : ID =

Vessel length : H =

Gas density =

Oil density =

Assume diameter : ID =

Assume diameter : ID =

Gas flow rate =

Gas mass flow =

Operating pressure =

Operating temperature =

Dp = (particle diameter)

C.Re

2

=

Vessel length : H =

(H/ID) =

(H/ID) =

Vessel length : H =

(H/ID) =

Assume diameter : ID =

Operating temperature =

Gas density =

Oil density =

C =

Vt = (terminal velocity)

Separator type =

Demister =

Gravitational acceleration =

SEPARATOR SIZING

Gas flow rate =

Operating pressure =

Example case GPSA

Gas mass flow =

Gas viscosity =

19.23 ft

3

/s

41.72 ft

2

7.3 ft = 87 inch

90 inch

180 inch 15 ft for (H/ID) = 2

270 inch 23 ft for (H/ID) = 3

360 inch 30 ft for (H/ID) = 4

Design Condition :

60 MMSCFD

39.8 lb/s Refer to Hysis

0.012 cP

500 psig

100

o

F

2.07 lb/ft

3

31.2 lb/ft

3

Vertical

Yes

32.2 ft/s

0.18 refer to Fig 7-9

0.144 for 500 psig

0.35 refer to Fig 7-9

0.28 for 500 psig

0.540 ft/s for K1

1.050 ft/s for K2

35.59 ft

2

for K1

ID = 6.73 ft = 81 inch

90 inch

180 inch for (H/ID) = 2

270 inch for (H/ID) = 3

360 inch for (H/ID) = 4

18.30 ft

2

for K2

ID = 4.83 ft = 58 inch

60 inch

120 inch 10 ft for (H/ID) = 2

180 inch 15 ft for (H/ID) = 3

240 inch 20 ft for (H/ID) = 4

0.35

In case there is no data due to absences

of vendor recommendation use K =

Select ID =

A =

H =

H =

H =

Refer to page 97 Oilfield processing

Volume 2 : Crude Oil, Francis S.

Manning

Select ID =

H =

H =

H =

Vt = (terminal velocity)

Vt = (terminal velocity)

A =

Separator type =

Demister =

Gravitational acceleration =

K1 =

K2 =

Gas flow =

Operating pressure =

Operating temperature =

Gas density =

Oil density =

H =

H =

H =

Gas flow rate =

A =

ID =

Select ID =

Gas viscosity =

Gas mass flow =

Design Condition :

25 MMSCFD

3000 BPD = 0.331 m

3

/min =

800 psig

80

o

F

3.4 lb/ft

3

= 54.5 kg/m

3

51.5 lb/ft

3

= 825.0 kg/m

3

35 Refer to Hysis

Vertical

0.8 Without demister

1.7 With demister

0.18 m/s Critical velocity

0.14 m/s Gas velocity without demister

0.31 m/s Gas velocity with demister

4.552 ft

3

/s = 0.129 m

3

/s

0.89 m

2

Without demister

0.42 m

2

With demister

1.07 m = 42.0 inches =

0.75 m = 29.5 inches =

43.3 inches = 1100.0 mm

31.50 inches = 800 mm

400 mm 0.6 minute residence time

100 mm 0.2 minute residence time

150 mm 0.2 minute residence time

304.8 mm

400 mm or h3 = 602.4 mm

602.4 mm 0.9 minute residence time

825 mm 2.4 minute residence time

900 minimum mm 2.4 minute residence time

1800 minimum mm 5.2 minute residence time

900 mm 2.6 minute residence time

457.2 mm 1.3 minute residence time

457.2 mm 0.7 minute residence time

552.4 mm 1.6 minute residence time

552.4 mm 0.8 minute residence time

552.4 mm 1.6 minute residence time

552.4 mm 0.8 minute residence time

h5 = minimum 200 mm

331223531 mm

3

1 minute residence time

949850 mm

2

h5 = 349 mm

662447062 mm

3

2 minute residence time

949850 mm

2

h5 = 697 mm

331223531 mm

3

1 minute residence time

502400 mm

2

h5 = 659 mm

662447062 mm

3

2 minute residence time

502400 mm

2

A5 =

V5 =

A5 =

A5 =

V5 =

A5 =

V5 =

selected h4 =

V5 =

h4a =

ID nozzle inlet =

selected h3 =

h4a =

h1 + h2 + h3 =

h1 + h2 + h3 =

h1 + h2 + h3 =

selected h1 + h2 + h3 =

h4b =

Refer to Ap Greid Manual Training

Vg2 =

Minimum gas flow area =

Use =

Va =

Actual gas flow rate =

Minimum gas flow area =

h1 =

h2 =

h3 =

Vg1 =

h2 =

Minimum ID of separator =

Minimum ID of separator =

Use =

Oil density =

API gravity =

Separator type =

Kc1 =

Kc2 =

SEPARATOR SIZING

Gas flow rate =

Oil flow rate =

Operating pressure =

Operating temperature =

Gas density =

h4b =

selected h4 =

h5 = 1319 mm

h6 = minimum 300 mm

V6 = 993670593 mm

3

3 minute residence time

A6 = 949850 mm

2

h6 = 1046 mm

V6 = 993670593 mm

3

3 minute residence time

A6 = 502400 mm

2

h6 = 1978 mm

h7 = minimum 150 mm

331223531 mm

3

1 minute residence time

949850 mm

2

h7 = 349 mm

662447062 mm

3

2 minute residence time

949850 mm

2

h7 = 697 mm

331223531 mm

3

1 minute residence time

502400 mm

2

h7 = 659 mm

662447062 mm

3

2 minute residence time

502400 mm

2

h7 = 1319 mm

h8a = 150 mm 0.4 minute residence time

h8b = 150 mm 0.2 minute residence time

h8a = 300 mm 0.9 minute residence time

h8b = 300 mm 0.5 minute residence time

SUMMARY :

ID = 800 mm = 2.62 ft

H = 5301 mm

Choosen H = 5350 mm 17.55 ft

(H/ID) = 6.69

Total liquid residence time = 8.0 minute

ID = 1100.0 mm = 3.61 ft

H = 2944 mm

Choosen H = 3000 mm 9.84 ft

(H/ID) = 2.73

Total liquid residence time = 10.0 minute

Normal level = 1948.21 mm

% liquid level at normal = 37 %

h2 =

V7 =

A7 =

A7 =

V7 =

A7 =

V7 =

A7 =

V7 =

h3 =

h1 =

WITH DEMISTER

WITHOUT DEMISTER

d

HHLA

HLA

NL

LLA

LLLA

Horizontal without demister

[1] Vapor liquid settling velocity

0.18 m/s Critical velocity

1.7 Assume production separator

0.31 m/s Gas velocity

[2] Vapor area :

0.42 m

2

0.60 m = 600.00 mm

600.00 mm

[3] Required liquid hold up times :

h4 = minimum 100 mm

331223531 mm

3

1 minute residence time

282600 mm

2

h4 = 1172 mm

662447062 mm

3

2 minute residence time

282600 mm

2

h4 = 2344 mm

h5 = minimum 300 mm

V5 = 993670593 mm

3

3 minute residence time

A5 = 282600 mm

2

h5 = 3516 mm

h6 =

h5 =

h4 =

ID= 800.0 mm

H = 5301.2 mm

(H/ID) = 6.63

h8 =

h7 =

Av =

ID =

Separator type =

Va =

Refer to Ap Greid Manual Training

K =

Vg =

V4 =

A4 =

Use ID =

V4 =

A4 =

h6 = minimum 100 mm

331223531 mm

3

1 minute residence time

282600 mm

2

h4 = 1172 mm

662447062 mm

3

2 minute residence time

282600 mm

2

h4 = 2344 mm

Vtotal = 1656117656 mm

3

hut = 5 minutes

[4] Drum sizing :

1 2

3.5

0.5

Preliminary sizing

V4 =

A4 =

V4 =

A4 =

Trial

Selected (L/ID) normally 3 <(L/ID) <4

Selected (h/ID)

Calculated vapor area Av =

331223531 mm

3

/min

Refer to Hysis

1066 mm

748 mm

Without demister

With demister

for ID < 1200 mm height from bottom of head to mesh pad

for no carbon deposite service height of mesh pad

for carbon deposite service

Refer to line sizing

Greater value is selected height from mesh pad to half of inlet nozzle

Without demister

With demister

Without demister height from half of inlet nozzle to high high level alarm

With demister

Without demister

With demister

height from high high alarm to high level alarm

Refer to Ap Greid Manual Training

SEPARATOR SIZING

WITH DEMISTER

WITHOUT DEMISTER

WITHOUT DEMISTER

WITH DEMISTER

normal level from high level alarm to low level alarm

height from low level to low low level alarm

Without demister for bottom connected to level transmitter

With demister for bottom connected to level transmitter height from low low level alarm to bottom head

Without demister for side connected to level transmitter

With demister for side connected to level transmitter

150.0 mm

400.0 mm

602.4 mm

WITHOUT DEMISTER

WITH DEMISTER

WITHOUT DEMISTER

WITH DEMISTER

WITH DEMISTER

WITHOUT DEMISTER

1977.8 mm

659.3 mm

552.4 mm

300.0 mm

659.3 mm

Refer to Ap Greid Manual Training

3 4

height from low low level alarm to bottom head

PROJECT : TAG NO. :

CLIENT : PETRONAS CARIGALI PAKISTAN TYPE :

SERVICE : DEETHANIZER REFLUX DRUM CASE :

DESIGN BASIS

BASED ON PROCESS FLOW DIAGRAM

GAS RATE 150 MMSCFD

GAS RATE FOR DESIGN 165 MMSCFD

LIQUID RATE 5 BLPD

LIQUID RATE FOR DESIGN 5.5 BLPD

AQUEOUS RATE 5 BAPD

AQUEOUS RATE FOR DESIGN 5.5 BAPD

OPERATING PRESSURE 964.7 PSIA

TEMPERATURE 120 F

LIQUID DENSITY 49.94 LB/CUFT

AQUEOUS DENSITY 62.42 LB/CUFT

MW GAS 16.49

GAS COMP. FACTOR 0.9

WITH MIST ELIMINATOR ( YES/NO ) YES

K FACTOR 0.2719

CALCULATION

GAS DENSITY 2.840 LB/CUFT

GAS DENSITY REFER TO DESIGN FOR CHECK LB/CUFT

MIXED LIQUID DENSITY 56.181 LB/CUFT

MIXED LIQUID DENSITY REFER TO DESIGN FOR CHECK LB/CUFT

ACTUAL GAS RATE 29.212 CUFT/SEC

ACTUAL GAS RATE REFER TO HYSIS FOR CHECK CUFT/SEC

LIQUID RATE 0.043 CUFT/MIN

LIQUID RATE REFER TO HYSIS FOR CHECK CUFT/MIN

GAS VELOCITY 1.179 FPS

MINIMUM GAS AREA 24.787 SQFT

MINIMUM DIAMETER 5.618 FT

DEMISTER CLEARANCE 3.000 INCH

DIAMETER 6.1 FT

1865 mm

PROPOSED DIAMETER 6.2 FT

74.80 INCH

1900.00 mm

LLLA

6

0.500

46.97

1095.96

1096.0

GUESSING GAS HEIGHT

- BOTTOM TO HHLL 36.000 IN

- DIVERTER 28.000 IN

- DIVERTER TO MIST ELIMINATOR 74.803 IN

- MIST ELIMINATOR THICKNESS 6.000 IN

- MIST ELIMINATOR TO TOP 30.402 IN

MINIMUM VESSEL HEIGHT S/S 14.60 FT

RETENTION TIME, MIN (Bottom Base)

RETENTION TIME, MIN (Level Base)

1452.03

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

LLA

1.000

12

62.23

SETTING LIQUID HEIGHT, INCH (T/T)

SETTING LIQUID HEIGHT, FT

LIQUID VOLUME, CUFT

356.1

4450.20 mm

PROPOSED VESSEL HEIGHT S/S 14.76 FT

177.17 INCH

4500 mm

NOZZLE SIZING

A) INLET NOZZLE

INLET NOZZLE DIAMETER VELOCITY DENSITY r X V

2

IN FPS LB/CUFT LB/SQFT

14 27.341 2.839 2121.960

14 27.341 2.839 2121.960

14 27.341 2.839 2121.960

Use = 14 Inch

B) OUTLET NOZZLE

VAPOR NOZZLE

OUTLET NOZZLE DIAMETER VELOCITY DENSITY r X V

2

IN FPS LB/CUFT LB/SQFT

14 27.340 2.840 2122.956

14 27.340 2.840 2122.956

14 27.340 2.840 2122.956

Use = 14 Inch

C) LIQUID NOZZLE

OUTLET NOZZLE DIAMETER VELOCITY DENSITY

IN FPS LB/CUFT VELOCITY =< 3.3

2 0.033 56.181

2 0.033 56.181

2 0.033 56.181

Use = 2 Inch

DIAMETER 74.803 INCH

HEIGHT 14.764 FT

H/D 2.368

LIQUID RETENTION TIME AT NLL 1570.73 MINUTES

NOTE

* INPUT DATA Note 3 GPSA Eq. 7-7

Note 1 ASSUMED SINCE NO LIQUID AVAILABLE Note 4 Gas Conditioning & Processing - Campbell Eq. 11.21, Eq. 11.22, Eq. 11.23

Note 2 GPSA Fig. 7-9 and Chemical Engineering Progrees. Design Two-Phase Separator Within the Right Limits W.Y.Svrcek, W.D. Monnery

Own Calculations :

304.80 mm 12 inch minimum 1.0 ft Fig 7-9. API Sect 7

304.80 mm 12 inch minimum 1.0 ft Fig 7-9. API Sect 7

304.80 mm 12 inch minimum 1.0 ft Fig 7-9. API Sect 7

711.20 mm 28 inch 2.3 ft Fig 7-9. API Sect 7

1900.00 mm 24 inch min or ID 6.2 ft Fig 7-9. API Sect 7

152.40 mm 6 inch 0.5 ft Fig 7-9. API Sect 7

772.20 mm 30 inch 2.5 ft Fig 7-10. API Sect 7

4450.20 mm 14.6 inch 14.6 ft

4500.00 mm 177 inch 14.8 ft

1900.00 mm 74.8 inch 6.2 ft

2.37

h5 =

h4 =

ID =

(H/ID) =

REMARK

OK

h1 =

hT =

Selected H =

OK

OK

h7 =

h6 =

h3 =

h2 =

h2 = 152.4 mm

HHLA

HLA

NL

LLA

LLLA

ID = 1900.0 mm

h5 =

h6 =

H = 4500.0 mm

(H/ID) = 2.37

711.2 mm

304.8 mm

h7 =

h1 = 772.2 mm

h3 = 1900.0 mm

h4 =

304.8 mm

304.8 mm

V-2701

VERTICAL, 2-PHASE

MAXIMUM FLOW RATE

MMSCFD 1.5

MMSCFD 10 % tolerance for design

BLPD Note 1

BLPD 10 % tolerance for design

BAPD Note 1

BAPD 10 % tolerance for design

PSIA *

*

LB/CUFT * Refer to Hysis Simulation

LB/CUFT * Refer to Hysis Simulation

* Refer to Hysis Simulation

* Refer to Hysis Simulation

(Vane Pack Mist Elim.)

Note 2

LB/CUFT

LB/CUFT * Refer to Hysis Simulation

LB/CUFT

LB/CUFT * Refer to Hysis Simulation

CUFT/SEC

CUFT/SEC * Refer to Hysis Simulation

CUFT/MIN

CUFT/MIN * Refer to Hysis Simulation

Note 3

SQFT

INCH 3"~6" for ring support of mist eliminator

INCH

* (SELECTED)

NLA HLA HHLA

14 24 36

1.167 2.000 3.000

67.31 92.74 123.26

1570.73 2164.19 2876.34

118.7 593.5 712.2

(2 x D inlet Nozzle) Fig 7-6. GPSA

(Minimum 24" or ID) Fig 7-6. GPSA

* (Minimum Recommended 4" at E-7 GPSA)

Fig 7-10. GPSA

1452.03

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

LLA

1.000

12

62.23

356.1

INCH

* (SELECTED)

Note 4

r X V

2

LB/SQFT

2121.960 OK

2121.960 OK

2121.960 OK

Note 4

r X V

2

LB/SQFT

2122.956 OK

2122.956 OK

2122.956 OK

Note 4

VELOCITY =< 3.3

INCH

MINUTES

Gas Conditioning & Processing - Campbell Eq. 11.21, Eq. 11.22, Eq. 11.23

Note 2 GPSA Fig. 7-9 and Chemical Engineering Progrees. Design Two-Phase Separator Within the Right Limits W.Y.Svrcek, W.D. Monnery

Fig 7-9. API Sect 7 712 minutes

Fig 7-9. API Sect 7 712 minutes

Fig 7-9. API Sect 7 712 minutes

Fig 7-9. API Sect 7 1661 minutes

Fig 7-9. API Sect 7 4437 minutes

Fig 7-9. API Sect 7 356 minutes

Fig 7-10. API Sect 7 1803 minutes

REMARK

REMARK

REMARK

OK

OK

OK

PROJECT : TAG NO. :

CLIENT : PETRONAS CARIGALI PAKISTAN TYPE :

SERVICE : DEETHANIZER REFLUX DRUM CASE :

Refer to : W.Y. Svrcek, W.D. Monnery," Design Two-Phase Separators Within the Right Limits

DESIGN BASIS

BASED ON PROCESS FLOW DIAGRAM

GAS RATE 150 MMSCFD

GAS RATE FOR DESIGN 165 MMSCFD

LIQUID RATE 5 BLPD

LIQUID RATE FOR DESIGN 5.5 BLPD

AQUEOUS RATE 5 BAPD

AQUEOUS RATE FOR DESIGN 5.5 BAPD

OPERATING PRESSURE 964.7 PSIA

66.53 BARA

TEMPERATURE 120 F

LIQUID DENSITY 49.94 LB/CUFT

AQUEOUS DENSITY 62.42 LB/CUFT

MW GAS 16.49

GAS COMP. FACTOR 0.9

WITH MIST ELIMINATOR ( YES/NO ) YES

K FACTOR 0.2719

CALCULATION

GAS DENSITY 2.840 LB/CUFT

GAS DENSITY REFER TO DESIGN FOR CHECK LB/CUFT

MIXED LIQUID DENSITY 56.181 LB/CUFT

MIXED LIQUID DENSITY REFER TO DESIGN FOR CHECK LB/CUFT

ACTUAL GAS RATE 29.212 CUFT/SEC

ACTUAL GAS RATE REFER TO HYSIS FOR CHECK CUFT/SEC

LIQUID RATE 0.043 CUFT/MIN

LIQUID RATE REFER TO HYSIS FOR CHECK CUFT/MIN

GAS VELOCITY 1.179 FPS

GAS VELOCITY FOR CONCERVATIVE DESIGN 1.179 FPS

MINIMUM GAS AREA 24.787 SQFT

MINIMUM DIAMETER 5.618 FT

DEMISTER CLEARANCE 3.000 INCH

DIAMETER 6.118 FT

1865 mm

PROPOSED DIAMETER 6.2 FT

74.80 INCH

1900.0 mm

LLLA

3

0.250

39.34

917.92

917.9

GUESSING GAS HEIGHT

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

LLA

0.500

6 SETTING LIQUID HEIGHT, INCH (T/T)

SETTING LIQUID HEIGHT, FT

RETENTION TIME, MIN (Bottom Base)

RETENTION TIME, MIN (Level Base)

LIQUID VOLUME, CUFT

178.0

46.97

1095.96

- BOTTOM TO HHLL 49 IN

- HHLA to BOTTOM OF MIST ELIMINATOR 37.40 IN

- MIST ELIMINATOR THICKNESS 6 IN

- MIST ELIMINATOR TO TOP 12 IN

MINIMUM VESSEL HEIGHT S/S 8.70 FT

2652 MM

PROPOSED VESSEL HEIGHT S/S 13.94 FT

167.32 INCH

4250 MM

DIAMETER 1900 MM

HEIGHT 4250 MM

H/D 2.237

LIQUID RETENTION TIME AT NLL 1808.11 MINUTES

NOZZLE SIZING

A) INLET NOZZLE

INLET NOZZLE DIAMETER VELOCITY DENSITY r X V

2

IN FPS LB/CUFT LB/SQFT

14 27.341 2.839 2121.960

14 27.341 2.839 2121.960

14 27.341 2.839 2121.960

Use = 14 Inch

B) OUTLET NOZZLE

VAPOR NOZZLE

OUTLET NOZZLE DIAMETER VELOCITY DENSITY r X V

2

IN FPS LB/CUFT LB/SQFT

14 27.340 2.840 2122.956

14 27.340 2.840 2122.956

14 27.340 2.840 2122.956

Use = 14 Inch

C) LIQUID NOZZLE

OUTLET NOZZLE DIAMETER VELOCITY DENSITY

IN FPS LB/CUFT VELOCITY =< 3.3

2 0.033 56.181

2 0.033 56.181

2 0.033 56.181

Use = 2 Inch

NOTE

* INPUT DATA Note 3 GPSA Eq. 7-7 then 0.75 x gas velocity for conservative design

Note 1 ASSUMED SINCE NO LIQUID AVAILABLE Note 4 Gas Conditioning & Processing - Campbell Eq. 11.21, Eq. 11.22, Eq. 11.23

Note 2 GPSA Fig. 7-9 and Chemical Engineering Progrees. Design Two-Phase Separator Within the Right Limits W.Y.Svrcek, W.D. Monnery

152.40 mm 6 inch 0.5 ft

2.14 mm 0.084 inch 0.01 ft

304.80 mm 12 inch 1.0 ft minimum v6 selected =

1.28 mm 0.051 inch 0.004 ft

304.80 mm 12 inch 1.0000 ft v5 selected =

482.60 mm 19 inch 1.6 ft

950.00 mm 37 inch 3.1 ft

787.40 mm 31 inch 2.6 ft

h3 = 2077.80 mm 82 inch 6.8 ft

h7 =

h6 selected =

h5 selected =

h3 =

h5 =

h4 =

h3 =

REMARK

OK

OK

OK

h6 =

2077.80 mm 82 inch 6.8 ft

152.40 mm 6 inch 0.5 ft

304.80 mm 12 inch 1.0 ft

772.20 mm 30 inch 2.5 ft

772.20 mm 30 inch 2.5 ft

4247.00 mm 167.2 inch 13.9 ft

4250.00 mm 167 inch 13.9 ft

1900.00 mm 74.8 inch 6.2 ft

2.24

h2 = 152.4 mm

HHLA

HLA

NL

LLA

ID = 1900.0 mm

h4 =

h3 selected =

h3 =

h1 =

hT =

Selected H =

h7 = 152.4 mm

h5 = 304.8 mm

304.8 mm h6 =

482.6 mm

2077.8 mm

H = 4250.0 mm

(H/ID) = 2.24

ID =

(H/ID) =

h1 = 772.2 mm

Selected h1 =

h2 =

h1 =

V-2701

VERTICAL, 2-PHASE

MAXIMUM FLOW RATE

Refer to : W.Y. Svrcek, W.D. Monnery," Design Two-Phase Separators Within the Right Limits

MMSCFD 1.5

MMSCFD 10 % tolerance for design

BLPD Note 1

BLPD 10 % tolerance for design

BAPD Note 1

BAPD 10 % tolerance for design

PSIA *

*

LB/CUFT * Refer to Hysis Simulation

LB/CUFT * Refer to Hysis Simulation

* Refer to Hysis Simulation

* Refer to Hysis Simulation

(Vane Pack Mist Elim.)

Note 2

LB/CUFT

LB/CUFT * Refer to Hysis Simulation

LB/CUFT

LB/CUFT * Refer to Hysis Simulation

CUFT/SEC

CUFT/SEC * Refer to Hysis Simulation

CUFT/MIN

CUFT/MIN * Refer to Hysis Simulation

Note 3

* Take 75%~100% from gas velocity

SQFT

INCH

INCH

* (SELECTED)

NLA HLA HHLA

18 30 49

1.500 2.500 4.083

77.49 108.00 156.33

1808.11 2520.27 3647.84

712.2 712.2 1127.6

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

LLA

0.500

6

178.0

46.97

1095.96

INCH

* (SELECTED)

* The ratio (H/D) should be in 1.5~6

MINUTES

Note 4

r X V

2

LB/SQFT

2121.960 OK

2121.960 OK

2121.960 OK

Note 4

r X V

2

LB/SQFT

2122.956 OK

2122.956 OK

2122.956 OK

Note 4

VELOCITY =< 3.3

GPSA Eq. 7-7 then 0.75 x gas velocity for conservative design

Gas Conditioning & Processing - Campbell Eq. 11.21, Eq. 11.22, Eq. 11.23

Note 2 GPSA Fig. 7-9 and Chemical Engineering Progrees. Design Two-Phase Separator Within the Right Limits W.Y.Svrcek, W.D. Monnery

Refer to Table 3. Low liquid level height

v6 = 0.2143 CUFT Refer to Table.2 Liquid holdup and surge times

v6 selected = 30.5033 CUFT 1.0 ft minimum 711.8 minutes

v5 = 0.1286 CUFT Refer to Table.2 Liquid holdup and surge times

v5 selected = 30.5033 CUFT 1.0 feet minimum 711.8 minutes

Refer to Fig. 1 Svrcek and Monnery

Refer to Fig 7-6. GPSA sec. 7

REMARK

REMARK

OK

OK

holding time=

holding time=

REMARK

OK

Refer to Fig. 1 Vertical 2 phase separator Svrcek & Monnery

Refer to Fig 24 Amistco Mest and Vane Mist Eliminator/Fig 6 The engineered mist eliminator/Fig. 7-10 GPSA sec. 7

PROJECT :

CLIENT : PETRONAS CARIGALI PAKISTAN

SERVICE : DEETHANIZER REFLUX DRUM

Refer to : W.Y. Svrcek, W.D. Monnery,"Design Two-Phase Separators Within the Right Limits"

DESIGN BASIS

BASED ON PROCESS FLOW DIAGRAM

GAS RATE

GAS RATE FOR DESIGN

LIQUID RATE

LIQUID RATE FOR DESIGN

AQUEOUS RATE

AQUEOUS RATE FOR DESIGN

OPERATING PRESSURE

TEMPERATURE

LIQUID DENSITY

AQUEOUS DENSITY

MW GAS

GAS COMP. FACTOR

WITH MIST ELIMINATOR ( YES/NO )

K FACTOR

K FACTOR WIT/WITHOUT MIST ELIMINATOR

CALCULATION

GAS DENSITY

GAS DENSITY REFER TO DESIGN FOR CHECK

MIXED LIQUID DENSITY

MIXED LIQUID DENSITY REFER TO DESIGN FOR CHECK

ACTUAL GAS RATE

ACTUAL GAS RATE REFER TO HYSIS FOR CHECK

LIQUID RATE

LIQUID RATE REFER TO HYSIS FOR CHECK

GAS VELOCITY

GAS VELOCITY FOR CONCERVATIVE DESIGN

HOLD UP VOLUME

SURGE VOLUME

1ST

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

LOW LIQUID LEVEL HEIGHT (LLA)

LOW LIQUID LEVEL HEIGHT (LLA)

SELECTED LLA

(LLA/ID)

(A

LLA

/A

T

)

A

LLA

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

H

V

=

H

V

=

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

MINIMUM LENGTH FOR ACCOMODATING HOLD UP/SURGE (L

HOLDUP-SURGE

)

SELECTED L

HOLDUP-SURGE

LIQUID DROP OUT TIME (T

DROP

)

ACTUAL VAPOR VELOCITY (U

VA

)

MINIMUM LENGTH FOR VAPOR LIQUID SEPARATION (L

MIN

)

SELECTED LENGTH OF SEPARATOR L

H

H

A

H

H

S

A

S

SUMMARY

PROPOSED DIAMETER (ID)

PROPOSED LENGTH (L)

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

2ND

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

LOW LIQUID LEVEL HEIGHT (LLA)

LOW LIQUID LEVEL HEIGHT (LLA)

SELECTED LLA

(LLA/ID)

(A

LLA

/A

T

)

A

LLA

H

V

=

H

V

=

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

MINIMUM LENGTH FOR ACCOMODATING HOLD UP/SURGE (L

HOLDUP-SURGE

)

SELECTED L

HOLDUP-SURGE

LIQUID DROP OUT TIME (T

DROP

)

ACTUAL VAPOR VELOCITY (U

VA

)

MINIMUM LENGTH FOR VAPOR LIQUID SEPARATION (L

MIN

)

SELECTED LENGTH OF SEPARATOR L

H

H

A

H

H

S

A

S

SUMMARY

PROPOSED DIAMETER (ID)

PROPOSED LENGTH (L)

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

3RD

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

LOW LIQUID LEVEL HEIGHT (LLA)

LOW LIQUID LEVEL HEIGHT (LLA)

SELECTED LLA

(LLA/ID)

(A

LLA

/A

T

)

A

LLA

H

V

=

H

V

=

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

MINIMUM LENGTH FOR ACCOMODATING HOLD UP/SURGE (L

HOLDUP-SURGE

)

SELECTED L

HOLDUP-SURGE

LIQUID DROP OUT TIME (T

DROP

)

ACTUAL VAPOR VELOCITY (U

VA

)

MINIMUM LENGTH FOR VAPOR LIQUID SEPARATION (L

MIN

)

SELECTED LENGTH OF SEPARATOR L

H

H

A

H

H

S

A

S

SUMMARY

PROPOSED DIAMETER (ID)

PROPOSED LENGTH (L)

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

ITERASI L

1 3650.0 MM

2 5100.0 MM

3 7000.0 MM

Min 12.0 Inch

HLA

ID

2150.0 MM

1900.0 MM

1700.0 MM

ID = 1900 MM

L = 3650 MM

LLA

NLA

TAG NO. : V-2701

TYPE : VERTICAL, 2-PHASE

CASE : MAXIMUM FLOW RATE

Refer to : W.Y. Svrcek, W.D. Monnery,"Design Two-Phase Separators Within the Right Limits"

145600 LB/HR

160160 LB/HR 10 % tolerance for design

46100 LB/HR Note 1

50710 LB/HR 10 % tolerance for design

0 LB/HR Note 1

0 LB/HR 10 % tolerance for design

989.70 PSIA *

68.25 BARA

650 F *

343.3 C

38.83 LB/CUFT * Refer to Hysis Simulation

0 LB/CUFT * Refer to Hysis Simulation

16.49 * Refer to Hysis Simulation

0.9 * Refer to Hysis Simulation

YES

0.2714 Note 2

0.2714 Note 2

LB/CUFT

4.010 LB/CUFT * Refer to Hysis Simulation

LB/CUFT

38.830 LB/CUFT * Refer to Hysis Simulation

CUFT/SEC

11.094 CUFT/SEC * Refer to Hysis Simulation

CUFT/MIN

21.766 CUFT/MIN * Refer to Hysis Simulation

0.800 FPS Note 3

0.800 FPS * Take 75%~100% from gas velocity

217.658 CUFT * Table 2. Liquid holdup and surge times

108.829 CUFT * Table 2. Liquid holdup and surge times

2.000 * Table 5. (L/D) Ratio Guidelines

7.024 FT 2141.0 MM

7.054 FT 2150.0 MM

39.059 SQFT

467.729 CUFT

10.000 INCH 254.0 MM Tabel 3. Low Liquid Level Height

10.527 INCH 267.4 MM

10.527 INCH 254.0 MM

0.118

0.066 Tabel 6. Cylindrical height and area conversion

2.593 SQFT

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

1.411 FT 430.0 MM

Min 2.0 FT 609.6 MM Fig 2. Horizontal 2 phase separator

2.000 FT 609.6 MM

0.284

0.233

9.115 SQFT

11.937 FT 3638.4 MM

11.975 FT 3650.0 MM

2.501 SEC

1.217 FT/SEC

3.044 FT

11.975 FT IF L

HOLDUP-SURGE

> L

MIN

THEN USE L

HOLDUP-SURGE

, IF L

HOLDUP-SURGE

< L

MIN

THEN INCREASE H

V

3.282 FT 1000.5 MM

18.176 SQFT

0.938 FT 285.9 MM

9.175 SQFT

7.054 FT 2150 MM

11.975 FT 3650 MM

1.698

* Table 7

17500 PSI

1/16 INCH 1.6 MM

0.850

1019.696 PSI * Design pressure

3.09 INCH 78.4 MM * Table 7

3.15 INCH 80.0 MM

2.984 INCH 75.8 MM * Design pressure

2.99 INCH 76.0 MM * Table 7

265.235 SQFT * Table 7

54.234 SQFT * Table 3

490.000 LB/CUFT * Table 3

47364.117 LB 21.5 TONNES

3.000 * Table 5. (L/D) Ratio Guidelines

6.136 FT 1870.4 MM

6.234 FT 1900.0 MM

30.503 SQFT

510.390 CUFT

10.000 INCH 254.0 MM Tabel 3. Low Liquid Level Height

10.117 INCH 257.0 MM

10.117 INCH 254.0 MM

0.134

0.080 Tabel 6. Cylindrical height and area conversion

2.426 SQFT

1.247 FT 380.0 MM

Min 2.0 FT 609.6 MM Fig 2. Horizontal 2 phase separator

2.000 FT 609.6 MM

0.321

0.277

8.448 SQFT

16.633 FT 5069.6 MM

16.732 FT 5100.0 MM

2.501 SEC

0.354 FT/SEC

0.886 FT

16.732 FT IF L

HOLDUP-SURGE

> L

MIN

THEN USE L

HOLDUP-SURGE

, IF L

HOLDUP-SURGE

< L

MIN

THEN INCREASE H

V

2.658 FT 810.3 MM

13.008 SQFT

0.742 FT 226.1 MM

6.621 SQFT

6.234 FT 1900 MM

16.732 FT 5100 MM

2.684

* Table 7

17500 PSI

1/16 INCH 1.6 MM

0.850

1019.696 PSI * Design pressure

2.74 INCH 69.5 MM * Table 7

2.83 INCH 72.0 MM

2.644 INCH 67.2 MM * Design pressure

2.68 INCH 68.0 MM * Table 7

327.509 SQFT * Table 7

42.355 SQFT * Table 3

490.000 LB/CUFT * Table 3

47168.818 LB 21.4 TONNES

4.000 * Table 5. (L/D) Ratio Guidelines

5.575 FT 1699.3 MM

5.577 FT 1700.0 MM

24.420 SQFT

560.816 CUFT

10.000 INCH 254.0 MM Tabel 3. Low Liquid Level Height

9.789 INCH 248.6 MM

9.789 INCH 254.0 MM

0.149

0.094 Tabel 6. Cylindrical height and area conversion

2.284 SQFT

1.115 FT 340.0 MM

Min 2.0 FT 609.6 MM Fig 2. Horizontal 2 phase separator

2.000 FT 609.6 MM

0.359

0.322

7.873 SQFT

22.892 FT 6977.3 MM

22.966 FT 7000.0 MM

2.501 SEC

0.340 FT/SEC

0.850 FT

22.966 FT IF L

HOLDUP-SURGE

> L

MIN

THEN USE L

HOLDUP-SURGE

, IF L

HOLDUP-SURGE

< L

MIN

THEN INCREASE H

V

2.165 FT 659.8 MM

9.477 SQFT

0.579 FT 176.6 MM

4.785 SQFT

5.577 FT 1700 MM

22.966 FT 7000 MM

4.118

* Table 7

17500 PSI

1/16 INCH 1.6 MM

0.850

1019.696 PSI * Design pressure

2.45 INCH 62.4 MM * Table 7

2.52 INCH 64.0 MM

2.372 INCH 60.3 MM * Design pressure

2.52 INCH 64.0 MM * Table 7

402.204 SQFT * Table 7

33.907 SQFT * Table 3

490.000 LB/CUFT * Table 3

48358.917 LB 21.9 TONNES

(L/ID) W

1.70 21.5 TONNES

2.68 21.4 TONNES

4.12 21.9 TONNES

Min 12.0 Inch

HV = 609.6 MM

HLA

226.1 MM

810.3 MM

254.0 MM

L = 3650 MM

LLA

NLA

HLL =

Hold up =

Surge =

1456

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

IF L

HOLDUP-SURGE

> L

MIN

THEN USE L

HOLDUP-SURGE

, IF L

HOLDUP-SURGE

< L

MIN

THEN INCREASE H

V

IF L

HOLDUP-SURGE

> L

MIN

THEN USE L

HOLDUP-SURGE

, IF L

HOLDUP-SURGE

< L

MIN

THEN INCREASE H

V

IF L

HOLDUP-SURGE

> L

MIN

THEN USE L

HOLDUP-SURGE

, IF L

HOLDUP-SURGE

< L

MIN

THEN INCREASE H

V

HLA

8.4 SQFT A

V

=

A

V

NLA

LLA

A

LL

=

6.6 SQFT

13.0 SQFT

2.4 SQFT

A

S

=

A

H

=

A

LL

A

H

A

S

PROJECT :

CLIENT : PETRONAS CARIGALI PAKISTAN

SERVICE : DEETHANIZER REFLUX DRUM

Refer to : W.Y. Svrcek, W.D. Monnery,"Successfully Specify Three-Phase Separators"

DESIGN BASIS

BASED ON PROCESS FLOW DIAGRAM

GAS RATE

GAS RATE FOR DESIGN

LIQUID RATE

LIQUID RATE FOR DESIGN

AQUEOUS RATE

AQUEOUS RATE FOR DESIGN

OPERATING PRESSURE

TEMPERATURE

LIQUID DENSITY

LIQUID VISCOSITY

AQUEOUS DENSITY

AQUEOUS VISCOSITY

MW GAS

GAS COMP. FACTOR

WITH MIST ELIMINATOR ( YES/NO )

K FACTOR

K FACTOR WIT/WITHOUT MIST ELIMINATOR

CALCULATION

GAS DENSITY

GAS DENSITY REFER TO DESIGN FOR CHECK

ACTUAL GAS RATE

QV = ACTUAL GAS RATE REFER TO HYSIS FOR CHECK

LIQUID RATE

QLL =LIQUID RATE REFER TO HYSIS FOR CHECK

AQUEOUS RATE

QHV =AQUEOUS RATE REFER TO HYSIS FOR CHECK

GAS VELOCITY

GAS VELOCITY FOR CONCERVATIVE DESIGN

TIME FOR HOLD UP

TIME FOR SURGE

V

H

V

S

V

H

+ V

S

1

ST

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

H

V

ASSUME HV = 0.2 ID

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

2

ND

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

ASSUME HV = 0.4 ID

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

3

RD

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

ASSUME HV = 0.5 ID

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

4

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

ASSUME HV = 0.6 ID

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

5

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

ASSUME HV = 0.7 ID

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

6

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

ASSUME HV = 0.7 ID

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

7

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

ASSUME HV = 0.2 ID

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

8

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME HV = 0.4 ID

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

9

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

ASSUME HV = 0.6 ID

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

10

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

ASSUME HV = 0.7 ID

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

11

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME HV = 0.2 ID

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

12

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

ASSUME HV = 0.4 ID

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

13

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

ASSUME HV = 0.6 ID

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

14

TH

ITERATION :

ASSUME (L/ID)

DIAMETER (ID)

SELECTED ID

TOTAL CROSS SECTIONAL AREA (A

T

)

VESSEL VOLUME

H

V

ASSUME HV = 0.7 ID

H

V

SELECTED H

V

=

(H

V

/ID)

(A

V

/A

T

)

A

V

H

LLL

H

LLL

SELECTED H

LLL

(H

LLL

/ID)

(A

LLL

/A

T

)

A

LLL

H

W

L

2

H

HL

= H

LL

(H

HL

/ID)

(A

HL

/A

T

)

A

HL

A

LL

KS

U

HL

U

LH

SELECTED U

t

HL =

t

LH

L

1

L

1

SELECTED L

1

L = L1 + L2

USE L

f

U

VA

L

MIN

USE L

MIN

NOTE : L << L

MIN

SELECTED L

(L/ID)

ASSUME 2:1 ELLIPTICAL DISH HEAD

USE SA-516 70 CARBON STEEL

S

CORROSION ALLOWANCE

ASSUME WELDING JOINT EFFICIENCY

P

t

S

SELECTED t

S

t

H

SELECTED t

H

A

S

A

H

r

W

SUMMARY :

ITERASI Hv Hv ID L

1 ASSUME HV = 0.20 ID 650.0 MM 3250.0 MM 3500.0 MM

2 ASSUME HV = 0.40 ID 1300.0 MM 3250.0 MM 10850.0 MM

3 ASSUME HV = 0.50 ID 1625.0 MM 3250.0 MM 6500.0 MM

4 ASSUME HV = 0.60 ID 1950.0 MM 3250.0 MM 6100.0 MM

5 ASSUME HV = 0.70 ID 2275.0 MM 3250.0 MM 7600.0 MM

6 ASSUME HV = 0.65 ID 2112.5 MM 3250.0 MM 5900.0 MM

7 ASSUME HV = 0.20 ID 570.0 MM 2850.0 MM 3900.0 MM

8 ASSUME HV = 0.40 ID 1140.0 MM 2850.0 MM 3900.0 MM

9 ASSUME HV = 0.60 ID 1710.0 MM 2850.0 MM 16100.0 MM

10 ASSUME HV = 0.70 ID 1995.0 MM 2850.0 MM 12150.0 MM

11 ASSUME HV = 0.20 ID 520.0 MM 2600.0 MM 4150.0 MM

12 ASSUME HV = 0.40 ID 1040.0 MM 2600.0 MM 4650.0 MM

13 ASSUME HV = 0.60 ID 1560.0 MM 2600.0 MM 16550.0 MM

14 ASSUME HV = 0.70 ID 1820.0 MM 2600.0 MM 14300.0 MM

3RD

ITERATION IS SELECTED

then (L/ID) is set to value minimum 2

H

HLL

= H

W

A

NLL

A

NLL

/A

T

H

NLL

/ID

H

NLL

SUMMARY

PROPOSED DIAMETER (ID)

PROPOSED LENGTH (L)

(L/ID)

H

V

H

LLL

H

NLL

H

HLL

H

W

H

HL

H

LL

L2

L1

4

(L/ID)

Assumption

2

2

3

3

3

2

2

2

2

3

4

4

4

304.8 MM OR 12 INCH

GAS

HLL = 813 MM

HV = 1625 MM

L = 6500 MM

(L/ID) = 2

HHL = 813 MM

ID = 3250 MM

1320.2 MM

L1 = 4377 MM

INTERFACE

HEAVY LIQUID

LIGHT LIQUID

GAS

TAG NO. : V-2701

TYPE : VERTICAL, 2-PHASE

CASE : MAXIMUM FLOW RATE

Refer to : W.Y. Svrcek, W.D. Monnery,"Successfully Specify Three-Phase Separators"

235000 LB/HR 2350

235000 LB/HR

45000 LB/HR Note 1

45000 LB/HR

7500 LB/HR Note 1

7500 LB/HR

39.70 PSIA *

2.74 BARA

100 F *

37.8 C

40.50 LB/CUFT * Refer to Hysis Simulation

0.24 cP

62 LB/CUFT * Refer to Hysis Simulation

0.682 cP

16.49 * Refer to Hysis Simulation

0.9 * Refer to Hysis Simulation

YES

0.3453 Note 2

0.3453 Note 2

LB/CUFT

0.190 LB/CUFT * Refer to Hysis Simulation

CUFT/SEC

343.567 CUFT/SEC * Refer to Hysis Simulation

CUFT/MIN

18.519 CUFT/MIN * Refer to Hysis Simulation

CUFT/MIN

2.016 CUFT/MIN * Refer to Hysis Simulation

5.030 FPS Note 3

5.030 FPS * Take 75%~100% from gas velocity

10.000 MIN * Refer to Tabel 6

5.000 * Refer to Tabel 6

185.185 CUFT

92.593 CUFT

277.778 CUFT

2.000 * Table 7. (L/D) Ratio Guidelines

10.566 FT 3220.5 MM

10.663 FT 3250.0 MM

89.250 SQFT

2.133 FT 650.0 MM

0 % tolerance for design

0 % tolerance for design

0 % tolerance for design

PT.ISTANA KARANG LAUT

VERTICAL SEPARATOR

2.000 FT 609.6 MM *Minimum

2.133 FT 650.0 MM

0.200

0.142

12.710 SQFT

12.331 INCH 313.2 MM

13.000 INCH 330.2 MM * Table 9

13.000 INCH 330.2 MM

0.102

0.053

4.744 SQFT

8.530 FT 2600.0 MM

3.869 FT 1179.3 MM

4.265 FT 1300.0 MM

0.400

0.373

4.855 SQFT

71.684 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

4.875 MIN

2.024 FT 617.1 MM

1.259 FT 383.9 MM

2.024 FT 617.1 MM

5.893 FT 1796.3 MM

5.906 FT 1800.0 MM

0.424 SEC

27.031 FT/SEC

11.460 FT 3493.1 MM

11.483 FT 3500.0 MM

11.483 FT 3500.0 MM

1.077

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.363 INCH 9.2 MM * Table 8

0.394 INCH 10.0 MM

0.362 INCH 9.2 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

384.460 SQFT

123.926 SQFT

490.000 LB/CUFT

10165.128 LB

2.000 * Table 7. (L/D) Ratio Guidelines

10.566 FT 3220.5 MM

10.663 FT 3250.0 MM

89.250 SQFT

4.265 FT 1300.0 MM

2.000 FT 609.6 MM *Minimum

4.265 FT 1300.0 MM

0.400

0.373

33.334 SQFT

12.331 INCH 313.2 MM

13.000 INCH 330.2 MM * Table 9

13.000 INCH 330.2 MM

0.102

0.053

4.744 SQFT

6.398 FT 1950.0 MM

5.428 FT 1654.5 MM

3.199 FT 975.0 MM

0.300

0.252

3.281 SQFT

52.635 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

3.657 MIN

30.129 FT 9183.4 MM

0.029 FT 9.0 MM

30.129 FT 9183.4 MM

35.558 FT 10837.9 MM

35.597 FT 10850.0 MM

0.848 SEC

4.6 TONNES

10.307 FT/SEC

8.740 FT 2663.8 MM

8.858 FT 2700.0 MM

35.597 FT 10850.0 MM

3.338

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.362 INCH 9.2 MM * Table 8

0.394 INCH 10.0 MM

0.362 INCH 9.2 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

1191.826 SQFT

123.926 SQFT

490.000 LB/CUFT

23144.436 LB

2.000 * Table 7. (L/D) Ratio Guidelines

10.566 FT 3220.5 MM

10.663 FT 3250.0 MM

89.250 SQFT

5.331 FT 1625.0 MM

2.000 FT 609.6 MM *Minimum

5.331 FT 1625.0 MM

0.500

0.500

44.624 SQFT

12.331 INCH 313.2 MM

13.000 INCH 330.2 MM * Table 9

13.000 INCH 330.2 MM

0.102

0.053

4.744 SQFT

5.331 FT 1625.0 MM

6.965 FT 2122.9 MM

2.666 FT 812.5 MM

0.250

0.196

2.542 SQFT

10.5 TONNES

42.084 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

3.047 MIN

12.353 FT 3765.3 MM

0.061 FT 18.7 MM

12.353 FT 3765.3 MM

19.318 FT 5888.3 MM

19.357 FT 5900.0 MM

1.060 SEC

7.699 FT/SEC

8.161 FT 2487.4 MM

8.202 FT 2500.0 MM

21.325 FT 6500.0 MM

2.000

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.362 INCH 9.2 MM * Table 8

0.394 INCH 10.0 MM

0.362 INCH 9.2 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

713.997 SQFT

123.926 SQFT

490.000 LB/CUFT

15462.805 LB

2.000 * Table 7. (L/D) Ratio Guidelines

10.566 FT 3220.5 MM

10.663 FT 3250.0 MM

89.250 SQFT

0.000 CUFT

6.398 FT 1950.0 MM

2.000 FT 609.6 MM *Minimum

6.398 FT 1950.0 MM

0.600

0.627

55.916 SQFT

7.0 TONNES

12.331 INCH 313.2 MM

13.000 INCH 330.2 MM * Table 9

13.000 INCH 330.2 MM

0.102

0.053

4.744 SQFT

4.265 FT 1300.0 MM

9.716 FT 2961.4 MM

2.133 FT 650.0 MM

0.200

0.142

1.851 SQFT

31.482 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

2.438 MIN

10.138 FT 3090.0 MM

0.082 FT 25.0 MM

10.138 FT 3090.0 MM

19.854 FT 6051.4 MM

20.013 FT 6100.0 MM

1.272 SEC

6.144 FT/SEC

7.815 FT 2382.0 MM

7.874 FT 2400.0 MM

20.013 FT 6100.0 MM

1.877

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.362 INCH 9.2 MM * Table 8

0.394 INCH 10.0 MM

0.362 INCH 9.2 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

670.059 SQFT

123.926 SQFT

490.000 LB/CUFT

14756.448 LB

2.000 * Table 7. (L/D) Ratio Guidelines

10.566 FT 3220.5 MM

10.663 FT 3250.0 MM

89.250 SQFT

0.000 CUFT

7.464 FT 2275.0 MM

2.000 FT 609.6 MM *Minimum

7.464 FT 2275.0 MM

0.700

0.748

66.730 SQFT

12.331 INCH 313.2 MM

13.000 INCH 330.2 MM * Table 9

13.000 INCH 330.2 MM

0.102

0.053

4.744 SQFT

3.199 FT 975.0 MM

15.627 FT 4763.1 MM

1.599 FT 487.5 MM

0.150

0.094

1.222 SQFT

21.297 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

1.828 MIN

9.193 FT 2802.0 MM

0.109 FT 33.3 MM

9.193 FT 2802.0 MM

24.820 FT 7565.0 MM

24.934 FT 7600.0 MM

1.484 SEC

5.149 FT/SEC

7.640 FT 2328.7 MM

7.710 FT 2350.0 MM

6.7 TONNES

24.934 FT 7600.0 MM

2.338

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.362 INCH 9.2 MM * Table 8

0.394 INCH 10.0 MM

0.362 INCH 9.2 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

834.827 SQFT

123.926 SQFT

490.000 LB/CUFT

17405.286 LB

2.000 * Table 7. (L/D) Ratio Guidelines

10.566 FT 3220.5 MM

10.663 FT 3250.0 MM

89.250 SQFT

0.000 CUFT

6.931 FT 2112.5 MM

2.000 FT 609.6 MM *Minimum

6.931 FT 2112.5 MM

0.650

0.688

61.414 SQFT

12.331 INCH 313.2 MM

13.000 INCH 330.2 MM * Table 9

13.000 INCH 330.2 MM

0.102

0.053

4.744 SQFT

3.732 FT 1137.5 MM

12.029 FT 3666.5 MM

1.866 FT 568.8 MM

0.175

0.118

1.528 SQFT

26.308 SQFT

0.333 * Table 1

7.9 TONNES

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

2.133 MIN

7.188 FT 2190.8 MM

0.120 FT 36.7 MM

7.188 FT 2190.8 MM

19.217 FT 5857.3 MM

19.357 FT 5900.0 MM

1.378 SEC

5.594 FT/SEC

7.708 FT 2349.5 MM

7.710 FT 2350.0 MM

19.357 FT 5900.0 MM

1.815

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.362 INCH 9.2 MM * Table 8

0.394 INCH 10.0 MM

0.362 INCH 9.2 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

648.090 SQFT

123.926 SQFT

490.000 LB/CUFT

14403.270 LB

3.000 * Table 7. (L/D) Ratio Guidelines

9.230 FT 2813.3 MM

9.350 FT 2850.0 MM

68.632 SQFT

0.000 CUFT

1.870 FT 570.0 MM

2.000 FT 609.6 MM *Minimum

2.000 FT 609.6 MM

0.214

0.157

10.759 SQFT

11.675 INCH 296.6 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

6.5 TONNES

0.107

0.057

3.933 SQFT

7.350 FT 2240.4 MM

5.150 FT 1569.6 MM

3.675 FT 1120.2 MM

0.393

0.365

4.378 SQFT

53.496 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

4.201 MIN

5.896 FT 1797.1 MM

0.100 FT 30.4 MM

5.896 FT 1797.1 MM

11.046 FT 3366.7 MM

11.155 FT 3400.0 MM

0.398 SEC

31.934 FT/SEC

12.697 FT 3870.2 MM

12.795 FT 3900.0 MM

12.795 FT 3900.0 MM

1.368

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.326 INCH 8.3 MM * Table 8

0.394 INCH 10.0 MM

0.326 INCH 8.3 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

375.672 SQFT

95.299 SQFT

490.000 LB/CUFT

9103.412 LB 4.1 TONNES

3.000 * Table 7. (L/D) Ratio Guidelines

9.230 FT 2813.3 MM

9.350 FT 2850.0 MM

68.632 SQFT

0.000 CUFT

3.740 FT 1140.0 MM

2.000 FT 609.6 MM *Minimum

3.740 FT 1140.0 MM

0.400

0.373

25.633 SQFT

11.675 INCH 296.6 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.107

0.057

3.933 SQFT

5.610 FT 1710.0 MM

7.111 FT 2167.3 MM

2.805 FT 855.0 MM

0.300

0.252

3.028 SQFT

39.971 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

3.207 MIN

5.452 FT 1661.7 MM

0.119 FT 36.3 MM

5.452 FT 1661.7 MM

12.562 FT 3829.0 MM

12.795 FT 3900.0 MM

0.744 SEC

13.403 FT/SEC

9.966 FT 3037.7 MM

10.007 FT 3050.0 MM

12.795 FT 3900.0 MM

1.368

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.326 INCH 8.3 MM * Table 8

0.394 INCH 10.0 MM

0.326 INCH 8.3 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

375.672 SQFT

95.299 SQFT

490.000 LB/CUFT

9103.412 LB

3.000 * Table 7. (L/D) Ratio Guidelines

9.230 FT 2813.3 MM

9.350 FT 2850.0 MM

68.632 SQFT

0.000 CUFT

5.610 FT 1710.0 MM

2.000 FT 609.6 MM *Minimum

5.610 FT 1710.0 MM

0.600

0.627

42.999 SQFT

11.675 INCH 296.6 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.107

0.057

3.933 SQFT

3.740 FT 1140.0 MM

12.801 FT 3901.7 MM

1.870 FT 570.0 MM

0.200

0.142

1.709 SQFT

23.924 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

4.1 TONNES

2.138 MIN

39.945 FT 12175.4 MM

0.036 FT 10.8 MM

39.945 FT 12175.4 MM

52.746 FT 16077.1 MM

52.822 FT 16100.0 MM

1.115 SEC

7.990 FT/SEC

8.912 FT 2716.4 MM

9.022 FT 2750.0 MM

52.822 FT 16100.0 MM

5.649

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.326 INCH 8.3 MM * Table 8

0.394 INCH 10.0 MM

0.326 INCH 8.3 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

1550.852 SQFT

95.299 SQFT

490.000 LB/CUFT

27995.743 LB

3.000 * Table 7. (L/D) Ratio Guidelines

9.230 FT 2813.3 MM

9.350 FT 2850.0 MM

68.632 SQFT

0.000 CUFT

6.545 FT 1995.0 MM

2.000 FT 609.6 MM *Minimum

6.545 FT 1995.0 MM

0.700

0.748

51.315 SQFT

11.675 INCH 296.6 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.107

0.057

3.933 SQFT

12.7 TONNES

2.805 FT 855.0 MM

20.755 FT 6326.0 MM

1.403 FT 427.5 MM

0.150

0.094

1.128 SQFT

16.189 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

1.603 MIN

19.050 FT 5806.5 MM

0.074 FT 22.4 MM

19.050 FT 5806.5 MM

39.805 FT 12132.6 MM

39.862 FT 12150.0 MM

1.301 SEC

6.695 FT/SEC

8.712 FT 2655.5 MM

8.858 FT 2700.0 MM

39.862 FT 12150.0 MM

4.263

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.326 INCH 8.3 MM * Table 8

0.394 INCH 10.0 MM

0.326 INCH 8.3 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

1170.364 SQFT

95.299 SQFT

490.000 LB/CUFT

21878.964 LB

4.000 * Table 7. (L/D) Ratio Guidelines

8.386 FT 2556.1 MM

8.530 FT 2600.0 MM

9.9 TONNES

57.120 SQFT

0.000 CUFT

1.706 FT 520.0 MM

2.000 FT 609.6 MM *Minimum

2.000 FT 609.6 MM

0.234

0.179

10.202 SQFT

11.265 INCH 286.1 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.117

0.066

3.746 SQFT

6.530 FT 1990.4 MM

6.434 FT 1961.2 MM

3.265 FT 995.2 MM

0.383

0.352

4.225 SQFT

42.693 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

3.732 MIN

7.058 FT 2151.4 MM

0.098 FT 29.7 MM

7.058 FT 2151.4 MM

13.493 FT 4112.5 MM

13.615 FT 4150.0 MM

0.398 SEC

33.676 FT/SEC

13.390 FT 4081.3 MM

13.451 FT 4100.0 MM

13.615 FT 4150.0 MM

1.596

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.302 INCH 7.7 MM * Table 8

0.315 INCH 8.0 MM

0.302 INCH 7.7 MM * Design pressure

0.394 INCH 10.0 MM * Table 8

364.688 SQFT

79.313 SQFT

490.000 LB/CUFT

7240.293 LB

4.000 * Table 7. (L/D) Ratio Guidelines

8.386 FT 2556.1 MM

8.530 FT 2600.0 MM

57.120 SQFT

0.000 CUFT

3.412 FT 1040.0 MM

2.000 FT 609.6 MM *Minimum

3.412 FT 1040.0 MM

0.400

0.373

21.334 SQFT

11.265 INCH 286.1 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.117

0.066

3.746 SQFT

5.118 FT 1560.0 MM

8.670 FT 2642.5 MM

2.559 FT 780.0 MM

0.300

0.252

3.028 SQFT

32.758 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

2.925 MIN

6.468 FT 1971.3 MM

0.116 FT 35.4 MM

6.468 FT 1971.3 MM

3.3 TONNES

15.137 FT 4613.8 MM

15.256 FT 4650.0 MM

0.678 SEC

16.105 FT/SEC

10.925 FT 3329.8 MM

10.991 FT 3350.0 MM

15.256 FT 4650.0 MM

1.788

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.302 INCH 7.7 MM * Table 8

0.315 INCH 8.0 MM

0.302 INCH 7.7 MM * Design pressure

0.750 INCH 8.0 MM * Table 8

408.626 SQFT

79.313 SQFT

490.000 LB/CUFT

10113.204 LB

4.000 * Table 7. (L/D) Ratio Guidelines

8.386 FT 2556.1 MM

8.530 FT 2600.0 MM

57.120 SQFT

0.000 CUFT

5.118 FT 1560.0 MM

2.000 FT 609.6 MM *Minimum

5.118 FT 1560.0 MM

0.600

0.627

35.786 SQFT

11.265 INCH 286.1 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.117

0.066

3.746 SQFT

3.412 FT 1040.0 MM

15.794 FT 4813.9 MM

4.6 TONNES

1.706 FT 520.0 MM

0.200

0.142

1.709 SQFT

19.625 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

1.950 MIN

38.430 FT 11713.4 MM

0.040 FT 12.0 MM

38.430 FT 11713.4 MM

54.223 FT 16527.3 MM

54.298 FT 16550.0 MM

1.018 SEC

9.601 FT/SEC

9.769 FT 2977.5 MM

9.843 FT 3000.0 MM

54.298 FT 16550.0 MM

6.365

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.302 INCH 7.7 MM * Table 8

0.315 INCH 8.0 MM

0.302 INCH 7.7 MM * Design pressure

0.315 INCH 8.0 MM * Table 8

1454.357 SQFT

79.313 SQFT

490.000 LB/CUFT

20744.397 LB

4.000 * Table 7. (L/D) Ratio Guidelines

8.386 FT 2556.1 MM

8.530 FT 2600.0 MM

57.120 SQFT

0.000 CUFT

5.971 FT 1820.0 MM

9.4 TONNES

2.000 FT 609.6 MM *Minimum

5.971 FT 1820.0 MM

0.700

0.748

42.707 SQFT

11.265 INCH 286.1 MM

12.000 INCH 304.8 MM * Table 9

12.000 INCH 304.8 MM

0.117

0.066

3.746 SQFT

2.559 FT 780.0 MM

26.042 FT 7937.5 MM

1.280 FT 390.0 MM

0.150

0.094

1.128 SQFT

13.284 SQFT

0.333 * Table 1

29.831 INCH/MIN

10.498 INCH/MIN

10.498 INCH/MIN

1.463 MIN

20.882 FT 6364.9 MM

0.075 FT 22.8 MM

20.882 FT 6364.9 MM

46.924 FT 14302.3 MM

46.916 FT 14300.0 MM

1.187 SEC

8.045 FT/SEC

9.550 FT 2910.8 MM

9.678 FT 2950.0 MM

46.916 FT 14300.0 MM

5.500

* Table 8

17500 PSI

1/16 INCH 1.6 MM

0.850

69.700 PSI * Design pressure

0.302 INCH 7.7 MM * Table 8

0.315 INCH 8.0 MM

0.302 INCH 7.7 MM * Design pressure

0.315 INCH 8.0 MM * Table 8

1256.635 SQFT

79.313 SQFT

490.000 LB/CUFT

18201.513 LB

(L/ID) W

L for Hold

up and surge

L for vapor

liquid

separation

1.08 4.61 TONNES 1800.0 MM 3500.0 MM NOT OKE OKE NOT OKE

3.34 10.50 TONNES 10850.0 MM 2700.0 MM OKE NOT OKE NOT OKE

2.00 7.01 TONNES 5900.0 MM 2500.0 MM OKE OKE OKE

1.88 6.69 TONNES 6100.0 MM 2400.0 MM OKE OKE OKE

2.34 7.89 TONNES 7600.0 MM 2350.0 MM OKE NOT OKE NOT OKE

1.82 6.53 TONNES 5900.0 MM 2350.0 MM OKE OKE OKE

1.37 4.13 TONNES 3400.0 MM 3900.0 MM NOT OKE OKE NOT OKE

1.37 4.13 TONNES 3900.0 MM 3050.0 MM OKE OKE NOT OKE

5.65 12.70 TONNES 16100.0 MM 2750.0 MM OKE NOT OKE NOT OKE

4.26 9.92 TONNES 12150.0 MM 2700.0 MM OKE NOT OKE NOT OKE

1.60 3.28 TONNES 4150.0 MM 4100.0 MM OKE OKE NOT OKE

1.79 4.59 TONNES 4650.0 MM 3350.0 MM OKE OKE NOT OKE

6.37 9.41 TONNES 16550.0 MM 3000.0 MM OKE NOT OKE NOT OKE

5.50 8.26 TONNES 14300.0 MM 2950.0 MM OKE NOT OKE NOT OKE

5.331 FT 1625.0 MM

31.332 SQFT

0.351

0.382

4.073 FT 1241.4 MM

10.663 FT 3250 MM

21.325 FT 6500 MM

2.000

5.331 FT 1625 MM

1.083 FT 330 MM

4.073 FT 1241 MM

5.331 FT 1625 MM

5.331 FT 1625 MM

2.666 FT 813 MM

2.666 FT 813 MM

6.965 FT 2123 MM

14.361 FT 4377 MM