Académique Documents

Professionnel Documents

Culture Documents

Chapter 04 Seal

Transféré par

dewidar1234Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 04 Seal

Transféré par

dewidar1234Droits d'auteur :

Formats disponibles

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

1

Protector (Seal)

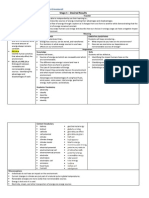

Table of Content

Section Content Page

1 Seal section functions 2

2 Seal section basic type 3

2.1 Labyrinth seal

2.2 Positive seal

3 Mechanical face seal 11

4 Axial thrust bearings 13

5 Modular protector 17

6 Seal operation cycle 20

7 Application 25

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

2

Protector (Seal)

What is Protector?

Protector is located between the intake/GS above, and the

motor below. It serves as a vital link in the entire ESP

system.

It has several functions and each of them has to be

considered carefully for overall system design.

4.1. Seal Section Functions

4.1.1. Equalize pressure

It equalizes the pressure inside and outside of the

system and at the same time provides room for motor oil

thermal expansion.

The Protector needs to balance the pressure inside the

system and the pressure outside.

How does it do this??

o By maintaining a fluid interface between the motor oil

and the well fluid of different specific gravity

(labyrinth protector), if the well fluid specific gravity

is greater than 0.85, or

o Maintain separation of the two fluids through an elastomer

bag (bag protector), if the well fluid specific gravity is

lower than 0.85.

o Protector is open to the well-bore, allowing the motor

pressure to remain the same as that in the well annulus

around it.

o The labyrinth design uses the difference in specific

gravity of the well fluid and the motor oil to keep them

apart even though they are in direct contact.

4.1.2. Absorb thrust

Another function of the Protector is to absorb the

thrust generated by the pump. It can either be upthrust or

downthrust, depending on the pumping conditions.

The seal sections position is driven by the need to support

the pump shaft thrust load, so that none of the thrust is

transferred to the motor thrust bearing. The seal section

has room for a large thrust bearing with more capacity than

is possible in the motor head (where the motor thrust

bearing is located). Also, the seal section does not have to

support the motor rotor weight, allowing more capacity for

pump thrust support.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

3

The thrust bearing works on hydrodynamic lubrication

principle. The runner carrying the thrust forces is riding

on a hydrodynamic oil film created by the relative motion

between the runner and the bearing. There are three types of

bearing (Reda).

Fig (4.1) Thrust Bearing

Standard bearing Babbitt (lead based)

HL Bronze bearing - (9000 LBS 540 series, 60 HZ)

HL bearing Polymer coated tilting pad bearing

(12000 LBS 540 series, 60 HZ)

4.1.3. Isolate motor oil

It isolates the clean dielectric motor oil from well

bore fluid. Preventing well fluid entry is critical for

bearing lubrication and electric isolation strength. For

this reason multiple redundant isolation chambers have

become standard.

4.1.4. Transmit torque

One other function which the Protector carries out is

transmission of the motor torque to the pump since it is

physically located between the two.

Although this may seem a little trivial, in the selection

process we need to be certain that the Protector shaft is

capable of delivering the full torque required without

exceeding its yield strength which could result in a broken

shaft.

4.2. Seal Section Basic Types

4.2.1. Labyrinth Type

Fig (4.2) shows a typical labyrinth type isolation chamber in

the lower chamber. The labyrinth design uses the difference in

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

4

specific gravity of the well fluid and the motor oil to keep

them apart even though they are in direct contact.

The heavier gravity well fluid is separated by gravity.

A U-tube design keeps the heavy well fluid going lower

into the unit keeping the thrust bearing and motor full of

clean oil. With this design, the motor oil and well fluid

are in contact.

The labyrinth chamber is isolated from the shaft rotation by

the shaft tube so that no mixing will occur by unit turning.

The well fluid is generally immiscible with motor oil so,

even though there is a direct contact; there is no tendency

to contaminate the motor oil.

Fig (4.2) typical labyrinth type

Fig (4.3) shows motor oil expansion and contraction in the

labyrinth type (Top of unit is in contact with well fluid via

the pump intake and bottom of unit is in direct contact with

motor head)

A schematic layout is shown in fig (4.4). It is referred to as

"labyrinth" or "U tube" style chamber.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

5

Typically, there is a mechanical seal located at the top of

this chamber and mounted on the shaft. Its function is to

prevent the well fluid from traveling directly down the shaft

and through the chamber. The mechanical seal will be discussed

in detail in a later section.

Fig (4.4)

For pressure equalization to the well annulus, a passageway is

provided in the seal head connecting the area just above the

mechanical face seal to the outside annular section of the

labyrinth chamber.

The complete fluid flow path through the chamber is shown in

fig (4.5).

As the temperature of the unit increases, the dielectric oil

expands up the inner annular section formed by the shaft and

the shaft support tube. At the top of this annulus, the

dielectric oil migrates over to the middle annular section

formed by the shaft support tube and middle tube. It then

travels down this section and up the outer annular section

formed by middle tube and the outer housing. The dielectric

oil then travels through the passageway connecting the area

above the mechanical face seal. Upon the contraction, the

dielectric oil follows the reverse path through the chamber.

During expansion mode, motor oil (dielectric oil) is being

vented through the chamber to the well bore. As the unit cools

down and the motor oil inside the unit contracts, fluid

outside the chamber (well fluid) is pulled back along the flow

path into the outer annulus of the chamber. As well fluid

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

6

usually has a higher specific gravity than the motor oil, it

will settle to the bottom of that annular section.

Therefore, as the unit goes through further thermal cycling,

the well fluid in this chamber will U-tube back and forth

between the middle and outer annular sections. If there is a

several expansion cycle, then the well fluid can be U-tubed

out of the middle annulus and additional motor oil can be

displaced by well fluid. If there is a sever contraction, well

fluid could be pulled high enough into the middle annulus to

flow over into the inner annulus and down into the cavity

below the chamber.

One weakness of this style is the fact that the two fluids

have a common interface. With time, the motor oil will see a

degradation of dielectric strength because of water saturation

or wetting from the well fluid.

Fig (4.5) flow diagram

There are conditions when it is not convenient to use this

type of protector:

Well fluid,

The heavier gravity well fluid is separated by gravity.

A "U-tube" design keeps the heavy well fluid from going

lower into the unit keeping the thrust bearing and motor

full of clean motor oil.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

7

With this design, the motor oil and well fluid are in direct

contact. The labyrinth chamber is isolated from the shaft

rotation by the shaft tube so that no mixing will occur by the

unit turning.

The well fluid is generally immiscible with the motor oil so,

even though there is direct contact; there is no tendency to

contaminate the motor oil.

When the well fluid is lighter gravity than the motor oil

(i.e. about 0.85). The motor oil will go to the bottom of the

chamber rather than the top causing the motor fluid to be

replaced by well fluid pretty quickly.

Fig (4.6) The well fluid is lighter than the dielectric oil

Horizontal or Highly Deviated Wells.

Labyrinth Protectors also will not work in horizontal or

highly deviated wells. The gravity separation design requires

the unit to be mostly upright. This Protector can operate in

some amount of deviation but the expansion volume is somewhat

reduced.

Deviation from vertical at the setting depth has a significant

effect on the expansion / contraction capacity of all

labyrinth type chambers. In the extreme situation case the up-

down-up labyrinth path becomes left-right-left. Needless to

say, the usefulness of density separation in this extreme

situation is eliminated.

Fig (4.7) shows labyrinth chamber in 90

O

deviation and its

remaining capacity. The capacity of the chamber is reduced in

direct proportion to the deviation angle.

It is important to make sure that the labyrinth type chambers

have enough expansion capacity for the application at the

installed deviation angle. If the a chamber does not have

enough capacity, well fluid can pass the chamber in one

thermal cycle. The amount of oil expansion / contraction at

each isolation chamber depends upon three variables:

1. The amount of oil below each chamber.

2. The oils coefficient of thermal expansion.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

8

3. The operating thermal cycles of all oil volumes below the

chamber.

Fig (4.7) Labyrinth Type in Horizontal Position

4.2.2. Positive Type

Often referred to as a "bag" or "bladder" style

chamber, this design incorporates a positive barrier between

the well fluid and motor oil. The middle tube of the labyrinth

style chamber is replaced with flexible membrane which seals

around the chamber shaft support tube.

An illustration of this chamber is shown in fig (4.8)

Fig (4.8) positive seal

The positive seal is applied where the well fluid and motor

oil gravities are similar or where a well is highly deviated.

The positive barrier style chamber has a mechanical face seal

located on the shaft above the chamber. Its function it to

protect the shaft radial support bushing and to prevent well

fluid from migrating directly down the shaft and through the

chamber. It is important to protect the shaft pushing to

preserve the proper functioning of the mechanical face seal.

Pressure equalization to the well annulus is provided for by a

flow passageway communicating from the interior section of the

membrane, to the outer section, then through the head to the

well bore.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

9

A flow diagram is shown in fig (4.9).

On expansion, the dielectric oil travels from the area below

this chamber, up through a communicating passageway to the

inner annular section. At the top of this section, it flows

into the interior section of the membrane through a set of

communication holes located near the top the shaft support

tube.

After the membrane interior section is equalized or filled,

the fluid will continue up the inner annular section to the

communication passageway at the top of the chamber. There it

will pass through two, low pressure check valves set in

series, to the outer section of the chamber.

The use of multiple check valves will enhance their functional

reliability in case of one of them fails to seal. The fluid

will then flow through another communication passageway to

area above the mechanical seal.

On contraction, the check valves remain seated and the

flexible membrane will compensate for the volume reduction by

collapsing inward. The pressure in the outer section is

equalized by the flow of the well fluid back into this section

of the chamber from the area above the face seal.

The higher specific gravity well fluid will settle to the

bottom of this section away from direct contact with the check

valves.

Upon further thermal cycling, the flexible membrane will

expand as the fluid heats up and contract as fluid cools down.

Unless the maximum temperature of the initial thermal cycle is

exceeded, there should be no further expansion of motor oil

out of the membrane interior section.

Figure (4.9) flow diagram

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

10

Fig (4.10) Typical Bag Type

The bag is made of a high temperature / high performance

elastomer which can withstand the harsh downhole environments

typically encountered. The bag keeps the well fluid and the

clean motor oil completely separate from each other on either

side of the elastomer that the bag is made of.

When the motor oil expands or contracts, the bag simply

expands or contracts to accommodate the necessary volume

change.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

11

Fig (4.7)

Bag Type in inflated and deflated position

Positive Seal Protectors Limitations

The positive seal Protector offers a great deal of

flexibility and is useful in a wide variety of applications.

One area where care needs to be taken with this type of

Protector is with harsh well chemicals as may be experienced

with a treatment program. As with any oil field elastomer,

care must be taken to ensure that the rubber will not be

damaged by anything it will encounter in the well (See table

4.1)

Table (4.1)

* Temperature Limit above indicates maximum operating temperature for the

pecific REDA compound. An elastomeric component will operate at a

temperature higher than the well ambient temperature depending on its

location in the equipment. Contact REDA for specific application assistance.

1 = Excellent long term resistance (very low swell/maintains very high

physical properties)

2 = Good long term resistance (moderate swell/maintains high physical

properties)

3 = Fair - depends upon exposure time and temperature (good short term

resistance)

4 = Poor - no resistance even in short term

Table (4.1) Ealstomer Selection

4.3. Mechanical Face Seals

Each independent isolation chamber has its own mechanical

face seal, usually located at top of each chamber. The

mechanical seal is a dynamic seal that prevents well fluid

migration down the shaft. It has rotating assembly that fixed

to the shaft and a stationary component called a seat or

primary ring. Fig (4.11) shows a mechanical seal and all four

of its critical seal location.

Each mechanical face seal includes three static seals. The

first is the o-ring between the stationary seat and the bore

in which it is inserted. The third static seat is between the

rubber bellows and the shaft.

Each of static seals uses rubber materials which are

compressed against hard surfaces with an appropriate finish.

The rubber materials must be selected for compatibility with

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

12

the well fluid and any chemical treatments. A leak at any of

the three static seals location will cause well fluid to fill

the chamber which the mechanical face seal protects.

Fig (4.11) Mechanical Face Seal

The dynamic seal location is between the rotating face and

stationary seat. The rotating face and stationary seat must be

extremely flat on the surface in contact with the other. Any

surface defects can cause dynamic seal to leak. It is also

important that the rotating face must be moving in a very

circular path. The dynamic seal is a wet seal with motor oil

extending partially across the face from one side, and well

fluid extending in from the other. Significant eccentricity in

the rotation well cause the motor oil and well fluid to

intermingle and result in a pumping affect across the seal

face, usually outward. Sand and scale can damage the dynamic

seal faces and cause leaks. In wells with significant amount

of scale and/or sand, ceramics or tungsten carbide are good

selections for the faces in the uppermost mechanical face

seals.

Proper filling of the motor and seal section is critical

to the mechanical health of the bearings in both components.

However, even under ideal conditions, a small amount of air

may remain in the system after filling. Any air remaining in

the motor or seal section will tend to rise up and form pocket

under mechanical seals. The motor, having more oil volume and

laminated construction, is the most likely source of residual

air. An air pocket will reduce the dynamic seal face

lubrication and provide insulation. Reduce lubrication causes

more heat generation and insulation raises the seal face

temperature, further reducing lubricity. A graphite seal face

will tolerate loss of lubrication much better than other

materials, due to its self lubricating nature.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

13

Therefore, a graphite rotating mechanical seal face is

frequently used in lower position(s), where air is most likely

to form pockets.

The metal components of the mechanical face seal are

commonly available in either stainless steel or monel. The

spring is most often attacked first due to it being in pre-

stressed condition. Monel should be specified for the

uppermost mechanical seal spring(s), when H

2

S acid or other

chemistry is present that could lead to corrosion or hydrogen

stress cracking in stainless steel. When the spring is

upgraded to monel, the rest of the mechanical seals metal

component are also often upgraded.

4.4. Axial thrust Bearings

ESP system predominately use tilting pad type plane

thrust bearing. This type of bearing generates much less heat,

tolerates more contamination and support more thrust under

3600 rpm operating condition, compared to rolling element

bearings. A variety of thrust bearing designs are available in

the industry and the ESP manufacturer guidelines for thrust

capacity should be adhered to when selecting the thrust

bearing design.

Several factors affect the thrust capacity of the bearing and

thrust exerted on it by the pump.

The first factor is the pump stage type. Different pump sages

produce different thrust characteristics, even through the

stages may appear quite similar.

The second factor is how each stage transmits its thrust onto

its support. Floater type stages transmit their thrust

directly onto the mating diffuser below. Floater pumps produce

shaft downthrust equal to the differential pressure generated,

multiplied by the area of the shafts cross section. Stages

fixed to the shaft transmit their thrust entirely onto the

shaft. Fixed stage pumps typically generate more shaft thrust

than floater pumps and the thrust level is characteristic of

the stage hydraulics.

Third factor is speed. The seal thrust bearing capacity varies

approximately in direct proportion to the speed for a limit

range above and below 3600 rpm. Meanwhile, the pump thrust

tends to change in relation to the square of the rotating

speed. The net result is that you can carry few stages at

higher speed and more stages at lower speed.

The forth factor is the viscosity index of the oil type being

used in the seal. More viscous oils will carry higher loads

under the same condition. However, more viscosity also causes

the radial bearings with fixed clearances to generate more

heat and this can cause problems, practically in the motor

rotor bearings. A good rule of thumb is to use the same oil in

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

14

the seal as that recommended by ESP manufacturer for proper

performance of the motor radial bearings, under the expected

operation conditions. This will result in an appropriate

viscosity index selection.

The fifth factor is the temperature of the seal section thrust

bearing lubricating oil. As temperature increases, viscosity

decreases, thereby reducing the thrust capacity.

In one set of circumstances, the pump down thrust can actually

increase of the life of the system. Mixed flow pump stages are

often hydraulically balanced by a seal ring on the top of each

impeller. If this seal balance ring becomes worn by erosion

and/or corrosion, the resulting flow over the top of the stage

can cause the pressure on the top of the stage to rise. The

pressure increase can cause doubling of the pump stage

downthrust, and sometimes more. This is only a factor for the

seal section if the impellers are fixed to the shaft so that

they transmit their thrust onto the seal section. So, if you

have hydraulic balance (mixed flow) stages, fixed to the pump

shaft and operating in an erosion or corrosion condition, then

the thrust exerted on the seal section can increase

significantly over the life of the system.

Proper thrust bearing design and selection is critical to seal

assembly. Applications requiring high pump TDH (Total Dynamic

Head) outputs coupled with the inherent diametric restrictions

of ESP equipment have demanded rigorous service from these

bearings.

The basic operating principles of hydrodynamic thrust bearing

designs utilized in ESP's are very similar.

The stationary bearing surface is divided into a number of

separated pads, with each pad allowed to pivot under operating

conditions.

The bearing is submerged in lubricating oil, which adheres to

the moving and stationary surfaces and is thus carried into

spaces between the thrust runner and the bearing pads.

Tapered lands are machined on the pad edges to aid this

process.

Fluid pressure builds along the entrance side of the pads,

causing the pads to tilt. This tilting action allows the

formation of a wedge-shaped oil film, generating sufficient

pressure to completely separate the runner and thrust pads.

This separation minimizes friction and wear to the bearing

surfaces insuring long bearing life.

Fig (4.12) depicts the hydrodynamic thrust bearing operation

mode.

A common bearing design employed in ESP's is the pedestal or

solid shoe type, illustrated in fig (4.13). the individual

bearing pads are mounted on pedestals located at the center of

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

15

each pad. The pedestals are designed to deflect slightly in

operation, allowing the pads to tilt and form the necessary

oil; film.

For applications requiring higher loading capacity, a self-

equalizing tilting pad thrust bearing is available, shown in

fig (4.14). These bearings use a series of leveling link to

control individual pad heights so that the load is shared

equally by all pads.

The individual pads are supported by balls or spherical faced

links, allowing them to pivot freely. This freedom of motion

coupled with a self aligning feature, typically permits

allowable bearing loads of 400-500 psi, twice the capability

of solid shoe bearing.

Fig (4.12) hydrodynamic thrust bearing operation

Fig (4.13) Solid shoe thrust bearin

A more recent development in thrust bearing design is swing-

pad bearing, shown in fig (4.15). the individual pads are

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

16

round in shape, consist of spherical segments of bonded

alternate metal elastomer layers. Instead of tilting on a

centerline, the pads swing in the direction of the curvature

thus allowing the film wedge to form.

Fig (4.14) modified Kingsbury thrust bearing

Fig (4.15) swing pad thrust bearing

This bearing has been successfully applied in ESP's at face

loading pressures to 800 psi and has been laboratory tested

under ESP loading conditions to 1000 psi without failure.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

17

4.5. The Modular Protector

The modular protector system consists of a single

infrastructure upon which all protector types are built. Since

all chamber types (such as labyrinth or bag) have been

designed with common interfaces, they can be placed in almost

any order and, theoretically, in any quantity. There are

practical limits to the number of chambers, however, imposed

by maximum available shaft length, power consumption, and

cost. The system is shown schematically in fig (4.16).

Initially, protectors with two or three chambers are planned,

though this will be subjected to change once the protectors

are in production. The new system can be used to make a

version without any chambers as well. This would essentially

be a bearing section which could be added between the main

protector and motor to provide a back up thrust bearing.

If a back up bearing is desired, a bearing only section could

be added between the motor and protector which would provide

additional protection in the case of wear debris cause

failure.

4.4.1. Reda Designation of Protector Types (See fig(4.17)

Due to the enormous number of types of protectors which

can be made using this system, a standardized system of

designating the configuration has been arrived at. The first

part of the designation will consists of letters designating

the chambers and their interconnection, beginning with the top

chamber and using the following configurations:

L = Labyrinth B = bag S = Series

P = Parallel

For example, the designation [LSBPB] indicates that there is a

labyrinth chamber on the top in series with a bag chamber

which in parallel with another bag chamber. The designation

[LSL] describes a chamber model similar to 66L protector.

MP = Modular Protector

HL = High Load (bearing)

HS = High Tensile Strength (Shaft)

FS = Ferritic Steel (Material of base, head and housing)

It is important to note that there are several restrictions in

the specification of chambers:

o Parallel labyrinth chambers are not currently supported.

Labyrinth chambers in parallel with bag are not available.

o It is not generally accepted to put a single bag chamber in

series with parallel bag chamber.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

18

Fig (4.16) Modular Protector System

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

19

Fig (4.17) Reda Designation

4.4.2. Centrilift Designation of Seal Types (See table(4.2)

and fig (4.18))

Table (4.2) Centrilift designation

Fig (4.18)

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

20

4.6. Seal Operation Cycle.

o All modular Protectors come "pre-filled.

o During field assembly, the FST (Field Service

Technician) will "top up" the protector to replace any

oil lost during the assembly process.

o Vent plugs are replaced at intervals.

Fig (4.19) servicing the protector prior to installation.

This is an view of an LSB protector. The red arrows indicate

the oil flow path during filling. The vent plugs are replaced

at intervals to ensure all air is removed from the unit.

Since the protector is serviced at surface, the motor oil

temperature will be the current Outside Ambient Temperature

(OAT), fig (4.20)

Fig (4.20) Protector holds 100% oil

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

21

System landing at setting depth, oil expands, fig (4.21).

Given that the system can only hold 100% volume, the system

will dump the 9% overboard. This oil will never be

recovered.

Fig (4.21) system landing at setting depth, oil expands.

Motor Operates, oil expands more, fig (4.22).

When the system is started for the first time, the internal

heating of the motor will increase its temperature until the

motor reaches its operating temperature (MOT). This will

cause an additional expansion of oil, typically another 2-

4%.

Fig (4.22) motor Operates, oil expands more.

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

22

Motor Operates, oil expands more, fig (4.23).

But again, the system can only hold 100% volume. The 2-4%

oil expanded will again be lost to the well bore.

Fig (4.23) motor Operates, oil expands more.

Motor stops, oil contracts, fig (4.24).

Now the system is only 96 - 98% full of motor oil so the

protector will then have a small amount of well fluid in the

first chamber making up the balance of the volume.

Fig (4.24) motor Stops,, oil contracts

Bag contracts

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

23

Motor operating cycles-on, oil expands, fig (4.25).

As the unit cycles, the system can loose additional motor

oil due to several reasons: Motor Temp, Specific Gravity,

Gas in Motor Oil, Emulsions, etc.

Fig (4.25) motor Operates, oil expands.

Motor operating cycles-off, oil contracts fig (4.26).

Fig (4.26) motor Operating ,cycle off, oil contacts.

Pulling the unit to surface, oil contracts, fig (4.27).

Bag expands

Bag contracts

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

24

When the unit is pulled, the motor oil will cool once again

to surface temperature (OAT). Most bag damage is caused

during system removal from the well and not during down hole

operation.

Fig (4.27) pulling the unit to surface, oil contracts

Fig (4.28) seal operation cycles

Bag contracts

more

Electric Submersible Pumps Mohamed Dewidar 2013

Chapter 4

25

4.7. Application

One of the primary reason for the existence of the

Modular Protector system is its ability to supply a protector

configured for specific set of well conditions. The

information given below is to aid in specifying a system

appropriate to the application:

High GOR or Low Specific Gravity Fluid

In wells with low specific gravity fluids a labyrinth

chamber serves very little function. Since the well fluid

floats on top of the motor oil, it accumulates at top of the

chamber where it is easily drawn in when the oil cools and

contracts at shutdown.

If there is a high gas concentration, especially free gas

with saturated oil, the gas can come out of solution in the

protector chamber as the pump pulls the fluid level down and

reduces the down hole pressure. As the gas comes out of

solution, it rises to the top of the chamber and could

actually push the fluid out of the protector chamber.

This may not a big problem until fluid os pushed from the

next labyrinth chamber below and falls below the gas cap

when the unit restarts. Depending upon the type of cycling

the unit is subjected to, gas can then be pulled off the top

of the upper chamber into the next chamber down, thus

displacing oil, and could eventually pump a large amount of

oil out of the protector.

The recommendation in these cases would be to have a

positive (bag) seal chamber on the top of the protector to

provide a solid barrier to gas or low SG fluid entry.

Low Angle Operation

A labyrinth decreases in effectiveness as the equipment is

operated closer to horizontal. In general, it is best to use

bag chambers if low angle operation is anticipated.

High Water Cut

This typically the best use of a labyrinth chamber, where

gravity separation is most effective. Of course a bag

chamber is also effective in these cases. All things being

equal, a labyrinth on top and bag below can be one of the

most effective combinations for this basic application.

Fluid which Degrades Bag Material

In these cases, it is necessary to run either an all

labyrinth chamber protector or labyrinth protector over the

bag chambers. In general, the fluids which are causing the

bags problems are probably also effecting the seal bellows

and o-rings as well, so one should know as much as they can

about these fluids before designing a protector for

them.(See table 4.1 for elastomer selection).

Vous aimerez peut-être aussi

- Rochester CarbDocument79 pagesRochester CarbLawrence Smith100% (4)

- Chapter - 02 Centrifugal PumpDocument83 pagesChapter - 02 Centrifugal Pumpdewidar1234100% (4)

- Chapter - 02 Centrifugal PumpDocument83 pagesChapter - 02 Centrifugal Pumpdewidar1234100% (4)

- Application Engineering: Reda Esp System ComponentsDocument4 pagesApplication Engineering: Reda Esp System Componentselsayed amerPas encore d'évaluation

- ESP Failure Analysis of Forties Experience ApacheDocument14 pagesESP Failure Analysis of Forties Experience ApacheMohamed AshrafPas encore d'évaluation

- Chapter - 09 ESP Design ExamplesDocument16 pagesChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Chapter - 06 Power CableDocument50 pagesChapter - 06 Power Cabledewidar1234100% (5)

- 01 - 1 Pump - Floater Vs CompressionDocument34 pages01 - 1 Pump - Floater Vs CompressionAndre Damara100% (2)

- ESP Reliability Theory and Failure AnalysisDocument1 pageESP Reliability Theory and Failure Analysisazareiforoush100% (1)

- Pump CurvesDocument135 pagesPump CurvesVlassis Sarantinos100% (1)

- Chapter 01 IntroductionDocument12 pagesChapter 01 Introductiondewidar1234100% (1)

- NOVOMET. Instruction of Tap and Power Rating CalculationDocument3 pagesNOVOMET. Instruction of Tap and Power Rating CalculationmolanoavilaPas encore d'évaluation

- ESP Design 2018Document57 pagesESP Design 2018Mustafa0108910% (1)

- IBA Test Prep MaterialDocument3 pagesIBA Test Prep MaterialAmmar Hassan67% (9)

- Electric Submersible Pump BasicsDocument146 pagesElectric Submersible Pump BasicsAbhoe Stank100% (6)

- Chapter - 10 Recommended Practice For ESP Failure AnalysisDocument64 pagesChapter - 10 Recommended Practice For ESP Failure Analysisdewidar123492% (12)

- Chapter 07 TransformerDocument48 pagesChapter 07 Transformerdewidar1234100% (3)

- Chapter 07 TransformerDocument48 pagesChapter 07 Transformerdewidar1234100% (3)

- Chapter - 08 Switchboard and VSDDocument44 pagesChapter - 08 Switchboard and VSDdewidar1234100% (2)

- Second Grading Grade 9Document2 pagesSecond Grading Grade 9VINES100% (1)

- Artificial Lift System LDocument106 pagesArtificial Lift System LG Inba MalarPas encore d'évaluation

- ESP SystemsDocument22 pagesESP SystemsNabila GhaisaniPas encore d'évaluation

- Jet PumpDocument21 pagesJet Pumpdewidar1234100% (2)

- Term Paper On Fluid Coupling and Torques Converter Converted 1Document24 pagesTerm Paper On Fluid Coupling and Torques Converter Converted 1OLUBABA100% (3)

- Use of ESP Equipment in Special ConditionsDocument68 pagesUse of ESP Equipment in Special Conditionsalexis_viteriPas encore d'évaluation

- ESP 9-Step DesignDocument31 pagesESP 9-Step Designeng.osama100% (2)

- Self Lubricated BearingsDocument16 pagesSelf Lubricated Bearingsfedericoceriati100% (1)

- Chapter - 03 ESP MotorDocument80 pagesChapter - 03 ESP Motordewidar1234100% (2)

- Capillary Injection System Restores Production in Offshore Gas WellsDocument6 pagesCapillary Injection System Restores Production in Offshore Gas WellsLuisAlbertoVazquezPas encore d'évaluation

- SD4-6 - Final ESP Design PDFDocument11 pagesSD4-6 - Final ESP Design PDFkonan84167% (3)

- References No 4Document355 pagesReferences No 4Tu Dang TrongPas encore d'évaluation

- Regulation 391ADocument6 pagesRegulation 391Adnageshm4n244100% (1)

- Design Overview: Basic Design and Maintenance InstructionsDocument8 pagesDesign Overview: Basic Design and Maintenance InstructionsOctopusPas encore d'évaluation

- Artificial Lift: Abdullah Bin ZiadDocument39 pagesArtificial Lift: Abdullah Bin ZiadGilbertPas encore d'évaluation

- ESP WeatherfordDocument4 pagesESP WeatherfordLedavid Leonel Flores RiveraPas encore d'évaluation

- Design of PCP WellsDocument28 pagesDesign of PCP Wellsdubang6975% (4)

- Analysis of Warping and Shear Stress For Ship StructuresDocument134 pagesAnalysis of Warping and Shear Stress For Ship StructuresSergio LanzellottoPas encore d'évaluation

- Artificial Lift Training - CopieDocument141 pagesArtificial Lift Training - CopiesereptPas encore d'évaluation

- 4 Run Life OpsDocument29 pages4 Run Life Opshatem_eldawyPas encore d'évaluation

- Dual EspDocument8 pagesDual EspdoubleulandPas encore d'évaluation

- Urea BrochureDocument0 pageUrea BrochureiosiiosiPas encore d'évaluation

- 7 European Electric Submersible Pump Round Table Aberdeen, ScotlandDocument8 pages7 European Electric Submersible Pump Round Table Aberdeen, Scotlandshy_boyPas encore d'évaluation

- Hydraulic CouplingDocument44 pagesHydraulic Couplingsen_subhasis_58100% (1)

- Summary of Problems and Their Solutions: Ref #Esp Yr Location Problem Solution 8 7 82Document27 pagesSummary of Problems and Their Solutions: Ref #Esp Yr Location Problem Solution 8 7 82amramazon88Pas encore d'évaluation

- Spe 80945 MSDocument10 pagesSpe 80945 MSLuciano FucelloPas encore d'évaluation

- ESP Surface Component EnglishDocument33 pagesESP Surface Component EnglishJoab BrazPas encore d'évaluation

- Esp SLBDocument19 pagesEsp SLBmohit narayanPas encore d'évaluation

- Progressive Cavity Pumps: Training GuideDocument18 pagesProgressive Cavity Pumps: Training GuideRyodi HanandaPas encore d'évaluation

- NFC 33-209Document2 pagesNFC 33-209shivam dwivedi0% (1)

- Electric Submersible Pumps For The Petroleum IndustryDocument20 pagesElectric Submersible Pumps For The Petroleum Industrysouthli100% (1)

- PCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsDocument66 pagesPCP AE1 - DAY 1.1 Introduction To PCP System and ComponentsCristhian LópezPas encore d'évaluation

- 05 IntakesDocument42 pages05 Intakesام فاطمة البطاطPas encore d'évaluation

- The Ultimate PCP Rod SolutionDocument5 pagesThe Ultimate PCP Rod SolutionSteve MarfissiPas encore d'évaluation

- Best Method To Balance Torque Loadings On A Pumping Unit GearboxDocument11 pagesBest Method To Balance Torque Loadings On A Pumping Unit GearboxNiurkarisPas encore d'évaluation

- ESP PumpsDocument42 pagesESP Pumpsmostafa_ibrahim007Pas encore d'évaluation

- 17 MaximusDocument24 pages17 Maximusام فاطمة البطاطPas encore d'évaluation

- ESP Screening ToolDocument46 pagesESP Screening ToolDaniel ChiriacPas encore d'évaluation

- ESP DesignDocument5 pagesESP DesignNavneet SinghPas encore d'évaluation

- Rod Pumping Deviated WellsDocument26 pagesRod Pumping Deviated WellsIslemPas encore d'évaluation

- 9 Surface Equipment PDFDocument47 pages9 Surface Equipment PDFAli AliPas encore d'évaluation

- Electric Submersible PumpDocument14 pagesElectric Submersible PumpIzzah Ishak100% (1)

- GE - ESP BrochureDocument16 pagesGE - ESP Brochureandreé VillalobosPas encore d'évaluation

- 1 PROSPER IntroductionDocument7 pages1 PROSPER IntroductionGustavo ChacónPas encore d'évaluation

- Pump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test MeasurementsDocument13 pagesPump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test Measurementsenriqueg_53Pas encore d'évaluation

- EspDocument5 pagesEspsaeedPas encore d'évaluation

- OF11-0007R00 LWM PCP Data Sheet PDFDocument2 pagesOF11-0007R00 LWM PCP Data Sheet PDFShadySadanyPas encore d'évaluation

- WOT DST PresentationDocument29 pagesWOT DST PresentationAndreina AlarcónPas encore d'évaluation

- Fill Only The Yellow Cells !: Pump Rate Pump RateDocument3 pagesFill Only The Yellow Cells !: Pump Rate Pump RateCristian BarbuceanuPas encore d'évaluation

- Bottomhole Pressure 0504083Document6 pagesBottomhole Pressure 0504083Daniel DadziePas encore d'évaluation

- 1 Stack Component Codes: Halda Etroleum OmpanyDocument7 pages1 Stack Component Codes: Halda Etroleum Ompanyislam atifPas encore d'évaluation

- Submersible Pump: Pump (ESP) ) Is A Device Which Has A Hermetically Sealed MotorDocument5 pagesSubmersible Pump: Pump (ESP) ) Is A Device Which Has A Hermetically Sealed MotoralphadingPas encore d'évaluation

- 05 - 3 ProtectorsDocument35 pages05 - 3 ProtectorsAndre Damara100% (1)

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaPas encore d'évaluation

- Streamline Numerical Well Test Interpretation: Theory and MethodD'EverandStreamline Numerical Well Test Interpretation: Theory and MethodPas encore d'évaluation

- JP - Chapter 04Document3 pagesJP - Chapter 04dewidar1234100% (4)

- File 00000003Document303 pagesFile 00000003monica laraPas encore d'évaluation

- Aestiva MRIDocument18 pagesAestiva MRImalamandeaceroPas encore d'évaluation

- Physcis Unit Test 3Document5 pagesPhyscis Unit Test 3Yuta NeyaPas encore d'évaluation

- Overhead Line Design NotesDocument35 pagesOverhead Line Design NotesiaessackjeePas encore d'évaluation

- Drawing Numbering System: Client: ProjectDocument23 pagesDrawing Numbering System: Client: ProjectPrasanna kumar subudhiPas encore d'évaluation

- A Lens Is Defined As A Portion of A Refracting Medium Bordered by Two Curved Surfaces Which Have A Common AxisDocument12 pagesA Lens Is Defined As A Portion of A Refracting Medium Bordered by Two Curved Surfaces Which Have A Common AxisSaif HassanPas encore d'évaluation

- Method Statement For Bridge Load Test: 1. PurposeDocument10 pagesMethod Statement For Bridge Load Test: 1. PurposeAnonymous HN7WMQBmcPas encore d'évaluation

- Micrologic Trip CurvesDocument3 pagesMicrologic Trip Curves322399mk7086Pas encore d'évaluation

- LogiComm Pattern ControlDocument2 pagesLogiComm Pattern ControlNordson Adhesive Dispensing SystemsPas encore d'évaluation

- Chapter 1Document125 pagesChapter 1王富安Pas encore d'évaluation

- Sum Frequency Generation (SFG)Document52 pagesSum Frequency Generation (SFG)Vincent J. CataldiPas encore d'évaluation

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocument8 pagesTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungPas encore d'évaluation

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFRokhmatuSivaPas encore d'évaluation

- EE5103/ME5403 Lecture Two Computer Control and Discrete-Time SystemsDocument49 pagesEE5103/ME5403 Lecture Two Computer Control and Discrete-Time SystemsFeiPas encore d'évaluation

- TLE10 Electronics Q1 Wk7 Mathematical - Analysis of Parallel CircuitDocument12 pagesTLE10 Electronics Q1 Wk7 Mathematical - Analysis of Parallel Circuitismael delosreyesPas encore d'évaluation

- Apex CCTV - Catalog Q2-2013Document78 pagesApex CCTV - Catalog Q2-2013avtechpanamaPas encore d'évaluation

- A Kinetic Model of The Peirce-Smith Converter: Part I. Model Formulation and ValidationDocument11 pagesA Kinetic Model of The Peirce-Smith Converter: Part I. Model Formulation and ValidationJaime MoralesPas encore d'évaluation

- FRAP 30mmDocument97 pagesFRAP 30mmSkeevekillerPas encore d'évaluation

- ENSC3024 Ideal Gas Lab 1Document12 pagesENSC3024 Ideal Gas Lab 1Max ShervingtonPas encore d'évaluation

- Electronic Structure of The N-V Center in Diamond: ExperimentsDocument14 pagesElectronic Structure of The N-V Center in Diamond: Experimentspranav1999Pas encore d'évaluation

- Robotics Question Bank IIDocument2 pagesRobotics Question Bank IIsai sudeepPas encore d'évaluation

- Assignment FluidDocument11 pagesAssignment Fluidadam ishakPas encore d'évaluation

- UBD Physics Unit 2 - Energy and The EnviornmentDocument5 pagesUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaPas encore d'évaluation