Académique Documents

Professionnel Documents

Culture Documents

SEN 003 Installation

Transféré par

Falko SatDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SEN 003 Installation

Transféré par

Falko SatDroits d'auteur :

Formats disponibles

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

SEN-003

REVERSE

PARKING

SENSOR

INSTALLATION

INSTRUCTIONS

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

SEN-003 REVERSE PARKING AID

INSTALLATIONINSTRUCTIONS

Congratulations on choosing the SEN-003 Reverse

ParkingAid for your vehicle. With correct installation

the sensor will provide years of trouble-free reverse

parking.

The sensor works by bouncing calibrated sound waves

off obstacles behind the vehicle. Adigital display and

beeper informs the driver howclose the rear bumper is

toimpact.

To avoid distracting the driver while driving forwards,

the SEN-003 is active only when reverse gear is

engaged.

The digital display shows the approximate distance

between the rear bumper and the obstacle (in metres).

From a maximum distance of 2.0 metres down to 0.3

metres.

The display also shows two direction indicators which

will tell the driver whether the obstacle is located to the

left, right or middle of the rear bumper. More bars in

eachindicator light up as the obstacle becomes closer.

The peizo buzzer inside the digital display provides

the audible feedback fromthe sensors. As the distance

reduces, the beeps from the buzzer become more

intense.

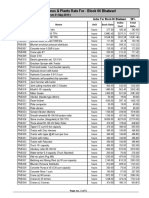

2.0- 1.0 1 1

0.9- 0.6 2 2

0.5- 0.4 3 3

0.3- 0.0 Constant 3

The SEN-003 control module generates the electronic

signals used by the sensor heads. The module has a

socket for each of the four sensors, one socket for

power and a socket for the digital display to plug in.

The control module can be mounted in the boot (near

reverse light power circuit).

The SEN-003 will provide much better coverage with

four heads rather then only two heads are used. All

heads must be pluggedinandoperational.

DIGITALDISPLAY

CONTROLMODULE

Distance Beeps Bars

Digital display mounting

Front mountingdigital display

The exact location for mounting the digital display

will vary across all vehicles. Follow these rules for

best result: -

Must be visible todriver.

Must not be in direct sunlight - excessive heat will

warpthe plastic anddestroythe electronics.

Must be kept totally moisture free and mostly dust

free.

The display comes with double sided tape; remove the

backing and stick firmly to mounting location. Ensure

the surface is free of oil, dust and moisture before

applying.

The digital display data cable is long enough to

traverse most passenger vehicles. The suggested

display location is in the middle of the rear parcel

shelf. The numbers displayed will appear reversed

when looking through the rear view mirror. It is

recommended for optimum safety considerations that

the driver is looking to the rear as reversing and thus

views the displaylocatedonthe rear parcel shelf.

The display data cable plugs into the control module

via the DS socket.

Mounting the display at the front of the cabin may be

necessary in vehicles without rear parcel shelves

(station wagons, pickup trucks, 4WDs and alike). It is

still recommended that the driver faces backwards

while reversing.

The control module should be mounted inside the boot

in a location where it will not suffer water or dust

ingressions. Ensure any luggage placed in the boot

cannot knockagainst the control module.

l

l

l

Control module mounting

DISPLAY LOOM

DIGITAL DISPLAY

CONTROL MODULE

R

R1

L1

L

Sensor & module location and effective fields.

Distance in metres.

Direction indicators.

Digital display layout.

Complete kit.

It is that these instructions are read

thoroughly prior to installation.

Check limitations, considerations & disclaimer.

essential

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

ULTRASONICSENSORS

The SEN-003 is supplied with four sensors which

produce the ultrasonic sound waves that measure the

distance toobstacles.

All sensors are supplied as ready for flush mounting. If

the vehicle only suits a bracket mount installation, the

sensors may be fitted to the brackets supplied. Ensure

the key on the sensors line up with keyway in the

bracket.

The coverage by the ultrasonic fields is determined by

the spacing of the sensors. Mount the array of sensors

centrally, with no less than 300mm and no more than

600mmbetweeneachsensor.

Caution should be paid to the position of the outer

sensors. If the sensors are too far fromthe corner point

of the bumper, an obstacle that may only just hit the car

maynot be detected.

The optimum height of each sensor is around 550mm

from the ground. This specification is flexible, but

performance will suffer if the distance is exceeded too

much. See Sensor Head Positioning and

Considerations section and the diagrams on the last

page for outline onpossible installationproblems.

The outer sensors plug into the control module via the

R and L sockets. The inner sensors plug in via the

R1 andL1 sockets.

If using the system with only 2 heads, please use L &

R, or L1& R1and space the sensors at 1/3 distance in

fromthe edge of the bumper.

When flush mounting the sensors it is critical to ensure

there is enough clearance behind the bumper. Each

sensor will require a 21.5mm hole with 50mm of free

space. When drilling holes, select a drill bit

smaller than the sensor head. Then carefully expand

the hole witha file toaccommodate the head.

The SEN-003 kit provides 4 tapered flush wedges to

adjust the angle of the heads when fitted flush in the

bumper. The wedges may be used to correct the angle

of the sensor heads onthe Xor Yaxis (or part of both).

When mounting the sensors with the brackets

supplied, a suitable location is required to allowfitting

flush and below the bumper. If the bumper profile

angle is radically off line, the kit comes with mounting

wedges. The wedges come in the different offset

angles - 7degrees , 11degrees &15degrees.

Each wedge will correct the angle of the bracket as

needed. Multiple wedges may be used on each head,

onlyif another mountinglocationcannot be found.

IMPORTANT - Ensure heads are not impeded by rear

Sensor separationdistances

Sensor headplug-inorder

Flushmount drilling

Twoheads only

Bracket mount drilling

always

Bracket

Bumper

Screw

Wedge

Range of wedges and fitting orientation.

DS POWER L L1 R1 R

Reverse light.

RED BLACK

CHASSIS

Positive

reverse

light

circuit.

Electrical connections.

50%

400mm 400mm 400mm

550mm

Ideal sensor spacing.

BRACKET

HEAD

LEAD

INSERTION

DIRECTION

Assembled head and bracket.

FLUSH WEDGE

ULTRASONIC

HEAD

BUMPER

BUMPER

ULTRASONIC

HEAD

TAPERED FLUSH WEDGES

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

mountedspare tyre (4WDs) nor towbar position.

Once the sensors are mounted, the cables will need to

enter the boot through a common opening. If an

opening is not available, a hole must be drilled in a

hidden location. Any bare metal must be sealed with a

rust inhibiting compound. Agrommet must be used to

avoid chafing through the cable insulation. Then use

water resistant sealant to prevent water and fumes

from travelling though any vacant space in the

grommet. All cables running across the vehicle must

be securelyfastenedwithcable ties.

,

angle

face

,

T s

, s they may be detected as

also

:

L .

Allowwater behindthe sensor.

The sensor tomove andbecome misaligned.

between 500 and 65

never

7

limits of the measurements stated.

Before drilling, use double side tape to fix the sensor

heads to the proposed locations and test their

effectiveness. Once a satisfactory setup is achieved,

markthe locations andcontinue the installation.

close to the lower limit

closer er

limit more fail to detect lowo

and/or angle bumper as the

vehicle weight changes

marking

,

a 20kg is

, bumper height may lift by

adding weight to As the vehicle is

loaded, the p head direction may

change.

The parking aid can not make measurements when

the a trailer is attached to the vehicle. The trailer is

constantlydetectedas the closest obstacle.

Paintingconsiderations

When matching sensor head and bumper colour avoid

applying excessive paint. Combined layers of primas,

under coats and top coats that are too thick on/across

the active parts of the heads will muffle the output

and reduce (if not completely defeat) the

effectiveness of the sensor.

Recommendedpaint procedure:

Remove the shine of the sensor heads by rubbing

with very fine wet/dry

sanding paper. Enure all

moisture is removed

before continuing.

An excellent way to

mask the cables and

back of the sensors is to

drill holes in the box in

which the SEN-003 was

supplied. Insert the

cables through the holes

and push the heads in

snug.

Use a Prepwashequivalent to remove all oil and

dust whichmayhave built up duringhandling.

Apply a plastic adhesion promoter to bond the

next paint layer withthe plastic body.

Metal flake paints will require a ground coat of

paint tocover the blackplastic.

Applythe final colour tothe heads.

To locate the correct colour paint (and ground coat if

necessary) contact your local paint supplier, many are

able to make up a pressure pack with the correct

colour simply by supplying them with the paint code

detailedusuallyunder the bonnet.

Always read the application and safety directions on

the paint cans at each stage. The manufacturers know

howtoachieve the best results withtheir products.

l

l

l

Running sensor cable intovehicle

Trial run

Sensors toolowor angleddown

Sensors toohighor angledup

Vehicles l weight

Trailers

SENSOR HEAD POSI T I ONI NG &

CONSIDERATIONS

When choosing the optimum location for the sensor

heads consideration must be placed on the curvature,

and overhang of the bumper. The performance

of the sensors will be bias towards the direction they

are pointing i.e. if the bumper slopes towards the

ground the performance of the sensors will be bias

towards the ground. owbar , 4WDprotection bars /

steps, number plate surrounds, 4WD spare wheels

and sectional mouldings may impede the ability of the

sensor to function a

obstacles.

When selecting a suitable position for the sensor

heads consideration should be given to ensure the

sensor head sits flush in the bumper i.e. the bumper

shape may curve / angle to such a degree that the lip of

the sensor headoverhangs andwill

ook unsightly

The optimumheight fromthe ground for sensor heads

position is 0mm, this is not

always suitable for all vehicles due to bumper shape,

curvature, lamp locations, bumper overhang or

internal protection framework behind the bumper.

The parameters of sensor head height should be

lower than 400mm and no higher than 00mm.

Performance may be affected towards the lower and

higher

Sensor heads positioned may

be susceptible to reporting alerts caused by dipping

driveway entrances / exits, gradients, plants and

bushes.

Likewise sensor heads positioned to the high

are likely to bstacles i.e.

pipes, car parkrail guards or mini walls.

The height of the changes

, consider this when

measuring dimensions for sensor head

location

i.e. spare wheel removed for installation

purposes the

5 - 10mm.

The performance of the parking aid may be affected

by the vehicle.

Bumper curvature / shape

Sensor headheight

oad

arking aid sensors

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

SENSOR HEAD MOUNTING IS CRITICAL

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

Loaded car may angle perfectly mounted heads towards the ground.

!

LOADED

CAR

Heads mounted too high, sensor may miss all low objects.

TOO

HIGH

Heads are mounted too low, sensor may pick up slight changes in road surface.

TOO

LOW

Heads are angled down, sensor may detect subtle changes in road surface.

ANGLED

DOWN

Heads are angled up, sensor may miss low objects and delay the detection of all objects.

ANGLED

UP

Perfect, field is directed straight out missing road surface.

PERFECT

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

SYSTEMLIMITATIONSANDDISCLAIMER

l

l

The SEN-003 reverse parking aid should never be used as a complete replacement for visual reverse

parking. Any feedbackshould be used on anadvisorylevel.

The manufacturer accepts no responsibility nor liability for damage to any vehicle, property or other, caused

directlyor indirectlythroughthe use of this product.

1. Mask rear

bumper both

below and above

approximate

sensor locations.

This will help with

marking and

reduce scratching

the bumper.

2. Check behind

bumper to ensure

sensor heads will

have enough

clearance and

cables can be

fixed to anchor

points.

3. Temporarily

mount each

sensor head in its

approximate

position using

tape. Notice the

centre heads have

been spread

further to allow the

ultrasonic field to

miss the tow bar.

4. Temporarily

wire up all

connections and

test coverage by

moving firm object

in and out of the

field. Sensors

should respond

only when object

is within the car

profile.

5. When satisfied

with results,

measure and

separate heads

with greater

accuracy. This car

has a 300,600,300

split between the

heads (aligned

central to tow bar).

6. Mark the

heights of all the

sensors. The VX

Commodore

bumper is least

curved at 510mm

from the floor.

7. Cross your

fingers, close your

eyes and drill four

21.5mm holds in

your wifes

bumper !!!!!

.

Stop often to

remove schwarf

from drill bit to

avoid scratching.

(dont close your eyes)

8. When all holes

are drilled, remove

masking tape and

insert heads into

each hole. Secure

all cables inside

bumper.

9. Drill access

hole in a high

point to avoid road

debris in rear of

car. Apply zinc

based anti-rust

paint. Insert

rubber grommet to

avoid chafing

cables.

10. Fit controller

module inside

right or left

bulkhead (ensure

water can not

reach module).

Connect power to

reverse light wires.

Mount display

module and plug

in. Happy parking.

TYPICAL INSTALLATION

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

1. To mash the

sensor heads, drill

two holes in

cardboard box that

the sensors are

supplied in. Use

the hole saw

supplied.

2. Insert the

sensor head

cables through the

box top and push

into place.

3. The box will

stop the over

spray from

contaminating the

sensor cables and

plugs.

4. Use a very

(very) fine grade

of wet and dry

abrasive paper to

remove the shine

of the heads.

5. Use PREPWASH

to remove any

grease, oil & dust.

Ensure the clean

surface is not

touched again until

after the painting

procedure is

complete. Solvent

fluid must be

enamel compatible.

6. Apply FLEXI-

PRIME plastic

adhesion

promoter. Two

light coats are

preferred to one

thick coat ***.

Leave in dust free

location to dry.

7. Apply lacquer

ground coat if

required - many

metallic paint

colours require

this extra coat to

cover the heads

black colour. eg

GMH F146 needs

a Golden Honey

ground coat.

8. Apply coat(s) of

bumper colour.

Many thin coats

are preferred to

one thick coat.

9. Leave in a dust

free location to dry

between coats.

10. Ingredients

1. Prepwash

2. Primer coats(s)

3. Ground coat(s)

4. Final coat(s)

When completely

dried/hardened,

insert into vehicle

bumper.

TYPICAL COLOUR MATCHING/APPLICATION

*** Follow paint manufacturers safety and application instructions for best result.

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

SEN-003_INSTALL_COMPLETE.CDR, CREATED/UPDATED:29/08/2005.

DYNAMCOPTY LTD

SECURI NG VEHI CLES WORLDWI DE

AUSTRALIA WIDE INSTALLER HELPLINE 1800 811 815

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Method Statement For Plunge ColumnDocument17 pagesMethod Statement For Plunge Columnvikas100% (2)

- RenaultDocument186 pagesRenaultMochamad fandi Dharmawan100% (3)

- Galaxy 60 ManualDocument9 pagesGalaxy 60 ManualFalko SatPas encore d'évaluation

- Resumer ElectriciteDocument2 pagesResumer ElectriciteFalko SatPas encore d'évaluation

- VNC User GuideDocument152 pagesVNC User GuideFalko SatPas encore d'évaluation

- Learn HTMLDocument122 pagesLearn HTMLyahia2009100% (3)

- Video - Rear Monitor Intec Model CVM450LPPADocument6 pagesVideo - Rear Monitor Intec Model CVM450LPPAFalko SatPas encore d'évaluation

- Aerobie 2Document1 pageAerobie 2Falko SatPas encore d'évaluation

- 050 Tutorial Install Map For MapSourceDocument7 pages050 Tutorial Install Map For MapSourceAgus WahyudiPas encore d'évaluation

- C 1bac Ex 06 - 01Document1 pageC 1bac Ex 06 - 01Мохамед Ель ФахімPas encore d'évaluation

- Apple Composite AV CableDocument16 pagesApple Composite AV CablezaskribdoPas encore d'évaluation

- Exam Blanc KeniDocument3 pagesExam Blanc KeniFalko SatPas encore d'évaluation

- SVTR 14Document5 pagesSVTR 14Falko SatPas encore d'évaluation

- Camset5A - Version Ii Owner'S Manual Car Rear View SystemDocument10 pagesCamset5A - Version Ii Owner'S Manual Car Rear View SystemFalko SatPas encore d'évaluation

- Exam Local PC 2011Document2 pagesExam Local PC 2011Falko SatPas encore d'évaluation

- Report Generator 900-999Document156 pagesReport Generator 900-999Falko SatPas encore d'évaluation

- With 7" Rear View Mirror Monitor: Owner'ManualDocument2 pagesWith 7" Rear View Mirror Monitor: Owner'ManualFalko SatPas encore d'évaluation

- CP 4047156162Document16 pagesCP 4047156162Falko SatPas encore d'évaluation

- Manual Garmin GpsDocument30 pagesManual Garmin GpsJavier CasiquePas encore d'évaluation

- Ce 9 Phy 2 Sem 0708Document2 pagesCe 9 Phy 2 Sem 0708Falko SatPas encore d'évaluation

- 050 Tutorial Install Map For MapSourceDocument7 pages050 Tutorial Install Map For MapSourceAgus WahyudiPas encore d'évaluation

- Mapsource For Beginners - A Complete Step by Step Guide: Waypoint: RouteDocument28 pagesMapsource For Beginners - A Complete Step by Step Guide: Waypoint: RoutedrvojePas encore d'évaluation

- Genuine PartsDocument24 pagesGenuine PartsFalko SatPas encore d'évaluation

- Abd AzizDocument238 pagesAbd AzizFalko SatPas encore d'évaluation

- Chut LibDocument8 pagesChut LibFalko SatPas encore d'évaluation

- Veja de Transponders !!!: Os Novos PreçosDocument2 pagesVeja de Transponders !!!: Os Novos PreçosChaveiro ConfiançaPas encore d'évaluation

- Block 06 Bhatwari - ResourceRate - MachineDocument3 pagesBlock 06 Bhatwari - ResourceRate - MachineManojPas encore d'évaluation

- Ertl Toys & Collectibles: 2021 CATALOGDocument12 pagesErtl Toys & Collectibles: 2021 CATALOGKuhnPas encore d'évaluation

- TBT PuwerDocument15 pagesTBT PuwerPaul CassidyPas encore d'évaluation

- BATAL LELANGDocument9 pagesBATAL LELANGYpPas encore d'évaluation

- Manual 3030f EDocument40 pagesManual 3030f ESchiller Paradies100% (1)

- MahindraDocument1 pageMahindrapuneet988880% (1)

- Thesis MercedesDocument8 pagesThesis Mercedesdianaturnerspringfield100% (2)

- Element Filter FSF-4530 9424-LF637Document2 pagesElement Filter FSF-4530 9424-LF637Pascual YeguezPas encore d'évaluation

- Safety & Maintenance Checklist-Wheel HarvesterDocument1 pageSafety & Maintenance Checklist-Wheel HarvesterParth PatelPas encore d'évaluation

- RCCCDocument1 pageRCCCBIKRAM KUMAR BEHERAPas encore d'évaluation

- Application No.: LLR Fresh AcknowledgementDocument1 pageApplication No.: LLR Fresh AcknowledgementsrinadhPas encore d'évaluation

- Isuzu FTR 850 Tautliner Truck Test Drive ReviewDocument2 pagesIsuzu FTR 850 Tautliner Truck Test Drive ReviewMutalu PhosiwaPas encore d'évaluation

- GSE for Ramp OperationsDocument25 pagesGSE for Ramp OperationsHRD100% (1)

- MTO Drivers HandBookDocument233 pagesMTO Drivers HandBookKrishnakant UdavantPas encore d'évaluation

- Our Customer Support Is User-Friendly As Well.: Ags: Automated Gear Shift Ags: Automated Gear ShiftDocument2 pagesOur Customer Support Is User-Friendly As Well.: Ags: Automated Gear Shift Ags: Automated Gear Shift123gilliganPas encore d'évaluation

- Designed To Handle Jumbo Rolls.: Applications ModelsDocument2 pagesDesigned To Handle Jumbo Rolls.: Applications ModelsYakupovmmPas encore d'évaluation

- Permisos Circulacion Otorgados 2013Document300 pagesPermisos Circulacion Otorgados 2013Mariela CárcamoPas encore d'évaluation

- Elle Word MixDocument4 pagesElle Word Mixscott.maisonPas encore d'évaluation

- Ford 350 Super Duty 2018 PDFDocument56 pagesFord 350 Super Duty 2018 PDFAdalid Ortiz RodriguezPas encore d'évaluation

- Ra 6539 PDFDocument4 pagesRa 6539 PDFFrances SamsonPas encore d'évaluation

- Hafiz Bintang From Classed Si-2cDocument4 pagesHafiz Bintang From Classed Si-2cBrian Christoper S. PanggorgaPas encore d'évaluation

- List of Perkins Engines - Wikipedia PDFDocument33 pagesList of Perkins Engines - Wikipedia PDFLAli0% (1)

- Oem20cross20ref20paper208 08 1B.220143602Document104 pagesOem20cross20ref20paper208 08 1B.220143602Adriana100% (1)

- RHD Bridge & Road From Vehicle Toll Collection Rate (Existing & Proposed)Document5 pagesRHD Bridge & Road From Vehicle Toll Collection Rate (Existing & Proposed)michaelmbdPas encore d'évaluation

- Https Vahan - Parivahan.gov - in Vahanservice Vahan Ui Onlineservice Form 23 RC Report - XHTMLDocument1 pageHttps Vahan - Parivahan.gov - in Vahanservice Vahan Ui Onlineservice Form 23 RC Report - XHTMLPawan KumarPas encore d'évaluation

- CT Roadside Assistance HandbookDocument2 pagesCT Roadside Assistance Handbookali2000aya3157Pas encore d'évaluation

- Material Specifications Data SheetDocument3 pagesMaterial Specifications Data SheetDoug Seybert100% (2)