Académique Documents

Professionnel Documents

Culture Documents

Petroleum Reservoir Simulation - Khalid Aziz

Transféré par

agusnurcahyoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Petroleum Reservoir Simulation - Khalid Aziz

Transféré par

agusnurcahyoDroits d'auteur :

Formats disponibles

PETROLEUM RESERVOIR SIMULATION - BASIC

CONCEPTS

Khalid Aziz

February 24, 2005

Stanford University, Stanford, CA 94305-2220

Contents

1 Introduction and Overview 3

1.1 Why Simulate Reservoirs? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 How Simulators are Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Historical Perspective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Major Benets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Major Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Modern Tools for Forecasting Reservoir Performance 9

2.1 Introduction to Reservoir Simulation Technology . . . . . . . . . . . . . . . . . . 9

2.2 Fundamental Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Fluid System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Reservoir Grid and Rock Properties . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Flow Equations and Recovery Mechanism . . . . . . . . . . . . . . . . . . 11

2.2.4 Solution of Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.5 History Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Types of Reservoir Simulators in Use 15

3.1 Type Based on Fluid Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.1 Black Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.2 Extended Black Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.3 Compositional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.4 Limited Compositional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Type Based of Reservoir System . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 Single Porosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1

3.2.2 Dual Porosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.3 Dual Porosity, Dual Permeability . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Type Based on Recovery Method . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1 Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 In Situ Combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.3 Thermal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.4 Chemical Flood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.5 Gas Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Type Based on Solution Method . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.1 IMPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.2 Implicit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.3 Adaptive Implicit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.4 Sequential Implicit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5 Type Based on Gridding Techniques . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.1 Block-Centered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.2 Point-Distributed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.3 Curvilinear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.4 Hybrid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5.5 Voronoi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5.6 Flexible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Data Requirements and Sources 19

4.1 Data Needed and Data Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Sources of Reservoir Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.1 Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2 Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.3 Well Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.4 Seismic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.5 Performance History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Sources of Fluid Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.1 PVT Studies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.2 Correlations and Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 Impact of Data of Various Types . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Limitations of Current Technology and Current Research 21

6 Computer-Requirements 22

2

7 Concluding Remarks 22

8 Nomenclature 22

1 Introduction and Overview

In every endeavor that involves costs and possible benets, the risk can be reduced with the use

of tools that can mimic future behavior. Because in complex systems like petroleum reservoirs it

is impossible to make forecasts that are precise, or even accurate under all conditions, both the

forecasts and forecasting tools are constantly rened to make more and more reliable predictions.

Because of the limited information that is normally available about the system being modeled

the petroleum reservoir and the uids within it there is always considerable degree of un-

certainty associated with predictions of performance. Furthermore, incomplete understanding

of the mechanisms involved in uid displacements in porous media may also cause the results

to deviate from reality. The job of a simulation team is to minimize this uncertainty in a way

that is consistent with the objectives of the organization that pays the cost of the study. The

degree of sophistication of the model and its use has to be carefully balanced with the benets

to the organization. For example even if it was possible to do so, a pore scale simulation of

an entire reservoir is not desirable. This would be like tracking the motion of each molecule in

a pipeline to calculate the pressure drop in that system. Such a model would be inconsistent

with the objectives of the study, which is to predict the pressure drop in the pipeline due to the

average behavior of the molecules in a control volume that is large with respect to the size of

the molecules but small with respect to the size of the pipe. Similarly for modeling ow in a

petroleum reservoir it reasonable to average the ow over several pores, but in most cases the

system would be over simplied if an entire reservoir is treated as a single block as in tradition

material balance calculations.

All experts agree that great benets in improved accuracy result from improvements

in reservoir description. Identication of major ow units, faults and fractures can probably

improve the predictions more than any other single factor. Further improvements result when

reservoir heterogeneities can be dened in greater and greater detail. The intelligent use of in-

formation about the reservoir obtained at dierent scales with new and traditional measurement

tools provides signicant challenges to the reservoir engineer.

In this review the state-of-the-art of reservoir simulation will be discussed from the point

of view those who have scientic training but are not experts in this eld.

These notes do not provide a comprehensive literature review, but they do provide

suitable references for further study. The interested reader should consult books like that of

Aziz and Settari (1979) [3].

1.1 Why Simulate Reservoirs?

Petroleum engineers use reservoir simulators to enhance the eciency of oil and gas production

or storage operations. Simulators are used or can be used at every stage of the operation in

answer important questions:

After the discovery of a eld and during the development of an economic feasibility study,

simulators can be used to obtain valuable information about the expected performance

of the reservoir. This kind of information can be used to study the economic feasibility

3

of the project and for risk assessment. Because of the limited information that would be

normally available about the reservoir at this stage, only rough calculations can be made.

In many cases standard reservoir engineering calculations, rather than reservoir simulation,

are adequate during early stages of reservoir development. One of the advantages of

using reservoir simulation early in the life of a reservoir is that analyses conducted at

this stage would be completely consistent with more sophisticated calculations at future

stages. Furthermore, early initiation of the reservoir management team to the simulator

helps (i) in the identication of data that would be important at future stages, and (ii)

the organization of the data in a way that would make it most useful.

Once it has been decided to develop a eld and additional information has been obtained

from eld delineation wells, the simulator can be used to design eld development (full eld

or pilot). This would include number and location of wells, type of wells (conventional or

horizontal) and design of wells (casing program, tubing size, completion type) to be drilled

initially. Information obtained from the simulator about production rates, breakthrough

times for gas and water, gas and water rates, and wellhead pressures can be used for the

design of production facilities.

After initial eld development and as production data are obtained, the simulator can be

used to rene initial design and optimize eld operations. Matching of eld production

history with predictions from the simulator provides condence about future predictions

and helps in the understanding of mechanisms that are active in the reservoir to help or

hinder the recovery of oil. This process continues through the entire production phase of

the eld.

Starting with the initial development phase and ending with eld abandonment, the sim-

ulator can be used to evaluate dierent schemes for improving oil recovery and their eco-

nomic impact. Expected performance of waterooding, gas injection or some sophisticated

enhanced oil recovery scheme can all be investigated with an appropriate simulator. As

economic conditions change, the simulator can provide valuable information on possible

options for enhancing protability.

Finally the simulator can be used to study the optimum time for eld abandonment and the

manner in which the eld should be abandoned. Possible advantages of new technologies

like horizontal wells can be investigated to see if productive life can be extended.

When used intelligently, the simulator is a powerful tool that can assist the petroleum

engineer and the management with important decisions. As we will discuss later; improper use

of this tool can also lead lo disastrous results.

1.2 How Simulators are Used

While in a broad sense the simulator is used to predict performance of petroleum reservoirs, its

use in any give case can be for a variety of specic reasons:

Improving reservoir description through history matching. After the best possible

of description of a reservoir has been obtained from the analysis of cores, logs, well tests and

seismic data, there is usually still considerable uncertainty about reservoir properties. It is

often possible to identify major ow units, and barriers near wells, through the matching

of good production data with model predictions. Because the history matching process

is non-unique (several dierent adjustments of reservoir properties can provide equally

4

good matches of data), it has to be repeated as more and more information about the

reservoir becomes available.

Analysis of laboratory experiments. Most information is extracted from laboratory

experiments if they can also be modeled. Traditionally simple analytical models based

on assumptions that may not be always valid have been used. More recently the reser-

voir simulator itself has been used for the analysis of experiments that are conducted for

determining parameters like relative permeability and capillary pressure, and experiments

that are conducted for understanding of the displacement of oil by some injected uid (core

displacements, slim-tube displacements, etc.) Once an appropriate laboratory experiment

has been matched, the simulator provides a natural tool for scale-up to the eld or pilot

scale.

Understanding of ow mechanisms. In some cases the mechanisms of oil displacement

at a small scale (order of few millimeters) is quite dierent from what must be modeled

at the eld scale. Consider for example the displacement of oil by a gas (nitrogen, carbon

dioxide or some hydrocarbon gas). Because the viscosity of the injected uid is much less

than that of the oil in the reservoir, the injected uid tends to nger through the oil.

These ngers are caused both by the hydrodynamic instability of the displacement process

and spatial variations in reservoir permeability (heterogeneities). But these ngers that

are only a few millimeter wide are too small to be modeled at the eld scale where the block

dimensions can be many meters or even kilometers in each direction. Hence it is important

to incorporate their averaged behavior in eld scale simulators. Fine grid simulation of

these ngers can provide important information for the averaging rules. Other examples

of the use of models to understand ow mechanisms include in situ combustion and steam

displacement (with or without foam).

Development of simple models and correlations. There are situations where it is

desirable to develop a simple model or correlation for quick forecasts or for imbedding

them inside a full eld model. Such correlations have been traditionally developed with

data collected through laboratory or eld experimentation. In recent years such physical

experiments have been augmented with numerical experiments with simulators to yield

data for the development of simple models or correlations. Examples of such applica-

tions are conning correlation, correlations of block eective permeabilities in heterogeneous

rocks, steam injection (cyclic and displacement) models.

Reservoir performance forecasting. All of the above applications of simulators are

simply preliminary steps towards getting to the nal goal of making reliable forecasts of

reservoir performance. Such forecasts can be made for the initial design of production sys-

tems, expansion of production facilities, reservoir optimization, troubleshooting, resolution

disputes among parties with interest in the same eld, assessment of risks at each stage

of eld development, management decisions, monitoring reservoir performance, training

of engineers and geologists, timing and implementation of enhanced oil recovery schemes,

establishing need for additional data collection, location of new wells, and to assess value

of new technologies like horizontal wells. The availability of data and the sophistication

of the simulation at each stage of reservoir development is dierent.

Education and training. Simulators are powerful learning tools for engineers.

1.3 Historical Perspective

Reservoir simulation is nothing but a natural evolution aided by developments in computer

software and hardware technology of classical reservoir engineering and the use of physical

5

and analog models.

Since the early 1930s reservoirs have been mathematically modeled as single homoge-

neous blocks for material balance calculations. Such a model was simple enough to perform

calculations even by hand (initially by slide rules, then by mechanical calculators, now by elec-

tronic calculators and personal computers). Such calculations ignore reservoir heterogeneities

and treat the reservoir as a tank with uniform rock and uid properties, pressure and tem-

perature. Enhancements in such model calculations were obtained by incorporating simple

analytical models for pressure gradients around a well (solution of the diusion equation for one

dimensional radial ow) and for one-dimensional two-phase displacements (Buckley-Leverett

theory).

Starting with the development and availability of digital computers in early 1950s,

engineers started solving nonlinear equations for simple ows (one-dimensional, single-phase) by

using nite-dierence methods. This meant that the reservoir could be replaced in the model by

a series of blocks, rather than a single block as in conventional material balance calculations. As

the power of computers has increased, the simulators have become more and more sophisticated.

The period from about 1970 to the present can be considered the time of the birth of

modern reservoir simulators. During this period tremendous advances have been made in several

areas:

Understanding reservoir ow mechanisms and reservoir geology.

Improved understanding and mathematical modeling through equations of state of the

phase behavior of petroleum uids (how oil and gas phases and their composition changes

with pressure and temperature).

Numerical techniques for the solution of ow equations, which form a large system of

highly nonlinear coupled set of equations.

Numerical techniques for the solution of large sparse matrix equation.

Development of super computers, workstations and parallel computers.

Software tools with Graphical User Interface (GUI) for data entry and visualization of

results.

Improvements in compilers (FORTRAN, C and C++) and development of new program-

ming concepts (object oriented design).

Whereas a typical simulator in the 1960s was the result of one persons eorts, the

modern simulator is developed by a team of experts. As a result of the feature demanded by the

user, modern simulator can contain well over a million lines of code. Emerging object oriented

approaches to the design of simulators are likely to have a major impact in the design and use

of future simulators (Verma and Aziz, 1996) [11].

While developments of the past have been signicant, much work remains. For example,

our understanding of simultaneous three phase (oil, gas and water) ows in porous media is still

primitive. This and other limitations of current technology will be discussed later in this paper.

1.4 Major Benets

Design and performance analysis of a complex system like an oil eld requires that one

consider the interaction of many dierent parts of the system. For example, we have to

6

consider uid/uid interaction (mass transfer between phases, changes in the amount and

composition of each phase), uid/rock interaction (multiphase, multicomponent ow in

irregular pore spaces, surface properties of the rock system), reservoir/well interaction

(inow of uids from the reservoir to production wells and outow from injection wells),

reservoir/reservoir interaction in a eld with several reservoirs, and the interaction of

gathering or injection system with the reservoir (control of reservoirs by constraints placed

at some point in the production or injection system). Traditionally, each component of

such systems has been analyzed separately, and simplifying assumptions have been made

to make the problem tractable. While reservoir simulation allows a more rigorous analysis

of the problem than is possible by any other means, signicant limitations still exist. With

the expanding power of modern computers, it is just becoming possible to not only model

each component accurately but also consider the interaction of dierent components of the

system with each other.

Another important benet of simulation is that it allows the integration of data from

dierent sources and their use. In addition it becomes possible to look at the value of

information of dierent types through sensitivity studies with simulators.

Modern simulation tools coupled with stochastic simulation provide an opportunity to

get an assessment of uncertainty for each development or production scenario that may

be under consideration. This can be accomplished through simulations using multiple

reservoir descriptions that all honor available data.

1.5 Major Problems

Notwithstanding many major technological breakthroughs over the past twenty years or so,

there are still many areas where the demands of the users and our need for understanding far

exceed the capabilities of modern reservoir simulators:

Three-phase ow. The relative resistance to the ow of dierent phase (oil, gas or wa-

ter) in the porous media is handled in the simulator through the introduction of relative

permeability as a multiplier to absolute permeability in Darcys law. While reasonably re-

liable techniques are available for measuring two-phase relative permeabilities, the same is

not true for three-phase relative permeabilities. As a matter of fact, three phase measure-

ments are so dicult that they are rarely made even in research laboratories. Normally

two sets of two-phase data (oil-gas and oil-water) are to predict three-phase permeabilities

in the simulator. Several such models are available, but there is no way to tell which, if

any, of the models will be reliable in a given situation.

Thermodynamic equilibrium. All commercial simulators assume that as uids ow in

to a grid block they instantaneously reach thermodynamic equilibrium. This assumption

becomes reasonable if the grid blocks are suciently small. However, in some situations

(e.g. simulation of gas injection with large grid blocks) this assumption can lead to im-

proper handling mass transfer between phases during the simulation process.

Simulation of large, complex elds. Typically reservoir engineers handle the simula-

tion of large elds either by using very large grid blocks or by dividing the reservoir into

smaller units. In the case where large grid blocks are used all uid and rock properties are

averaged over the entire grid block. Furthermore, only one set of saturations and pressures

are associated with each grid block. This means that any variations in these parameters

within the grid block are ignored. This can lead to unreliable (often optimistic) predictions.

Physical parameters are replaced by pseudo functions that are designed to mimic true

7

behavior. Unfortunately there are no rigorous methods for calculating pseudo functions

and their use can lead to incorrect results. Furthermore, pseudo functions change with

changing conditions and hence they are not robust. When the reservoir is divided in into

small units that can be handled with blocks of reasonable size, the interaction among var-

ious units is dicult to handle and often ignored. New domain decomposition techniques

and parallel computations oer signicant opportunities to overcome these limitations.

Many of the major problems are related to the modeling of large reservoirs with gridblocks

that are too large to adequately represent either the reservoir or the recovery process. Even

with the largest and most powerful computers of today, diculties arise in the simulation of

large reservoirs. Gridding a large reservoir can also be a very dicult and time consuming

task, requiring many man months of time for just a single possible reservoir description

(Pettersen, 1992).

Modeling of wells. Field scale reservoir simulation is done with gridblocks that are

orders of magnitude larger than the magnitude the size of the well. This means that the

pressure of a large gridblock cannot be assumed to be the pressure of one or more wells

that might be in that grid block. Usually single phase ow assumptions are made to

relate the well pressure to the block pleasure through a well geometric factor. Well models

have only been derived for two-dimensional ow in homogeneous reservoirs for steady-state

or pseudo steady-state cases. Only limited information exists for three-dimensional ow

(partial well completion, wells that are not oriented along grid lines) and transient ow

conditions.

Another complication in modeling wells arises due to the variation of saturations within

a gridblock (gas or water coning, edge water encroachment). Since the ow of various

phases into the well is controlled by the relative permeabilities of those phases and hence

saturations near the well, using average gridblock saturations can lead to large errors.

Both of the above problems are reduced by grid renement around wells. But current

techniques for local grid renement lead to the substantial increases in computational

time.

Modeling of surface facilities. Petroleum engineers typically model reservoirs and

surface facilities separately. This leads to a miss-match at the interface between these

two systems. The reason for doing this is again to reduce computational time. New

techniques utilizing domain decomposition and parallel processing are emerging to handle

this problem.

Integration of data from dierent sources. Reservoir description should be based on

reservoir data at dierent scales and from all sources. Integration of all available data into

one or more usable reservoir descriptions has been a problem. New research on stochastic

techniques is starting to provide some powerful tools to handle this problem.

Fluid description. Reservoir uids are extremely complex mixtures of hundreds of dif-

ferent components. It is dicult to obtain and use a complete description (analysis) of

reservoir oil and gas. Analytical techniques for making the analysis are dicult to use

and expensive. Traditionally petroleum engineers have lumped the hydrocarbon mixture

in the reservoir into two pseudo components. They are oil and gas at standard (stock

tank) conditions. This highly simplied description is inadequate for many purposes, es-

pecially when EOR techniques are being considered. We have the problem: how to nd

an optimum set of pseudo components and how to characterize them? All necessary uid

properties of pseudo components must be calculated from the characterizing parameters.

Unfortunately in many reservoir simulations inadequate description of uids is used.

8

Modeling physical dispersion. One of the outstanding problems of reservoir simulation

is the modeling of physical dispersion. The diculty results from the fact that numerical

techniques (nite-dierence methods) used in reservoir simulation with large gridblocks

lead to large errors that behave just like physical dispersion. Fortunately in many case

the eects of physical dispersion need not be considered explicitly, but in other situations

for example in the simulation of tracer ow one must control numerical dispersion so

that physical dispersion can be modeled. High order nite-dierence and nite-element

techniques have been successful only in limited situations to solve this problem.

Assessment of risk through reservoir modeling. Every step of the simulation process

involves assumptions and approximations. The predictions made by a single simulation run

have only a nite probability of being right. Assessment of this uncertainty and through it

risk involved in making investments based on reservoir performance predictions is bound

to be a major future challenge for simulation teams (Ballin et al. 1992) [4].

2 Modern Tools for Forecasting Reservoir Performance

2.1 Introduction to Reservoir Simulation Technology

Reservoir simulation is a blend of engineering, physics, chemistry, mathematics, numerical analy-

sis, computer programming, and engineering experience and practice. Basically the reservoir is

divided into grid blocks and the transient ow of uids between various grid blocks and between

grid blocks and wells is computed under certain specied conditions (rate or pressure) at the

wells. But considerable experience is needed in determining how the reservoir is divided into

blocks, how properties are assigned to these blocks and what assumptions are made in writing

and solving the ow equations. Unless sound judgment based on experience is used at every

step of this process, the entire exercise becomes completely unwieldy. This is the reason why

successful development and application of this technology has remained primarily in the hands

of those who understand (to varying degrees) all aspects of this technology. Some practical

aspects are discussed by Aziz (1989) [1].

2.2 Fundamental Concepts

2.2.1 Fluid System

After a reservoir has been divided into grid blocks, equations of mass balance are written over

each grid block. Before writing the equations of mass balance we must understand that mass is

conserved for each component (methane, ethane, propane, etc.) of a system. In system where

mass transfer between phases (oil, gas and water) is allowed, the mass of a phase is not conserved.

This immediately leads to a serious diculty. First of all natural hydrocarbon systems contain

hundreds of components. Secondly, determination of exact amount of each component in a

specic oil is a highly complex task. Even if we could determine the complete analysis of a

hydrocarbon (consisting of oil and gas phases) system, the use of this information in actual

reservoir simulation would be virtually impossible with current technology, except perhaps for

highly simple (consisting of only a few components) systems. There are two main reasons for

this:

1. The number of equations to be solved for each grid block at each timestep depends on

the number of components. The computational work increases sharply as the number of

equations increases.

9

2. Characterization of all of the hydrocarbon components is usually dicult and sometimes

impossible.

Fortunately there is no need to use a large number of components in doing reservoir

simulation. Instead the actual components in the reservoir are lumped together into a few

pseudo components, and the mass balance is written for these pseudo components. Most of the

standard reservoir studies are done with what are called black oil models. These models are a

natural evolution of traditional reservoir engineering where the reservoir uids were assumed to

consist of only three pseudo components with the composition of oil, gas and water at standard

or stock tank conditions. For example, in such a model reservoir oil would be made up of oil

and gas pseudo components (which by denition are oil and gas at standard conditions).

2.2.2 Reservoir Grid and Rock Properties

Grid selection is one the most dicult and time consuming tasks in the simulation of geologically

complex reservoirs (Palagi and Aziz, 1991 and 1993; Aziz, 1993; Verma and Aziz, 1996) [7, 9, 2,

11]. A reservoir simulator predicts reservoir performance by solving ow equations on a discrete

grid that is chosen by the simulation engineer to represent the reservoir. The grid is normally

selected with one or more of the following considerations in mind:

1. Geology and size of the reservoir and the available data used for reservoir description.

2. Type of uid displacement or depletion process to be modeled.

3. Past and anticipated eld development (location and type of wells).

4. Numerical accuracy desired.

5. Available software options.

6. Objectives of the simulation study.

7. Competence of the simulation engineer or team.

8. Available computer resources, time constraints or project budget.

In the early days of reservoir simulation it was often the last of the above considerations

that determined the number of grid blocks, and then the available software limited the choice

of grid types to usually block-centered Cartesian or cylindrical grid. Research in reservoir

simulation and hardware developments, especially over the past ten years, have greatly extended

the gridding options available to the user. Modern commercial simulators typically oer one or

more of the following techniques:

Standard Cartesian or cylindrical block centered grid

Local Grid Renement

Hybrid Grid

Curvilinear (Stream-Tube) Grid

Voronoi or PEBI Grid (Generalization of Point-Distributed Grid)

Corner Point Geometry

10

Dynamic Grid

Automatic Grid Generation

Elastic Grid Adjustment Methods

Control Volume Finite Element Methods

Mixed Flexible Grids

While this abundance of options provides exibility, it can also make the choice of the

appropriate grid bewildering for the person using the simulator.

2.2.3 Flow Equations and Recovery Mechanism

Conservation of mass is the mathematical expression of (Aziz and Settari, 1979) [3]:

[mass inux overtime] = [mass accumulation overtime]

Before writing the mathematical equation we have to know the mechanisms that will contribute

to the inux of mass. In most situations convective ow is all that is important and this is the

basis of standard reservoir simulators discussed below.

The conservation of mass for component c (for Black-Oil models c = oil, gas and water

at standard conditions) combined with Darcys law yields the following set of ow equations:

t

Nn

j

Np

p

T

c,pi,j

(

p,j

p,i

) q

w

c,i

(M

c,i

)

n+1

(M

c,i

)

n

(1)

where the transmissibility between nodes i and j is dened by:

T

c,pi,j

=

f

c

AKk

rp

c,p

d

p

i,j

(2)

and mass of component c in the grid block i at timestep n is given by:

M

n

c,i

=

Np

p

V

b,i

S

p

c,p

n

i

(3)

In the equations in this volume index N

p

stands for number of phases (oil, water and

gas in standard simulators). All symbols are dened in the nomenclature section.

The well ow rate of a component is related to the ow rate of phase into the well:

q

w

c,i

=

Np

c,p

q

w

p

i

(4)

The ow rate of a phase to a well is given by:

q

w

p,i

= WI

i

K

w

i

k

w

r,p

p,i

w

p,i

(5)

11

Figure 1: Gridblock i and its connections

The superscript w is intended to indicate well terms. Note that the permeability and

relative permeability of well in block i can be dierent from the corresponding values for that

block. The well index (WI) includes the inuence of all geometric factors (well radius, skin,

location of well in the block, completion interval, eective well block radius).

For each block one equation of the type of Eq. (1) is written for each component or

pseudo component, c, in the system. The required geometric propertied of the gridblock are:

block volume V

b

, the area A of each block face and distance d between i and j for each connection.

This method of writing ow equations is known as the Control Volume Finite Dierence (CVFD)

method and it reduces to the standard nite-dierence method for Cartesian grids. An important

characteristic of this method is that in Eq. (1) the ow across the gridblock face between i and

j depends only on the component of the potential gradient in me direction i j. For non-

orthogonal coordinate systems, the ow calculation across a block face would depend on all

components of the gradient of the potential on the surface. Hence an error in ow calculations

results, if in a non-orthogonal grid only the component of the gradient in the i j direction is

considered.

The terms on the left hand side of Eq. (1) represent net inux for block i over time

step t and the right hand side represents the net accumulation of mass in block i over the

same time. The rst term on the left hand side represents ow across block boundaries and

the second term represents ow from wells (positive for production wells). The index j is for

blocks that are connected to block i, the block for which the mass balance is written. Note

that the connections of block i need not be just to the neighbors of this block. A block can be

connected to other blocks through wells or faults. The shape of the gridblock and location of

the grid point within the block will inuence the evaluation of each of these terms. The ow

between blocks is calculated by multiplying the interblock transmissibility with the dierence

in potential between the blocks (Fig. 1).

This ow term depends on both the grid geometry and the location of the grid point

in the block. The grid points should be selected so that the nite-dierence approximation of

the gradient of pressure is as accurate as possible. In other words the dierence in potential

between the two nodes on either side of a boundary divided by the distance between the nodes

should be a good approximation at the boundary for the average potential gradient normal to

the boundary. The accumulation term uses the gridblock volume and the pressure at the node

12

to calculate the mass in the block at dierent times. For this purpose the grid point should be

as close to the mass center of the block as possible. Finally, for the calculation of well ow a

well model is required to relate the well block pressure to the well pressure. The well model

depends on the grid type and for certain kinds of grid the well model has to be adjusted as the

ow eld in the reservoir changes (Palagi and Aziz, 1992) [8]. We will consider these factors as

we discuss dierent types of grids in the next section

2.2.4 Solution of Equations

Once a grid has been dened and ow equations for each grid block and all the wells have been

written, the next step is to solve these equations. The system of equations to be solved is a

highly nonlinear, tightly coupled set. Typically Newtons method or one of its variations is used

to linearize the system of equations. This linear set of equations has to be solved repeatedly for

each timestep to achieve convergence to the solution of nonlinear equations. In most simulation

studies, most of the computer time is used in solving linear systems of equations. For large

practical problems, these equations have to solved by iterative methods. For standard grids the

coecient matrix for the linear system has a banded structure that can be exploited, but this

structure is lost for problems with unstructured or exible grids, because of the large amount of

computer time required to solve the linear system of equations, attempts are made to speedup

this process by taking advantage of the machine architecture (parallel, vector).

2.2.5 History Matching

A reservoir simulator provides the engineer with a tool for making rapid comparisons of alternate

operating policies or a detailed prediction of the future reservoir performance. The simulated

performance may be compared with actual performance to obtain an improved set of reservoir

parameters that are consistent with the performance history of the reservoir. This process is

known as history mulching.

It is important to recognize that history matching actually uses a simulator in a reverse

mode. The response variables (eld observations) over some period of time are assumed known.

The unknowns are the input parameters (reservoir description, uid description).This so-called

inverse problem or parameter identication problem involves an attempt to nd the best set

of input data coupled with appropriate control variables that reproduce the past performance

This inverse problem has no unique solution. History of the reservoir over a limited time can be

reproduced by many quite dierent sets of input data. Even unphysical parameters like negative

permeabilities can produce what might appear to be reasonable results over the production

history period. Obviously, however, use of such unreal parameters will lead to performance

predictions that are completely unreliable. Hence bounds placed must be placed on the input

parameters to constrain them within reasonable ranges. Furthermore, the parameters adjusted

to achieve a desired change in simulator output should be carefully selected. Again because

multiple adjustments of input data can produce very similar results over a limited period of

time. A good understanding of how the simulator works the kind of recovery mechanism that

id operative in the reservoir can be very important at this stage.

A sensitivity analysis can be performed to examine the behavior of the model as the

input parameters are individually varied over their ranges. Frequently, such an exercise may

indicate a given reservoir response is insensitive to a certain input parameter. It is impossible

to identify such parameters by history matching. On the other hand, if the response is highly

sensitive to one or more parameters, then a good x on its (their) values is possible through

history matching. Even when a reasonable history match has been obtained, it is a mistake to

13

assume that the nal adjusted input parameters, say permeabilities, for example, are the actual

values in the reservoir. They are simply a set of numbers, constrained within reasonable ranges

that reproduce the desired response variables. There may be other values of the same variable,

that are constrained within the same ranges, that would yield an equally good match.

The data available for history matching are usually pressures, GORs and WORs on

a eld and individual well basis. In some instances, the total eld rate may be a historical

variable that is matched. Obviously, because of the many distributed parameters throughout

the system, there are many degrees of freedom available to the model user in undertaking

a history match. Random selection of input parameters, without regard to the cause/eect

relationships between the input parameters and response variables is usually not productive.

Basic reservoir engineering considerations can help in developing a systematic approach. The

simulation engineer should understand how input parameters aect:

pressure distribution in the reservoir,

average pressure level,

saturation distribution in the reservoir; and

bottomhole owing pressure.

It is instructive to consider and understand the ow equations that are being solved by

the simulator (Eq. (1)).

Pressure Distribution

The pressure distribution in a reservoir is established as a result of uid ow. This in

turn is governed by the transmissibility (Eq. (2)) which is a function of the product of

permeability and relative permeability (Kk

r

). Consequently, the modication of one of

these will eectively change the product and alter the pressure distribution. Obviously

permeability aects the ow of all phases while relative permeability aects the ow of

individual phases. So adjustments in overall pressure distribution should be obtained

initially by adjusting the absolute permeability.

Pressure Level

Pressure level in a reservoir is determined largely by the total reservoir pore volume and

the change in pore volume with pressure. The pore volume is determined from reservoir

dimensions and the porosity, while the change in pore volume with pressure is reected

by rock compressibility. When multiple phases are present the total compressibility of the

uid/rock system controls the pressure level. While liquid and rock compressibilities can

be similar in magnitude, gas compressibility is much higher. Hence when gas is present,

its compressibility dominates.

Saturation Distribution

The distribution of uid saturations in a reservoir will aect well injection and production

rates, and consequently, WORs and GORs. They are functions of relative permeability

ratios. Since simulators permit dierent sets of relative permeabilities for each well, WOR

and GOR can be matched by either local or global alterations of these parameters. Of

course local (well) values are adjusted when changes in the well region are desired. It is

worth noting that any alteration in relative permeability also changes the transmissibility

and hence the pressure distribution.

14

Bottomhole Flowing Pressure

For given ow rate bottomhole pressure is determined by productivity or injectivity indices

(Eq. (3)). Their initial values are based on well test and reservoir data. Adjustments are

often necessary to match history.

Overall Procedure

It is necessary to set up a systematic step-wise approach to history matching. The proce-

dure involves uncoupling, as far as possible, the search for parameters that aect pressure

from those that aect saturation. Because this is impossible to do entirely, some iterations

are required to rene the set of input parameters.

Most history matching is done in practice by the following steps:

1. Check initial volumes in place by adjusting reservoir dimensions, porositys and initial

saturations.

2. Match pressure distribution by adjusting permeabilities.

3. Match saturations by adjusting relative permeabilities.

4. Match well pressures by adjusting well indices.

5. Iterate as necessary.

In recent years eorts have been made to develop techniques that guide the simulation

engineer through the development of sensitivity matrices, which contain information on the eect

of changes in reservoir parameters on reservoir performance. These matrices are developed by

making multiple runs through a systematic change in parameters. Such approaches are bound

to become more common in the future.

3 Types of Reservoir Simulators in Use

While the trend in recent years has been to wards the development of multipurpose simulators,

there are still a large variety of simulators available in the market. A brief description of various

classes of simulators follows.

3.1 Type Based on Fluid Description

The most common classication of simulators bused on the uid description is given here.

3.1.1 Black Oil

A large majority of simulations done in the oil industry (and all reservoir engineering calcula-

tions) are based on the black oil assumption. Under this assumption the reservoir oil is a mixture

of stock-tank oil and gas produced at standard conditions. The reservoir gas is assumed to be

the same as the gas produced at standard conditions. This means that only two mass balance

equations are needed per gridblock to represent the hydrocarbon system. These two equations

along with the equation for the conservation of water complete the system of mass balance

equations needed for each gridblock.

15

3.1.2 Extended Black Oil

A standard black oil model can be extended by allowing the oil (or condensate) to vaporize into

the gas phase. This means that the reservoir gas is now a mixture of stock tank oil and gas

produced at the surface. This simple extension does not increase the number of equations to

be solved and the amount of additional computational eort is relatively small. Such models

improve the ability of standard black oil models to simulate light oil or condensate reservoirs.

Fluids are normally described through densities at standard conditions, formation volume factors

and solubility ratios.

3.1.3 Compositional

A compositional simulator allows one to describe the hydrocarbon system by arbitrary number

of real and/or pseudo components. These uid components are based on a limited or full analysis

of the produced oil and gas. One pseudo component may be formed by lumping several real

components. All components are characterized by their critical properties. The properties of

real (pure) components are available in standard handbooks and they are built in the program.

Critical properties of pseudo components are calculated from other data (density or API gravity,

normal boiling point, molecular weight) through empirical correlations. Once the hydrocarbon

system is fully described, all properties required for uid ow calculations are predicted from

equations of state or other correlations.

3.1.4 Limited Compositional

A limited compositional model usually restricts the number of hydrocarbon components to three.

This greatly enhances the ability to model light oil or condensate reservoirs over what is possible

with standard black oil models.

3.2 Type Based of Reservoir System

The most common classication of simulators based on the rock type is given here.

3.2.1 Single Porosity

In standard (single porosity) reservoir simulators the reservoir rock is considered to be single

continuum with properties that can vary in space and time.

3.2.2 Dual Porosity

In highly fractured reservoirs is not appropriate to average the fracture properties with the

matrix properties. In such systems the reservoir rock is considered to be composed of two

overlapping continua, one the fracture system and other the matrix system. Flow is allowed

between the matrix and the fracture system, but the reservoir bulk ow is considered to take

place only in fracture system. This doubles the number of equations that must be solved for each

gridblock, but the matrix conservation equations are simple, because no ow take place between

gridblocks through the matrix. This assumption is justied when the fracture permeability is

orders of magnitude higher then the matrix permeability.

16

3.2.3 Dual Porosity, Dual Permeability

In highly fractured reservoirs is not appropriate to average the fracture properties with the

matrix properties. In such systems the reservoir rock is considered to be composed of two

overlapping continua, one the fracture system and other the matrix system. Flow is allowed

between the matrix and the fracture system. This doubles the number of equations that must be

solved for each gridblock, and because the transmissibility of the two systems are very dierent,

the equations are also much harder to solve. This assumption is justied when the fracture

permeability is considerably higher then the matrix permeability, but matrix permeability is

also signicant for ow between blocks.

3.3 Type Based on Recovery Method

3.3.1 Steam

In standard reservoir simulation the reservoir is assumed to stay at its original temperature.

Thus there is no need to solve the energy balance equation. This additional equation is required

if thermal energy is added to the reservoir through steam. The black oil steam simulator is

special kind of thermal simulator in which the number of equations solved per gridblock is

maintained at three by assuming that there is no hydrocarbon gas in the system. In this case

only the gas phase that consists entirely of water can be modeled.

3.3.2 In Situ Combustion

An in situ combustion simulator allows chemical reactions among real or pseudo components.

Such system require a minimum of around eight components to describe the process. With

eight components nine conservation equations (one energy equation) must be solved for ever

gridblock. This makes greatly increase the amount of work per timestep (because number of

equations has increased) and the number of timesteps (because the equations to be solved are

highly nonlinear).

3.3.3 Thermal

A thermal model can handle both steam and in situ combustion.

3.3.4 Chemical Flood

Chemical ood simulators are compositional model that are designed to handle complex chemical

reactions and phase behavior involved in chemical ooding.

3.3.5 Gas Injection

Typically requires more than two hydrocarbon components.

17

3.4 Type Based on Solution Method

3.4.1 IMPES

In a simulator that solves three conservation equations per gridblock (e.g. black oil simulator) the

three primary unknowns are usually one pressure and two saturations. The IMPES model solves

for the pressure eld implicitly (by solving pressure equations for all grid blocks simultaneously)

and then solves for saturations explicitly. While this approach greatly reduces the computational

eort per timestep, it places a limit on the maximum timestep size.

3.4.2 Implicit

In this approach all mass balance equations are solved simultaneously and there is no theoretical

limit on the size of timestep. This however increases the computational eort required per time

step.

3.4.3 Adaptive Implicit

This technique tries to take advantage of the best features of IMPES and Implicit methods by

adapting the degree of implicitness to the needs of dierent regions of the reservoir.

3.4.4 Sequential Implicit

This technique is tries to relax the timestep limitation of IMPES by solving for saturations

implicitly after the determination of pressure implicitly.

3.5 Type Based on Gridding Techniques

3.5.1 Block-Centered

This the traditional grid used in reservoir simulation. The reservoir is divided into gridblocks

and grid nodes (where pressures, saturations and other variables are calculated) are centered in

each gridblock.

3.5.2 Point-Distributed

In this approach the grid nodes are placed rst and the block boundaries are located so that

they are bisect the line joining the grid nodes on either side and are normal to this line. This

approach is a bit harder to use but the error of discretization is lower than in the block-centered

grid.

3.5.3 Curvilinear

This kind of grid attempts to reduce errors by following streamlines and equipotential line. Since

these lines change with changes in ow directions, such grids have limited general applicability.

18

3.5.4 Hybrid

In this approach more than one kinds of grids are combined. For example, in order to model

coning around wells, cylindrical grid is imbedded in Cartesian gridblocks.

3.5.5 Voronoi

This is a generalization of point-distributed grid where that a block can have arbitrary number

of connections with other blocks. Every point inside a Voranoi gridblock is closer to its own grid

node than to any other grid node. This condition is sucient to generate a Voronoi grid. This

type of grid oers tremendous exibility in modeling sharp changes in pressure and saturations

near well, and in modeling complex reservoir structures.

3.5.6 Flexible

Very general exible grids based on tetrahedra are being developed. They are discussed in a

paper by Verma and Aziz (1996) [12]. These grids can be used to model complex reservoir

features and well congurations.

4 Data Requirements and Sources

4.1 Data Needed and Data Use

In order to proceed with simulating a petroleum reservoir using a standard black oil model, we

must

describe the reservoir rock system by providing its dimensions (areal and vertical extent,

depth, faults, fractures), properties (permeability, porosity, rock compressibility) as a func-

tion of position,

provide initial distribution of pressure and uids (saturations) in the reservoir,

provide conditions (pressure, ux) at the boundaries of the region to be simulated, and

provide properties (density, viscosity, capillary pressure, relative permeability) of the uids

in the reservoir as a function of pressure and /or saturations.

Data are used in simulators at the scale of the gridblock. Eective properties of grid-

blocks can be quite dierent from the measured values in the laboratory (from cores) or eld

tests. Proper use of data requires integration and upscaling, which in most cases is a dicult

task.

4.2 Sources of Reservoir Data

4.2.1 Core

Most of the direct measurements are made on selected reservoir cores to obtain porosity, perme-

ability, lithology, capillary pressure and relative permeability. Some of these properties depend

on the state of the core at the time of recovery and its preservation. Since cores may not be

19

recovered from the entire pay zone and measurements are only made on few selected cores, they

will dier from eective block properties even near the well from which the core is obtained.

4.2.2 Log

Well logs provide important information over the entire zone logged. Results can be analyzed

to obtain porosity, uid contacts, fractures and their orientation, lithology, and uid types.

4.2.3 Well Test

Well test provide information for a region of inuence around a well or between wells. Results

can be analyzed to obtain pore volume, permeability, reservoir type (single or dual porosity) and

distance to boundaries. Often the analysis can yield multiple solutions, in such cases additional

information is required to obtain a unique picture of the reservoir around the well.

4.2.4 Seismic

Seismic is the only tool that can yield information on the entire reservoir. Important infor-

mation on porosity and reservoir architecture. Recent work indicates that information on uid

distribution may also be obtained. Seismic is also being used to monitor reservoir performance.

4.2.5 Performance History

As discussed earlier history matching of reservoir performance helps tune information obtained

from other sources.

4.3 Sources of Fluid Data

4.3.1 PVT Studies

A PVT (pressure-volume-temperature) analysis provides information on how the volume of

reservoir oil, gas and water changes with pressure. This includes the eects uid compressibility

and the solubility of gas in oil and water. The amount of gas dissolved in oil and water at dierent

pressures is also reported. This coupled with the densities of uids at standard conditions

provides a complete PVT description of the reservoir uids based on the black oil assumption.

Fluid systems that can not be adequately described by the black oil model (two pseudo

component) are treated as compositional systems. These systems are analyzed to obtain the

amounts of various real and pseudo components that can be used to describe the uid.

4.3.2 Correlations and Models

In black oil systems the PVT data, if obtained to mimic reservoir depletion, can be used directly

in reservoir simulation studies. In compositional systems analysis (along with the characteriza-

tion of pseudo components) is used with EOS (equations of state) to predict the PVT behavior

of hydrocarbon uids.

In some cases when adequate information is not available from PVT studies of black oil

systems, correlations are used. Such correlations usually lead to poor accuracy.

20

4.4 Impact of Data of Various Types

In the section on history matching, the impact of data on various reservoir variables (pressure,

saturations, production rate, bottomhole pressure, WOR, GOR) was discussed. Reservoir sim-

ulator provides an ideal tool to investigate the impact of various data on key predictions to be

made with a simulator. Sensitivity studies should be performed to see how simulator results for

the reservoir in question change with variations in input data. A carefully planned sensitivity

study can help in the identication of data that are most important for the study.

In most cases accurate estimation of uids in place (pore volume and saturations),

and the identication of major ow paths (high permeability regions that connect wells and

dierent regions of the reservoir, fractures) and barriers to ow (faults) are a crucial starting

point for making reliable predictions. The simulator itself can be an important aid in rening

this information - through history matching, provided sucient good quality production history

data are available.

5 Limitations of Current Technology and Current Research

While great advances have been made in the simulation technology since its birth approximately

40 years ago, there are still many unresolved problems that are me subject of current research.

These limitations have been discussed throughout these notes, particularly in the section on

major problems. The greatest improvement in performance predictions is expected to result

from improved reservoir description and our ability to use this information in the simulator.

Improved logging, well testing and seismic techniques along with geostatistical tools for data

integration are providing new insight about reservoir heterogeneities. The proper use of this

information requires simulators with exible grids that can be easily generated to satisfy various

criteria. Such simulators are in various stages of development, and some are starting to appear on

the market. Great deal of work is still needed in the development of ecient ways of generating

and using exible grids.

In the area of modeling EOR processes we are largely limited to modeling only portions

(for example one-eighth of a ve-spot) of the reservoir. Main reasons for this are numerical

dispersions and the high computational eort required to solve the equations. In some cases

inadequate process description also limits our ability to model EOR processes like in situ com-

bustion and foam ooding.

Reservoir cannot be isolated from production facilities, yet most simulations are done by

making this assumptions. Full eld simulation that includes all coupled production facilities is

the next challenge. Current techniques for this are inaccurate and crude. Multiphase ow in the

production systems and lack of adequate techniques for modeling them are a serious limitations.

Once adequate full eld models have been developed, then we have the possibility to do full

eld optimizations and risk assessment using such models. Domain decomposition and parallel

computation are likely to have a major impact on success in this area.

Traditional reservoir simulators with eld oriented options desired by the users can

easily approach one million or more line of code. Development, upgrading and maintenance

of such large programs developed with traditional procedural languages (like FORTRAN) has

become a monumental task. As a result, most of the major oil companies have opted to use

software developed by commercial vendors. There are indications that this trend may change as

object based design using the features of object oriented languages like C++ (Verma and Aziz,

1996) [11]. Object based technology will allow the development dierent objects by dierent

21

teams. Furthermore, this approach will make it easier to exploit emerging hardware and other

software technologies.

6 Computer-Requirements

Reservoir simulations of large reservoir are often limited by the capacity and speed of computers.

While many routine simulations can be conducted on workstations, larger problems require super

computers and parallel processors. Software currently in use is rarely able to take full advantage

of available hardware. Utilization new hardware like parallel machines is even harder. With

good software tools, reservoir simulation engineers will require the power of the most powerful

computers.

7 Concluding Remarks

1. Reservoir simulation is a powerful and essential tool for reservoir management.

2. While there are still some serious limitations, intelligent use of this technology can provide

solutions to many problems.

3. Reservoir description, process understanding, exible gridding, full eld simulation and op-

timization, and risk assessment through simulation are some of important areas of current

research.

4. New object based software design based on object oriented languages like C++ is expected

to make it easier to take advantage of emerging hardware and software technologies.

8 Nomenclature

ow potential

viscosity

porosity

c,p

concentration of component c in phase p

t timestep size during simulation

A cross-sectional area of a block boundary between two grid blocks

c index for component for which the material balance equation is written

d distance between grid nodes

f transmissibility correction factor

i index for block for which the material balance is written

j index for blocks that are connected to the block i for which the material is written

K absolute permeability

k

r

relative permeability

M mass of material (component) in the block at a given time

n timestep number

22

N

n

number of connected blocks to block i

N

p

number of phases in the system

p phase index = oil, water or gas

q

w

well ow rate

S saturation

T transmissibility

V

b

block volume

References

[1] Aziz, K. Ten golden rules for the simulation engineer. JPT (November 1989).

[2] Aziz, K. Reservoir simulation grids: Opportunities and problems. JPT (July 1993).

[3] Aziz, K., and Settari, A. Petroleum Reservoir Simulation. Applied Science Publishers,

1979.

[4] Ballin, P., Journel, A., and Aziz, K. Prediction of uncertainty in reservoir perfor-

mance forecasting. Journal of Canadian Petroleum Technology 31, 4 (April 1992).

[5] Batycky, R. P., Thiele, M. R., and Blunt, M. J. A streamline simulator to model

eld scale three-dimensional ow. Tech. Rep. SCRF Report 9, Stanford, May 1996.

[6] Bissell, R. Calculation of optimal parameters for history matching. In ECMOR 4 (Roros,

Norway, 1994).

[7] Palagi, C., and Aziz, K. Use of voronoi grid in reservoir simulation. In SPE 66th Annual

Technical Conference and Exhibition (Dallas, TX, October 6-9 1991).

[8] Palagi, C., and Aziz, K. Handling of wells in reservoir simulators. In Fourth International

Forum on Reservoir Simulation (Salzburg, Austria, August 31 - September 4 1992).

[9] Palagi, C., and Aziz, K. The modeling of ow in heterogeneous reservoirs with voronoi

grid. In SPE Symposium on Reservoir Simulation (New Orleans, Feb. 28 - March 3 1993).

[10] Pettersen, O. The Gullfaks eld A modelling challenge. In Fourth International Forum

on Reservoir Simulation (Salzburg, Austria, August 31 - September 4 1992).

[11] Verma, S., and Aziz, K. FLEX: An object-oriented reservoir simulator. In the Petroleum

Computer Conference (Dallas, Texas, 1996).

[12] Verma, S., and Aziz, K. Two- and three-dimensional exible grids for reservoir simula-

tion. In ECMOR 5 (Leobon, Austria, 1996).

23

Vous aimerez peut-être aussi

- Pressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationD'EverandPressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationÉvaluation : 2 sur 5 étoiles2/5 (1)

- Heriot - Watt University - Production Technology IDocument476 pagesHeriot - Watt University - Production Technology IBrahim Letaief75% (12)

- Working Guide to Reservoir Rock Properties and Fluid FlowD'EverandWorking Guide to Reservoir Rock Properties and Fluid FlowÉvaluation : 3 sur 5 étoiles3/5 (1)

- Reservoir SimulationDocument487 pagesReservoir SimulationAbhinav Shahi100% (2)

- ResSimExam ComboDocument79 pagesResSimExam ComboMary BeachPas encore d'évaluation

- Petroleum Reservoir Simulation: The Engineering ApproachD'EverandPetroleum Reservoir Simulation: The Engineering ApproachPas encore d'évaluation

- Eclipse Tutorial1Document7 pagesEclipse Tutorial1louis75% (4)

- History Matching a Full Field Reservoir Simulation ModelDocument238 pagesHistory Matching a Full Field Reservoir Simulation ModelPercival Wulfric BrianPas encore d'évaluation

- Waterflooding Using EclipseDocument18 pagesWaterflooding Using EclipseAakriti BhandariPas encore d'évaluation

- Reservoir Simulation History Matching and ForecastingDocument60 pagesReservoir Simulation History Matching and ForecastingnoorPas encore d'évaluation

- Modern Chemical Enhanced Oil Recovery: Theory and PracticeD'EverandModern Chemical Enhanced Oil Recovery: Theory and PracticeÉvaluation : 4 sur 5 étoiles4/5 (2)

- Linear Displacement Effficiency - in Waterflooding (Compatibility Mode)Document96 pagesLinear Displacement Effficiency - in Waterflooding (Compatibility Mode)Hu Kocabas100% (2)

- Introduction To Reservoir EngineeringDocument28 pagesIntroduction To Reservoir EngineeringChijioke Zion OkabiePas encore d'évaluation

- HW3 SolutionDocument5 pagesHW3 SolutionMohammad Iqbal Mahamad Amir100% (4)

- PVT Property Correlations: Selection and EstimationD'EverandPVT Property Correlations: Selection and EstimationÉvaluation : 5 sur 5 étoiles5/5 (1)

- Reservoir Performance Prediction Using MBAL SoftwareDocument77 pagesReservoir Performance Prediction Using MBAL SoftwareRoss Waring100% (2)

- Reservoir Modeling For Simulation PurposesDocument7 pagesReservoir Modeling For Simulation PurposesPradityan Febri YudhistiraPas encore d'évaluation

- A Practical Companion to Reservoir StimulationD'EverandA Practical Companion to Reservoir StimulationÉvaluation : 5 sur 5 étoiles5/5 (1)

- Dynamic Reservoir Simulation of The Alwyn Field Using Eclipse.Document108 pagesDynamic Reservoir Simulation of The Alwyn Field Using Eclipse.nwosu_dixonPas encore d'évaluation

- Advanced Production Decline Analysis and ApplicationD'EverandAdvanced Production Decline Analysis and ApplicationÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Eclipse Tutorial 2 Jan 2018Document10 pagesEclipse Tutorial 2 Jan 2018Konul AlizadehPas encore d'évaluation

- Key concepts and properties of oil and gas reservoirsDocument164 pagesKey concepts and properties of oil and gas reservoirsPhong NguyenPas encore d'évaluation

- Streamline Numerical Well Test Interpretation: Theory and MethodD'EverandStreamline Numerical Well Test Interpretation: Theory and MethodPas encore d'évaluation

- Reservoir Simulation and ECLISPEDocument78 pagesReservoir Simulation and ECLISPEAlesa Acosta Jara50% (2)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesD'EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesÉvaluation : 5 sur 5 étoiles5/5 (7)

- Principles of Transient Testing: 1.1.1 Description of A Well TestDocument23 pagesPrinciples of Transient Testing: 1.1.1 Description of A Well TestEdgar Chiquito100% (3)

- Integrated Reservoir Asset Management: Principles and Best PracticesD'EverandIntegrated Reservoir Asset Management: Principles and Best PracticesÉvaluation : 4 sur 5 étoiles4/5 (4)

- Water Influx Models ExplainedDocument43 pagesWater Influx Models Explainedlee100% (1)

- Well Test Analysis for Fractured Reservoir EvaluationD'EverandWell Test Analysis for Fractured Reservoir EvaluationÉvaluation : 5 sur 5 étoiles5/5 (1)

- School of Energy, Geoscience, Infrastructure & Society: Time Zone 1Document17 pagesSchool of Energy, Geoscience, Infrastructure & Society: Time Zone 1Guluzada Ulvi100% (1)

- Dynamic Well Testing in Petroleum Exploration and DevelopmentD'EverandDynamic Well Testing in Petroleum Exploration and DevelopmentPas encore d'évaluation

- CH - 2 Pressure Buildup Tests PDFDocument68 pagesCH - 2 Pressure Buildup Tests PDFMohannad Abdulrahman75% (4)

- Stratigraphic reservoir characterization for petroleum geologists, geophysicists, and engineersD'EverandStratigraphic reservoir characterization for petroleum geologists, geophysicists, and engineersPas encore d'évaluation

- Wellbore Storage Effects on Pressure Transient AnalysisDocument6 pagesWellbore Storage Effects on Pressure Transient AnalysisVictor Fernandez0% (1)

- Practical Petroleum Geochemistry for Exploration and ProductionD'EverandPractical Petroleum Geochemistry for Exploration and ProductionPas encore d'évaluation

- PVTP Complete PDFDocument778 pagesPVTP Complete PDFojrfgmrfPas encore d'évaluation

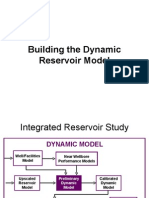

- Building the Dynamic Reservoir ModelDocument80 pagesBuilding the Dynamic Reservoir Model조호범Pas encore d'évaluation

- Hydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesD'EverandHydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesPas encore d'évaluation

- Reservoir Engineering NotesDocument270 pagesReservoir Engineering Notesimogen200780% (15)

- Reservoir CharacterizationD'EverandReservoir CharacterizationLarry LakeÉvaluation : 4 sur 5 étoiles4/5 (3)

- Reservoir SimDocument39 pagesReservoir SimsereptPas encore d'évaluation

- Calibrating Dynamic Models with History MatchingDocument42 pagesCalibrating Dynamic Models with History Matchingali100% (1)

- The Practice of Reservoir Engineering (Revised Edition)D'EverandThe Practice of Reservoir Engineering (Revised Edition)Évaluation : 5 sur 5 étoiles5/5 (3)

- Intro To FDP Project v2Document11 pagesIntro To FDP Project v2AndréPatrícioPas encore d'évaluation

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Reservoir ManagementDocument136 pagesReservoir ManagementDJou DiPas encore d'évaluation

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeD'EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeÉvaluation : 4 sur 5 étoiles4/5 (2)

- Fundamentals of Basic Reservoir Engineering 2010Document293 pagesFundamentals of Basic Reservoir Engineering 2010jollyrex92% (12)

- Reservoir Petrophysics Class NotesDocument223 pagesReservoir Petrophysics Class Notesginozky86% (7)

- Exercise of Analysis/Calculation of Water Availability and Water DemandDocument22 pagesExercise of Analysis/Calculation of Water Availability and Water DemandagusnurcahyoPas encore d'évaluation

- Konsumsi Energi dan Dampak Lingkungan dari Selubung BangunanDocument31 pagesKonsumsi Energi dan Dampak Lingkungan dari Selubung BangunanagusnurcahyoPas encore d'évaluation

- Chapter 9 Financial Aspect For Sustainable Rural Electrification IDocument24 pagesChapter 9 Financial Aspect For Sustainable Rural Electrification IagusnurcahyoPas encore d'évaluation

- 13 Measures For Promotion of RuralDocument10 pages13 Measures For Promotion of RuralagusnurcahyoPas encore d'évaluation

- Accident Investigation FormDocument8 pagesAccident Investigation FormagusnurcahyoPas encore d'évaluation

- 005abbreviation (English)Document2 pages005abbreviation (English)agusnurcahyoPas encore d'évaluation

- Wet Gas - Fluid Recombination: SeparatorsDocument11 pagesWet Gas - Fluid Recombination: Separatorsagusnurcahyo100% (1)

- Fire Protection FacilitiesDocument103 pagesFire Protection Facilitiesagusnurcahyo100% (1)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Chapter 09 Construction ManagementDocument7 pagesChapter 09 Construction ManagementagusnurcahyoPas encore d'évaluation

- 12 Technology TransferDocument22 pages12 Technology TransferagusnurcahyoPas encore d'évaluation

- 0011target AreaDocument1 page0011target AreaagusnurcahyoPas encore d'évaluation

- Pb8mat 08 Bahan Manajemen Sumber Daya ManusiaDocument38 pagesPb8mat 08 Bahan Manajemen Sumber Daya ManusiaagusnurcahyoPas encore d'évaluation

- UU 15 TH 85Document39 pagesUU 15 TH 85agusnurcahyoPas encore d'évaluation

- Table of Content Control Panel Crude Oil HeaterDocument1 pageTable of Content Control Panel Crude Oil HeateragusnurcahyoPas encore d'évaluation