Académique Documents

Professionnel Documents

Culture Documents

Abb Special Report 2008-02 38-42

Transféré par

hansamvCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Abb Special Report 2008-02 38-42

Transféré par

hansamvDroits d'auteur :

Formats disponibles

Small footprint,

high performance

Design of an air-insulated switchgear substation based on new technology

Lei Jing, Hans-Erik Olovsson, Jianzhong Fan, Richard Thomas

As cities grow, so does their hunger for electrical power. To achieve

the necessary bulk transmission, the highest voltage level of a citys

power supply is continuously changing: from 110 kV to 220 kV, even

reaching 500 kV in some mega-cities in China and other countries.

This calls for extra-high-voltage (EHV) substations to act as load hubs

in the city. However, such developments lead to a conflict between

substation footprint and power requirement. In general, the higher the

voltage level, the more power a substation handles and the larger the

area it needs. Such demands, however, conflict with typical limita-

tions that are prevalent in city areas. The shortage of land is the most

important among these and the huge investment cost is also a very

serious challenge. Furthermore, as an energy distribution center for

very many people, such a substation must perform with high

reliability and availability. All this underpins the case for a com-

pact substation, featuring reduced customer costs and a

smal l er footpri nt whi l e maintaining high availability.

38 Special Report Dancing with the Dragon

ABB Review

Powering the economy

39 Special Report Dancing with the Dragon

ABB Review

Small footprint, high performance

Powering the economy

load-hub substations located in the

city center. The demand for and value

of land is so high, that any compact

substation solution becomes attractive.

One obvious approach is to use gas-

insulated switchgear (GIS), which

would occupy only 30,000 m

2

for the

same SLD as in

1

[1]. This will, how-

ever, be more costly than air-insulated

substations. According to China State

Grid [1], a GIS substation requires

around 40 percent higher investment.

Therefore, an alternative for the tradi-

tional air-insulated switchgear (AIS)

substation, with less footprint and

customer cost is required.

Safety, environment, and

noise are all factors to be

considered in the approval

of a substation.

The technology solution

Applying new technologies, ABB can

design AIS substations with reduced in-

stallation cost and a smaller footprint.

New circuit breaker

A section view of a 500 kV bay is

shown in

3

. The diagram shows that

the disconnectors take up most of the

space as each circuit breaker needs

two disconnectors for safe isolation.

With the modern and well proven SF

6

circuit breakers (CB) of the self blast

ly to install, not only because of the

large numbers of intelligent electronic

devices (IED) and computers, but due

to the extensive cabling for measure-

ment and control.

However, in an urban substation, the

key factor is land-related cost. The

purchase is an integral part of this

process, but is only the last step. Un-

like general commodities, land cannot

be obtained with money alone. Safety,

environment, and noise are all factors

to be considered in the approval of a

substation. The smaller the plot of

land, the less impact a substation has

on its surroundings.

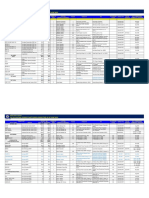

1

shows the single-line diagram (SLD)

of a 500 kV substation [1]. In this sub-

station, there are six 500 kV diameters

(1 circuit breaker scheme) and

twelve 220 kV double busbar bays.

In this substation, all primary equip-

ment is so large that often an area of

60,000 m

2

is used

2

. Obviously, it is

difficult to find a suitable location for

such an installation in the city.

The fast-increasing power demand,

however, makes such substations in-

dispensable. Plans of the Beijing elec-

tric power company see a 500 kV dou-

ble-ring network around the city be-

ing completed in 2010. This will fea-

ture 10 substations (each for 500 kV

and 2600 MW). These include four

T

odays technology is making these

objectives attainable. Firstly, new

primary equipment permits a drastic

reduction in the footprint area. A rev-

olution in circuit-breaker design led

by ABB is allowing switchgear config-

uration or even integration to be rede-

fined, decreasing costs both in terms

of land acquisition and equipment

cost. Secondly, innovative optical sen-

sors are replacing the traditional ex-

pensive and large current transformers

(CT). These non-traditional CTs are so

small that they can be easily integrat-

ed with the breaker in the same cir-

cuit. Thirdly, the use of such sensors

is an integral aspect of a digital sub-

station. This not only enhances sub-

station performance, but also saves on

investment, eg, cables for secondary

instrument transformer circuits and for

the control of circuit breakers, discon-

nectors, and earthing switches.

In an urban substation,

the key factor is

land-related cost.

Traditional air-insulated substations

Utilities must meet huge construction

and installation costs when investing

in a substation. Obviously, primary

equipment, such as transformers and

circuit breakers, are very expensive,

especially when these are for extra

high voltages. Further, the substation

automation system (SAS) is itself cost-

1

Single line diagram (SLD) of a typical 500 kV substation

2

Layout of a typical 500 kV substation using air-insulated switchgear

(AIS)

40 Special Report Dancing with the Dragon

ABB Review

Small footprint, high performance

Powering the economy

locked in the open position, fulfilling

the disconnecting function require-

ment and maintenance on adjacent

parts of the switchgear or network

can be carried out. Further, eliminat-

ing the air-exposed disconnector con-

tacts also provides for lower mainte-

nance and higher switchgear reliabili-

ty. Disconnecting CB requirements are

specified in the IEC standard

62271-108

4

.

With the modern and

well proven SF

6

circuit

breakers of the self blast

and/or puffer type,

ABB now can offer an

alternative that provides

opportunities to both

simplify substations and

save space.

DCBs can save not only equipment

cost, but also reduce the footprint and

related construction costs while in-

creasing availability. A layout compar-

ison between conventional and Com-

bined 145 kV based switchyards is

shown in

5

.

Innovative sensors

Besides the disconnector, the tradi-

tional CT (current transformer) also

occupies a lot of space in

3

. Howev-

er, new sensing technology makes the

alternative solution possible.

4

Disconnecting circuit breakers with two

a

and one

b

breaking chamber

a b

and/or puffer type, ABB now can of-

fer an alternative that provides oppor-

tunities to both simplify substations

and save space. A new disconnecting

circuit breaker (DCB), named Com-

bined, has been developed and man-

ufactured [2]. The disconnection func-

tion for Combined is integrated in the

breaking chamber. There are no addi-

tional contacts or other components

for the disconnecting function in the

SF

6

breaking chamber. When the cir-

cuit breaker contacts are in the open

position, they can be mechanically

5

Space requirement of 145 kV substation (traditional)

a

compared to

the same functionality achieved with the Combined breaker

b

77 m

50 m

4

9

m

5

4

m

a

b

Disconnecting facility, to be used in

case of maintenance or failure of DCB

Disconnecting Circuit Breaker

3

Section view of a 500 kV 1 diameter

41 Special Report Dancing with the Dragon

ABB Review

Small footprint, high performance

Powering the economy

cable is then also replaced by the net-

work, resulting in a more reliable and

cost optimized SA system.

Layout reconfiguration and

optimization

Based on the new technologies above,

the substation footprint can be re-

duced by more than 50 percent, while

at the same time increasing its avail-

ability and reliability.

Using the Faraday Effect,

FOCS can easily measure

the current with a fiber

optic loop placed around

the conductor.

Moreover, the use of DCB not only

permits the disconnector to be elimi-

nated, but also allows the busbar

topo logy to be improved. Since the

maintenance interval for a Combined

DCB is 15 years, the replacement of

double by a sectionalized single bus-

unit, the digital values can be trans-

mitted to bay level IEDs via the fiber

optic network, replacing the large

amount of copper cables. Figure

7a

represents the technical evolution of

SA from Process (bottom ) up to

NCC (top) from conventional (left)

to intelligent (right). Figure

7b

shows

the architecture of IEC 61850 based

SAS, which is the concrete implemen-

tation of the intelligent system in

Figure

7a

. For a three-phase power

line, at least three groups of measur-

ing cables are eliminated with the

intelligent system. Furthermore, as

there is no magnetic saturation in

FOCS, one set of FOCS can be used

for both monitoring and protection,

or even metering. In this way, further

cabling can be saved.

Moreover, if an intelligent breaker

IED, compatible to IEC61850-9-2, is

designed and embedded in the circuit

breaker, the control will use the same

fiber-optic network with current and

voltage sensing function. The control

Innovative sensors are beginning to

replace regular CT in recent years.

Fiber-optic current sensors (FOCS)

present an excellent alternative [3].

Using the Faraday Effect, FOCS can

easily measure the current with a fiber

optic loop placed around the conduc-

tor. The resulting simple installation is

shown in

6

. Another benefit is the

smaller footprint compared to the

large electromagnetic CT.

Additionally, in respect to digital sig-

nal processing, FOCS can interface

with process-level devices in a substa-

tion automation system (SAS). Conse-

quently, the IEC 61850 process bus

(-9-2) concept can be implemented,

reducing need of secondary cabling

and simplifying construction and com-

missioning work.

IEC 61850-9-2 application

As mentioned above, FOCS can trans-

fer all measured values in digital for-

mat.Thus, if a FOCS is applied with

an IEC 61850-9-2 compatible merging

6

ABB FOCS measuring principle

a

, installation

b

, two conventional Hall effect dc current transducers for 400 kA

c

and the measurement coil

d

.

Sensor

electronics

Sensor

fiber cable

Control cubicle (optional)

Sensor head

Current carrying

busbars

Light source, detector,

signal processor

FOCS Controller

Interfaces

ABB PowerLINK

PRFIBUS DP

Analog outputs

Current-

depending

phase shift

Orthogonal linear

light waves

y

x

Retarder

Mirror

Optical Fiber

Left and right

circular light

waves

Sensing Fiber

Current

conductor

y

x

F

a b

d c

42 Special Report Dancing with the Dragon

ABB Review

Small footprint, high performance

Powering the economy

Lei Jing

ABB Corporate Research

Beijing, China

lei.jing@cn.abb.com

Hans-Erik Olovsson

ABB Power Systems

Vsters, Sweden

hans-erik.olovsson@se.abb.com

Jianzhong Fan

ABB Power Systems, HVDC

Beijing, China

john-jianzhong.fan@cn.abb.com

Richard Thomas

ABB Power Products

Ludvika, Sweden

richard.thomas@se.abb.com

References

[1] 500 kV Substation Typical Design, China State

Grid

[2] DCB Buyers and Application Guide, ABB

[3] Bohnert, K., Guggenbach, P. A revolution in high

dc current measurement. ABB Review 1/2005,

610.

bar system is justified without avail-

ability being compromised. Compar-

ing the layouts in

8

and

9

, it can be

seen how busbar and related discon-

nectors are eliminated, simplifying

the layout.

The use of a combined

disconnecting circuit

breaker as primary

equipment opens the

opportunity for greatly

improved efficiency in

substation construction,

operation and layout.

In addition, because FOCS and an

intelligent interface are used, the

cable and related auxiliaries can

be done away with, resulting in a

much simplified control setup and

simplifying connections to the

primary equipment.

8

Traditional switchgear layout with disconnectors and circuit breakers

Line Line

132 kV

Transformer Transformer

9

Switchgear with disconnecting circuit breakers (DCB)

Line Line

132 kV

Transformer Transformer

7

Digital substation configuration

Switching ahead

An air insulated substation can be

designed to be more reliable and cost

efficient by introducing new equip-

ment and technologies. The use of a

combined disconnecting circuit break-

er as primary equipment opens the

opportunity for greatly improved

efficiency in substation construction,

operation and layout. The innovative

current sensor together with an intelli-

gent interface enables the implemen-

tation of the IEC 61850-based process

bus protocol.

a

SAS evolution

Technology Overview

conventional modern intelligent

Network level

Station level

Bay level

Process level

modern

(retrofit)

intelligent

(retrofit)

parallel,

hartwired

caling

parallel,

hartwired

caling

parallel,

hartwired

caling

Process

bus

Interbay

bus

Interbay

bus

Station

bus

Station

bus

RTU RTU RTU

RTU RTU RTU

b

IEC 61850 based SAS

Cigre 2008 ABB Substation

Automation

IEC61850 based SA-System

MicroSCADA

RTU560

REL670

REC670

REF615

SCADA

EMS

DMS

Bay control

IEC 61850-8-1

IEC 61850-9-2

Station

computer

and HMI

RTU

380 kV

feeder

terminal

MUP

gateway

20 kV

Bay protection

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- White PaperDocument16 pagesWhite PaperhansamvPas encore d'évaluation

- SG5 Power Switch Gears AssembliesDocument13 pagesSG5 Power Switch Gears AssemblieshansamvPas encore d'évaluation

- SPCS Order 758 Sudden Pressure Report Final 02132014 PDFDocument34 pagesSPCS Order 758 Sudden Pressure Report Final 02132014 PDFhansamvPas encore d'évaluation

- Nema Ics 6Document24 pagesNema Ics 6hansamv100% (1)

- Iec60364 PDFDocument105 pagesIec60364 PDFMircea Murar60% (5)

- Stds 19 0004 00 PUBS 3002 8Document79 pagesStds 19 0004 00 PUBS 3002 8Leander ChuaPas encore d'évaluation

- PhotoDocument1 pagePhotohansamvPas encore d'évaluation

- TextDocument2 pagesTexthansamvPas encore d'évaluation

- C57 19 100 1995 PDFDocument30 pagesC57 19 100 1995 PDFhansamvPas encore d'évaluation

- PAGASADocument1 pagePAGASAhansamvPas encore d'évaluation

- Luzon Committed 2019 Jan DecemberDocument7 pagesLuzon Committed 2019 Jan DecemberhansamvPas encore d'évaluation

- Solar TechDocument31 pagesSolar TechhansamvPas encore d'évaluation

- Eliminate Problematic and Momentary Relay Actions: Qualitrol 909Document4 pagesEliminate Problematic and Momentary Relay Actions: Qualitrol 909AbdulJabbarSethar50% (2)

- Buy AirPods With Wireless Charging Case - Apple (PH)Document1 pageBuy AirPods With Wireless Charging Case - Apple (PH)hansamvPas encore d'évaluation

- Solar TechDocument31 pagesSolar TechhansamvPas encore d'évaluation

- Write Up 2 AttachmentDocument2 pagesWrite Up 2 AttachmenthansamvPas encore d'évaluation

- PhotoDocument1 pagePhotohansamvPas encore d'évaluation

- Ansi C 119.4 PDFDocument28 pagesAnsi C 119.4 PDFIngJGMPas encore d'évaluation

- White PaperDocument16 pagesWhite PaperhansamvPas encore d'évaluation

- Battery Room Ventilation and SafetyDocument62 pagesBattery Room Ventilation and SafetyingatvPas encore d'évaluation

- SPCS Order 758 Sudden Pressure Report Final 02132014 PDFDocument34 pagesSPCS Order 758 Sudden Pressure Report Final 02132014 PDFhansamvPas encore d'évaluation

- SPCS Order 758 Sudden Pressure Report Final 02132014 PDFDocument34 pagesSPCS Order 758 Sudden Pressure Report Final 02132014 PDFhansamvPas encore d'évaluation

- Development of Natural EsterDocument15 pagesDevelopment of Natural Esterrdwchy100% (1)

- Luzon Committed Oct 2018Document6 pagesLuzon Committed Oct 2018hansamvPas encore d'évaluation

- Ansi C 119.4 PDFDocument28 pagesAnsi C 119.4 PDFIngJGMPas encore d'évaluation

- PGC Inquiries Chapter 7 Grid ProtectionDocument7 pagesPGC Inquiries Chapter 7 Grid ProtectionhansamvPas encore d'évaluation

- Appendixe 1 STR 1386 TestsDocument7 pagesAppendixe 1 STR 1386 TestshansamvPas encore d'évaluation

- Mercalco PDFDocument33 pagesMercalco PDFBethylGoPas encore d'évaluation

- Itce16 Mohammad TariqDocument41 pagesItce16 Mohammad TariqhansamvPas encore d'évaluation

- List of Existing Power Plants (Grid-Connected) As of June 2019Document5 pagesList of Existing Power Plants (Grid-Connected) As of June 2019hansamvPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chapter No 3 GASES TEXTBOOK EXERCISEDocument21 pagesChapter No 3 GASES TEXTBOOK EXERCISErehmanPas encore d'évaluation

- Cleaning Validation MACO Swab Rinse Ovais v1.1Document8 pagesCleaning Validation MACO Swab Rinse Ovais v1.1Mit PatelPas encore d'évaluation

- Crowd Synchrony On The Millennium Bridge: Nature December 2005Document3 pagesCrowd Synchrony On The Millennium Bridge: Nature December 2005Tito MudanyePas encore d'évaluation

- Chemistry ReportDocument7 pagesChemistry ReportAlasdair McFadzeanPas encore d'évaluation

- Circuit Theory - Test PaperDocument3 pagesCircuit Theory - Test PapersvkchaudhuriPas encore d'évaluation

- J. William Helton, Orlando Merino (Author) - Classical Control Using H-Infinity Methods - Theory, Optimization and Design (Society For Industrial Mathematics, 1998,0898714192)Document309 pagesJ. William Helton, Orlando Merino (Author) - Classical Control Using H-Infinity Methods - Theory, Optimization and Design (Society For Industrial Mathematics, 1998,0898714192)Hipólito AguilarPas encore d'évaluation

- Nebular Theory WsDocument5 pagesNebular Theory WsSheila MaliitPas encore d'évaluation

- Afd 082516 33 1 37 1 PDFDocument74 pagesAfd 082516 33 1 37 1 PDFToots PomperadaPas encore d'évaluation

- Unit 2 - EntropyDocument37 pagesUnit 2 - EntropyDeepank SachdevPas encore d'évaluation

- 4K410 - Exercises 2014-2015Document17 pages4K410 - Exercises 2014-2015Abhishek SharmaPas encore d'évaluation

- Algebra Cheat Sheet: Basic Properties & FactsDocument4 pagesAlgebra Cheat Sheet: Basic Properties & FactsAnonymous wTQriXbYt9Pas encore d'évaluation

- AcidBase Equilibrium WorksheetDocument4 pagesAcidBase Equilibrium WorksheetAmirah SyahirahPas encore d'évaluation

- Blender Art - 15 - March 2008Document75 pagesBlender Art - 15 - March 2008blackcougar100% (18)

- Scalar Energy - A Completely New World Is Possible - Bill MorganDocument4 pagesScalar Energy - A Completely New World Is Possible - Bill MorganEverest DnmsPas encore d'évaluation

- Spreadsheets To BS 8110: Single Column BaseDocument25 pagesSpreadsheets To BS 8110: Single Column BaseIr Ahmad AfiqPas encore d'évaluation

- Isotropichardening UMATDocument16 pagesIsotropichardening UMATMAIKEL ANDRES VINCES MENDOZAPas encore d'évaluation

- Sections 4.6 - 4.7 Momentum Equation For Control Volume With Arbitrary Acceleration 4.7 The Angular-Momentum PrincipleDocument10 pagesSections 4.6 - 4.7 Momentum Equation For Control Volume With Arbitrary Acceleration 4.7 The Angular-Momentum Principlepackman465100% (1)

- The Celestial Sphere: Ecliptic and EquatorDocument4 pagesThe Celestial Sphere: Ecliptic and Equatorxlearner100% (1)

- Journal 2Document10 pagesJournal 2Ajay kPas encore d'évaluation

- Filter Media Analysis FinalDocument6 pagesFilter Media Analysis Finalziko23Pas encore d'évaluation

- Underbalanced Drilling in ShaleDocument19 pagesUnderbalanced Drilling in ShaleKarwan IbrahimPas encore d'évaluation

- Pourjafari ResumeDocument2 pagesPourjafari ResumebahmanPas encore d'évaluation

- Earthquak Analysis in AnsysDocument14 pagesEarthquak Analysis in AnsysIgor GjorgjievPas encore d'évaluation

- Properties of Water at Home LabDocument5 pagesProperties of Water at Home Labkim_peplerPas encore d'évaluation

- Thermodynamics & Heat Engines: Basic ConceptsDocument28 pagesThermodynamics & Heat Engines: Basic ConceptsTHEOPHILUS ATO FLETCHERPas encore d'évaluation

- Heat and Mass Transfer: Fundamentals & Applications: Errata SheetDocument3 pagesHeat and Mass Transfer: Fundamentals & Applications: Errata SheetYamaneko ShinPas encore d'évaluation

- Lecture 02 Energy-Rayleigh-Ritz 2015Document40 pagesLecture 02 Energy-Rayleigh-Ritz 2015Mustapha BelloPas encore d'évaluation

- Seismic Data Analysis-NewDocument77 pagesSeismic Data Analysis-NewsrujjjnPas encore d'évaluation

- 04 N Wave InterfereDocument5 pages04 N Wave InterfereVina PermatasariPas encore d'évaluation