Académique Documents

Professionnel Documents

Culture Documents

Manual La The Procedure

Transféré par

Donovan BonnerTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manual La The Procedure

Transféré par

Donovan BonnerDroits d'auteur :

Formats disponibles

STANDARD OPERATING PROCEDURE

1/2

MANUAL LATHE PROCEDURE

MANUAL LATHE PROCEDURE

A. SAFETY

1. Wear personal protective equipment.

Use a face shield where flying chips are present or a chuck shield if equipped

with one.

Wear rubber gloves when working with coolant.

2. Remove the chuck wrench immediately after adjusting the chuck.

3. Make sure the forward/ reverse lever is fully disengaged before using the chuck

wrench.

4. Always let the chuck come to a complete stop before touching the part or the chuck.

5. If in some instances flying chips are unavoidable, please use a curtain to prevent

other operators from being subjected to burns, etc.

6. Be very careful while filing, emerying and when using a deburring tool.

7. Do not operate the lathe wearing loose clothing, finger rings or other jewelry. Long

hair must be tied up or tucked under the hard-hat.

8. Never attempt to remove chips by hand, turn off the lathe and use a chip hook or a

brush.

9. Never polish a part with emery cloth wrapped around your hand, hold the emery cloth

using your thumb and forefinger only.

10. When emerying a threaded part use a course grit sandpaper to minimize the surface

to surface contact, which will reduce the tendency for the emery cloth to want to grab.

11. When changing or inverting secondary jaws

Inspect the condition of the bolts- if they are not in good condition they must

be replaced.

Inspect internal and external threads

Inspect all mating surfaces for wear burrs etc.

12. When re-installing the secondary jaws (soft jaws) you must torque the cap

screws.

The following are recommended torque specs for 3/8; 1/2 alloy cap screws.

3/8x 24TPI, max 50 ft/lbs.

x20TPI, max 120 ft/lbs.

STANDARD OPERATING PROCEDURE

2/2

MANUAL LATHE PROCEDURE

B. OPERATING

1. Ensure the main power is turned off when doing Total Preventive Maintenance.

2. Know where the emergency stop button is located on your machine before operating.

3. Practice good house keeping, return tools to the proper location after use.

4. Try to eliminate long, stringy chips when machining as they can be easily caught up in

the chuck and cause personal injury, always exercise proper chip control.

5. Know machine speeds and feeds, if you are unsure please ask your supervisor.

6. Make sure cutting tools are used properly and for their intended application.

7. Do not try and fix the machine if there is a problem, ask your supervisor to contact

plant maintenance.

8. Ensure that auto stops are set before starting a job. Make sure cutting tools are

centered and securely fastened.

9. Ensure the lathe you operate and tooling is used with respect at all times.

10. Never use compressed air to clean the lathe, as small particles may become

embedded into parts of the machine causing damage, use a soft bristle brush.

11. Never leave a running (spindle turning) lathe unattended.

Vous aimerez peut-être aussi

- IOM-P14-R0 Quarter Turn BVDocument9 pagesIOM-P14-R0 Quarter Turn BVDonovan BonnerPas encore d'évaluation

- Generon CatalogDocument11 pagesGeneron CatalogDonovan BonnerPas encore d'évaluation

- Kgec ProfileDocument11 pagesKgec ProfileDonovan BonnerPas encore d'évaluation

- Iso9001 Manual With ProcedureDocument105 pagesIso9001 Manual With ProcedureAshwin KumarPas encore d'évaluation

- 1156 - India - BGAS CSWIP Painting Inspector Grade 2 - High Res - Feb 2012Document1 page1156 - India - BGAS CSWIP Painting Inspector Grade 2 - High Res - Feb 2012Sampath KumarPas encore d'évaluation

- 1165 - India - BGAS CSWIP Painting Inspector Grade 1 - High Res - Feb 2012Document1 page1165 - India - BGAS CSWIP Painting Inspector Grade 1 - High Res - Feb 2012Donovan BonnerPas encore d'évaluation

- Review of ISO 17021 V2Document5 pagesReview of ISO 17021 V2Donovan BonnerPas encore d'évaluation

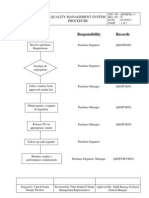

- Process Responsibility Records: Quality Management System ProcedureDocument1 pageProcess Responsibility Records: Quality Management System ProcedureDonovan BonnerPas encore d'évaluation

- Autocad2007 Crack NotesDocument1 pageAutocad2007 Crack NotesDonovan BonnerPas encore d'évaluation

- Training Record (AAR 01)Document1 pageTraining Record (AAR 01)Donovan BonnerPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Bondek User GuideDocument0 pageBondek User GuidemarioxguzmanPas encore d'évaluation

- 10-Hydrotesting of Soluforce Pipe SystemsDocument9 pages10-Hydrotesting of Soluforce Pipe SystemsEl hadi BouasriaPas encore d'évaluation

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajPas encore d'évaluation

- Workshop Manual - Daihatsu 3 Cyl 993cc Wiring DiagramDocument41 pagesWorkshop Manual - Daihatsu 3 Cyl 993cc Wiring Diagramโจ้ สแปร์แร็ค80% (5)

- RI 4 Defect CausesDocument50 pagesRI 4 Defect CausesSathishkumar Srinivasan100% (1)

- Site Observation ReportDocument8 pagesSite Observation ReportLUKE HUNGWEPas encore d'évaluation

- Advanced Planning and SchedulingDocument7 pagesAdvanced Planning and Schedulingsheebakbs5144100% (1)

- ARB220CW Tech SheetDocument2 pagesARB220CW Tech SheetJohn TrippPas encore d'évaluation

- 24 - 25 PF Furnace'12Document5 pages24 - 25 PF Furnace'12DSGPas encore d'évaluation

- Belt Conveyor Assembly HandbookDocument51 pagesBelt Conveyor Assembly HandbookJong Java100% (1)

- February 9 - Dynatrol CorporationDocument4 pagesFebruary 9 - Dynatrol CorporationClaire KroppPas encore d'évaluation

- 200clc, 230clc, and 270clc Repair Tm1931Document408 pages200clc, 230clc, and 270clc Repair Tm1931Rogelio Hernandez Garcia89% (18)

- TeflonDocument1 pageTeflonSanthosh KumarPas encore d'évaluation

- C El 115 PDFDocument23 pagesC El 115 PDFamini_mohiPas encore d'évaluation

- Nanobiochar and Biochar Based NanocompositesDocument12 pagesNanobiochar and Biochar Based NanocompositesJaini FakhrudinPas encore d'évaluation

- Flowserve Durco CatalogDocument36 pagesFlowserve Durco CatalogbryandownPas encore d'évaluation

- PuneDocument564 pagesPuneANSHUMANPas encore d'évaluation

- Lab Report#01: Safety Guidelines and Introduction To Manufacturing Processes LabDocument3 pagesLab Report#01: Safety Guidelines and Introduction To Manufacturing Processes LabMuhammad Owais AwanPas encore d'évaluation

- Ueg 36Document2 pagesUeg 36PRADO_COMETA50% (2)

- III-1 & III-2 Specifications Volume 2Document588 pagesIII-1 & III-2 Specifications Volume 2saleem buksh100% (1)

- Worm Gear OilDocument2 pagesWorm Gear OilDavidPas encore d'évaluation

- MICODocument4 pagesMICOmaniamsonPas encore d'évaluation

- PROSEDUR REFRIGERANT QUALITY GUIDANCE-Flame TestDocument2 pagesPROSEDUR REFRIGERANT QUALITY GUIDANCE-Flame TestAnonymous DFoXVEHIPas encore d'évaluation

- 6 - Baker Hughes - Glen BengeDocument21 pages6 - Baker Hughes - Glen BengegeosedPas encore d'évaluation

- Transmission Control Valve: Operación de SistemasDocument11 pagesTransmission Control Valve: Operación de Sistemasgalvis1020100% (1)

- Acroni PDFDocument15 pagesAcroni PDFIgor GrujićPas encore d'évaluation

- Pharm. LinimentsDocument38 pagesPharm. LinimentsDr-Md Abul BarkatPas encore d'évaluation

- Zinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsDocument4 pagesZinc and Tin Alloy Wire Used in Thermal Spraying For Electronic ApplicationsBang AnPas encore d'évaluation

- General Motion Control: A Complete Range of Motion Products For Efficient Machine AutomationDocument47 pagesGeneral Motion Control: A Complete Range of Motion Products For Efficient Machine AutomationDan PopescuPas encore d'évaluation

- Secadores KaeserDocument13 pagesSecadores KaeserDiego Laya PicadoPas encore d'évaluation