Académique Documents

Professionnel Documents

Culture Documents

Paper Stock Pumping

Transféré par

Jery Indra Putra HarianjaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Paper Stock Pumping

Transféré par

Jery Indra Putra HarianjaDroits d'auteur :

Formats disponibles

Paper St oc k Pumpi ng

Paper Stock has characteristics that make it more difficult to handle than water. These are:

Fiber length

Freeness (tendency to dewater)

Degree of agitation

Entrained air

Consistency of the stock

Broke Service

Broke service pumps in the standby mode must operate at relatively low flow with a throttle discharge.

At the time of the break, the pump must rapidly remove the broke to a broke storage area for

reprocessing. These wide flow swings create heavy mechanical loads that must be taken into account

when selecting the pump.

Some mills use a two-pump system, with the smaller pump (called the trim pump) handles the low flow

and the low head recirculation requirements of the hydropulper. The second pump (broke transfer)

comes on-line when there is a break in the sheet. This pump transfers the broke at high flow rates and

high heads to the broke storage area.

Centrifugal Cleaner Service

Due to the nature of the cleaner process, the pumps installed in the various stages are subjected to

abrasive operating conditions. The stock consistency is 0.5% or higher.

Pumps feeding the primary and secondary bank of cleaners can be either end suction or double suction.

Tertiary cleaner pump should always be end suction pumps in 316ss or CD4 materials. The open

impellers are well suited to handle the high amount of debris and abrasives present in the tertiary and

higher stages. The open impeller provides much longer service life that enclosed impellers.

Shower Service

Some of the paper machine shower services are felt, wire, trim, and knock-off. They require generation

of high pressures at flow rates varying form only a few gpm to 700-800 gpm. Generally single or multi-

stage pumps are used operating at two pole speeds. Pitot tube pumps are also used for this service.

The stuffing box pressures of these pumps are well above 50 psig, so mechanical seals or metallic

packings are required.

Coating Applications

Clay slurries, normally around 70% solids, have dilatants shear characteristics. That means the viscosity

of these slurries increases with increasing shear rates. If we operated an end suction pump with the

standard clearances (0.015 inches between the impeller and casing) the clay would solidify and stall the

pump. Typically, extra clearances are provided on both the front and back of the impeller. This is

usually achieved by machining off the face of the impeller to increase the clearances of the pump. Due

to the increased clearance inside the pump, the impeller and motor have to be oversized to compensate

for the pumps loss of efficiency.

Coating slurries, such as titanium dioxide, calcium carbonate, calcium stearate, and cooked starch

present their own special sets of pumps problems.

Calcium carbonate & Cooked Starch solutions can be handled like water

Calcium stearate at 70% exhibits a viscosity of 300 500 SSU

Viscosity is higher when the slurry flows through the pipe than when the slurry flows through a

pump. Conventional performance corrections for viscosity are used for these services.

The pump materials are 316SS and Alloy 20 where the coating slurries are treated with

sulphuric acid.

Many mills presently use progressive cavity, rotary piston, and gear pumps are used for these services

since these pumps exhibit lower shear rates, and require less suction head.

Black Liquor

Recovery and evaporator sections handling black liquor present many difficult pulp mill applications.

Weak black liquor (10-20% solids) is easily handled with no requirement for viscous correction.

Above 50%, a viscosity correction becomes necessary. Typical viscosities are 100-300 centipoises

depending on the temperature of the black liquor. The higher the temperature, the lower the viscosity.

When the solids are above 35%, all 316SS or CD4 construction is used.

Bleach Plant Services

These services present a challenge when is comes to corrosion. Various chemical services require pump

constructed of 316SS or 317SS stainless steel to titanium. When chlorine dioxide is present the

minimum material is 317SS. For chlorine dioxide with large amounts of free chlorine present, or for

calcium and sodium hypochlorite applications, titanium is preferred. Hastelloy B & C are not often

utilized in bleach plants because 317SS can be used at much lower cost.

Recovery Area Services

Green liquor, white liquor, and lime mud services usually involve abrasive solids that have a dramatic

effect on the pump life. Green liquor in particular is abrasive due to the inert materials left after burning.

White liquor is also considered abrasive. Clarified white liquor is less abrasive.

End suction pumps in minimum 316SS material are required for these services. CD4 is proven to be

more suitable for green liquor, white liquor, and lime mud services.

If these pumps are oversized, then there will be increased internal recirculation, which causes

accelerated wear and higher stuffing box pressures.

Concentric casings are less susceptible to this type of wear.

Rubber and hypalon lined pump are use for these services.

Digester Recirculation

Digester recirculation pumps are subjected to severe temperature and pressure swings. Thermal

expansion of the piping in such applications can cause severe loads to be placed on the pump casing. On

batch services the pump must come up to service temperature and pressure and then cool down between

batches. Because of the pressures and temperatures encountered, 300 lb pipe flange ratings are normally

used. To withstand the extreme pipe loads, pumps with spring-mounted baseplates are often utilized.

The spring mounting allows the pipe to move in horizontal and vertical planes without imposing

excessive flange loads on the pump.

Special packing or mechanical seals are usually required due to the high suction pressures found

throughout typical systems. In addition, the use of pressurized stuffing boxes is common due to the need

for preventing the abrasive pumpage from entering the stuffing box.

Fan Pump

This is the critical pump for the paper machine, in its achievement of high paper quality. This pump

today is driven by variable speed systems, rather than constant speed drives which require throttling

valves, and recirculation lines.

With the movement to larger machines and higher speeds it is critical that the suction piping and

discharge piping be closely analyzed.

Tangential inlets on the side of suction transition pieces tend to create very poor flow distribution to

both sides of the fan pump impeller. Therefore, recirculation and stock entries on the vertical centerline

are more desirable. Even more desirable is the dumping of the stock recirculation lines back into the

wire pit rather than into the suction piping.

Double suction pumps with impellers having split, staggered, and skewed vanes have long been

recognized as the most common pump for fan pump service. Todays current trends are pump with

casings and rotating elements of 316SS, especially for fine paper machines. Improved casting methods

have reduced pulsations.

It is extremely important that entrained air be eliminated on this service. Entrained air can cause

operational problems such as air binding, or inconsistencies in process flow resulting in line formation

on the sheet. Entrained air can also retard drainage, and therefore requiring slower machine speeds. Care

must be made to submerge the suction line so that vortexing does not occur. Also there should never be

any pockets that allow air to collect in the suction line. Furthermore, on pumps that are not top centerline

discharge models, so provision should be made for venting air that collects at the top of the casing.

LaBour Pump Company 901 Ravenwood Drive, Selma, Alabama 36701

Ph: (317) 924-7384 - Fax: (317) 920-6605 - www.labourtaber.com

A Product of Peerless Pump Company Copyright 2005 Peerless Pump Company

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Journal of Controlled Release: Alexander Wei, Jonathan G. Mehtala, Anil K. PatriDocument11 pagesJournal of Controlled Release: Alexander Wei, Jonathan G. Mehtala, Anil K. Patriprakush_prakushPas encore d'évaluation

- Chapter 2-The Column in GCDocument92 pagesChapter 2-The Column in GCkhanhvan2105Pas encore d'évaluation

- Astm 505M 12Document10 pagesAstm 505M 12Alan Isai Valdez CastrejónPas encore d'évaluation

- Nust ChemistryDocument137 pagesNust Chemistryahmed ilyasPas encore d'évaluation

- PCR Guided Notes AfterDocument2 pagesPCR Guided Notes Afterjbhuffman75Pas encore d'évaluation

- E.O.Paton Electric Welding Institute Activity in The FieldDocument10 pagesE.O.Paton Electric Welding Institute Activity in The FieldMaksimovPas encore d'évaluation

- Membrane EngDocument5 pagesMembrane EngMeirbekPas encore d'évaluation

- Genie: Hot Water Driven Vapor Absorption MachineDocument39 pagesGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyPas encore d'évaluation

- Raphex-2009pdf PDFDocument29 pagesRaphex-2009pdf PDFjoe jonesPas encore d'évaluation

- Sludge Dewatering PDFDocument36 pagesSludge Dewatering PDFPaul Maposa100% (2)

- Increase Gas Production 10%-40% with Jet PumpDocument2 pagesIncrease Gas Production 10%-40% with Jet Pumppolaris44Pas encore d'évaluation

- FTIR Analysis of Rapeseed Oil and Biodiesel Methyl EstersDocument2 pagesFTIR Analysis of Rapeseed Oil and Biodiesel Methyl Estersrgx1120% (1)

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocument7 pagesFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuPas encore d'évaluation

- S1 2016 330961 BibliographyDocument6 pagesS1 2016 330961 BibliographyVelda KartikaswastiPas encore d'évaluation

- Year 8 Science End of Term 1 Test: AnswerDocument11 pagesYear 8 Science End of Term 1 Test: Answerchan myaePas encore d'évaluation

- DEP 39011012 - Inf - 2018-02 - A01Document67 pagesDEP 39011012 - Inf - 2018-02 - A01g_325899365Pas encore d'évaluation

- Chemical NomenclatureDocument7 pagesChemical NomenclatureKeith Lavin100% (1)

- Nova Hunting The Elements Video GuideDocument3 pagesNova Hunting The Elements Video GuideJaclyn Dugger100% (1)

- Organic Chemistry Carbonyl CompoundsDocument34 pagesOrganic Chemistry Carbonyl CompoundsLovely Joysweet100% (2)

- Steel Forgings, Carbon and Alloy, For General Industrial UseDocument10 pagesSteel Forgings, Carbon and Alloy, For General Industrial UseRed RedPas encore d'évaluation

- Class11 - Environmental ChemistryDocument3 pagesClass11 - Environmental Chemistryh_fazilPas encore d'évaluation

- AKP123Document70 pagesAKP123goswamiphotostatPas encore d'évaluation

- Pta Petrochemical ProcessDocument27 pagesPta Petrochemical ProcessMugiiz BhattiPas encore d'évaluation

- Canadian Coast Guard Welding SpecificationDocument39 pagesCanadian Coast Guard Welding Specificationalvin dueyPas encore d'évaluation

- Matriculation Chemistry (Reaction Kinetics) Part 1Document13 pagesMatriculation Chemistry (Reaction Kinetics) Part 1ridwan100% (2)

- Chemical Operations Safety AuditDocument4 pagesChemical Operations Safety AuditDinda Naiya AzhariPas encore d'évaluation

- Appendix A & CDocument7 pagesAppendix A & CAmr HeshamPas encore d'évaluation

- Chapter 7Document6 pagesChapter 7Marco LuigiPas encore d'évaluation

- Line Sizing CriteriaDocument5 pagesLine Sizing CriteriaBILAL ILYASPas encore d'évaluation

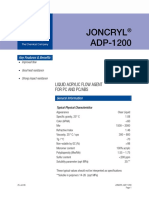

- 1200 TDSDocument2 pages1200 TDSRoxana LencinaPas encore d'évaluation