Académique Documents

Professionnel Documents

Culture Documents

Cavitation

Transféré par

Tara JenkinsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cavitation

Transféré par

Tara JenkinsDroits d'auteur :

Formats disponibles

Experiment 11: Cavitation Demonstration

Purpose:

Observation of the phenomenon of cavitation in a liquid (by reducing the

liquid to its vapour pressure)

Comparison of theoretical and actual pressure at cavitation conditions

Observation of air-release due to dissolved gasses in a liquid

Demonstration of reducing cavitation by increasing the static pressure in a

liquid

I ntroduction:

Under certain conditions, areas of low pressure can occur locally in a flowing fluid. If

the pressure in such areas falls below the vapour pressure, there will be local boiling

and a cloud of vapour bubbles will form. This phenomenon is known as cavitation

and can cause serious problems, since the flow of liquid can sweep this cloud of

bubbles on into an area of higher pressure where the bubbles will collapse suddenly.

Cavitation can affect the performance of hydraulic machinery such as pumps, turbines

and propellers, and the impact of collapsing bubbles can cause local erosion of metal

surfaces.

Apparatus Description:

This accessory consists of a circular Venturi-shaped test section manufactured from

clear acrylic to allow visualization inside the section. As the flow of water increases

the pressure at the throat falls in accordance with the Bernoulli equation until a limit

is reached corresponding to the vapour pressure of the liquid. At this low pressure

small bubbles of vapour form then collapse violently as the pressure rises again

downstream-a process called cavitation . .

Bourdon gauges indicate the pressure upstream of the contraction, inside the throat

and downstream of the expansion in the test section. Flow control valves upstream

and downstream of the test section allow the flow and pressure to be adjusted

allowing cavitation to be clearly demonstrated.

Figure 1: F1-28 Cavitation Demonstration

Theory:

In accordance with Bernoulli's equation the pressure at the throat of the Venturi-

shaped test section falls as the velocity of the water increases. However, the pressure

can only falls as far as the vapour pressure of the water at which point the water starts

to vaporise - Cavitation occurs. Any further increase in velocity cannot reduce the

pressure below the vapour pressure so the water vaporizes faster stronger Cavitation

occurs and Bernoulli's equation is not obeyed.

Procedure:

1- Open the ball valve (right hand end) fully then close the inlet diaphragm ( left hand

end) fully.

2- Close the flow control valve on F1-10. Switch on the F1-10 then slowly open the

flow control valve on F1-10 until is fully open.

3- Slowly open the inlet diaphragm valve and allow water to flow through the F1-28

until the clear acrylic test section and flexible connecting tube are full of water with

no air entrained.

4- Continue to open the inlet diaphragm valve slowly until fully open to obtain

maximum flow through the system. Note the milky formation within the test section

indicating the presence of cavitation.

5- Close the inlet valve until there is no visible cavitation in the test section typically

0.1 Bar on the inlet pressure gauge. Ensure that the test section remains full of water

6- Take reading for P

1

,P

2

and P

3

from the Borden gauges.

7- Perform a timed volume collection using the hydraulic bench and a suitable

stopwatch.

8- Slowly open the inlet valve by a small amount. Record the new values of P

1

,P

2

and

P

3

and perform another timed volume collection.

9- Repeat this procedure multiple times, opening the inlet valve a little more at each

step

10- On a graph, observe the relationship between flow rate and static pressure( P

2

).

Data & Results:

7 6 5 4 3 2 1

Sample

number

V(l)

T(sec)

Q(m3/s)

P1

P2

P3

Vous aimerez peut-être aussi

- F1-28 Cavitation DemonstrationDocument3 pagesF1-28 Cavitation DemonstrationFornade Andrei100% (1)

- Bernoulli's Theorem DemonstrationDocument16 pagesBernoulli's Theorem Demonstrationamirahabidin100% (1)

- Validates Bernoulli's Theorem in Tapered DuctDocument29 pagesValidates Bernoulli's Theorem in Tapered DuctAnonymous NyvKBWPas encore d'évaluation

- Venturi meter experiment proceduresDocument2 pagesVenturi meter experiment proceduresAnonymous mRBbdopMKf100% (1)

- Experiment 7 DiagramDocument7 pagesExperiment 7 Diagramartemio john clavePas encore d'évaluation

- Jet ReactionDocument4 pagesJet ReactionSelva RajPas encore d'évaluation

- FM05 Pitot Static Tube PDFDocument2 pagesFM05 Pitot Static Tube PDFAnonymous thaRdEcpD100% (2)

- Specific Energy Hydraulic Jumps WeirsDocument23 pagesSpecific Energy Hydraulic Jumps WeirsHaris jugnooPas encore d'évaluation

- Lab 2 Mini FLow ChannelDocument16 pagesLab 2 Mini FLow ChannelIr Fik TPas encore d'évaluation

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Document19 pagesSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaPas encore d'évaluation

- EXP 5 - Study of Hydraulic Jump in A Rectangular ChannelDocument9 pagesEXP 5 - Study of Hydraulic Jump in A Rectangular Channelsiva ramPas encore d'évaluation

- Impact of JetDocument5 pagesImpact of Jetميسرة33% (3)

- Lab7-Phelton Turbine Experiment-UpdatedDocument7 pagesLab7-Phelton Turbine Experiment-Updatedtomtoms92Pas encore d'évaluation

- LAB SHEET For Pelton Wheel 21 Sept 2011Document3 pagesLAB SHEET For Pelton Wheel 21 Sept 2011Mohd FazliPas encore d'évaluation

- Hydraulic Jump Lab ExperimentDocument6 pagesHydraulic Jump Lab ExperimentCarlos J. SantacruzPas encore d'évaluation

- Determine Floating Body StabilityDocument11 pagesDetermine Floating Body StabilityDember Paul100% (1)

- Fluid Mechanics Lab Manual for Civil Engineering StudentsDocument29 pagesFluid Mechanics Lab Manual for Civil Engineering Studentsvihangam yoga chandauli100% (1)

- Fluid Mechanics Lab 3.1Document13 pagesFluid Mechanics Lab 3.1mahmoudPas encore d'évaluation

- Report Hydraulic JumpsDocument11 pagesReport Hydraulic JumpsMayLeongPas encore d'évaluation

- Lab 4-Friction Losses and Minor LossesDocument7 pagesLab 4-Friction Losses and Minor LossesJJ Sean CruzPas encore d'évaluation

- Manning's Roughness Coefficient (N)Document11 pagesManning's Roughness Coefficient (N)Khurram MumtazPas encore d'évaluation

- Equipment For Engineering Education: Operating InstructionsDocument25 pagesEquipment For Engineering Education: Operating InstructionsAlyaAthifaAzzahraPas encore d'évaluation

- V Notch PracticalDocument13 pagesV Notch PracticalAnushaBheenuck0% (2)

- Verify Bernoulli's Theorem ExperimentallyDocument1 pageVerify Bernoulli's Theorem ExperimentallyBalRam DhimanPas encore d'évaluation

- Fluid Mechanics LabDocument12 pagesFluid Mechanics LabRonald Muñez BadicPas encore d'évaluation

- Measure Flow in Open ChannelsDocument5 pagesMeasure Flow in Open ChannelsKheshav Jhundoo100% (2)

- Flow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical StudyDocument6 pagesFlow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical Studyho_afsharPas encore d'évaluation

- Impact of JetDocument7 pagesImpact of JetHeng Xiu KohPas encore d'évaluation

- Pipe FrictionDocument4 pagesPipe FrictionShubham ChauhanPas encore d'évaluation

- Orifice Jet Flow Experiment GuideDocument3 pagesOrifice Jet Flow Experiment GuideshaneshaneshaneshanePas encore d'évaluation

- Impact of A Water JetDocument5 pagesImpact of A Water JetAnirban SardarPas encore d'évaluation

- Venturi Meter 1Document13 pagesVenturi Meter 1Da Champ CenaPas encore d'évaluation

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremVrushiket PatilPas encore d'évaluation

- Table of Content DocDocument17 pagesTable of Content DocjjPas encore d'évaluation

- MEC2404 Frictional Flow in Pipe Lab RepoDocument10 pagesMEC2404 Frictional Flow in Pipe Lab Repoatik100% (1)

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanPas encore d'évaluation

- Title: Energy Loss in Pipes: Name: Vincent Lacey Course Code: DT024/2 Date of Experiment: 11/03/10 Group BDocument5 pagesTitle: Energy Loss in Pipes: Name: Vincent Lacey Course Code: DT024/2 Date of Experiment: 11/03/10 Group BzoostyPas encore d'évaluation

- Exp 2 Friction LossesDocument15 pagesExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- Lab Expt 04 - Investigation of Forced VorticesDocument5 pagesLab Expt 04 - Investigation of Forced VorticesGIANNE MARIE AZURINPas encore d'évaluation

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Abstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesDocument18 pagesAbstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesHariz MiorPas encore d'évaluation

- Hydraulic Lab Manual 2017Document48 pagesHydraulic Lab Manual 2017Muhammad AdilPas encore d'évaluation

- Pelton TurbineDocument4 pagesPelton TurbineHenDricky Magosi100% (1)

- Pelton Turbine LabDocument12 pagesPelton Turbine LablufimanPas encore d'évaluation

- Free VortexDocument3 pagesFree VortexVrushiket Patil67% (3)

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Lab2FREE AND FORCE VORTEXDocument32 pagesLab2FREE AND FORCE VORTEXjuaxxo50% (2)

- List of Experiments of Fluid LabDocument24 pagesList of Experiments of Fluid LabGhufran Ahmed0% (1)

- Flow Experiment Determines Discharge CoefficientsDocument15 pagesFlow Experiment Determines Discharge CoefficientsLai YenPas encore d'évaluation

- Report Buckling of StructsDocument7 pagesReport Buckling of StructsAnonymous 59kjvq4OLBPas encore d'évaluation

- Flow Coefficient Determination of Submerged WeirsDocument12 pagesFlow Coefficient Determination of Submerged WeirsKevin OngjuncoPas encore d'évaluation

- Experiment 11 4 Hydraulics Lab 2Document5 pagesExperiment 11 4 Hydraulics Lab 2mohamadreza1368Pas encore d'évaluation

- Liquid Flow in Control Valves - Choked Flow, Cavitation and FlashingDocument14 pagesLiquid Flow in Control Valves - Choked Flow, Cavitation and FlashingSwapnilPas encore d'évaluation

- Control Valve Sizing For LiquidsDocument15 pagesControl Valve Sizing For Liquidsjabar sathikPas encore d'évaluation

- Bernoulli's Principle Demonstration (Lab Report)Document17 pagesBernoulli's Principle Demonstration (Lab Report)Arey Ariena94% (110)

- The Venturi PrincipleDocument7 pagesThe Venturi PrincipleHarrison Smith100% (1)

- Bernoulli S Principle Demonstration Lab ReportDocument17 pagesBernoulli S Principle Demonstration Lab ReportpehweihaoPas encore d'évaluation

- Venturi MeterDocument7 pagesVenturi MeterGregory Nick Toledo VelizPas encore d'évaluation

- Effix'Mr: DTT, T) L+ Frtizr' Frbrgal+Document1 pageEffix'Mr: DTT, T) L+ Frtizr' Frbrgal+Tara JenkinsPas encore d'évaluation

- Summer Training Guidelines 1Document17 pagesSummer Training Guidelines 1Tara JenkinsPas encore d'évaluation

- Lec 12Document21 pagesLec 12Tara JenkinsPas encore d'évaluation

- Mechanical - Dynamics of Machines - YouTubeDocument4 pagesMechanical - Dynamics of Machines - YouTubeTara JenkinsPas encore d'évaluation

- Quantity of Material (LPBS)Document8 pagesQuantity of Material (LPBS)Billy DPas encore d'évaluation

- Chemical EORDocument56 pagesChemical EORAugusto Viera ZapataPas encore d'évaluation

- Understanding Heat Transfer, Conduction, Convection and RadiationDocument24 pagesUnderstanding Heat Transfer, Conduction, Convection and RadiationIra MontillaPas encore d'évaluation

- Petroleum: NCEES Principles and Practice of Engineering ExaminationDocument4 pagesPetroleum: NCEES Principles and Practice of Engineering Examinationreza khPas encore d'évaluation

- Air Conditioning B767 FedexDocument65 pagesAir Conditioning B767 FedexWalter Jair Rodriguez Munoz (LATAM)100% (1)

- WeirDocument12 pagesWeirBabylyn Austria100% (1)

- Hydrodynamics Equation SheetDocument1 pageHydrodynamics Equation SheetsubnautaPas encore d'évaluation

- Kombi F - V4 BLC GP16 - ENGDocument12 pagesKombi F - V4 BLC GP16 - ENGradi firmandaniPas encore d'évaluation

- 330.ICM1500 Instrument Seals, Purges, and WinterizingDocument71 pages330.ICM1500 Instrument Seals, Purges, and WinterizingTpPas encore d'évaluation

- MANICA BOARDS and DOORS Tawanda Report On Boiler FinalDocument22 pagesMANICA BOARDS and DOORS Tawanda Report On Boiler FinalRobin BushuPas encore d'évaluation

- D6960 en PDFDocument8 pagesD6960 en PDFSaeid MirPas encore d'évaluation

- Fire Pump System Test ReportDocument12 pagesFire Pump System Test Reportcoolsummer1112143100% (2)

- Distillation Quiz 1Document7 pagesDistillation Quiz 1Tshwarelo MahlakoanePas encore d'évaluation

- Digital Notes on Refrigeration and Air Conditioning SystemsDocument76 pagesDigital Notes on Refrigeration and Air Conditioning Systemsdipsankar chatterjeePas encore d'évaluation

- ME-330 HMT Course Outline (S-20) PDFDocument3 pagesME-330 HMT Course Outline (S-20) PDFSuaid Tariq BalghariPas encore d'évaluation

- Stream FunctionDocument7 pagesStream Functionqwzeric0002Pas encore d'évaluation

- Optimum Design of Wind Tunnel Contractions MikhailDocument7 pagesOptimum Design of Wind Tunnel Contractions MikhailsekharsamyPas encore d'évaluation

- Heat Transfer Lect 4 (External Forced Convection)Document28 pagesHeat Transfer Lect 4 (External Forced Convection)Mostafa SabryPas encore d'évaluation

- Fume Scrubbers and Ventilation Systems GuideDocument2 pagesFume Scrubbers and Ventilation Systems GuideherikPas encore d'évaluation

- Sampling OverviewDocument5 pagesSampling OverviewMohdFikhriMohdLatiff100% (1)

- Advance Separation Techniques: Pressure Swing AdsorptionDocument26 pagesAdvance Separation Techniques: Pressure Swing AdsorptionJaykumar Bhupendrabhai PatelPas encore d'évaluation

- CHME 202 - Fluid Mechanics Homework #3Document10 pagesCHME 202 - Fluid Mechanics Homework #3d dPas encore d'évaluation

- Water TreatmentDocument45 pagesWater TreatmentSarim ChPas encore d'évaluation

- Heat Exchanger Lab Report - Reference MaterialDocument30 pagesHeat Exchanger Lab Report - Reference MaterialFarwa RizviPas encore d'évaluation

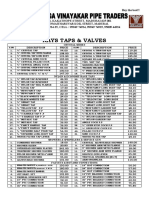

- Rays Taps & Valves: Sell The Best! Buy The Best!!Document3 pagesRays Taps & Valves: Sell The Best! Buy The Best!!annamalaicvPas encore d'évaluation

- Mfrs. & suppliers of evaporator, MEE, ATFD, ETP equipmentDocument10 pagesMfrs. & suppliers of evaporator, MEE, ATFD, ETP equipmentrajesh kothariPas encore d'évaluation

- AssignDocument2 pagesAssignHabtamu Tkubet EbuyPas encore d'évaluation

- Fundamentals of Gas Solids Liquids SeparationDocument16 pagesFundamentals of Gas Solids Liquids SeparationAhmed El-wench100% (2)