Académique Documents

Professionnel Documents

Culture Documents

Sauer DanFoss Joystick Catalog

Transféré par

Michael LinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sauer DanFoss Joystick Catalog

Transféré par

Michael LinDroits d'auteur :

Formats disponibles

520L0872 Rev HA Jun 2013

JS1000, JS6000

Joystick Grips

Technical

Information

JS1000, JS6000 Joystick Grips

Technical Information

2 520L0872 Rev HA Jun 2013

Revisions

Date Page Changed Rev.

24 Jun, 2013 21 Grip Button Color Options table HA

15 Jan, 2010 25 A Grip Front Plate Diagram illustration GA

17 Dec, 2009 10 - 11 Pro grip recommendation, IP rating FA

02 Sep, 2008 Cover obsolete joystick removed, replaced with ball grip EA

04 Jan, 2008 Various Content update DA

06 Dec, 2005 9 Operating and storage temperature updated C

Revisions

Revisions

2013 Sauer-Danfoss. All rights reserved.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer -Danfoss reserves the right to alter its products without prior notice. This also applies to products already

ordered provided that such alterations can be made without afecting agreed specifcations. All trademarks in

this material are properties of their respective owners. Sauer-Danfoss, the Sauer-Danfoss logotype, the Sauer-

Danfoss S-icon, PLUS+1, What really matters is inside and Know-How in Motion are trademarks of the Sauer-

Danfoss Group.

General Information Introduction ..................................................................................................................................................... 5

JS1000, JS6000 Grip Selection Guide ...................................................................................................... 5

Grip Options and Joystick Base Compatibility ............................................................................... 5

Product Confguration Model Code ................................................................................................... 6

JS1000 Grips JS1000 Grip Product Confguration Model Code ................................................................................ 7

PRO Grip ..........................................................................................................................................................10

Product Overview ...................................................................................................................................10

Model Code Nomenclature .................................................................................................................10

Specifcations ...........................................................................................................................................10

Connector Pin Assignments ................................................................................................................11

Front Plate Model Code Designations .............................................................................................12

Dimensions ...............................................................................................................................................13

Grip with Rocker Switch/Grip with Banana Switch ..........................................................................14

Product Overview ...................................................................................................................................14

Model Code Nomenclature .................................................................................................................14

Specifcations ...........................................................................................................................................14

Grip with Rocker Switch .............................................................................................................................15

Connector Pin Assignments ................................................................................................................15

Dimensions ...............................................................................................................................................15

Grip with Banana Switch ...........................................................................................................................16

Dimensions ...............................................................................................................................................16

Ball Grip ............................................................................................................................................................17

Product Overview ...................................................................................................................................17

Model Code Nomenclature .................................................................................................................17

Specifcations ...........................................................................................................................................17

Connector Pin Assignments ................................................................................................................17

Dimensions .....................................................................................................................................................18

JS6000 Grips JS6000 Grip Product Confguration Model Code ..............................................................................19

JS6000 Grip Function Connector Pin ....................................................................................................22

JS6000 Grip Function Connector Pin Assignments ....................................................................22

A Grip ................................................................................................................................................................23

Product Overview ...................................................................................................................................23

Model Code Nomenclature .................................................................................................................23

Front Plate Model Code Designations .............................................................................................25

Rocker Switch Profles ...........................................................................................................................25

Rocker Switch Specifcations ..............................................................................................................26

Rocker Switch Wiring Details ..............................................................................................................27

Push Button Specifcations ..................................................................................................................28

Push Button Wiring Details ..................................................................................................................28

Connector Pin Assignments ................................................................................................................29

Dimensions ...............................................................................................................................................32

MG Grip ............................................................................................................................................................33

Product overview ....................................................................................................................................33

Model Code Nomenclature .................................................................................................................34

Specifcations ...........................................................................................................................................34

Connector Pin Assignments ................................................................................................................35

Switch Wiring Details .............................................................................................................................36

Dimensions ...............................................................................................................................................36

JS1000, JS6000 Joystick Grips

Technical Information

3 520L0872 Rev HA Jun 2013

Contents

HKN Grip ..........................................................................................................................................................37

Product Overview ...................................................................................................................................37

Model Code Nomenclature .................................................................................................................37

Specifcations ...........................................................................................................................................37

Dimensions ...............................................................................................................................................37

Grip and Joystick Base

Service Parts

Service Part Information ............................................................................................................................38

JS6000 Grips

(continued)

JS1000, JS6000 Joystick Grips

Technical Information

4 520L0872 Rev HA Jun 2013

Contents

JS1000, JS6000 Joystick Grips

Technical Information

5 520L0872 Rev HA Jun 2013

General Information

Sauer-Danfoss joysticks ofer mobile machine product engineers a wide array of grip

designs. Each of the grip designs outlined in this document meets the demanding

conditions typically found in mobile equipment environments.

The many available grip features provide OEM engineers with options ofering a high

degree of protection from chemicals, high-pressure wash, shock, vibration and EMC

exposure. Sauer-Danfoss grips are appropriate for both in-cabin and out of cabin

applications and feature ergonomic forms that minimize machine operator fatigue.

This publication provides technical information required to specify the grip portion of

JS1000 and JS6000 joysticks. Sauer-Danfoss JS1000 Joystick Base Technical Information

manual 520L0826 and JS6000 Joystick Base Technical Information manual 520L0760

provide technical information required to specify joystick bases.

Grip Options and Joystick Base Compatibility

Use the following table to determine which joystick base mates with specifc

Sauer-Danfoss joystick grips.

Introduction

JS1000, JS6000

Grip Selection Guide

JS1000, JS6000 Grip Options and Joystick Base Compatibility

Grip functionality (maximum number)

Compatible with Proportional inputs

Grip designation JS1000 base JS6000 base Momentary switches Rocker Banana Roller Operator presence

PRO X X (6) X (2)

Grip with Rocker Switch X X (1)

Grip with Banana Switch X X (1)

Ball X

A X X (8) X (2) X (1)

MG X X (2) X (1)

HKN X

JS1000, JS6000 Joystick Grips

PRO grip

see pages 10 13

Grip with rocker switch/

Grip with banana switch

see pages 14 16

Ball grip

see pages 17 18

A grip

see pages 23 32

MG grip

see pages 33 36

HKN grip

see page 37

JS1000, JS6000 Joystick Grips

Technical Information

6 520L0872 Rev HA Jun 2013

General Information

Product Confguration Model Code

A product confguration model code (model code) is used to specify particular features

when ordering JS1000 or JS6000 joysticks. The model code begins with the product

family name and the remaining felds are flled in to confgure the product with the

desired features.

JS1000 and JS6000 model codes contain information relating to both base features and

grip features.

JS1000, JS6000

Grip Selection Guide

(continued)

JS1000, JS6000 Joystick Grips

Technical Information

7 520L0872 Rev HA Jun 2013

JS1000 Grips

JS1000 Grip

Product Confguration

Model Code

A Product Family

Code Description

JS1000 JS1000 joystick base with Deutsch connector, spring return to center

B Single or Dual Axis

Code Description

XY Dual axis function, forward and reverse with left and right, with guided axis

(force is increased in the corners)

NY Single axis function, forward and reverse

NG Dual axis function, without guided axis feel (free moving in all directions)

C Center Return Spring

Code Description

A Standard spring

B Heavy spring

D1 Electrical Interface Options

Code Description

J CAN with J1939 message protocol

S Analog voltage output

JS1000 grip product confguration model code example base part - A, B, C, D and E1

J S 1 0 0 0 X Y A J 3 3 1 T

A B C D E F G H J

1 2 3 1

PRO grip option top mount only.

D2 Joystick CAN Source Address

Code Description

NN

Noneuse with analog output

(when D1=S)

33 Source address = 33 (hex)

34 Source address = 34 (hex)

35 Source address = 35 (hex)

36 Source address = 36 (hex)

D3 Joystick Output Type

Code Description

N

Noneuse with analog output

(when D1=S)

1 CAN full scale output = 1000 counts

E1 Grip Mounting Options

Code Description

B Bottom mount (from below the panel, no boot retainer included, boot is captured between panel

and housing) with vent plug*

C Bottom mount (from below the panel, no boot retainer included, boot is captured between panel

and housing) without vent plug*

T Top mount (from above the panel, includes boot retainer for attaching boot to joystick housing)

with vent plug*

U Top mount (from above the panel, includes boot retainer for attaching boot to joystick housing)

without vent plug*

* Vent plug is a Gore-Tex moisture barrier. If the plug is not present, Ingress Protection below the base is unrated.

JS1000, JS6000 Joystick Grips

Technical Information

8 520L0872 Rev HA Jun 2013

JS1000 Grips

JS1000 Grip

Product Confguration

Model Code

(continued)

E2 Grip Mounting and Handle Options

Code Description

PRO PRO grip, CAN output. Complete section F, G, H, J

PR1 PRO grip, with no switch or proportional functions, CAN output.

K01 Ball grip Do not complete F, G, H, J

LSW Grip with analog rocker switch, 1.15 to 3.75 V DC range. Do not complete F, G, H, J

LSB Grip with banana switch, 1.15 to 3.75 V DC range. Do not complete F, G, H, J

PRO grip available with CAN option only. Grips with switches available with analog

option only.

F1 PRO Grip Function Layout

Code Description

R... Right handed grip

L... Left handed grip

F3 PRO Grip Function Layout

Code Type of proportional function

..R. Roller or wheel, not sealed

..N. None

JS1000 grip product confguration model code example joystick part - E2 and F

J S 1 0 0 0 X Y A J 3 3 1 T P R O R 3 R L

A B C D E F G H J

2 1 2 3 4

F2 PRO Grip Function Layout

Code Number of switches on the front plate

.0.. No switches

.1.. 1 switch

.2... 2 switches

.3.. 3 switches

.4.. 4 switches

.5.. 5 switches

F4 PRO Grip Function Layout

Code Position of proportional function

...N No proportional function required

...R

Vertical proportional function on the

Right-hand side

...L

Vertical proportional function on the

Left-hand side

...B

Horizontal proportional function on the

Bottom

...D

Vertical proportional functions on both

the left and the right-hand sides

...S

Horizontal proportional functions as

dual set on the top and the bottom

...T Horizontal proportional function on top

JS1000, JS6000 Joystick Grips

Technical Information

9 520L0872 Rev HA Jun 2013

JS1000 Grips

JS1000 grip product confguration model code example joystick part - F, G, H and J

1 2

F Grip Function Layout Examples

R0NN Right handed, 0 switches, No roller, No position R2RL Right handed, 2 switches, Roller, Left positioned

R1NN Right handed, 1 switches, No roller, No position R3RL Right handed, 3 switches, Roller, Left positioned

R2NN Right handed, 2 switches, No roller, No position R0RB Right handed, 0 switches, Roller, Bottom positioned

R3NN Right handed, 3 switches, No roller, No position R1RB Right handed, 1 switches, Roller, Bottom positioned

R4NN Right handed, 4 switches, No roller, No position R2RB Right handed, 2 switches, Roller, Bottom positioned

R5NN Right handed, 5 switches, No roller, No position R3RT Right handed, 3 switches, Roller, Top positioned

R0RR Right handed, 0 switches, Roller, Right positioned R0RD Right handed, 0 switches, 2 Roller, Dual positioned

R1RR Right handed, 1 switches, Roller, Right positioned R1RD Right handed, 1 switches, 2 Roller, Dual positioned

R2RR Right handed, 2 switches, Roller, Right positioned R0RS Right handed, 0 switches, 2 Roller, Stacked positioned

R3RR Right handed, 3 switches, Roller, Right positioned R1RS Right handed, 1 switches, 2 Roller, Stacked positioned

R0RL Right Handed, 0 switches, Roller, Left positioned R2NR Right handed, 2 switches, No roller, Right positioned

R1RL Right Handed, 1 switches, Roller, Left positioned R2NL Right handed, 2 switches, No roller, Left positioned

G1 PRO Grip Side Switch Orientation

Code Description

R. Right handed PRO Grip

L. Left handed PRO Grip

G2 PRO Grip Side Switch Color

Code Description

.R Red side switch

.Y Yellow side switch

.B Black side switch

.G Grey side switch

.N No side switch

H PRO Grip Front Plate Switch Color Selection Examples

Code Description

NNNNN No switches (diagram 0NN*)

RYBGR

Position 1 switch Red, position 2 switch Yellow, position 3 switch Black, position 4 switch Grey,

position 5 switch Red (diagram 5NN*)

YYYYY 5 Yellow switches (diagram 5NN*)

RNNRB

Position 1 switch Red, No position 2 switch, No position 3 switch, position 4 switch Red, position

5 switch Black (diagram 3NN*)

YRNNN

Position 1 switch Yellow, Position 2 switch Red, No position 3 switch, No position 4 switch, No

position 5 switch (diagram 2RL*)

* See PRO Grip front panel diagram, page 10. Number refers to button location on grip front panel. Select one

color code for each switch specifed.

J S 1 0 0 0 X Y A J 3 3 1 T P R O R 3 R L R Y Y N R N G N

A B C D E F G H J

JS1000 Grip

Product Confguration

Model Code

(continued)

J Operator Presence Switch Option Not Available

Code Description

N No: operator presence switch option not selected

JS1000, JS6000 Joystick Grips

Technical Information

10 520L0872 Rev HA Jun 2013

JS1000 Grips

Product Overview

The PRO grip is a patented ergonomic joystick grip that is designed to minimize operator

fatigue in operations requiring repetitive, precision movement over extended periods

of time. The grip is available in right and left hand versions. The profle of the PRO

grip ensures that the operators fngers are close to input functions thus maximizing

functional control. The hand rest at the base of the grip and soft feel elastomeric palm

insert contributes to a comfortable feel and provides additional protection for the

joystick boot.

A unique feature of the grip is the intelligent embedded electronics that allows joystick

input information to be multiplexed into a two-wire serial signal communicating with

base electronics. The intelligent electronics facilitate the compact design of the grip by

eliminating the need to pass large numbers of discrete wires through the joystick shaft.

The PRO grip is available with a maximum of six switch inputs or two proportional

inputs, or a mix of switch and proportional inputs.

The PRO grip is not recommended in an open cab environment.

Model Code Nomenclature

Grip and grip options are specifed using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS1000 joystick base, use code positions E2, F, G and J to

specify grip properties. Reference JS1000 Grip Product Confguration Model Code, pages 7

to 9.

The PRO grip uses all portions of the model code. Other JS1000 grips use only the E2

portion of the model code.

Specifcations

PRO grip switches and proportional rollers are internally wired to a microcontroller

located in grip. Grip information is included in joystick base CAN messages.

Electrical Specifcations

Description Specifcation

Switch action Momentary

Switch type Single pole, NO

Switch mechanical life 1 million cycles

Environmental Specifcations

Description Specifcation

Operating temperature -30C to 75C [-22F to 167F]

Storage temperature -40C to 85C [-40F to 185F]

Environmental sealing (without proportional roller) IP 43

PRO Grip

PRO Joystick Grip

JS1000, JS6000 Joystick Grips

Technical Information

11 520L0872 Rev HA Jun 2013

JS1000 Grips

PRO Grip

(continued)

Specifcations (continued)

Proportional Roller Specifcations

Description Specifcation

Roller action Spring return to center

Roller electrical output 1000 counts from null

Roller mechanical life 5 million cycles

Environmental sealing IP 40

Proportional rollers are not to be used in no cabin or open cabin joystick applications.

Connector Pin Assignments

PRO grips mounted on JS1000 joystick bases that have user inputsswitches,

proportional inputs or a mix of bothmust use the CAN electrical output option

to transmit grip switch and proportional function information. Refer to the JS1000

Joystick Base Technical Information manual 520L0826 for grip CAN message details and

connector pin assignments.

P005301E

0 switches

0 Prop

0NN 0RR 0RL 0RB 0RD

0RS

1NN 1RR 1RL 1RB

2NN 2NR 2RR 2RL 2RB

3NN

4NN

5NN

3RR 3RL

3RT

1RD

Right Prop

Legend:

Prop = Proportional function in grip

Pushbutton colors:

R = Red

Y = Yellow

B = Black

G = Grey

N = None

Left Prop Bottom/Top Prop Dual Prop Stacked Prop

Front Plate Confguration Example

1 switch

2 switches

3 switches

4 switches

Position 6

5 switches

2NL

1

1

1

P3

P3

P3

P3

P3

P3

P3

P4

P4

P4

P3 P4

P4

P3 P4

P3 P4

P4

2 2

1

2

1

2

3 3

2 3

2 3

3

R1RB - RY

P3

3

4

4

4

3

4

3

4

1 4

1 4

1 4

1 4

5

5

5

5 5 5

5

F1

F2

F3

F4

G2

G1

JS1000, JS6000 Joystick Grips

Technical Information

12 520L0872 Rev HA Jun 2013

JS1000 Grips

PRO Grip

(continued)

PRO Grip Front Plate Diagram

Front Plate Model Code Designations

4 x 4.57 0.05

[0.180 0.002]

59.4 0.5

[2.34 0.02]

74.2 0.5 DIA

[2.92 0.02]

9

.

4

0

.

5

[

0

.

3

7

0

.

0

2

]

5

3

.

4

6

0

.

5

[

2

.

1

0

.

0

2

]

6

.

3

5

0

.

5

[

0

.

2

5

0

.

0

2

]

Pin 6

Orientation

Feature

Pin 1

1

6

6

.

0

1

[

6

.

5

5

0

.

0

4

]

18

o

REF 18

o

REF

18

o

REF

18

o

REF

28.58 0.12

[1.125 0.005]

2

8

.

5

8

0

.

1

2

[

1

.

1

2

5

0

.

0

0

5

]

34.92 0.5

[1.38 0.02]

3

4

.

9

2

0

.

5

[

1

.

3

8

0

.

0

2

]

69.85 0.5

[2.75 0.02]

6

9

.

8

5

0

.

5

[

2

.

7

5

0

.

0

2

]

57.15 0.12

[2.25 0.005]

R2.0 0.5

[0.08 0.02]

5

7

.

1

5

0

.

1

2

[

2

.

2

5

0

.

0

0

5

]

P005 244E

Decreasing

X

Decreasing

X

Increasing

X

Increasing

X

Increasing

Y

Increasing

Y

Decreasing

Y

Decreasing

Y

JS1000, JS6000 Joystick Grips

Technical Information

13 520L0872 Rev HA Jun 2013

JS1000 Grips

Dimensions

Pro grip dimensions in millimeters [inches].

PRO Grip

(continued)

JS1000, JS6000 Joystick Grips

Technical Information

14 520L0872 Rev HA Jun 2013

JS1000 Grips

Product Overview

JS1000 grips with switches are intended to provide a simple, fexible and comfortable

operator control that includes a proportional input device at the top of the grip. Two

shapes are available for the proportional input device: V rocker or banana rocker. Both

grips use Hall sensing technology to detect rocker switch position.

The proportional input generates a nominal 0 to 5 Vdc signal that is used as a change of

state (switch) input.

Model Code Nomenclature

Grip and grip options are specifed using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS1000 joystick base, use code positions E2, F, G and J to

specify grip properties. Reference JS1000 Grip Product Confguration Model Code, pages 7

to 9.

The grip with rocker switch and grip with banana switch are designated using only the

E2 portion of the code.

Specifcations

Top Switch Electrical Specifcations

Description Specifcation

Supply voltage 5.0 0.5 Vdc

Maximum survival voltage 18 Vdc Continuous

Maximum current draw 10 mA

Output at maximum displacement 75% 8% of supply voltage

Output at null 50% 4% of supply voltage

Output at minimum displacement 23% 8% of supply voltage

Top Switch Environmental Specifcations

Description Specifcation

Operating temperature -40C to 80C [-40F to 175F]

Storage temperature -40C to 85C [-40F to 180F]

EMI/RFI rating 100 V/m

Mechanical life 6 million cycles

Grip with Rocker Switch/

Grip with Banana Switch

Grip with Rocker Switch Grip with Banana Switch

69.85 0.50

[2.75 0.02]

Decreasing

Y

Decreasing

X

Increasing

Y

Increasing

X

4X 4.57 0.05

[0.180 0.002]

59.4 0.50

[2.34 0.02]

R2.03 0.50

[0.08 0.02]

69.85 0.50

[2.75 0.02]

Decreasing

Y

Increasing

Y

110.63 0.50

[4.35 0.02]

3.80 [0.15] Max panel

Feed-through mounting

59.60 0.50

[2.35 0.02]

6.35 0.50

[.25 .02]

18 REF 18 REF

Decreasing

Y

Increasing

Y

18 REF 18 REF

2234A

Orientation

Feature

JS1000, JS6000 Joystick Grips

Technical Information

15 520L0872 Rev HA Jun 2013

JS1000 Grips

Dimensions

Grip with rocker switch dimensions in millimeters [inches].

Grip with Rocker Switch Connector Pin Assignments

Both grip-with-switch options may use either the JS1000 base analog or CAN output

option. Refer to the JS1000 Joystick Base Technical Information manual 520L0826 for grip

CAN message details and connector pin assignments.

Decreasing switch

Increasing switch

Increasing

switch

Decreasing

switch

69.85 0.50

[2.75 0.02]

Decreasing

Y

Decreasing

X

Increasing

Y

Increasing

X

4X 4.57 0.05

[.180 .002]

59.4 0.50

[2.34 0.02]

R2.03 0.50

[0.08 0.02]

69.85 0.50

[2.75 0.02]

Decreasing

Y

Increasing

Y

Increasing

X

Decreasing

X

115.43 0.50

[4.54 0.02]

3.80 [0.15] Max panel

feed-through mounting

59.60 0.50

[2.35 .02]

6.35 0.50

[.25 0.02]

18 REF 18 REF

18 REF 18 REF

2235A

Orientation

Feature

JS1000, JS6000 Joystick Grips

Technical Information

16 520L0872 Rev HA Jun 2013

JS1000 Grips

Dimensions

Grip with banana switch dimensions in millimeters [inches].

Grip with Banana Switch

JS1000, JS6000 Joystick Grips

Technical Information

17 520L0872 Rev HA Jun 2013

JS1000 Grips

Product Overview

The JS1000 Ball grip provides a simple and comfortable operator control. Manufactured

of high impact plastic, the grip is perfectly suited for mobile machine applications

requiring only X-Y control and no switch or proportional input options.

Model Code Nomenclature

Grip and grip options are specifed using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS1000 joystick base, use code positions E2, F, G and J to

specify grip properties. Reference JS1000 Product Confguration Model Code, pages 7 to 9.

The ball grip is designated using only the E2 portion of the code.

Specifcations

Environmental Specifcations

Description Specifcation

Operating temperature -40C to 80C [-40F to 175F]

Storage temperature -40C to 85C [-40F to 180F]

Environmental protection IP 66, 67

Ball Grip

Connector Pin Assignments

The ball grip has no electrical outputs. It can be mounted on JS1000 bases having either

a CAN or analog output. Refer to the JS1000 Joystick Base Technical Information manual

520L0826 for grip CAN message details and connector pin assignments.

Ball Joystick Grip

18

o

REF

3.8 [0.15]

Max panel

feed through mounting

18

o

REF

6

9

.

8

5

0

.

5

[

2

.

7

5

0

.

0

2

]

69.85 0.5

[2.75 0.02]

Decreasing

X

Decreasing

X

Increasing

X

Increasing

X

Increasing

Y

Increasing

Y

Decreasing

Y

Decreasing

Y

18

o

REF

18

o

REF

P005 243E

4 x 4.57 0.05

[0.180 0.002]

59.4 0.05

[2.34 0.002]

5

9

.

6

0

.

5

[

2

.

3

5

0

.

0

2

]

6

.

3

5

0

.

5

[

0

.

2

5

0

.

0

2

]

8

6

.

6

1

0

.

5

[

3

.

4

1

0

.

0

2

]

R2.03 0.5

[0.08 0.02]

Orientation

Feature

JS1000, JS6000 Joystick Grips

Technical Information

18 520L0872 Rev HA Jun 2013

JS1000 Grips

Ball Grip

(continued)

Dimensions

Ball grip dimensions in millimeters [inches].

JS1000, JS6000 Joystick Grips

Technical Information

19 520L0872 Rev HA Jun 2013

Base Grip

A B C D E F G H I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S N L N J 3 3 1 A 0 H 0 R V N N N N N N N N

JS6000 product confguration model code example base part - A, B, C, D, E, F and G

A Product Series

Code Description

JS6000 Series JS6000 Joystick

B Operational Axis Options

Code Description

XY Bi-directional: X and Y axis

NY Uni-directional: Y axis only (required for friction-holding)

C Shaft Position Sensing and Output Options

Code Description

PRR Potentiometer: single output per axis; V

o

= 10 to 90% of V

s

; 1.5 neutral threshold

PQQ Potentiometer: single output per axis; V

o

= 25 to 75% of V

s

; 1.5 neutral threshold

PSS Potentiometer: single output per axis; V

o

= 10 to 90% of V

s

; 5 neutral threshold

PTT Potentiometer: single output per axis; V

o

= 25 to 75% of V

s

; 5 neutral threshold

PUU Potentiometer: dual output per axis; V

o

= 10 to 90% of V

s

; 1.5 neutral threshold

HMM Hall efect: dual sensors per axis; Vs = 5 V

DC

; V

o

= 0.5 to 4.5 V

DC

CAN Hall efect: dual sensors per axis; Vs = 9 to 36 V

DC

; CAN 2.0B communication, 6 pin connector

CPL Hall efect: dual sensors per axis; Vs = 9 to 36 V

DC

; CAN 2.0B communication, 18 pin connector

D Centering Spring Options

Code Description

H Heavy force

M Medium force

L Light force

F Friction-hold (position maintained, center detent)

E Gate Pattern Options

Code Description

S Square, full output at 45 degree

F Mechanical Options

Code Description

NL No mechanical option; spring return to center only

FB Friction-held in Y axis; no X axis; center detent; 1.25 Nm [0.92 lbft] friction-hold force;

2.5 Nm [1.66 lbft] breakout force

FC Friction-held in Y axis; no X axis; center detent; 1.25 Nm [0.92 lbft] friction-hold force;

3.25 Nm [2.40 lbft] breakout force

HC Friction-held in Y axis; no X axis; center detent; 2.25 Nm [1.66 lbft] friction-hold force;

4.0 Nm [2.95 lbft] breakout force

G Direction (Microswitch) Options

Code Description

N No switches

Y Microswitches installed (analog potentiometer option only)

JS6000 Grip

Product Confguration

Model Code

JS6000 Grips

JS1000, JS6000 Joystick Grips

Technical Information

20 520L0872 Rev HA Jun 2013

JS6000 Grips

JS6000 grip product confguration model code example grip properties - I, J, K, L, M, N, O,

P, Q, R, and S

JS6000 Grip

Product Confguration

Model Code

(continued)

Handle type

Number of buttons

Code Description

T Top switch

D Operator presence switch

B Both top and operator switch

0 No top switch, no operator presence switch

L Left rocker location (vertical orientation)

R Right rocker location (vertical orientation)

B Both left and right (vertical orientation)

H Horizontal rocker location

0 No rocker switch

J A grip proportional rocker output

Code Defnition

R Potentiometer, 10% to 90% Vs

Q Potentiometer, 25% to 75% Vs

N None

K A grip proportional rocker style

Code Defnition

S Wave style

V V style

N None

I Grip switch details

H1 Electrical Interface Options

Code Description

S Analog (voltage output from joystick sensors or switches)

J CAN, SAE J1939 protocol

H2, 3 CAN Source Address*

Code Description

NN Noneuse with analog outputs when H1 = S

33 Source address = 0x 33

34 Source address = 0x 34

35 Source address = 0x 35

36 Source address = 0x 36

* Consult the factory if additional source addresses are required.

H4 Joystick Output Type

Code Description

N Noneuse with analog outputs when H1 = S

1 CAN full scale output = 1000 counts

I, J, K Grips, grip proportional rocker output and style

For grips designed to mate with the JS6000 joystick base, use code positions, I through S to specify grip

properties. Refer to Front Plate Model Code Designation, page 25 for rocker switch location examples.

A B C D E F G H I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S C L N J 3 3 1 A 0 H 0 R V N N N N N N N N

1 2 3 4

JS1000, JS6000 Joystick Grips

Technical Information

21 520L0872 Rev HA Jun 2013

JS6000 Grips

L, M, N, O, P, Q, R, S Grip options

For A grips use code positions L, M, N, O, P, Q, R, and S to specify grip button colors.

Grip Button Position to Model Code Conversion

Grip front plate button position* Corresponding master model code

1 L

2 M

3 N

4 O

5 P

6 Q

7 R

8 S

See A Grip Button Position Designations, pages 29 to 32.

Grip Button Color Options

Code Description

R Red

B Black*

G Green*

Y Yellow*

L Blue*

N No push button switch

* The red colored push-button switch is considered the default color. There is a fve-piece order minimum

each time the other color options are ordered.

JS6000 Grip

Product Confguration

Model Code

(continued)

JS1000, JS6000 Joystick Grips

Technical Information

22 520L0872 Rev HA Jun 2013

JS6000 Grips

JS6000 Grip Function Connector Pin Assignments

Pin assignments for the JS6000 connector that contains grip outputs are dependent

on the type of joystick shaft position sensor (potentiometer or Hall) and the electrical

output option (analog or CAN) selected for the joystick base. Analog base grip pin

assignments are found on pages 29 to 32 and page 35 of this manual. Pin assignments

for other analog base functions are found in the JS6000 Joystick Base Technical

Information manual 520L0760.

Grip pin assignments for joystick bases that have analog outputs depend on whether

a potentiometer or Hall sensor is used to measure the position of the joystick shaft. If a

potentiometer is used, the 12 pin connector on the joystick base is used for grip outputs.

If a Hall sensor is used, the 16 pin connector is used for grip outputs.

If the CAN electrical output option is selected, a 6 or 18 pin Deutsch connector is

provided in the base and input information from the grip is broadcast in a J1939

message format. Refer to the JS6000 Joystick Base Technical Information manual

520L0760 for details on J1939 CAN grip messages and Deutsch connector pin

assignments.

JS6000 Grip Function

Connector Pin

Push Button Switch

Top Switch

Operator Presence Switch

Left Rocker

2265

JS1000, JS6000 Joystick Grips

Technical Information

23 520L0872 Rev HA Jun 2013

JS6000 Grips

Product Overview

The A grip is a multi-function, ambidextrous ergonomic grip designed for a comfortable

user interface and maximum functional control. The grip features a modular design that

allows switch and proportional rocker location fexibility.

The A grip is available with combinations of up to eight switches and up to two

proportional inputs. One of the optional switches can be used to provide an operator

presence function on the grip. Available button colors are red, black, green, yellow, and

blue.

Model Code Nomenclature

Grip and grip options are specifed using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS6000 joystick base, use code positions I through S to

specify grip properties. Reference JS6000 Grip Product Confguration Model Code, pages

19 to 21.

Model Code for A Grip Front Plate Options

I

Code

Number of momentary

switchesgrip front plate

Number, location of proportional

rocker switchesgrip front plate

Number, location of momentary

switchesback of grip

A000 0 0 0

A00T 0 0 T

A00D 0 0 D

A00B 0 0 B

A0L0 0 L 0

A0LD 0 L D

A0R0 0 R 0

A0RD 0 R D

A0B0 0 B 0

A0BD 0 B D

A0H0 0 H 0

A0HD 0 H D

A0RB 0 R B

A0RT 0 R T

A0LB 0 L B

A0LT 0 L T

A100 1 0 0

A10T 1 0 T

A10D 1 0 D

A10B 1 0 B

A1L0 1 L 0

A1R0 1 R 0

A1H0 1 H 0

A Grip

A Joystick Grip

Multi-function Grip

JS1000, JS6000 Joystick Grips

Technical Information

24 520L0872 Rev HA Jun 2013

JS6000 Grips

I

Code

Number of momentary

switchesgrip front plate

Number, location of proportional

rocker switchesgrip front plate

Number, location of momentary

switchesback of grip

A1LD 1 L D

A1RD 1 R D

A1HD 1 H D

A1RT 1 R T

A1LT 1 L T

A1RB 1 R B

A1LB 1 L B

A200 2 0 0

A20T 2 0 T

A20D 2 0 D

A20B 2 0 B

A2L0 2 L 0

A2R0 2 R 0

A2H0 2 H 0

A2LD 2 L D

A2RD 2 R D

A2HD 2 H D

A2RB 2 R B

A2RT 2 R T

A2LB 2 L B

A2LT 2 L T

A300 3 0 0

A30T 3 0 T

A30D 3 0 D

A30B 3 0 B

A3R0 3 R 0

A3RD 3 R D

A3L0 3 L 0

A3LD 3 L D

A3RT 3 R T

A3LT 3 L T

A400 4 0 0

A40T 4 0 T

A40D 4 0 D

A40B 4 0 B

A500 5 0 0

A50D 5 0 D

A50B 5 0 B

A50T 5 0 T

A600 6 0 0

A60D 6 0 D

A60B 6 0 B

A60T 6 0 T

A Grip

(continued)

Model Code for A Grip Front Plate Options (continued)

2247B

A2H0

A2HD

A300

A30T

A30D

A30B

A400

A40T

A40D

A40B

2 3

X

2 3

1 4

2 3

1

A0B0*

A0H0

A0HD

A100

A10T

A10D

A10B

A3L0

A3LT

A3LD

A3LB

X Y

X

X

1

2

6

1

A1R0

A1RT

A1RD

A1RB

A1L0

A1LT

A1LD

A1LB

A1H0

A1HD

A500

A50T

A50D

A50B

2

1

3 Y

X

X

2 3

1 4

5

A200

A20T

A20D

A20B

A2R0

A2RT

A2RD

A2RB

A2L0

A2LT

A2LD

A2LB

A600

A60T

A60D

A60B

1

2

3

2 3

Y

X

2 3

4

1 4

6

5

A000

A00T

A00D

A00B

A0R0

A0RT

A0RD

A0RB

A0L0

A0LT

A0LD

A0LB

A3R0

A3RT

A3RD

A3RB

Y

X

Y

3

5

4

* For CAN and CAN+ output models, include grip confgurations: A0BD, A0BB, A0BT.

Profle of Wave Rocker Switch Option Profle of V Rocker Switch Option

2248

JS1000, JS6000 Joystick Grips

Technical Information

25 520L0872 Rev HA Jun 2013

JS6000 Grips

Front Plate Model Code Designations

Rocker Switch Profles

A Grip

(continued)

A Grip Front Plate Diagram

JS1000, JS6000 Joystick Grips

Technical Information

26 520L0872 Rev HA Jun 2013

JS6000 Grips

Rocker Switch Specifcations

The optional grip rocker switches use a conductive plastic potentiometer to generate

an analog output that is proportional to switch position. The wipers that run across the

potentiometer track are driven by the thumb operated rocker mechanism. Rocker switch

action is spring return to center.

Mechanical Specifcations

Description Specifcation

Breakout force 5 N [1.12 lbf ]

Operating force 15 N [3.37 lbf ]

Maximum applied force 50 N [11.24 lbf ]

Mechanical angle of movement 12

Electrical angle of movement 9

Expected life >5 million operations

Environmental Specifcations

Description Specifcation

Operating temperature -40C to 70C [-40F to 158F]

Storage temperature -40C to 80C [-40F to 176F]

Environmental sealing IP 65

Electrical Specifcations

Description Specifcation

Maximum load current Potentiometer wiper*

Directional switches: 200 mA

Maximum power dissipation 0.25 W at 25 C [77 F]

Output voltage ranges 25 to 75% Vs

10 to 90% Vs

Center tap voltage 50% Vs 2%

Center tap angle 1.5 either side of center

Directional switch operating angle 2.5 either side of center

Directional switch maximum supply voltage 36 Vdc

Directional switch current rating 5 mA

Center tap has an angle of 1.5

50% of the Vs is supplied at the center position

The track also has a directional switch with a center of switch

The direction switch changes state after a movement of 2.5 in each direction

The switch current rating is 5 mA

* The rocker is only to be used as a potentiometer and not as a variable resistor.

Wiper load must be resistance greater than 100 k.

A Grip

(continued)

Black

Pink White/red

(V+) (V-)

Pink/grey

Blue/orange Green

Left blank

Centre tap - yellow/red

Switch track

Potentiometer track

Forwards

0 V 5 V

Backwards

Black

White Pink/grey

(V-) (V+)

White/red

Blue

Blue

Yellow

Left blank

Centre tap - yellow/red

Switch track

Potentiometer track

Backwards

5 V 0 V

Forwards

Black

Pink White/red

(V+) (V-)

Pink/grey

Green

Left blank

Centre tap - yellow/red

Switch track

Potentiometer track

Left

0 V 5 V

Right

2249

Left Rocker

Right Rocker

Horizontal Rocker

JS1000, JS6000 Joystick Grips

Technical Information

27 520L0872 Rev HA Jun 2013

JS6000 Grips

Rocker Switch Wiring Details A Grip

(continued)

1

2

3

4

5

6

Blue Black

Yellow

Yellow/Orange

Green

Red

Violet

Pink with

marker sleeve

Black

Red/Green Blanck/White

Push Button Switches

Top Switch

Operator Presence Switch

2250

JS1000, JS6000 Joystick Grips

Technical Information

28 520L0872 Rev HA Jun 2013

JS6000 Grips

Push Button Specifcations

Push Button Electrical Specifcations

Description Specifcation

Switch action Momentary

Switch type Single pole, NO

Contact rating 200 mA at 50 Vdc - person present switch

100 mA at 50 Vdc - top and front plate switches

Contact resistance 50 M maximum

Mechanical life 1 million cycles

Push Button Environmental Specifcations

Description Specifcation

Operating temperature -40F to 70C [-40C to 158F]

Storage temperature -40F to 80C [-40C to 176F]

Environmental sealing IP 66

Operating force 3 N [0.674 lbf ]

Push Button Wiring Details

A Grip

(continued)

JS1000, JS6000 Joystick Grips

Technical Information

29 520L0872 Rev HA Jun 2013

JS6000 Grips

A Grip Button Position Designations

Pins 13 to 16 are not used on the 16 pin connector

Blank = Pin not used

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A000

A00T Top

switch

Common

A00D Operator

presence

Common Operator

presence

A00B Top

switch

Operator

presence

Common Operator

presence

A0L0 Switch

out L

Switch

out L

VoutL Center tap V+ V- Common

A0LD Switch

out L

Switch

out L

VoutL Center tap V+ Operator

presence

V- Common Operator

presence

A0LT Switch

out L

Switch

out L

VoutL Center tap V+ Top

switch

V- Common

A0LB Switch

out L

Switch

out L

VoutL Center tap V+ Operator

presence

Top

switch

V- Common Operator

presence

A0R0 Switch

out R

Switch

out R

Center tap V+ VoutR V- Common

A0RD Switch

out R

Switch

out R

Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A0B0 Switch

out L

Switch

out L

Switch

out R

Switch

out R

VoutL Center tap V+ VoutR V- Common

A0BD Switch

out L

Switch

out L

Switch

out R

Switch

out R

VoutL Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A0H0 Switch

out H

Switch

out H

VoutH Center Tap V+ V- Common

A0HD Switch

out H

Switch

out H

VoutH Centertap V+ Operator

presence

V- Common Operator

presence

Connector Pin Assignments

Warning

Potential uncommanded machine movement. JS6000 base and grip pinout

specifcations are a function of joystick base measurement sensor type and electrical

output (analog or CAN). For joysticks with analog output, the pinout assignments for the

12 and 16 pin connectors depend on whether a potentiometer or Hall sensor is used to

measure the position of the joystick shaft. If a potentiometer sensor is used, the 12 pin

connector is used for grip outputs. If a Hall sensor is used, the 16 pin connector is used

for grip outputs and pins 13 through 16 are not used. Refer to the Rocker Switch Wiring

Details, page 27 for information regarding the switch nomenclature used below. Refer

to Front Plate Model Code Designation, page 25 for information regarding the location

nomenclature for push button switches.

A Grip

(continued)

JS1000, JS6000 Joystick Grips

Technical Information

30 520L0872 Rev HA Jun 2013

JS6000 Grips

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A0RT Switch

out R

Switch

out R

Top

switch

Center tap V+ VoutR V- Common

A100 PB1 Common

A10T PB1 Top

switch

Common

A10D PB1 Operator

presence

Common Operator

presence

A10B PB1 Top

switch

Operator

presence

Common Operator

presence

A1L0 Switch

out L

Switch

out L

PB1 VoutL Center tap V+ V- Common

A1R0 PB3 Switch

out R

Switch

out R

Center tap V+ VoutR V- Common

A1H0 Switch

out H

PB2 Switch

out H

VoutH Center top V+ V- Common

A1LD Switch

out L

Switch

out L

PB1 VoutL Center tap V+ Operator

presence

V- Common Operator

presence

A1RD PB3 Switch

out R

Switch

out R

Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A1HD Switch

out H

PB2 Switch

out H

VoutH Center top V+ Operator

presence

V- Common Operator

presence

A1RT PB3 Switch

out R

Switch

out R

Top

switch

Center tap V+ VoutR V- Common

A1LT Switch

out L

Switch

out L

PB1 VoutL Center tap V+ Top

switch

V- Common

A1RB PB3 Switch

out R

Switch

out R

Top

switch

Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A1LB Switch

out L

Switch

out L

PB1 VoutL Center tap V+ Operator

presence

Top

switch

V- Common Operator

presence

A200 PB3 PB2 Common

A20T PB3 PB2 Top

switch

Common

A20D PB3 PB2 Operator

presence

Common Operator

presence

A20B PB3 PB2 Top

switch

Operator

presence

Common Operator

presence

A2L0 Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ V- Common

A Grip

(continued)

A Grip Button Position Designations

Pins 13 to 16 are not used on the 16 pin connector

Blank = Pin not used

Connector Pin Assignments (continued)

JS1000, JS6000 Joystick Grips

Technical Information

31 520L0872 Rev HA Jun 2013

JS6000 Grips

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A2R0 PB4 PB3 Switch

out R

Switch

out R

Center tap V+ VoutR V- Common

A2H0 Switch

out H

PB3 PB2 Switch

out H

VoutH Center tap V+ V- Common

A2LD Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ Operator

presence

V- Common Operator

presence

A2RD PB4 PB3 Switch

out R

Switch

out R

Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A2HD Switch

out H

PB3 PB2 Switch

out H

VoutH Center tap V+ Operator

presence

V- Common Operator

presence

A2RB PB4 PB3 Switch

out R

Switch

out R

Top

switch

Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A2RT PB4 PB3 Switch

out R

Switch

out R

Top

switch

Center tap V+ VoutR V- Common

A2LB Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ Operator

presence

Top

switch

V- Common Operator

presence

A2LT Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ Top

switch

V- Common

A300 PB3 PB2 PB1 Common

A30T PB3 PB2 PB1 Top

switch

Common

A30D PB3 PB2 PB1 Operator

presence

Common Operator

presence

A30B PB3 PB2 PB1 Top

switch

Operator

presence

Common Operator

presence

A3R0 PB4 PB3 Switch

out R

Switch

out R

Center tap V+ PB5 VoutR V- Common

A3RD PB4 PB3 Switch

out R

Switch

out R

PB5 Center tap V+ Operator

presence

VoutR V- Common Operator

presence

A3L0 Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ PB6 V- Common

A3LD Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ Operator

presence

PB6 V- Common Operator

presence

A3RT PB4 PB3 Switch

out R

Switch

out R

Top

switch

Center tap V+ PB5 VoutR V- Common

A3LT Switch

out L

Switch

out L

PB2 PB1 VoutL Center tap V+ PB6 Top

switch

V- Common

A400 PB4 PB3 PB2 PB1 Common

A Grip

(continued)

A Grip Button Position Designations

Pins 13 to 16 are not used on the 16 pin connector

Blank = Pin not used

Connector Pin Assignments (continued)

110 [4.33]

60 [2.36]

131.51 [5.18]

2251

Push Button Switch

Top Switch

Operator

Presence Switch

Left Rocker

JS1000, JS6000 Joystick Grips

Technical Information

32 520L0872 Rev HA Jun 2013

JS6000 Grips

A Grip

(continued)

A Grip Button Position Designations

Pins 13 to 16 are not used on the 16 pin connector

Blank = Pin not used

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A40T PB4 PB3 PB2 PB1 Top

switch

Common

A40D PB4 PB3 PB2 PB1 Operator

presence

Common Operator

presence

A40B PB4 PB3 PB2 PB1 Top

switch

Operator

presence

Common Operator

presence

A500 PB4 PB3 PB2 PB1 PB5 Common

A50D PB4 PB3 PB2 PB1 PB5 Operator

presence

Common Operator

presence

A50B PB4 PB3 PB2 PB1 Top

switch

Operator

presence

PB5 Common Operator

presence

A50T PB4 PB3 PB2 PB1 Top

switch

PB5 Common

A600 PB4 PB3 PB2 PB1 PB5 PB6 Common

A60D PB4 PB3 PB2 PB1 PB5 Operator

presence

PB6 Common Operator

presence

A60B PB4 PB3 PB2 PB1 Top

switch

PB5 Operator

presence

PB6 Common Operator

presence

A60T PB4 PB3 PB2 PB1 Top

switch

PB5 PB6 Common

Connector Pin Assignments (continued)

Dimensions

A grip dimensions in millimeters [inches].

JS1000, JS6000 Joystick Grips

Technical Information

33 520L0872 Rev HA Jun 2013

JS6000 Grips

Product overview

The MG multi-function grip is designed to provide an ergonomic solution to grip

applications requiring an operator presence function. The profle of the MG grip ensures

that the operators fngers are always close to the buttons to minimize operator fatigue

and maximize functional control. An optional hand rest feature is also available to further

minimize operator fatigue and provide additional protection for the joystick boot.

The grip is available with or without an operator presence lever switch, as well as up to

two low current switches at the top of the grip. If two top switches are present, they are

actuated through a rocker assembly.

MG Grip

0 Switch Option with

Operator Presence Lever

1 Switch Option with

Operator Presence Lever

2 Switch Option with

Operator Presence Lever

Grip with Hand

Rest Option

MG Joystick Grip

JS1000, JS6000 Joystick Grips

Technical Information

34 520L0872 Rev HA Jun 2013

JS6000 Grips

MG Grip

(continued)

Model Code Nomenclature

Grip and grip options are specifed using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS6000 joystick base, use code positions I, J and K to

specify grip properties. Reference JS6000 grip product confguration model code, pages 18

to 19.

MG grip model codes do not use model code positions J through S.

Model Code for MG Grip Switch Positions

Code Switch position* Operator presence lever Hand rest

MG00 No switches No lever No hand rest

MG01 Switch 1 No lever No hand rest

MG02 Switch 1, 2 No lever No hand rest

MG03 Switch 1,2 Included No hand rest

MG04 Switch 1,2 Included Included

MG05 Switch 1 Included Included

MG06 Switch 1,2 No lever Included

MG07 Switch 1 No lever Included

MG08 Switch 1 Included No hand rest

MG09 No switches Included Included

MG10 No switches No lever Included

MG11 No switches Included No hand rest

*Refer to Dimensions, page 36, for defnition of switch locations.

Specifcations

Electrical Specifcations

Description Specifcation

Contact resistance 50

Contact bounce 1 ms

Insulation resistance >100 M at 50 Vdc

Dielectric strength 500 V (50 Hz, 1 min.)

Switching current Max: 100 mA

Min : 10 A

Switching voltage Max: 30 Vdc

Min: 2 Vdc

Electrical life 1 million cycles at maximum voltage

Environmental Specifcations

Description Specifcation

Operating temperature -25C to 75C [-13F to 167F]

Storage temperature -30C to 80C [-22F to 178F]

Ingress protection IP 67 (operator presence lever may not operate in icing

conditions)

JS1000, JS6000 Joystick Grips

Technical Information

35 520L0872 Rev HA Jun 2013

JS6000 Grips

Connector Pin Assignments

Warning

Potential uncommanded machine movement. JS6000 base and grip connector pin

assignments are a function of joystick base shaft measurement sensor type and base

electrical output (analog or CAN). For joysticks with analog output, the pin assignments

for the 12 and 16 pin base connectors depend on whether a potentiometer or Hall

sensor is used to measure the position of the joystick shaft. If a potentiometer sensor

is used, the 12 pin connector is used for grip outputs. If a Hall sensor is used, the 16 pin

connector is used for grip outputs.

12 Pin Connector MG Grip Pin Assignments

Pin number Description

1 Not used

2 Not used

3 Switch 2

4 Operator presence

5 Operator presence

6 Switch 1

7 Not used

8 Not used

9 Not used

10 Not used

11 Not used

12 Common for switch 1, 2

16 Pin Connector MG Pin Assignments

Pin number Description

1 Not used

2 Not used

3 Switch 2

4 Operator presence

5 Operator presence

6 Switch 1

7 Not used

8 Not used

9 Not used

10 Not used

11 Not used

12 Common for switch 1,2

13 Not used

14 Not used

15 Not used

16 Not used

MG Grip

(continued)

Switch 1

Operator presence

1 Switch Option

Switch 1 Switch 2

2 Switch Option

Operator Presence Switch

2255

Yellow Blue/Orange

Blue Black Blue Green

Black

JS1000, JS6000 Joystick Grips

Technical Information

36 520L0872 Rev HA Jun 2013

JS6000 Grips

Switch Wiring Details MG Grip

(continued)

Dimensions

MG grip dimensions in millimeters [inches].

Height from

JS6000 Flange

188 [ 7.4 ]

28 [ 1.1 ]

114 [ 4.5 ]

14 [ 0.55 ]

54 [ 2.13 ]

40 [1.57]

50 [1.97]

2256

JS1000, JS6000 Joystick Grips

Technical Information

37 520L0872 Rev HA Jun 2013

JS6000 Grips

Product Overview

The HKN grip is a plain, high impact plastic knob grip that has no electrical interface. It is

designed to provide a comfortable grip for extended machine operation.

Model Code Nomenclature

Grip and grip options are specifed using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS6000 joystick base, use code positions I, through S to

specify grip properties. Reference JS6000 Grip Product Confguration Model Code, pages

19 to 21.

The HKN does not use master model code positions J through S.

The master model code for HKN grips is HKN0.

Specifcations

Environmental Specifcations

Description Specifcation

Operating temperature -40C to 80C [-40F to 176F]

Storage temperature -40C to 85C [-40F to 185F]

Environmental sealing IP 66

Dimensions

HKN Grip Dimensions

Maximum height above fange Maximum diameter

45 mm [1.76 in] 34.6 mm [1.36 in]

HKN Grip

HKN Joystick Grip

JS1000, JS6000 Joystick Grips

Technical Information

38 520L0872 Rev HA Jun 2013

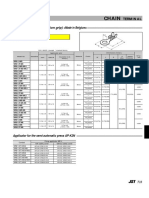

Grip and Joystick Base Service Parts

Service part availability for JS1000 joystick is a function of joystick base and grip

specifcations. Refer to the JS1000 Base Technical Information manual 520L0826 for

mating connector part information. Refer to the table below for service part information.

JS1000 Joystick Grip and Base Service Parts

Grip type Part description Replacement part ordering number

JS1000 ball grip Boot 10103388

Ball grip 10101913

Grip fastening screw 10101782

JS1000 grip with switch,

rocker and banana

Rocker switch cover 10101816

Banana switch cover 10103337

JS1000 PRO grip No replacement parts available

Service Part Information

JS1000, JS6000 Joystick Grips

Technical Information

39 520L0872 Rev HA Jun 2013

Notes

Local address:

Sauer-Danfoss GmbH & Co. OHG

Postfach 2460, D-24531 Neumnster

Krokamp 35, D-24539 Neumnster, Germany

Phone: +49 4321 871 0

Fax: +49 4321 871 122

Sauer-Danfoss ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444

Fax: +45 7488 4400

Sauer-Danfoss is a global manufacturer and supplier of high-

quality hydraulic and electronic components. We specialize in

providing state-of-the-art technology and solutions that excel in

the harsh operating conditions of the mobile of-highway market.

Building on our extensive applications expertise, we work closely

with our customers to ensure exceptional performance for a broad

range of of-highway vehicles.

We can help speed up system development, reduce costs and bring

your vehicles to market faster. Sauer-Danfoss Your Strongest

Partner in Mobile Hydraulics.

Go to www.sauer-danfoss.com for further product information.

Wherever of-highway vehicles are at work, so is Sauer-Danfoss.

We ofer expert worldwide support for our customers, ensuring

the best possible solutions for outstanding performance. And with

an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Bent Axis Motors

Closed Circuit Axial Piston Pumps

and Motors

Displays

Electrohydraulic Power Steering

Electrohydraulics

Hydraulic Power Steering

Integrated Systems

Joysticks and Control Handles

Microcontrollers and Software

Open Circuit Axial Piston Pumps

Orbital Motors

PLUS+1 GUIDE

Proportional Valves

Sensors

Steering

Transit Mixer Drives

Members of the Sauer-Danfoss Group

Comatrol

www.comatrol.com

Schwarzmller-Inverter

www.schwarzmueller-inverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Sauer-Danfoss-Daikin

www.sauer-danfoss-daikin.com

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Fax: +1 515 239 6618

Sauer-Danfoss-Daikin LTD.

Shin-Osaka TERASAKI 3rd Bldg. 6F

1-5-28 Nishimiyahara, Yodogawa-ku

Osaka 532-0004, Japan

Phone: +81 6 6395 6066

Fax: +81 6 6395 8585

w w w . s a u e r - d a n f o s s . c o m

Vous aimerez peut-être aussi

- Axial Piston MotorsDocument20 pagesAxial Piston MotorsJosé Emilio D' LeónPas encore d'évaluation

- Merlo T156 Telehandler Service Manual PDFDocument473 pagesMerlo T156 Telehandler Service Manual PDFChomi0% (1)

- A - Power Split Hydro-Mechanical Variable Transmission (HVT) For Off-Highway ApplicationDocument12 pagesA - Power Split Hydro-Mechanical Variable Transmission (HVT) For Off-Highway ApplicationchuhuynhPas encore d'évaluation

- Operation 31200753 06-27-2016 CE-AUS EnglishDocument206 pagesOperation 31200753 06-27-2016 CE-AUS EnglishnelsonyPas encore d'évaluation

- LINDE R-02 Hydraulic Motors For Open and Closed OperationDocument44 pagesLINDE R-02 Hydraulic Motors For Open and Closed OperationRomanko100% (1)

- Sauer Danfoss PVEDocument44 pagesSauer Danfoss PVEdozer_kamil100% (2)

- Overview Eng CD PDFDocument20 pagesOverview Eng CD PDFRafael Cortes100% (1)

- Wiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinDocument4 pagesWiper Motor Washer Motor Room Lamp Heater Roof Light Radio: CabinAnonymous yjK3peI7Pas encore d'évaluation

- Manuel de Operador GTH4013 EXDocument225 pagesManuel de Operador GTH4013 EXjonny david martinez perezPas encore d'évaluation

- Terex Gyro Service ManualDocument100 pagesTerex Gyro Service ManualMichael Belodon100% (2)

- Digital Level - Display DA13Document16 pagesDigital Level - Display DA13Sergio Belmar CrisostoPas encore d'évaluation

- Hyster Joystick EN PDFDocument18 pagesHyster Joystick EN PDFweldsaidiPas encore d'évaluation

- DFG 320Document123 pagesDFG 320Виталий КравченкоPas encore d'évaluation

- Danfoss TechnicalDocument24 pagesDanfoss TechnicalVaikis Oio100% (1)

- Manitou ManualDocument234 pagesManitou ManualxpenPas encore d'évaluation

- OmegaDocument2 pagesOmegaATHOLSCHWARZPas encore d'évaluation

- Service Manual: Loader Control SystemDocument48 pagesService Manual: Loader Control SystemJHONATANPas encore d'évaluation

- Linde DriveSystems CM PDFDocument37 pagesLinde DriveSystems CM PDFRagab AbulmagdPas encore d'évaluation

- Linde Ex H20-30Document2 pagesLinde Ex H20-30victorg107270Pas encore d'évaluation

- BC 672772 RBRS Service TraningDocument385 pagesBC 672772 RBRS Service TraningTeknik Makina100% (2)

- Manual Rc400 0Document66 pagesManual Rc400 0Fdfasdf100% (1)

- Instruction Manual Safety SystemDocument99 pagesInstruction Manual Safety SystemAndrey AndreyPas encore d'évaluation

- Pved CX TiDocument96 pagesPved CX TiYuriPasenkoPas encore d'évaluation

- VMQ PDFDocument78 pagesVMQ PDFoleg-spbPas encore d'évaluation

- Case Construction Backhoe Loader Tier3Document22 pagesCase Construction Backhoe Loader Tier3Nick E100% (1)

- R944CDocument12 pagesR944Cequipment9278Pas encore d'évaluation

- PVG32 PDFDocument146 pagesPVG32 PDFjose manuel barroso pantoja100% (7)

- Ospb Ospc Ospr OspdDocument32 pagesOspb Ospc Ospr Ospdluiscampos77Pas encore d'évaluation

- Palfinger Epsilon Gripping Solutions M SeriesDocument22 pagesPalfinger Epsilon Gripping Solutions M SeriescetinPas encore d'évaluation

- Motomit IT Kesla Basic SettingsDocument3 pagesMotomit IT Kesla Basic Settingsmichaud1979Pas encore d'évaluation

- Axial Piston Variable Pump A10V (S) O Series 31 AmericasDocument56 pagesAxial Piston Variable Pump A10V (S) O Series 31 AmericasFawzi AlzubairyPas encore d'évaluation

- PLUS+1® Compliant: OX024-x10 Function BlockDocument16 pagesPLUS+1® Compliant: OX024-x10 Function BlockGuima_df100% (1)

- LM Ap4802n InbDocument20 pagesLM Ap4802n InbWalace LucasPas encore d'évaluation

- Txserie GBDocument16 pagesTxserie GBIvanPas encore d'évaluation

- PC80MR-3 Wess005804 1203 PDFDocument16 pagesPC80MR-3 Wess005804 1203 PDFTamquadistu AlexPas encore d'évaluation

- Chap 70Document150 pagesChap 70Farid Rezig100% (2)

- Complete Hire Sydney Terex TA6 6t Dump Truck 6000kg Operators ManualDocument140 pagesComplete Hire Sydney Terex TA6 6t Dump Truck 6000kg Operators ManualDavid Eduardo Apaza CairaPas encore d'évaluation

- Hitch Control Valves EHR5 and EHR23: EnglishDocument28 pagesHitch Control Valves EHR5 and EHR23: EnglishmetinPas encore d'évaluation

- Liebherr A314 ManualDocument44 pagesLiebherr A314 ManualElena RomanPas encore d'évaluation

- JCB 926Document4 pagesJCB 926Nenad NedeljkovicPas encore d'évaluation

- Service Manual L14, 16 & 18 EMDocument34 pagesService Manual L14, 16 & 18 EMWSMengine WSMenginePas encore d'évaluation

- Start HereDocument23 pagesStart HereAntónio Correia100% (2)

- Sauer-Danfoss Mcx103b D Rotary Position Sensor TechnicalDocument8 pagesSauer-Danfoss Mcx103b D Rotary Position Sensor TechnicalJosé Fidencio Carrillo Moreno0% (1)

- WX148-168 GB PDFDocument24 pagesWX148-168 GB PDFmajastojkePas encore d'évaluation

- Manual de Parte CE-25-33-40 RTSDocument214 pagesManual de Parte CE-25-33-40 RTSCarlos MontalvoPas encore d'évaluation

- Edc DanfossDocument16 pagesEdc Danfosstomirueda0% (1)

- Medium Series: 6 9 Hydraulic BreakersDocument2 pagesMedium Series: 6 9 Hydraulic BreakersSebastián Fernando Canul MendezPas encore d'évaluation

- Go Silently at High Pressure & High Speed: CONTINUUM® SeriesDocument54 pagesGo Silently at High Pressure & High Speed: CONTINUUM® SeriesYazad DoctorrPas encore d'évaluation

- Terberg - RT223 4x4: DetailsDocument4 pagesTerberg - RT223 4x4: DetailsAbdelhadi HoussinPas encore d'évaluation

- Blue Line Hydraulic Breakers: Product RangeDocument6 pagesBlue Line Hydraulic Breakers: Product RangeChandra prakash Jangid0% (1)

- Instrukciya Po Ekspluatacii Gusenichnogo Ekskavatora Liebherr R 944 C Litronic Operation InstructionDocument282 pagesInstrukciya Po Ekspluatacii Gusenichnogo Ekskavatora Liebherr R 944 C Litronic Operation InstructionВолодимир Кривко100% (1)

- Operating Manual: Clean AheadDocument200 pagesOperating Manual: Clean AheadLucyan IonescuPas encore d'évaluation

- 72 516 PDFDocument65 pages72 516 PDFJITENDRA KUMAR SHARMAPas encore d'évaluation

- Linde H40 45 50Document6 pagesLinde H40 45 50Lucas IbañezPas encore d'évaluation

- Liftlux Diesel TrainingDocument77 pagesLiftlux Diesel TrainingIvaylo Petkov100% (1)

- Specificatii Tehnice1Document10 pagesSpecificatii Tehnice1Jozef100% (1)

- Genie Z 45 22 DC 4592Document110 pagesGenie Z 45 22 DC 4592SARAMQRPas encore d'évaluation

- Danfoss EHPS Steering ValveDocument52 pagesDanfoss EHPS Steering ValveDragan Lazic100% (1)

- HPV 02 VariablePump enDocument36 pagesHPV 02 VariablePump enMiguel BustamantePas encore d'évaluation

- Snowball Machine Gun - Build InstructionsDocument8 pagesSnowball Machine Gun - Build InstructionsMichael LinPas encore d'évaluation

- PT9420 PDFDocument6 pagesPT9420 PDFMichael LinPas encore d'évaluation

- Lab View Hand Out 04Document20 pagesLab View Hand Out 04Michael LinPas encore d'évaluation

- Labview Core2 Course Manual NewDocument135 pagesLabview Core2 Course Manual NewMichael LinPas encore d'évaluation

- CCST QuestionDocument17 pagesCCST Questionthe_tigdra100% (1)

- CSE Second Edition Sample PagesDocument17 pagesCSE Second Edition Sample Pages14071988Pas encore d'évaluation

- Counting Subsets of A Set: CombinationsDocument5 pagesCounting Subsets of A Set: CombinationsMichael LinPas encore d'évaluation

- Acrobat 9 Troubleshooting PDFDocument365 pagesAcrobat 9 Troubleshooting PDFMichael LinPas encore d'évaluation

- Sensor Systems Brochure For TurboMachineryDocument12 pagesSensor Systems Brochure For TurboMachineryMichael LinPas encore d'évaluation

- W540 Hardware Maintenance ManualDocument116 pagesW540 Hardware Maintenance ManualMichael LinPas encore d'évaluation

- SolidWorks Electrical InstallingDocument31 pagesSolidWorks Electrical InstallingMichael LinPas encore d'évaluation

- Mail-In Rebate: Last NameDocument1 pageMail-In Rebate: Last NameMichael LinPas encore d'évaluation

- LEOs Software Development Manual - Volume 2 APIDocument88 pagesLEOs Software Development Manual - Volume 2 APIMichael LinPas encore d'évaluation

- EdgeCAM Lesson2Document23 pagesEdgeCAM Lesson2aralvoiPas encore d'évaluation

- EdgeCAM Lesson1Document5 pagesEdgeCAM Lesson1Alex DosofteiPas encore d'évaluation

- Adigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011Document16 pagesAdigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011AnnyPas encore d'évaluation

- Gigabyte Ga b85m Ds3h A r10 PDFDocument30 pagesGigabyte Ga b85m Ds3h A r10 PDFMartha Lorena TijerinoPas encore d'évaluation

- TCGRX BullsEye Tablet SplitterDocument2 pagesTCGRX BullsEye Tablet SplittermalucPas encore d'évaluation

- BLG311 Cell Biology: Course Outline (Fall 2020)Document11 pagesBLG311 Cell Biology: Course Outline (Fall 2020)Emilija BjelajacPas encore d'évaluation

- Sub-Wings of YuvanjaliDocument2 pagesSub-Wings of Yuvanjalin_tapovan987100% (1)

- DIY Toolkit Arabic Web VersionDocument168 pagesDIY Toolkit Arabic Web VersionAyda AlshamsiPas encore d'évaluation

- 3-A Y 3-B Brenda Franco DíazDocument4 pages3-A Y 3-B Brenda Franco DíazBRENDA FRANCO DIAZPas encore d'évaluation

- (Bruno Bettelheim) Symbolic Wounds Puberty RitesDocument196 pages(Bruno Bettelheim) Symbolic Wounds Puberty RitesAmbrose66Pas encore d'évaluation

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- Action Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorDocument1 pageAction Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorEdelmar BenosaPas encore d'évaluation

- The Handmaid's TaleDocument40 pagesThe Handmaid's Taleleher shahPas encore d'évaluation

- Behavior Intervention MenuDocument56 pagesBehavior Intervention Menuapi-479527084100% (4)

- Assessment - UK Forestry Data ICT THEORY For CAT1Document13 pagesAssessment - UK Forestry Data ICT THEORY For CAT1Joanna AchemaPas encore d'évaluation

- ING C1 CO JUN2016 CorrectorDocument6 pagesING C1 CO JUN2016 CorrectoraciamePas encore d'évaluation

- Full Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full ChapterDocument13 pagesFull Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full Chapterpoetrycloudyzjm12q100% (19)

- Pipe Freezing StudyDocument8 pagesPipe Freezing StudymirekwaznyPas encore d'évaluation