Académique Documents

Professionnel Documents

Culture Documents

D 49 - 83 r96 Rdq5ltgzujk2rte

Transféré par

frostestDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

D 49 - 83 r96 Rdq5ltgzujk2rte

Transféré par

frostestDroits d'auteur :

Formats disponibles

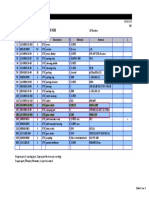

Designation: D 49 83 (Reapproved 1996)

e1

Standard Test Methods of

Chemical Analysis of Red Lead

1

This standard is issued under the xed designation D 49; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. Anumber in parentheses indicates the year of last reapproval. Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

e

1

NOTEKeywords and References were added editorially in May 1996.

1. Scope

1.1 These test methods cover procedures for the chemical

analysis of red lead having the approximate formula Pb

3

O

4

(probably PbO

2

2PbO).

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 50 Test Methods for Chemical Analysis of Yellow, Or-

ange, Red, and Brown Pigments Containing Iron and

Manganese

2

D 215 Practice for Chemical Analysis of White Linseed Oil

Paints

3

D 280 Test Methods for Hygroscopic Moisture (and Other

Matter Volatile Under the Test Conditions) in Pigments

2

D 1193 Specication for Reagent Water

4

D 1208 Test Methods for Common Properties of Certain

Pigments

2

D 1301 Test Methods for Chemical Analysis of White Lead

Pigments

2

D 1959 Test Method for Iodine Value of Drying Oils and

Fatty Acids

2

3. Treatment of Sample

3.1 If the pigment is lumpy or not nely ground, grind it to

a ne powder and mix thoroughly. Large samples may be

thoroughly mixed and a representative portion taken and

powdered if lumpy or not nely ground. The sample in all

cases shall be thoroughly mixed before taking portions for

analysis. All samples shall be preserved in stoppered bottles or

containers.

4. Purity of Reagents

4.1 Reagent grade chemicals shall be used in all tests.

Unless otherwise indicated, it is intended that all reagents shall

conform to the specications of the Committee on Analytical

Reagents of the American Chemical Society where such

specications are available.

5

Other grades may be used pro-

vided it is rst ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

the determination.

4.2 Unless otherwise indicated, references to water shall be

understood to mean reagent water conforming to Type II of

Specication D 1193.

5. Moisture

5.1 Determine moisture content with a 2-g specimen in

accordance with Method A of Test Method D 280. The speci-

men is dried for 2 h at 105C. The loss in weight is considered

as moisture.

6. Organic Color

6.1 Boil 2 g of the sample with 25 mL of 95 % ethyl alcohol,

let settle, decant the supernatant liquid; boil the residue with 25

mL of distilled water and decant as before; boil the residue

with 25 mL of diluted NH

4

OH (1 + 4) and again decant. Boil

another 2-g portion of the sample with 25 mL of chloroform,

let settle, and decant the supernatant liquid. If any one of the

above solutions is colored, organic coloring matter is indicated.

If the solutions remain colorless, organic colors are probably

absent.

NOTE 1If it is desired to test for organic colors resistant to the above

reagents, the test procedures described in the following books may be

used, taking into account the nature of the pigment involved (1,2,3).

6

7. Total Lead and Insoluble Matter

7.1 Treat 1 g of the sample with 15 mL of HNO

3

(1 + 1) and

sufficient H

2

O

2

to dissolve all PbO

2

on warming. If any

1

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and are the direct responsibility

of Subcommittee D 01.31 on Pigment Specications.

Current edition approved Dec. 20, 1983. Published January 1984. Originally

published as D 49 17 T. Last previous edition D 49 82.

2

Annual Book of ASTM Standards, Vol 06.03.

3

Annual Book of ASTM Standards, Vol 06.01.

4

Annual Book of ASTM Standards, Vol 11.01.

5

Reagent Chemicals, American Chemical Society Specications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD.

6

The boldface numbers in parentheses refer to a list of references at the end of

these test methods.

1

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

insoluble matter is present, add 25 mL of water, boil, lter, and

wash with hot water. The insoluble matter contains free SiO

2

and should be examined for BaSO

4

and silicates, if appreciable.

7.2 To the original solution or ltrate from the insoluble

matter add 20 mL of H

2

SO

4

(sp gr 1.84) and evaporate to SO

3

fumes. Cool, add 150 mL of water, and 150 mL of 95 % ethyl

alcohol, let stand cold for 2 h, lter, on a Gooch crucible, wash

with 95 % alcohol, dry at 105 to 110C, and weigh as PbSO

4

.

Calculate to PbO.

7.3 Red lead is rarely adulterated, but should the specimen

contain soluble barium compounds, the PbSO

4

obtained in 8.2

will contain BaSO

4

. In this case, precipitate the lead as sulde

from a slightly acid (HCl) solution, dissolve the PbS in hot

diluted HNO

3

, and determine the lead as sulfate or chromate.

7.4 If the specimen contains signicant amounts of calcium

or magnesium, boil the HNO

3

H

2

O

2

solution (7.1) until all

the lead is converted into nitrate and then determine the lead as

PbCrO

4

.

7.5 If soluble barium, calcium, or magnesium are to be

determined, precipitate the lead as sulde from a slightly acid

solution (HCl), dissolve the PbS in hot diluted HNO

3

, and

determine the lead as sulfate. Boil the ltrate from the PbS to

expel H

2

S, add a little bromine water to oxidize iron (if

present), boil to expel bromine, and precipitate the barium with

a few millilitres of H

2

SO

4

(1 + 3). Filter and weigh as BaSO

4

.

Calculate to BaO or BaCO

3

. To the ltrate from the BaSO

4

add

NH

4

OH in slight excess, lter off any precipitate of

Fe(OH)

3

+ Al(OH)

3

, wash with hot water. Manganese, if

present, can be precipitated by adding bromine and NH

4

OH

and warming. Filter, wash with hot water, ignite, and weigh as

Mn

3

O

4

. Unite all the ltrates, make slightly acid with acetic

acid, heat to boiling and pass H

2

S into the hot solution until

saturated (20 to 30 min); add 5 g of NH

4

Cl and let stand 5 h,

lter off any ZnS, wash with H

2

S water, dissolve the ZnS in hot

diluted HCl and determine the zinc by titration with

K

4

Fe(CN)

6

. Or, boil off the H

2

S, lter out any separated sulfur

and determine the zinc as Zn

2

P

2

O

7

. Calcium may be deter-

mined in the ltrate from the ZnS by expelling H

2

S and then

adding NH

4

OH and ammonium oxalate. Titrate the calcium

oxide precipitate using the procedure described in 13.3 of Test

Methods D 50. In the ltrate from calcium determine magne-

sium by precipitating with sodium phosphate solution, nally

weighing as Mg

2

P

2

O

7

.

8. Lead Peroxide (PbO

2

) and True Red Lead (Pb

3

O

4

)

NOTE 2Method of Diehl (4) modied by Topf (5)not applicable

when substances are present, other than oxides of lead, that liberate iodine

under conditions given, or substances such as metallic lead which reduce

PbO

2

to PbO without the liberation of iodine.

8.1 Solutions Required: (a) Red Lead SolutionDissolve in

1-L beaker 600 g of crystallized sodium acetate and 48 g of KI

in about 500 mL of acetic acid (1 + 3) (made by mixing 150

mL of glacial acetic acid with 450 mL of water). Warm the

beaker and contents on a steam bath, stirring occasionally, until

a clear solution is obtained. Cool this solution to room

temperature, dilute to exactly 1000 mL with the acetic acid

(1 + 3) and mix thoroughly. If preferred, the red lead solution

may be prepared separately for each titration, as follows:

Dissolve 30 g of the crystallized sodium acetate and 2.4 g of KI

in 25 mL of the acetic acid (1 + 3), warming gently and stirring

until a clear solution is obtained. Cool this solution to room

temperature, dilute to 50 mL with the acetic acid solution

(1 + 3), and mix thoroughly.

8.2 Sodium Thiosulfate Solution (0.1N)Dissolve 24.83 g

of sodium thiosulfate (Na

2

S

2

O

3

5H

2

O), freshly pulverized and

dried between lter paper, and dilute with water to 1 litre at the

temperature at which the titrations are to be made. The solution

is best made with well-boiled water free from CO

2

, or let stand

8 to 14 days before standardizing, as described in Section 5 of

Test Method D 1959.

8.3 Starch SolutionStir 2 to 3 g of potato starch with 100

mL of salicylic acid solution (1 %), and boil the mixture until

the starch is practically dissolved, then dilute to 1 L (Note 3),

or prepare as described in 7.8.2 of Test Method D 1959.

NOTE 3Lead PeroxideIf the pigment contains an appreciable

amount of nitrite (nitrate has no effect on the method), leach out

water-soluble matter as below, dry the residue and determine PbO

2

as

above, calculating to basis of original specimen.

9. Procedure

9.1 Weigh 1 g of the nely ground sample, transfer to a

200-mL Erlenmeyer ask, add 20 mL of water; then add as

quickly as possible 40 mL of the red lead solution at room

temperature. If the sample is red lead that has been extracted

from a paint or paste, in place of the water use 10 mL of a

mixture of 7 parts by volume of chloroform and 3 parts by

volume of glacial acetic acid, and then add without delay the

red lead solution. Add 30 mL of water containing 5 or 6 g of

sodium acetate and titrate at once with 0.1 N Na

2

S

2

O

3

solution,

adding the latter rather slowly and keeping the liquid con-

stantly in motion by whirling the ask. When the solution has

become light yellow, rub-up any undissolved particles with the

rod until free iodine no longer forms, wash off rod, add the

Na

2

S

2

O

3

solution until pale yellow, add starch solution, and

titrate until colorless. Add the 0.1 N iodine solution until blue

color is just restored and subtract the amount used for the

volume of Na

2

S

2

O

3

that had been added.

10. Calculation

10.1 Calculate the lead peroxide and true red lead contents

as follows:

PbO

2

5 I 3 0.942

Pb

3

O

4

5 PbO

2

3 2.866 5 I 3 2.7

where: I 5 iodine value of the Na

2

S

2

O

3

solution,

0.942 5

PbO

2

I

2

5

239.19

253.81

, and (1)

2.86616 5

Pb

3

O

4

PbO

2

5

685.57

239.19

11. Zinc

11.1 If the volume is appreciable, evaporate off the alcohol

from the ltrate from total lead, make alkaline with NH

4

OH,

then acid with HCl (sp gr 1.19), add 3 mL more of HCl, dilute

to about 250 mL with water, heat nearly to boiling and titrate

with standard K

4

Fe(CN)

6

solution in accordance with 16.1.11

of Method D 215. Report as ZnO (includes cadmium). Iron,

D 49

2

copper, or other interfering substances should rst be removed

as described in 25.2.3 of Practice D 215.

12. Matter Soluble in Water

12.1 Determine the amount of water soluble material

present in accordance with the procedure in Section 5 of Test

Methods D 1208 or determine in accordance with Test Method

D 1301.

13. Total Silica

13.1 Digest 5 g of the sample in a covered casserole with 5

mL of HCl and 15 mL of HNO

3

(1 + 1). Evaporate to dryness

to dehydrate. Cool, treat with hot water and HNO

3

, boil, lter,

wash with hot acid ammonium acetate solution, then dilute

HCl and nally hot water. Ignite and weigh as SiO

2

. The

residue may be treated with H

2

SO

4

and HF in cases of doubt as

to purity.

14. Carbon Dioxide

14.1 Determine carbon dioxide by the evolution method,

using diluted HCl and stannous chloride.

15. Soluble Sulfates

15.1 Sulfates Other Than Barium SulfateTreat 0.5 g of the

sample with 5 mL of water, 3 g of NH

4

Cl, and 5 mL of HCl

saturated with bromine. Digest (covered) on steam bath about

15 min. Add 25 mL of water, neutralize with dry Na

2

CO

3

, and

add about 2 g more. Boil 10 to 15 min, let settle, dilute with hot

water, lter, and wash with hot water. Redissolve in HCl,

reprecipitate as above, and wash thoroughly with hot water.

Acidify the united ltrates with HCl, adding a slight excess;

boil and add a slight excess of BaCl

2

solution (10 %). Let stand

on a steam bath for 1 h. Filter and wash with hot water. Ignite

and weigh as BaSO

4

. Calculate to SO

3

(includes SO

3

formed

from SO

2

).

15.2 Or, dissolve 0.5 g of the sample in 25 mL of water, 10

mL of NH

4

OH (sp gr 0.90) and HCl in slight excess; dilute to

about 150 mL with water and add a piece of aluminum foil

which should about cover the bottom of the beaker (being held

on the bottom by means of a stirring rod). Heat gently till all

lead is precipitated, decant through a lter, pressing the lead

sponge with a attened rod, and washing with hot water. Add

to the ltrate a little bromine water, boil until bromine is

expelled, add 15 mL of BaCl

2

solution (10 %), let stand on a

steam bath for 1 h, lter, wash with hot water, ignite, and weigh

as BaSO

4

(any SrSO

4

present is not decomposed in this

method).

7

16. Iron Oxide

16.1 Determine iron oxide in accordance with Section 12 of

Method D 50, or in a large beaker, treat 20 g of the sample with

20 mL of water, 20 mL of HNO

3

(sp gr 1.42), and 3 mL of

formaldehyde solution. Warm until all PbO

2

is dissolved, dilute

with water, warm, lter off insoluble matter, and wash with hot

water. Ignite lter and insoluble matter, and evaporate with

H

2

SO

4

and HF. To ltrate from insoluble matter add 14 mL of

H

2

SO

4

(1 + 1), lter off PbSO

4

, and wash. Dissolve the residue

from HF and H

2

SO

4

in H

2

SO

4

and add to the ltrate from

PbSO

4

. Dilute to 500 mL and determine iron colorimetrically

in an aliquot, using the same amounts of HNO

3

, H

2

SO

4

, and

formaldehyde in the comparison solution Ref (7). Calculate to

Fe

2

O

3

.

17. Keywords

17.1 chemicals analysis; lead dioxide; red lead; tetra lead

oxide

REFERENCES

(1) Zerr, and Mayer, Tests for Coal Tar Colors in Aniline Lakes.

(2) Schultz, and Julius, A Systematic Survey of the Organic Coloring

Matters.

(3) Mulliken, Identication of Pure Organic Compounds; Commercial

Dyestuffs, Vol III.

(4) Dinglers, Dinglers Polytechnisches Journal, DPJOA, Vol 246, p. 196.

(5) Zeitschrift fr Analytische Chemie, ZANCA, Vol 26, p. 296.

(6) Skoog, D. A. and West, D. M., Fundamentals of Analytical Chemistry,

Holt, Rinehart and Winston, Inc., New York, 1969, p. 192.

(7) Lunge-Berl, Chemische-technisch Untersuchungs-Methoden, Vol 2,

p. 95, 6th Ed.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

7

The solubility of BaSO

4

is increased by the presence of aluminum chloride (6).

D 49

3

Vous aimerez peut-être aussi

- PULLALIGN-Lite 2-Page-Flyer G PDFDocument2 pagesPULLALIGN-Lite 2-Page-Flyer G PDFfrostestPas encore d'évaluation

- F 2203 - 02 RjiymdmDocument3 pagesF 2203 - 02 Rjiymdmfrostest100% (1)

- F 2096 - 02 RjiwotytmdiDocument5 pagesF 2096 - 02 RjiwotytmdifrostestPas encore d'évaluation

- Prophi PDFDocument2 pagesProphi PDFfrostestPas encore d'évaluation

- F 2217 - 02 RjiymtcDocument3 pagesF 2217 - 02 RjiymtcfrostestPas encore d'évaluation

- F 2227 - 02 RjiymjcDocument4 pagesF 2227 - 02 RjiymjcfrostestPas encore d'évaluation

- F 2228 - 02 RjiymjgDocument5 pagesF 2228 - 02 Rjiymjgfrostest100% (1)

- F 2250 - 03 RjiyntaDocument3 pagesF 2250 - 03 RjiyntafrostestPas encore d'évaluation

- Determining The Writeability of Print Media: Standard Practice ForDocument2 pagesDetermining The Writeability of Print Media: Standard Practice ForfrostestPas encore d'évaluation

- F 2250 - 03 RjiyntaDocument3 pagesF 2250 - 03 RjiyntafrostestPas encore d'évaluation

- D 4774 - 94 Rdq3nzqtotqDocument3 pagesD 4774 - 94 Rdq3nzqtotqfrostestPas encore d'évaluation

- F 2251 - 03 RjiynteDocument4 pagesF 2251 - 03 RjiyntefrostestPas encore d'évaluation

- F 2296 - 03 RjiyotyDocument3 pagesF 2296 - 03 RjiyotyfrostestPas encore d'évaluation

- D 5094 - 90 r97 RduwotqtotbsotcDocument3 pagesD 5094 - 90 r97 RduwotqtotbsotcfrostestPas encore d'évaluation

- D 3652 - D 3652m - 93 r99 Rdm2ntitotnsotkDocument3 pagesD 3652 - D 3652m - 93 r99 Rdm2ntitotnsotkfrostestPas encore d'évaluation

- D 5331 - 98 RduzmzetukveDocument4 pagesD 5331 - 98 RduzmzetukvefrostestPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Inspirational Quotes General and ExamsDocument6 pagesInspirational Quotes General and Examsasha jalanPas encore d'évaluation

- Farmhouse Style Plans - Farm & CountryDocument6 pagesFarmhouse Style Plans - Farm & Countryhanif azriPas encore d'évaluation

- Muharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFDocument154 pagesMuharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFjeff tehPas encore d'évaluation

- Annotated Bib-BirthingDocument3 pagesAnnotated Bib-Birthingapi-312719022Pas encore d'évaluation

- Video Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabDocument1 pageVideo Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabBusur DataPas encore d'évaluation

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsPas encore d'évaluation

- American Pile Driving Equipment Equipment CatalogDocument25 pagesAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- Radiation Formula SheetDocument5 pagesRadiation Formula SheetJakeJosephPas encore d'évaluation

- Developing Agility and Quickness (Etc.) (Z-Library) - 66Document2 pagesDeveloping Agility and Quickness (Etc.) (Z-Library) - 66guypetro6Pas encore d'évaluation

- Sop ExcelDocument104 pagesSop ExcelRizky C. AriestaPas encore d'évaluation

- 3592 Operator GuideDocument103 pages3592 Operator GuideNaim GhattasPas encore d'évaluation

- Strange Christmas TraditionsDocument2 pagesStrange Christmas TraditionsZsofia ZsofiaPas encore d'évaluation

- Pelton2014 Para-Equilibrium Phase DiagramsDocument7 pagesPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaPas encore d'évaluation

- Curso VII Lectura 2. New Rural Social MovementsDocument12 pagesCurso VII Lectura 2. New Rural Social MovementsFausto Inzunza100% (1)

- B.Pharm - Semester - III-10.07.2018Document16 pagesB.Pharm - Semester - III-10.07.2018SAYAN BOSEPas encore d'évaluation

- Etl 213-1208.10 enDocument1 pageEtl 213-1208.10 enhossamPas encore d'évaluation

- Nurtured Womb e BookDocument22 pagesNurtured Womb e BookSteph's Desserts100% (1)

- WPCE Wireline Lubricator With Threaded Unions PDFDocument1 pageWPCE Wireline Lubricator With Threaded Unions PDFDidik safdaliPas encore d'évaluation

- Notice - Appeal Process List of Appeal Panel (Final 12.1.24)Document13 pagesNotice - Appeal Process List of Appeal Panel (Final 12.1.24)FyBerri InkPas encore d'évaluation

- Presentation 1Document7 pagesPresentation 1Abdillah StrhanPas encore d'évaluation

- Editor: Lalsangliana Jt. Ed.: H.Document4 pagesEditor: Lalsangliana Jt. Ed.: H.bawihpuiapaPas encore d'évaluation

- NREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFDocument35 pagesNREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFJosePPMolinaPas encore d'évaluation

- Aesa Based Pechay Production - AbdulwahidDocument17 pagesAesa Based Pechay Production - AbdulwahidAnne Xx100% (1)

- Instructor: DR - Ashok Kaushal: Orthogonal ViewsDocument49 pagesInstructor: DR - Ashok Kaushal: Orthogonal ViewsKristi GjokaPas encore d'évaluation

- Classical Feedback Control With MATLAB - Boris J. Lurie and Paul J. EnrightDocument477 pagesClassical Feedback Control With MATLAB - Boris J. Lurie and Paul J. Enrightffranquiz100% (2)

- Human Eye 5Document7 pagesHuman Eye 5NanditaPas encore d'évaluation

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDocument65 pagesIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaPas encore d'évaluation

- An Evaluation of The Strength of Slender Pillars G. S. Esterhuizen, NIOSH, Pittsburgh, PADocument7 pagesAn Evaluation of The Strength of Slender Pillars G. S. Esterhuizen, NIOSH, Pittsburgh, PAvttrlcPas encore d'évaluation

- Inverse Curve Trip Time Calculation: Enter Values in White CellDocument3 pagesInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxPas encore d'évaluation

- 3TRIGODocument5 pages3TRIGOCielo Pabilan ObemioPas encore d'évaluation