Académique Documents

Professionnel Documents

Culture Documents

Eaton: Medium Duty Piston Pump

Transféré par

Fernando SabinoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Eaton: Medium Duty Piston Pump

Transféré par

Fernando SabinoDroits d'auteur :

Formats disponibles

Eaton

Medium Duty Piston Pump

Model 70360 Variable Displacement Piston Pump

40,6 cm

3

/r [2.48 in

3

/r] or 49,2 cm

3

/r [3.00 in

3

/r] Displacements

Manual Controlled -02

Repair Information

No. 07-627

December 1998

2

Model 70360

Table of Contents

Introduction ......................................................................................................... 2

Identification........................................................................................................ 3

Tools Required .................................................................................................... 3

Parts Drawing ...................................................................................................... 4 - 5

Parts List ............................................................................................................. 6 - 7

Repair information

Disassembly .................................................................................................. 8 - 10

Reassembly ................................................................................................... 11 - 12

Fault - Logic Troubleshooting .............................................................................. 13 - 17

Start-up Procedure .............................................................................................. 18

Introduction

This manual provides service information for Eaton Models 70360 variable displacement piston pumps. Step

by step instructions for the complete disassembly, inspection, and reassembly of the pump are given. The

following recommendations should be followed to insure successful repairs.

Remove the pump from the application.

Cleanliness is extremely important.

Clean the port areas thoroughly before disconnecting the hydraulic lines.

Plug the pump ports and cover the open hydraulic lines immediately after they're disconnected.

Drain the oil and clean the exterior of the pump before making repairs.

Wash all metal parts in clean solvent.

Use compressed air to dry the parts. Do not wipe them dry with paper towels or cloth.

Compressed air should be filtered and moisture free.

Always use new seals when reassembling hydraulic pumps.

Lubricate the new rubber seals with a petroleum jelly (Vaseline

) before installation.

Torque all bolts over gasketed joints, then repeat the torquing sequence to makeup for gasket

compression.

Verifying the accuracy of pump repairs on an authorized test stand is essential.

Introduction

3

Model 70360

Tools Required

9/16, 7/8, 1-1/8 in. sockets and/or end

wrenches

Torque wrench (203 N

.

m [150 lbf

.

ft] capacity)

Ratchet wrench

7/16 in. Allen wrench or bit socket

Internal and external retaining ring pliers

Small screwdrivers (2)

Hammer (soft face)

Light Petroleum Jelly

Seal driver or similar tool

Serial Number Code:

A 96 01 31 JB

Tester's Initials

Day of Month (two digits)

Month (two digits)

Revision level of parts list.

Last two digits of year built.

( 91 for 1991 etc.)

Identification Numbers - Manually Variable Displacement Piston Pump

Identification label on control arm side of housing.

A - Product Number Description

70360 = Single Piston Pump

78362 = Single Piston Pump with Gear Pump

78361 = Tandem Piston Pumps

78363 = Tandem Piston Pumps with Gear Pump

B - Sequential Numbering

C - Engineering Design Code

Single Pump - Product Number:

7 0 3 6 0 - R A A - 02

Tandem Pumps - Product Number:

7 8 3 6 3 - R A B - 02

A

A

B

B

Each order must include the following information.

1. Product and/or Part Number

2. Serial Number Code

3. Part Name

4. Quantity

C

C

4

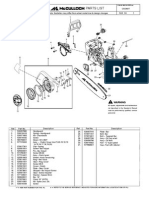

Model 70360

Parts

Drawing

Pump drawn below is typical of a righthand rotation pump.

24-1

28

14

3

12

59

59

10-1

10

6

6

11

11

9

44

20

41

5

16

17

16

5

4

27

Shaft assembly for

rear pump of tandem.

27

32

24

54

54-1

53

Port

(D2)

Port

(D2)

53-1

20

5

16

17

4

16

5

Shaft assembly for

single pump

or front pump

of tandem.

70360-RXX-02

A980131JB

Identification Label

Located on Control Arm Side

5

Model 70360

Parts

Drawing

Note "V" notch

locations

Lefthand

Rotation

Righthand

Rotation

Valve Plate

Identification

25-1

Used in place of Auxiliary pump.

Refer to Backplate

Assembly Identification section

for additional backplates.

K2-1

K2-2

K2-3

K1-1

K1-2

K1-3

(K3-2)

(K3-1)

(K3-3)

Port (A)

Port

(C1)

Port

(C1)

Port (S)

Port (C2)

Port (B)

Port (A)

Port (B)

26

25-2

15

2

25

25-3-3

25-3b

22

7

8-1

8

23

7

8-1

8

38

30

31

39

29

18

19

61

40

25-3

45

29-1

33

36

43

K3

K2

37-1

37

25-1

25-2

26

15

2

25

22

7

8-1

8

23

7

8-1

8

18

25-3

25-3-3

25-3-3

25-3b

19

K1

Assembly for unit without

gerotor charge pump.

Assembly for single pump

or rear pump of tandem.

25-3-3

6

Model 70360

Parts List

Item Qty. Description

2 2 Dowel Pin

3 1 Crush Ring

+ 4 1 Retaining Ring

+ 5 2 Retaining Ring

6 6 Screw

7 2 Spring

8 2 Plug Assembly

+ 8-1 2 O-ring, 2,38 mm Dia. x 22,23 mm I.D. [.0937 in. Dia. x .875 in. I.D.]

9 1 Rotating Kit Assembly

10 1 Cover Plate SA

+ 10-1 1 Seal, Trunnion Shaft

11 6 Washer

12 1 Cover Plate SA

1 Bearing Cup

14 1 Bearing Cup

+ 15 1 Housing Gasket

16 2 Thrust Race

17 1 Needle Thrust Bearing

18 2 Cap Screws

19 2 Cap Screws

+ 20 1 Shaft Seal, Drive

20 1 Spacer (Used in rear pump of tandem in place of drive shaft seal.)

22 1 Relief Valve for Port "A"

23 1 Relief Valve for Port "B"

24 1 Housing Assembly

24-1 1 Bearing (press fit)

25 1 Backplate Assembly

26 1 Valve Plate

27 1 Drive Shaft

28 1 Camplate - Square End Trunnion

2 Bearing Cone

29 1 Charge Pump Adaptor

30 1 Inner Gerotor

31 1 Outer Gerotor

32 1 Key, Drive Shaft

+ 33 1 O-ring (In K2 & K3 kit)

34 1 Coupler

35 1 Mounting Bracket

36 1 Cover Plate (In K3 kit)

37 1 Plug Assembly

+ 37-1 1 O-ring, 2,21 mm Dia. x 16,36 mm ID. [.087 in. Dia. x .644 in. ID.]

38 1 Key, Gerotor Pump Adapter

+ 39 1 Molded O-ring

40 2 Washer

41 1 Washer

42 1 Key, Camplate Trunnion

43 2 Cap Screws, Cover Plate (In K3 kit)

44 1 Insert, Camplate

45 6 Washer

53 1 Plug Assembly

+ 53-1 1 O-ring, 2,20 mm Dia. x 16,35 mm ID. [.087 in. Dia. x .644 in. ID.]

54 1 Plug Assembly

+ 54-1 1 O-ring, 2,20 mm Dia. x 16,35 mm ID. [.087 in. Dia. x .644 in. ID.]

+ 59 2 O-ring, 2,38 mm Dia. x 88,9 mm ID. [.0937 in. Dia. x 3.5 in. ID.]

7

Model 70360

Parts List

Item Qty. Description

Mounting Kits

K1 1 Tandem Piston Pump Mounting Kit

K1-1 1 41T Coupler, 33,02 mm [1.3 in.] long

+ K1-2 1 O-ring, 1,59 mm Dia. x 101,6 mm ID. [.0625 in. Dia. x 4 in. ID.]

K1-3 2 Cap Screws

K2 1 Gear Pump Mounting Kit

+ K2-1 1 O-ring, 1,59 mm Dia. x 82,55 mm ID. [.0625 in. Dia. x 3.25 in. ID.]

K2-2 1 Washer

K2-3 2 Cap Screws

K3 1 Cover Plate Kit

+ K3-1 1 O-ring, 1,59 mm Dia. x 82,55 mm ID. [.0625 in. Dia. x 3.25 in. ID.]

K3-2 1 Cover Plate

K3-3 2 Cap Screws

Seal Repair Kits

1 Seal Repair Kit for 70360 piston pump. (Order two for tandem pumps)

1 Control Shaft Bearing Shim Kit (to replace crush ring after replacement of major part).

Legend + Common parts to seal repair kits.

8

Model 70360

Disassembly

The following disassembly

procedure applies to a single pump

with or without gear pump The

repair procedure for tandem

pumps, once they are separated, is

basically the same. The basic

configuration differences between a

single and tandem pumps are the

backplates, pump shafts and

housing assemblies. In most

cases, only the rear pump of tandem units contain a charge

pump, which is common to both the front and rear pump. The

rear tandem pump does not incorporate a shaft seal.

Thoroughly clean the Eaton Model 70360 or 78362 variable

displacement pump before any

repairs are attempted. When

working on tandem pumps,

separate the front and rear pumps

first.

1 Support the pump with the

input shaft down. Use a 9/16 in.

socket or end wrench to remove

the pump adapter cover plate or

gear pump (see Figure 2).

2 Use a pick or similar tool to

remove the adapter cover plate or

gear pump o-ring (see Figure 3).

3 Use a 7/16 in. Allen wrench or

bit socket remover to remove the

charge pressure relief valve spring

retainer from the pump adaptor

assembly (see Figure 4).

4 Use a pencil magnet or similar

tool to carefully remove the charge

pressure spring and poppet from

the pump adaptor assembly (see

Figure 5). Use caution not to drop

the charge pump poppet into the

pump adaptor assembly.

5 The charge pressure relief

valve and poppet may be of the

standard or high pressure type. The

(6.9 to 10.3 bar [100 to 150 PSI])

standard spring and poppet are

shown on the bottom and the

optional high pressure (13.7 to

20.7 bar [200 to 300 PSI]) spring

and poppet is shown on the top.

The same charge pressure relief valve spring retainer is used

with either the standard or high

pressure (see Figure 6).

6 Use a 7/8 in. socket or end

wrench to remove the optional

bypass valve assembly from the

backplate (see Figure 7).

7 The internal seal may be replaced by first removing the

small retaining ring on the end of the bypass valve. Remove

and replace the o-rings (see Figure 8).

8 Use a 1-1/16 in. socket or end

wrench to remove the two high

pressure relief valves from the

pumps backplate assembly (see

Figure 9). Each system relief valve

assembly is identified by both its

part number and relief valve setting

as shown on in Parts Information

Manual 06-639.

9 Firmly support the pump

assembly. Use a 9/16 in. socket or

end wrench to remove the four cap

screws retaining the charge pump

adapter assembly.

10 With the cap screws removed,

remove the charge pump adaptor

assembly from the backplate (see

Figure 11).

Note: The front pump assemblies

do not have charge pump adapter

assemblies.

11 Turn the adapter assembly

over. Use an o-ring pick or similar

tool remove the o-ring seal (see

Figure 12).

12 Inspect the gerotor pocket and needle bearing located in

the charge pump adapter. The needles in the needle bearing

must remain intact in the bearing cage.

Repair Information

Figure 1

Figure 2

Figure 3

Figure 5

Figure 4

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

9

Model 70360

13 When the needle bearing

assembly is replaced, the

numbered end of the bearing must

face toward the flange side of the

adapter to the dimension as shown

(see Figure 13).

14 With the charge pump adapter

removed, remove the charge pump

assemblies outer and inner gerotor

ring. Next, remove the small drive

key from the pump shaft (see

Figure 14 and 15).

15 Charge pumps are available in

two different displacements Charge

pump displacements are based on

the thickness of the gerotor

assembly and the depth of the pocket located in the charge

pump adapter. To determine the displacement, refer to the

table below.

Gerotor Pocket Depth

Displacement Depth of Pocket

cm

3

/r [in

3

/r] mm [in.]

6.9 [.42] 6.35 [.25]

13.8 [.84] 12.7 [.50]

16 To separate the backplate

assembly from the dowel pins in

the pump housing assembly, insert

two screwdrivers between

backplate and housing assembly

and pry upward (see Figure 16).

17 After separation, remove the

backplate from the housing

assembly.

18 Turn the backplate assembly

over and inspect the needle

bearing. The needles in the needle

bearing must remain intact in the

bearing cage (see Figure 17).

19 When the needle bearing

assembly is replaced, the

numbered end of the bearing must

face the valve plate side of the

backplate to the dimension as

shown (see Figure 18).

20 With the backplate removed,

remove the gasket from the pump

housing assembly and discard (see

Figure 19).

21 Remove the valve plate from the piston block assembly.

Note: This valve plate may have stuck to the backplate

assembly that was just previously removed.

22 Valveplate directional rotation (CW or CCW) is identified

by the location of the metering slots located on the face of the

valve plates. Pump input

rotation should always turn

into the metering slots (see

Figure 20). A clockwise

valve plate is shown on the

left and a counter clockwise

valveplate is on the right.

Note: Whenever pump input rotation is changed, the valve

plate must be replaced along with the desired rotation charge

pump adapter.

23 Remove the rotating kit assembly by carefully retaining it

in the housing assembly. Lift the housing and rotating kit

assembly and turn over assemblies allowing the rotating kit

assembly to slide down the input shaft and out of the pump

housing.

24 The model 70360 variable

displacement pumps are

available in two different

displacements. The 40,6 cm

3

/r

[2.48 in

3

/r] rotating kit

assembly is shown below on

the left. The 49,2 cm

3

/r [3.00 in

3

/r] rotating kit assembly is

shown below on the right. The 49,2 cm

3

lr [3 00 in

3

/r] rotating

assembly is easily identified by having larger pistons and

cutouts in the spider (see Figure 21).

25 With the rotating kit

assembly removed, remove the

piston assemblies, spider and

spider pivot from the piston

barrel (see Figure 22).

26 Inspect the piston

assemblies, spider, spider pivot

and piston block. The piston block

assembly usually requires no

further disassembly unless the pins

or block spring are damaged.

27 When any excessive wear or

scratches are noted on the face of

the piston block, the block

assembly must be replaced (see Figure 23).

DO NOT LAP THE FACE OF PISTON BLOCK ASSEMBLY.

Numbered End

Gerotor Pocket

2.41 mm

[.095 in.]

Flange

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

2.79 mm

[.110 in.]

1.91 mm

[.075 in.]

Numbered End

Figure 18

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Repair Information - Disassembly

10

Model 70360

28 To remove the input shaft

assembly, use a pair of internal

snap ring pliers and remove the

shaft seal retaining ring from the

housing assembly (see Figure 24).

29 With the retaining ring

removed, use a small press to

press the shaft seal and input shaft

assembly from the housing

assembly (see Figure 25).

30 With the input shaft assembly

removed, disassemble the

assembly for inspection by

removing the shaft seal, washer,

retaining ring thrust washers and

bearing (see Figure 26).

Note: The rear pump on tandem

units uses a spacer in place of shaft

seals.

31 To remove the camplate from

the housing assembly, use a 9/16

in. socket or end wrench and

remove the three cap screws

retaining the trunnion cover plate

assembly. Start at the cover plate

with control shaft first (see Figure

27).

32 With the retaining cap screws

removed, insert two small

screwdrivers in the notches located

in the cover plate assembly and pry

upward. Make sure bearing cup

comes off with the cover plate (see

Figure 28).

Note: The crush ring in the control

arm trunnion cover does not need

to be removed (see Figure 29). The

only time the crush ring needs to

be removed is when either the

trunnion cover, the camplate

assembly or the housing assembly is replaced. A shim kit is

then required in the crush rings place.

33 Reposition the pump assembly to remove opposite cover

plate. The bearing cup in this cover plate is press fit and not

removable. Repeat steps 31 through 32.

34 With housing in the upright

position, slide the camplate toward

the control side and lift it from the

pump housing (see Figure 30).

Note: The camplate control shaft

will go out either side of the pump

housing. Be sure to note on which

side of the housing the control

shaft protrudes before removing camplate from housing for

correct reassembly orientation.

35 Use an o-ring pick or similar tool to remove the o-ring

seals from the two counter-bores in the housing or the cover

plates (see Figure 31).

36 To remove the control side

cover plate lip seal, use a small

press and press the lip seal inward

(see Figure 32).

39 Remove the thrust plate from

the camplate. The thrust plate is reversible and either side may

face the camplate (see Figure 33).

40 Inspect the housing

assemblies front needle bearing. If

the needles remain in their cage

and move freely, replacement

usually is not required (see Figure

34).

41 When the needle bearing is

replaced, the numbered end of the

needle bearing must face away

from the housing and pressed to

the dimension as shown (see Figure

35).

Figure 24

Figure 25

Figure 26

Figure 27

Repair Information - Disassembly

Figure 32

Figure 34

1.78 mm

[.07 in.]

Numbered End

Flange End of Housing

Figure 35

Figure 28

Figure 29

Figure 30

Figure 31

Figure 33

11

Model 70360

Reassembly

1 Before reassembling the pump, replace all worn and

damaged parts, assemblies, seals and o-rings. Lubricate the

seals and o-rings with petroleum jelly to help retain them

during reassembly and to provide lubrication to the input and

control shaft seals. Lubricate all finished part surfaces freely

with clean hydraulic fluid to help provide start up lubrication

between all rotating parts.

2 To reassemble the camplate

assembly into the pump housing,

tilt the camplate slightly and install

the control side of the camplate

through the previously noted or

marked side of the housing

assembly (see Figure 36).

3 With the camplate installed,

lubricate the tapered bearing on the

non-control arm side of the

camplate.

4 Lubricate and install the o-ring

seal into counter-bore of housing

(see Figure 37).

5 Install the trunnion cover over

bearing and onto pump housing.

Install the three cap screws and

torque to 40,7 Nm [30 ft. lbs.] (see

Figure 38).

6 Lubricate and install the

control arm shaft seal into the

control arm trunnion cover. Install

with the lip of the seal facing

upward or to the inside of the

pump (see Figure 39).

7 If the housing, trunnion covers or camplate assembly have

not been replaced, the existing crush ring may be re-used. If

you have replaced anyone of the above a shim kit must replace

the crush ring. See Parts Information manual 06-639.

8 Place the bearing cup into trunnion cover over the crush

ring or shims (see Figure 40).

9 Lubricate and install the o-ring

seal into counter-bore of housing

(see Figure 41).

10 Install the trunnion cover over

the control shaft and into the pump

housing. Install the three retaining

cap screws and torque to 40,7 Nm

[30 ft. lbs.] (see Figure 42).

11 Using your fingers, tilt the

camplate back and forth to check

the trunnion bearing preload.

Proper preload is achieved when

the camplate has a very slight

tilting resistance. The camplate

must not have any side clearance.

12 Reassemble the input shaft

assembly by installing the thrust

washer, thrust bearing, second

thrust washer, retaining ring,

washer and shaft seal (see Figure

43).

Note: The lip of the shaft seal must

point toward the center of the input

shaft.

13 Install the input shaft assembly

into the housing assembly. Push

the shaft seal in just far enough so

you can start the shaft seal

retaining ring.

14 Use a pair of snap ring pliers

to install retaining snap ring into

the housing assembly (see Figure

44).

15 Use a seal driver or similar tool

to press or drive the snap ring and

seal into the housing assembly (see

Figure 45).

CAUTION! Press or drive inward until the snap ring snaps into

the snap ring groove located in the pump housing assembly.

16 The thrust plate is reversible. Either side will fit into the

camplate. In most cases if any irregularities are noted it is best

to replace the thrust plate (see

Figure 46).

17 Lubricate and install the

thrustplate over the input shaft

assembly and into the camplate.

The thrustplate must rest firmly in

its pocket located in the camplate.

Figure 38

Figure 42

Figure 43

Figure 44

Figure 45

Repair Information

Figure 39

Figure 37

Figure 36

Figure 41

Figure 40

Figure 46

12

Model 70360

18 Reassemble the rotating kit

assembly by first aligning the

splines in the pivot with the splines

in the block. Install the pivot on the

block assembly pins (see Figure

47).

19 Use a small socket or similar

tool to help retain the pivot in the

centered position. Lubricate and

install the spider and piston

assemblies onto the pivot and

pistons into the piston block

assembly (see Figure 48).

20 Hold the housing assembly in

the vertical position then carefully

install the rotating kit by first

aligning with the splines on the

input shaft. With splines aligned,

install the rotating kit into the pump

housing (see Figure 49). Use

caution to ensure all parts are kept

in their proper position.

21 With the rotating kit installed,

reposition the housing assembly in

the input shaft down position and

install a new housing gasket (see

Figure 50).

22 Lightly coat the backplate side

of the valve plate with petroleum

jelly for retention during assembly.

Install the valve plate over the

needle bearing, aligning the small

slot on the outside of the valve

plate with the dowel pin in the

backplate (see Figure 51).

23 Carefully install the backplate

assembly by aligning it with the

dowel pins located in the pump

housing. Use caution not to

dislodge the valve plate (see Figure

52).

24 Lightly coat the charge pump

assemblies drive key with

petroleum jelly and install it in the

drive shaft assembly (see Figure

53).

25 Align the keyway of the

gerotors inner ring, then lubricate

and install the inner ring and outer

ring over the input shaft and onto

the backplate assembly (see Figure

54).

Note: Before installing the charge

pum adaptor plate, offset the outer

ring of the geroter as shown.

26 With the gerotor assembly

installed, install new o-ring into

charge pump adapter plate and

place adapter onto backplate over

gerotor. Retain with cap screws.

Torque cap screws to 52,9 to 56 Nm

[39 to 42 ft. lbs.] (see Figure 55).

27 Install the two high pressure

relief valves. Torque valves 128,8 to

142,4 Nm [95 to105 ft. lbs.] (see

Figure 56).

28 Lubricate and reassemble the

bypass valve assembly. Install the

bypass valve into the backplate.

Torque valve to 36,6 to 40,6 Nm

[27 to 30 ft. lbs.] (see Figure 57).

29 Coat the charge pressure

poppet with petroleum jelly and

place poppet onto spring and install

into the adapter plate (see Figure

58).

30 Install the hollow charge

pressure relief valve retainer into

the adapter plate. Torque retainer

to 6,8 to 9,5 Nm [5 to 7 ft. lbs.].

31 Lubricate and install the o-ring

on the cover plate or gear pump.

Install the cover plate or gear pump

and two cap screws. Torque cap

screws to 36,6 to 40 Nm [27 to 31

ft. lbs.].

The Model 70360 or 78362 variable displacement pump is now

ready for test and reinstallation.

Figure 47

Figure 48

Figure 49

Figure 50

Figure 51

Figure 52

Figure 54

Figure 55

Figure 56

Figure 57

Figure 58

Repair Information - Reassembly

Figure 53

13

Model 70360

7

0

3

6

0

-R

X

X

-0

2

A

9

8

0

1

3

1

J

B

1

Inspect

?

Repair

or

Replace

Defective

Action

Step

Comment

Number

Decision

Solution

Symptom:

Gauges Recommended

Inlet vacuum gauge: 2 bar to 1 bar [30 PSI to 30 inHg]

System pressure gauge: 700 bar [10,000 PSI]

Charge pressure gauge: 0 to 50 bar [0 to 600 PSI]

Case pressure gauge: 0 to 25 bar [0 to 300 PSI]

Explanatory

Diagram

This fault - logic troubleshooting guide is a

diagnostic aid in locating transmission problems.

Match the transmission symptoms with the problem

statements and follow the action steps shown in the

box diagrams. This will give help in correcting minor

problems eliminating unnecessary machine down

time.

Following the fault - logic diagrams are diagram

action comments of the action steps shown in the

diagrams. Where applicable, the comment number of

the statement appears in the action block of the

diagrams.

Recommended Gauge Locations

Figure 59

Pressure Ports

Tee In Line to Check

System Pressure

Charge Pump Suction Port

Tee In Line to Check Inlet

Vacuum

Drain Port

Tee In Line to Check

Case Pressure

Auxiliary Port

Check Charge Pressure

Fault - Logic Troubleshooting

Identification Label

Located on Control Arm Side

14

Model 70360

Fault - Logic Troubleshooting

Inspect

Servo Control

(If used)

OK

1 2

Inspect

External Control

Linkage

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Symptom: Neutral Difficult or Impossible to Find

Inspect

Heat

Exchanger

OK OK OK

4 5 6

Check

Oil Level in

Reservoir

Fill to

Proper

Level

Defective Below Level

Repair

or

Replace

Check

System

Pressure

Reduce

System

Load

High

OK

9

Inspect

Charge Relief

Valve

OK

11

Inspect

Charge

Pump

13

Inspect

Motor

12

Inspect

Inlet Screen

or Filter

Replace

Clogged

OK

8

Check

Charge

Pressure

10

Low

OK

OK

Replace

Pump &

Motor

Inspect Pump

Bypass Valve

(If used)

OK

7

Inspect Heat

Exchanger

Bypass Valve

(If used)

OK

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Symptom: System Operating Hot

15

Model 70360

Inspect

Servo Control

(If used)

OK OK

1 2 3

Inspect

External Control

Linkage

Defective

Repair

or

Replace

Inspect

System Relief

Valves

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Symptom: Operates in One Direction Only

Inspect

Servo Control

(If used)

OK OK OK

2 7

Defective

Repair

or

Replace

Inspect

Motor

12

Replace

Clogged

Check

Charge

Pressure

10

Low

OK

Inspect Pump

Bypass Valve

(If used)

Replace

Pump &

Motor

Defective

Repair

or

Replace

Inspect

Inlet Screen

or Filter

OK OK OK

8 13

Defective

Repair

or

Replace

Inspect

Charge Relief

Valve

11

Inspect

Charge

Pump

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Symptom: System Response Sluggish

Fault - Logic Troubleshooting

16

Model 70360

Check External

Control

Linkage

OK OK OK

4 1 7

Check

Oil Level in

Reservoir

Fill to

Proper

Level

Defective Below Level

Repair

or

Replace

Check

System

Pressure

OK

9

Inspect

Charge Relief

Valve

OK

11

Inspect

Charge

Pump

13

Inspect

Motor

12

Inspect

Inlet Screen

or Filter

Replace

Clogged

OK

8

Check

Charge

Pressure

10

Low

OK

OK

Replace

Pump &

Motor

Inspect

Servo Control

(If used)

OK

2

Inspect Pump

Bypass Valve

(If used)

OK

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Defective

Repair

or

Replace

Defective

Repair

or

Replace

High

Reduce

System

Load

Symptom: System Will Not Operate In Either Direction

Fault - Logic Troubleshooting

17

Model 70360

Diagram Action Step Comments

1 Inspect External Control Linkage for:

a. misadjustment or disconnection

b. binding, bending or breakage

c. misadjusted, damaged or broken neutral return spring

2 Inspect Servo Control Valve for: (if used)

a. proper inlet pressure

b. misadjusted, damaged or broken neutral return spring

c. galled or stuck control spool

d. galled or stuck servo piston

3 Inspect System Relief Valves* for:

a. improper pressure relief setting

b. damaged or broken spring

c. valve held off seat

d. damaged valve seat

4 Check Oil Level in Reservoir:

a. consult owner/operators manual for the proper type

fluid and level

5 Inspect Heat Exchanger for:

a. obstructed air flow (air cooled)

b. obstructed water flow (water cooled)

c. improper plumbing (inlet to outlet)

d. obstructed fluid flow

6 Inspect Heat Exchanger Bypass Valve for: (if used)

a. improper pressure adjustment

b. stuck or broken valve

7 Inspect Pump Bypass Valve for: (if used)

a. held in a partial or full open position

8 Inspect Inlet Screen or Filter for:

a. plugged or clogged screen or filter element

b. obstructed inlet or outlet

c. open inlet to charge pump

9 Check System Pressure:

a. See figure 59 for location of pressure gauge installation.

b. consult owner/operators manual for maximum system

relief valve settings

10 Check Charge Pressure:

a. See figure 59 for location of pressure gauge installation.

b. consult owner/operators manual for maximum charge

relief valve settings

11 Inspect Charge Relief Valve for:

a. improper charge relief pressure setting *

b. damaged or broken spring

c. poppet valve held off seat

12 Inspect Motor for:

a. disconnected coupling

13 Inspect Charge Pump for:

a. broken or missing drive key

b. damaged or missing o-ring

c. excessive gerotor clearance

d. galled or broken gerotor set

* System/Charge Relief Valve Pressure Settings for Eatons

Variable Displacement Controlled Piston Pumps

Inlet Vacuum 6 inHg max.

Case Pressure 25 PSI maximum

Charge Pressure 100 to 150 PSI Standard

200 to 250 PSI Optional

250 to 300 PSI Optional

System Pressure 5000 PSI maximum

3000 PSI continuous

The high pressure relief valves are all factory preset and

cannot be readjusted.

The pressure setting and assembly number is stamped on

each high pressure relief valve cartridge.

Valve Identification Example:

32060-IA 5000

Relief Valve Setting

Relief Valve Assembly Number

Fault - Logic Troubleshooting

18

Model 70360

When initially starting a new or rebuilt transmission system, it

is extremely important to follow the start-up procedure. It

prevents the chance of damaging the unit which might occur if

the system was not properly purged of air before start-up.

1 After the transmission components have been properly

installed, fill the pump housing at least half full with filtered

system oil. Connect all hydraulic lines and check to be sure

they are tight.

2 Install and adjust all control linkage.

3 Fill the reservoir with an approved oil that has been filtered

through a 10 micron filter. Refer to Eaton Hydraulics

Technical Data sheet number 3-401 titled Hydraulic Fluid

Recommendations.

4 Gasoline or L.P. engines: remove the coil wire and turn the

engine over for 15 seconds. Diesel engines: shut off the

fuel flow to the injectors and turn the engine over for 15

seconds.

5 Replace the coil wire or return the fuel flow to the injectors.

Place the transmission unit in the neutral position, start the

engine and run it at a low idle. The charge pump should

immediately pick up oil and fill the system. If there is no

indication of fill in 30 seconds, stop the engine and

determine the cause.

6 After the system starts to show signs of fill, slowly move

pump camplate to a slight cam angle. Continue to operate

system slowly with no load on motors until system

responds fully.

7 Check fluid level in the reservoir and refill if necessary to

the proper level with an approved filtered oil.

8 Check all line connections for leaks and tighten if

necessary.

The machine is now ready to be put into operation.

Frequent filter changes are recommended for the first two

changes after placing the machine back into operation. Change

the first filter in 3-5 hours and the second in approximately 50

hours. Routinely scheduled filter changes are recommended

for maximum life of the hydraulic system.

Start-up Procedure

19

Model 70360

Eaton Corporation

Hydraulics Division

15151 Hwy. 5

Eden Prairie, MN 55344

Fax: 612/937-7130

Eaton Ltd.

Hydraulics Division

Glenrothes, Fife

Scotland, KY7 4NW

Telephone: +44 (0)1592-771-771

Fax: +44 (0)1592-773-184

Eaton GmbH

Hydraulics Products

Am Schimmersfeld 7

40880 Ratingen, Germany

Telephone: +49 (0)2102-406-830

Fax: +49 (0)2102-406-800

ISO-9001 CERTIFICATED FIRM

DET NORSKE VERITAS INDUSTRY BV, THE NETHERLANDS

ACCREDITED BY

THE DUTCH COUNCIL

FOR CERTIFICATION

Reg. No. 24

Quality System Certified

Products in this catalog are manufactured

in an ISO-9001-certified site.

http://www.eaton.com

Form No. 07-627

December 1998

Copyright Eaton Corporation, 1996, 1998

All Rights Reserved

Printed in USA

Vous aimerez peut-être aussi

- Service Manual 300050007500 PermconDocument19 pagesService Manual 300050007500 PermconMiguel Angel Santos PintadoPas encore d'évaluation

- Eaton: Medium Duty Piston PumpDocument20 pagesEaton: Medium Duty Piston PumpChristian StalinPas encore d'évaluation

- Eaton: Medium Duty Piston PumpDocument20 pagesEaton: Medium Duty Piston PumpjuampacervantesPas encore d'évaluation

- 06 626Document16 pages06 626David RamirezPas encore d'évaluation

- Plano Hidráulico 430-D PDFDocument4 pagesPlano Hidráulico 430-D PDFJose Alberto IzquielPas encore d'évaluation

- JDocument32 pagesJlutherblackPas encore d'évaluation

- Danfoss HST Public Documents Web Content c022873Document8 pagesDanfoss HST Public Documents Web Content c022873Timon200550% (2)

- Montacarga HidraulicaDocument16 pagesMontacarga HidraulicaNicol's LupacaPas encore d'évaluation

- SF 6721 PDFDocument10 pagesSF 6721 PDFSamuel Frank VejarPas encore d'évaluation

- Denison-Parker Premier SeriesDocument40 pagesDenison-Parker Premier SeriesDamPas encore d'évaluation

- A10v45 RexrothDocument3 pagesA10v45 RexrothJoaquin ReyesPas encore d'évaluation

- HY02 8001 CDEU Gold - Cup UK PDFDocument86 pagesHY02 8001 CDEU Gold - Cup UK PDFOleg080Pas encore d'évaluation

- Piston Pump (Brake, Hydraulic Fan)Document7 pagesPiston Pump (Brake, Hydraulic Fan)EVER DAVID SAAVEDRA HUAYHUAPas encore d'évaluation

- Gidronasosy Serii PMV10Document48 pagesGidronasosy Serii PMV10alsief1951Pas encore d'évaluation

- TG Series Tractors TG210, TG230, TG255, AND TG285 Equipped With Megaflow RAC. 87025178 Nao Hydraulic SchematicDocument2 pagesTG Series Tractors TG210, TG230, TG255, AND TG285 Equipped With Megaflow RAC. 87025178 Nao Hydraulic SchematicbrunosamaeianPas encore d'évaluation

- Roto KSCDocument4 pagesRoto KSCdaniel ortegaPas encore d'évaluation

- Parker (PAVC33 PAVC38) Hydraulic Piston Pumps Service Literature Service PartsDocument10 pagesParker (PAVC33 PAVC38) Hydraulic Piston Pumps Service Literature Service PartsAnonymous gKfTqXObkDPas encore d'évaluation

- ContentsDocument21 pagesContentsEng-Mohammed SalemPas encore d'évaluation

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariPas encore d'évaluation

- TDV 100Document6 pagesTDV 100林育豪Pas encore d'évaluation

- 09 Cat BHL B&C Hydsys3Document15 pages09 Cat BHL B&C Hydsys3Mahmmod Al-QawasmehPas encore d'évaluation

- Transmission - Valve, Regulator and Oil PumpDocument2 pagesTransmission - Valve, Regulator and Oil PumpSilvio Roman100% (1)

- HMF-02 Installation and Start-Up InstructionsDocument4 pagesHMF-02 Installation and Start-Up InstructionsxxshPas encore d'évaluation

- Hagglunds Viking MK 64 163000 Bo LN 0100 PDFDocument26 pagesHagglunds Viking MK 64 163000 Bo LN 0100 PDFKOSTAS100% (1)

- QXV - 100 B 000019 enDocument39 pagesQXV - 100 B 000019 enGutsavoPas encore d'évaluation

- PC300 MD300 GSG AT Command R2a ENDocument272 pagesPC300 MD300 GSG AT Command R2a ENFawad Uddin100% (1)

- SP12C - SP14CJ Service ManualDocument173 pagesSP12C - SP14CJ Service ManualMMM-MMMPas encore d'évaluation

- Status Mode: Systems OperationDocument12 pagesStatus Mode: Systems OperationDANIEL VARGAS RODRIGUEZPas encore d'évaluation

- M318S-Steering PumpDocument88 pagesM318S-Steering Pumpzeck28Pas encore d'évaluation

- Re 01200Document24 pagesRe 01200Ahmed Abd ElhakeemPas encore d'évaluation

- Vicker Pumps Specsx708Document91 pagesVicker Pumps Specsx708omni_partsPas encore d'évaluation

- Sauerdanfoss Series s90 Pumps Catalogue en 520l0603Document68 pagesSauerdanfoss Series s90 Pumps Catalogue en 520l0603Mohamed HarbPas encore d'évaluation

- Pruebas y Ajustes Caja D7HDocument83 pagesPruebas y Ajustes Caja D7HAlfredo GuzmánPas encore d'évaluation

- ZFP Ebook LP NFZ 2011 inDocument470 pagesZFP Ebook LP NFZ 2011 inOswald Schbaltz100% (1)

- Series 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Document68 pagesSeries 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Jose Manuel Barroso PantojaPas encore d'évaluation

- Shutdown: No Equipment Selected No Equipment Selected No Equipment SelectedDocument2 pagesShutdown: No Equipment Selected No Equipment Selected No Equipment SelectedFrezgi Birhanu100% (1)

- Marzo - Manual de Bpl-2023Document306 pagesMarzo - Manual de Bpl-2023Javier De Luna CanoPas encore d'évaluation

- BAR Cargolift Tail LiftDocument1 pageBAR Cargolift Tail Liftcargilldave1906100% (1)

- Auto/Manual Switch Warning: Language Code Product Group No. Date Applies ToDocument4 pagesAuto/Manual Switch Warning: Language Code Product Group No. Date Applies ToFawzi AlzubairyPas encore d'évaluation

- HIDRAULICODocument2 pagesHIDRAULICOAlcides Chilo OllachicaPas encore d'évaluation

- Parts Information: Char-LynnDocument5 pagesParts Information: Char-LynnRidha AbbassiPas encore d'évaluation

- Servodirectii OrbitaleDocument12 pagesServodirectii OrbitaleIonescu AngelPas encore d'évaluation

- A10VSODocument40 pagesA10VSOJulio Carrero100% (1)

- Maflosh 02 IngDocument44 pagesMaflosh 02 IngNicoleta CosteaPas encore d'évaluation

- Cat Hy14 1600 Denison Products PDFDocument438 pagesCat Hy14 1600 Denison Products PDFEmiliano MercadoPas encore d'évaluation

- Char Lynn Hydaulic Steering Catologue 2003 Part1Document50 pagesChar Lynn Hydaulic Steering Catologue 2003 Part1Sunthron SomchaiPas encore d'évaluation

- Model Fa5 and Fa5T: Parts, Operation and Maintenance ManualDocument80 pagesModel Fa5 and Fa5T: Parts, Operation and Maintenance Manualalfredo_mtz_097100% (2)

- Diagrama Hidraulico PDFDocument12 pagesDiagrama Hidraulico PDFRimbert100% (1)

- A2FE + ID Br61Document1 pageA2FE + ID Br61muhammadPas encore d'évaluation

- Mcculloch Parts DiagramDocument3 pagesMcculloch Parts DiagramSorin BendelaPas encore d'évaluation

- BrandDocument66 pagesBrandCentral HydraulicsPas encore d'évaluation

- HGAService Rotory Steering ValveDocument30 pagesHGAService Rotory Steering ValveChristopher FinkPas encore d'évaluation

- Steering Unit: Service ManualDocument28 pagesSteering Unit: Service ManualmusafirPas encore d'évaluation

- Repfllr Pflrts . . I: at BoschDocument4 pagesRepfllr Pflrts . . I: at BoschEng-Mohammed SalemPas encore d'évaluation

- J-Gear Pumps CatalogueDocument21 pagesJ-Gear Pumps CatalogueturandotPas encore d'évaluation

- Eaton 70145-Rdy-02Document20 pagesEaton 70145-Rdy-02Nate SpaydPas encore d'évaluation

- 2RZ 3RZ SCDocument21 pages2RZ 3RZ SCDiego Pillco0% (1)

- 06 639Document15 pages06 639Fernando Sabino100% (1)

- EECD0001Document36 pagesEECD0001Sergey Gusev100% (3)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Caseih Staiger PBDocument1 366 pagesCaseih Staiger PBFernando SabinoPas encore d'évaluation

- 3410 3411 H179Service TrainingDocument668 pages3410 3411 H179Service TrainingWilliam Giovanni Madariaga Malebrán97% (35)

- 420 Mobile Piston Pump Design Code CDocument41 pages420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- Workshop ManualDocument837 pagesWorkshop ManualFernando Sabino100% (1)

- Finotek SolenoidDocument1 pageFinotek SolenoidFernando SabinoPas encore d'évaluation

- Cat 350-375 TDocument60 pagesCat 350-375 TFernando Sabino100% (1)

- Finotek Komtasu 2Document1 pageFinotek Komtasu 2Fernando SabinoPas encore d'évaluation

- Finotek 1Document1 pageFinotek 1Fernando SabinoPas encore d'évaluation

- Kawasaki K3VL Technical Brochure BlueDocument68 pagesKawasaki K3VL Technical Brochure BlueFernando Sabino100% (1)

- EM140 Final Drive Layout PDFDocument1 pageEM140 Final Drive Layout PDFFernando SabinoPas encore d'évaluation

- Caseih Serie 20Document1 267 pagesCaseih Serie 20Fernando Sabino100% (3)

- Reincarnated As A Sword Volume 12Document263 pagesReincarnated As A Sword Volume 12Phil100% (1)

- UEFA Stadium Design Guidelines PDFDocument160 pagesUEFA Stadium Design Guidelines PDFAbdullah Hasan100% (1)

- Reconceptualising Smart CitiesDocument80 pagesReconceptualising Smart CitiesDevang Parekh100% (1)

- Progress Test 1 Units 1-6: Exercise 1 Personal InformationDocument3 pagesProgress Test 1 Units 1-6: Exercise 1 Personal InformationLuis Villaverde VerasteguiPas encore d'évaluation

- LESSON 1 Overview of Toeic Speaking WritingDocument29 pagesLESSON 1 Overview of Toeic Speaking WritingPhạm Thị HuyềnPas encore d'évaluation

- Manual WP 34s 3 1Document211 pagesManual WP 34s 3 1richrichri100% (1)

- NRC Report On FitzPatrick Condenser LeaksDocument15 pagesNRC Report On FitzPatrick Condenser LeaksTim KnaussPas encore d'évaluation

- RB September 2014 The One Thing Kekuatan Fokus Untuk Mendorong ProduktivitasDocument2 pagesRB September 2014 The One Thing Kekuatan Fokus Untuk Mendorong ProduktivitasRifat TaopikPas encore d'évaluation

- 08 03 Runge-Kutta 2nd Order MethodDocument11 pages08 03 Runge-Kutta 2nd Order MethodJohn Bofarull GuixPas encore d'évaluation

- KISS Notes The World CommunicatesDocument30 pagesKISS Notes The World CommunicatesJenniferBackhus100% (4)

- Group No. - Leader: MembersDocument7 pagesGroup No. - Leader: MembersJONATHAN NACHORPas encore d'évaluation

- ProbabilityDocument29 pagesProbabilitymaryrosePas encore d'évaluation

- 50 Interview Questions For Adryenn AshleyDocument5 pages50 Interview Questions For Adryenn AshleyAdryenn AshleyPas encore d'évaluation

- English 3 Reading Nat 1Document23 pagesEnglish 3 Reading Nat 1robelynemendoza17Pas encore d'évaluation

- Cs6109 - Compiler Design: Lab AssignmentDocument8 pagesCs6109 - Compiler Design: Lab AssignmentvezhaventhanPas encore d'évaluation

- Against The Legalization of Drugs - James Q. WilsonDocument9 pagesAgainst The Legalization of Drugs - James Q. WilsonOhLord VaderPas encore d'évaluation

- Different Types of Speeches According To DeliveryDocument18 pagesDifferent Types of Speeches According To DeliveryJoy Agustin100% (1)

- Lesson Plan - Special Right Triangles ReteachDocument1 pageLesson Plan - Special Right Triangles Reteachapi-448318028Pas encore d'évaluation

- Intersection of Psychology With Architecture Final ReportDocument22 pagesIntersection of Psychology With Architecture Final Reportmrunmayee pandePas encore d'évaluation

- May 29Document2 pagesMay 29gerrymattinglyPas encore d'évaluation

- Sample Legal Advice Problems and AnswersDocument4 pagesSample Legal Advice Problems and AnswersJake Bryson DancelPas encore d'évaluation

- Heres The Rest of Him-Kent H Steffgen-1968-192pgs-GOVDocument192 pagesHeres The Rest of Him-Kent H Steffgen-1968-192pgs-GOVJeffrey Smith100% (1)

- Child and Adolescent Psychiatry ST1Document6 pagesChild and Adolescent Psychiatry ST1danielPas encore d'évaluation

- Convekta Training MethodsDocument9 pagesConvekta Training MethodsTech PadawanPas encore d'évaluation

- Mechanics of Materials Lab 1-Zip Tie Tensile TestingDocument7 pagesMechanics of Materials Lab 1-Zip Tie Tensile TestingcoolshavaPas encore d'évaluation

- Shear Force and Bending MomentssDocument32 pagesShear Force and Bending Momentssمحمد شمسPas encore d'évaluation

- 182021.04.23 Perfect ContinuousDocument2 pages182021.04.23 Perfect ContinuousadrianbulahkobetsPas encore d'évaluation

- Sonnet 39 ArticleDocument2 pagesSonnet 39 ArticlelalyitaPas encore d'évaluation

- How Is The Frog's Stomach Adapted To Provide An Increased Digestive Surface?Document6 pagesHow Is The Frog's Stomach Adapted To Provide An Increased Digestive Surface?Jemuel Bucud LagartoPas encore d'évaluation

- All State CM and Governers List 2022Document4 pagesAll State CM and Governers List 2022Tojo TomPas encore d'évaluation