Académique Documents

Professionnel Documents

Culture Documents

Structural Members: Struts and Ties Direct Stress and Strain, Dimensional Changes

Transféré par

cataiceTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Structural Members: Struts and Ties Direct Stress and Strain, Dimensional Changes

Transféré par

cataiceDroits d'auteur :

Formats disponibles

D.J.DUNN FREESTUDY.CO.

UK 1

EDEXCEL NATIONAL CERTIFICATE/DIPLOMA

MECHANICAL PRINCIPLES

OUTCOME 2 ENGINEERING COMPONENTS

TUTORIAL 3 FASTENINGS

2 ENGINEERING COMPONENTS

Structural members: struts and ties; direct stress and strain, dimensional changes;

combined effects of direct and thermal loading, factor of safety.

Compound members: series and parallel connected compound bars made up of two

materials; direct stress and strain in each material, dimensional changes.

Fastenings: shear stress in fastenings e.g. riveted joints, bolted joints and hinge pins

subjected to single and double shearing forces

You should judge your progress by completing the self assessment exercises. These may be sent for

marking at a cost (see home page).

On completion of this tutorial you should be able to do the following.

Define shear stress and strain.

Define the modulus of elasticity and rigidity.

Solve basic problems involving stress, strain and modulus.

It is assumed that the student is already familiar with the concepts of FORCE.

1. SHEAR STRESS

Shear force is a force applied sideways on to the material (transversely loaded). This occurs

typically:

(i) When a pair of shears cuts a material

Figure 1

(ii) When a material is punched

Figure 2

(iii) When a beam has a transverse load.

Figure 3

(iv) When a pin carries a load.

Figure 4

Shear stress is the force per unit area carrying the load. This means the cross sectional area of the

material being cut, the beam and pin respectively. Shear stress = F/A.

The symbol is called Tau. The sign convention for shear force and stress is based on how it shears

the materials and this is shown below.

Figure 5

D.J.DUNN FREESTUDY.CO.UK 2

In order to understand the basic theory of shearing, consider a block of material being deformed

sideways as shown.

Figure 6

6. SHEAR STRAIN

The force causes the material to deform as shown. The shear strain is defined as the ratio of the

distance deformed to the height x/L.

The end face rotates through an angle . Since this is a very small angle, it is accurate to say the

distance x is the length of an arc of radius L and angle so that

= x/L

It follows that is the shear strain. The symbol is called Gamma.

7. MODULUS OF RIGIDITY G

If we were to conduct an experiment and measure x for various values of F, we would find that if

the material is elastic, it behave like a spring and so long as we do not damage the material by using

too big a force, the graph of F and x is a straight line as

shown.

The gradient of the graph is constant so F/x = constant and

this is the spring stiffness of the block in N/m.

If we divide F by the area A and x by the height L, the

relationship is still a constant and we get

constant

Ax

FL

L

x

A

F

= =

Figure 7

But F/A = and x/L = so constant

Ax

FL

L

x

A

F

= = =

This constant will have a special value for each elastic material and is called the Modulus of

Rigidity with symbol G.

G

=

D.J.DUNN FREESTUDY.CO.UK 3

8. ULTIMATE SHEAR STRESS

If a material is sheared beyond a certain limit it becomes permanently distorted and does not spring

all the way back to its original shape. The elastic limit has been exceeded. If the material is stressed

to the limit so that it parts into two(e.g. a guillotine or punch), the ultimate limit has been reached.

The ultimate shear stress is

u

and this value is used to calculate the force needed by shears and

punches.

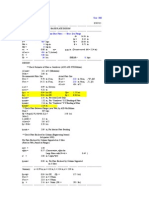

WORKED EXAMPLE No.4

Calculate the force needed to guillotine a sheet of metal 5 mm thick and 0.8 m wide given that

the ultimate shear stress is 50 MPa.

SOLUTION

kN 200 or N 000 200 4000 x 50 A x F so

A

F

N/mm 50 is stress shear ultimate The mm 4000 5 x 800 A

mm 5 x mm 800 rectangle a is cut be to area The

2 2

= = = =

= =

WORKED EXAMPLE No.5

Calculate the force needed to punch a hole 30 mm diameter in a sheet of metal 3 mm thick

given that the ultimate shear stress is 60 MPa.

SOLUTION

kN 16.965 or N 16965 282.7 x 60 A x F so

A

F

N/mm 60 is stress shear ultimate The mm 282.7 3 x 30 x A

x t d ss x thickne nce circumfere the is cut be to area The

2 2

= = = =

= =

=

WORKED EXAMPLE No.6

Calculate the force needed to shear a pin 8 mm diameter given that the ultimate shear stress is

60 MPa.

SOLUTION

kN 3.016 or N 3016 50.26 x 60 A x F so

A

F

N/mm 60 is stress shear ultimate The 50.26mm

4

8 x

A

4

d

A area circular the is sheared be to area The

2 2

2

= = = =

= =

=

D.J.DUNN FREESTUDY.CO.UK 4

SELF ASSESSMENT EXERCISE No.3

1. A guillotine must shear a sheet of metal 0.6 m wide and 3 mm thick. The ultimate shear stress

is 45 MPa. Calculate the force required. (Answer 81 kN)

2. A punch must cut a hole 30 mm diameter in a sheet of steel 2 mm thick. The ultimate shear

stress is 55 MPa. Calculate the force required. (Answer10.37 kN)

3. Two strips of metal are pinned together as shown with a rod 10 mm diameter. The ultimate

shear stress for the rod is 60 MPa. Determine the maximum force required to break the pin.

(Answer 4.71 kN)

Figure 8

9. DOUBLE SHEAR

Consider a pin joint with a support on both ends as

shown. This is called a CLEVIS and CLEVIS PIN. If the

pin shears it will do so as shown.

By balance of forces, the force in the two supports is F/2

each.

The area sheared is twice the cross section of the pin so it

takes twice as much force to break the pin as for a case of

single shear. Double shear arrangements doubles the

maximum force allowed in the pin.

Figure 9

D.J.DUNN FREESTUDY.CO.UK 5

WORKED EXAMPLE No.7

A pin is used to attach a clevis to a rope. The force in the rope will be a maximum of 60 kN.

The maximum shear stress allowed in the pin is 40 MPa. Calculate the diameter of a suitable

pin.

SOLUTION

mm 30.9

750 x 4

d

4

d

mm 750 A

m 10 x 750

40x10 x 2

60000

2

F

A

2A

F

is sress shear the so shear double in is pin The

2

2

2 6

6

= =

= =

= = =

=

SELF ASSESSMENT EXERCISE No.4

1. A clevis pin joint as shown above uses a pin 8 mm diameter. The shear stress in the pin must

not exceed 40 MPa. Determine the maximum force that can be exerted. (Answer 4.02 kN)

2.

Figure 10

A rope coupling device shown uses a pin 5 mm diameter to link the two parts. If the shear

stress in the pin must not exceed 50 MPa, determine the maximum force allowed in the ropes.

(Answer 1.96 kN)

FINAL NOTE

Shear stress and modulus of rigidity are important in the studies of twisting of shafts and this is

covered in anther tutorial.

D.J.DUNN FREESTUDY.CO.UK 6

Vous aimerez peut-être aussi

- ShearDocument7 pagesShearcataicePas encore d'évaluation

- Experiment 6 and Experiment 7Document5 pagesExperiment 6 and Experiment 7Gebre TensayPas encore d'évaluation

- Metacentre and Metacentric HeightDocument4 pagesMetacentre and Metacentric HeightleonPas encore d'évaluation

- 8 Stresses in BeamDocument6 pages8 Stresses in BeamAnkit SinghPas encore d'évaluation

- Lect 1Document19 pagesLect 1Kong DuiDuiPas encore d'évaluation

- Curvilinear Motion and ProjectilesDocument15 pagesCurvilinear Motion and ProjectilesAltammar1367% (3)

- Mechanics of Deformable Bodies: Lectures on Theoretical PhysicsD'EverandMechanics of Deformable Bodies: Lectures on Theoretical PhysicsPas encore d'évaluation

- PPT3 - Mechanical Behavior, Testing and Manufacturing Properties of Materials Rev (New)Document30 pagesPPT3 - Mechanical Behavior, Testing and Manufacturing Properties of Materials Rev (New)aekimPas encore d'évaluation

- Glimpse of Deformation Theory OssermanDocument10 pagesGlimpse of Deformation Theory OssermanbhaumiksauravPas encore d'évaluation

- Strength of MaterialsDocument17 pagesStrength of MaterialskalpanaPas encore d'évaluation

- Od & Parking StudiesDocument154 pagesOd & Parking StudiesMichael KpeglahPas encore d'évaluation

- Lab 6 - Maximum Power Transfer and PF Improvement - 2012Document5 pagesLab 6 - Maximum Power Transfer and PF Improvement - 2012劉成Pas encore d'évaluation

- Chapter 3Document87 pagesChapter 3nns100% (1)

- Tutorial 3 DeflectionDocument4 pagesTutorial 3 DeflectionAbelBayartPas encore d'évaluation

- Parallel Planes (Or Torque or Twisting MomentDocument26 pagesParallel Planes (Or Torque or Twisting MomentGetachew AbebePas encore d'évaluation

- Foley StaticsStrengthsDocument733 pagesFoley StaticsStrengthsDenis Gachev100% (2)

- Design, Fabrication and Testing of Human Powered Water PurifierDocument8 pagesDesign, Fabrication and Testing of Human Powered Water PurifierIJRASETPublicationsPas encore d'évaluation

- Hooke LawDocument3 pagesHooke LawLiuJiewChuanPas encore d'évaluation

- Chapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Document80 pagesChapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Dr. Aung Ko LattPas encore d'évaluation

- Kinematic Equations and Free FallDocument97 pagesKinematic Equations and Free FallMuhammad AslamPas encore d'évaluation

- Tensile TestDocument9 pagesTensile Testonkod1Pas encore d'évaluation

- Center of Pressure and Hydrostatic Force On A Submerged Body-RevDocument7 pagesCenter of Pressure and Hydrostatic Force On A Submerged Body-RevAnkit MittalPas encore d'évaluation

- Homework 2Document6 pagesHomework 2sirali940% (1)

- Materials Engr.Document7 pagesMaterials Engr.Ryan TogononPas encore d'évaluation

- Chapter 1 Introduction To Engineering Principles and UnitsDocument47 pagesChapter 1 Introduction To Engineering Principles and Unitseng_yap_1Pas encore d'évaluation

- Material TestingDocument54 pagesMaterial TestingJochelle Mae Pecson100% (1)

- Hydrostatic Pressure Plane SurfaceDocument5 pagesHydrostatic Pressure Plane SurfaceAmmir HakimPas encore d'évaluation

- Physical Properties of FluidDocument12 pagesPhysical Properties of Fluidridzuan260496Pas encore d'évaluation

- TrigonometryDocument3 pagesTrigonometryJohnCarloTigue0% (1)

- 4 Failure CriteriaDocument43 pages4 Failure Criteriaali381Pas encore d'évaluation

- Chap4b-Axially Loaded MembersDocument27 pagesChap4b-Axially Loaded Membersskhan247100% (1)

- Eu 1 Module 1 Part IIIDocument50 pagesEu 1 Module 1 Part IIIglainePas encore d'évaluation

- Elemen MesinDocument23 pagesElemen MesinMonika NikaPas encore d'évaluation

- Kajidaya Bahan - Shear and Moment Diagrams Case StudyDocument8 pagesKajidaya Bahan - Shear and Moment Diagrams Case StudyzalPas encore d'évaluation

- 081 - ME8594, ME6505 Dynamics of Machines - Notes PDFDocument78 pages081 - ME8594, ME6505 Dynamics of Machines - Notes PDFKrish NarayananPas encore d'évaluation

- Laboratory Assignments On Experiment 1: Measurement of Self-Inductance by Maxwell's BridgeDocument2 pagesLaboratory Assignments On Experiment 1: Measurement of Self-Inductance by Maxwell's BridgesparshPas encore d'évaluation

- PKG 825 Lab 1 Mechanical PropertiesDocument8 pagesPKG 825 Lab 1 Mechanical PropertiesFanni09Pas encore d'évaluation

- Lathe Machine Lab ReportDocument5 pagesLathe Machine Lab ReportEdgar ThorpePas encore d'évaluation

- EC311: Fluid Mechanics Tutorial Sheet 01Document3 pagesEC311: Fluid Mechanics Tutorial Sheet 01chilaluPas encore d'évaluation

- FLEXURAL 12 (Autosaved)Document42 pagesFLEXURAL 12 (Autosaved)Ezen ChiPas encore d'évaluation

- Chapter 1 MergedDocument65 pagesChapter 1 MergedAdi SaputraPas encore d'évaluation

- Kinetics of Rigid BodyDocument32 pagesKinetics of Rigid BodyAdrian AbdillaPas encore d'évaluation

- Engineering-Mechanics Notes PDFDocument100 pagesEngineering-Mechanics Notes PDFMahesh RamtekePas encore d'évaluation

- UEME1132/UEME1323 Statics Assignment (30%)Document20 pagesUEME1132/UEME1323 Statics Assignment (30%)shintanPas encore d'évaluation

- Moment Area TheoremDocument3 pagesMoment Area TheoremzidaaanPas encore d'évaluation

- Review of Related LiteratureDocument5 pagesReview of Related LiteratureJay Ar GalangPas encore d'évaluation

- Experiment 1Document5 pagesExperiment 1Timmy TrinhPas encore d'évaluation

- Fluid Mechanics - 01 Problem - CIVE2400-2007 PDFDocument4 pagesFluid Mechanics - 01 Problem - CIVE2400-2007 PDFTania Edna Bhakty SoetjiptoPas encore d'évaluation

- RCH Som 01 IntroductionDocument51 pagesRCH Som 01 IntroductionSatish DhanyamrajuPas encore d'évaluation

- Acceleration Analysis of MechanismsDocument32 pagesAcceleration Analysis of MechanismsThahir Shah100% (1)

- Open Ended Full Report CEWB121Document18 pagesOpen Ended Full Report CEWB121Nur FarehaPas encore d'évaluation

- Torsion TestDocument7 pagesTorsion Testilya danisyahPas encore d'évaluation

- CE224 MDB - Module 1: StressDocument8 pagesCE224 MDB - Module 1: Stressaileen eustaquioPas encore d'évaluation

- Environmental Engineering Principles (Inglés) (Presentación) Autor Dave ReckhowDocument14 pagesEnvironmental Engineering Principles (Inglés) (Presentación) Autor Dave ReckhowJuankmilo Poveda AraquePas encore d'évaluation

- Tensile Test WorksheetDocument5 pagesTensile Test WorksheetRaj Das100% (1)

- Exp 1 G5Document24 pagesExp 1 G5Abdullah Helmi100% (1)

- Stress Part2Document7 pagesStress Part2raiden timberlandPas encore d'évaluation

- Stress PDFDocument13 pagesStress PDF9966197483Pas encore d'évaluation

- Mechanical Science for Technicians: Volume 1D'EverandMechanical Science for Technicians: Volume 1Évaluation : 5 sur 5 étoiles5/5 (1)

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDDocument10 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataicePas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- (Lec Dt3 Journal BearingsDocument25 pages(Lec Dt3 Journal BearingscataicePas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Tm214323 Fastener TorqueDocument36 pagesTm214323 Fastener TorquecataicePas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Beam Analysis BS5950Document229 pagesBeam Analysis BS5950cataicePas encore d'évaluation

- ANC-2 Ground LoadsDocument24 pagesANC-2 Ground LoadscataicePas encore d'évaluation

- Report Metodo SchrenkDocument16 pagesReport Metodo SchrenkDario ForestierePas encore d'évaluation

- Base Plate ASDDocument7 pagesBase Plate ASDcataicePas encore d'évaluation

- Angleflexseat - Xls (Revision 1.2)Document4 pagesAngleflexseat - Xls (Revision 1.2)cataicePas encore d'évaluation

- ASEC7-05 & IBC 2006 Earthquake Lateral Forces - Protected-30!06!2012Document27 pagesASEC7-05 & IBC 2006 Earthquake Lateral Forces - Protected-30!06!2012cataicePas encore d'évaluation

- Chapter 1Document9 pagesChapter 1TemesgenAbiyPas encore d'évaluation

- Activity 2 3 2 Tensile Testing With The SsaDocument9 pagesActivity 2 3 2 Tensile Testing With The Ssaapi-282283753Pas encore d'évaluation

- ISM2006 Plasticity Modelling Abaqus FEM Code v2Document27 pagesISM2006 Plasticity Modelling Abaqus FEM Code v2EsoElmoghazyPas encore d'évaluation

- Chapter 1 - Stress and StrainDocument72 pagesChapter 1 - Stress and StrainNazhan HaziqPas encore d'évaluation

- CH 06Document84 pagesCH 06IlhamBintang100% (1)

- Nonlinear Biaxial Stress-Strain LawDocument13 pagesNonlinear Biaxial Stress-Strain Lawமாறன் செங்கேணிPas encore d'évaluation

- D 2990 - 95 - Rdi5otatotu - PDFDocument18 pagesD 2990 - 95 - Rdi5otatotu - PDFsusanaPas encore d'évaluation

- HDBK-1017 Materials ScienceDocument112 pagesHDBK-1017 Materials ScienceMClark100% (1)

- Compressive and Shear Strengths of Straw Log Bearing WallDocument21 pagesCompressive and Shear Strengths of Straw Log Bearing WallPatti StouterPas encore d'évaluation

- DSA InconelDocument12 pagesDSA InconeltazzorroPas encore d'évaluation

- RDT 99005Document96 pagesRDT 99005Hashem EL-MaRimeyPas encore d'évaluation

- FinalDocument17 pagesFinalKashif NaukhezPas encore d'évaluation

- Tissue BiomechanicsDocument49 pagesTissue BiomechanicsDarshana NagalePas encore d'évaluation

- Mechanism of Chip FormationDocument4 pagesMechanism of Chip Formationakjeevanantham79Pas encore d'évaluation

- Dr. Jens Bold - PRSENTATION - Virtual Material Characterization Using MultiScale DesignerDocument42 pagesDr. Jens Bold - PRSENTATION - Virtual Material Characterization Using MultiScale DesignerOliver RailaPas encore d'évaluation

- Neuber Plasticity Correction R&O Material CurveUR2202Document1 pageNeuber Plasticity Correction R&O Material CurveUR2202Eduardo Javier Granados SanchezPas encore d'évaluation

- Ch06 Mechanical PropertiesDocument49 pagesCh06 Mechanical PropertiesEva NovitaliaPas encore d'évaluation

- Calibration and Evaluation of Seven Fracture ModelsDocument25 pagesCalibration and Evaluation of Seven Fracture ModelsDarkprogPas encore d'évaluation

- The Compatible Stress Field Method - IDEA StatiCa Detail 20 (Theoretical Background)Document35 pagesThe Compatible Stress Field Method - IDEA StatiCa Detail 20 (Theoretical Background)JulianPas encore d'évaluation

- CH 1Document15 pagesCH 1Milashu SisayPas encore d'évaluation

- Aluminum Foam, "Alporas": The Production Process,: Properties and ApplicationsDocument5 pagesAluminum Foam, "Alporas": The Production Process,: Properties and ApplicationsLuis CarranzaPas encore d'évaluation

- Massivbau Munchen 03 2008Document11 pagesMassivbau Munchen 03 2008oramona1Pas encore d'évaluation

- MSE 235 Technical Lab ReportDocument9 pagesMSE 235 Technical Lab ReportBobby LarkerPas encore d'évaluation

- 3mech DaeDocument72 pages3mech DaeUmer Iftikhar AhmedPas encore d'évaluation

- Reinforced Concrete Structural Walls Test Database and Modeling ParametersDocument334 pagesReinforced Concrete Structural Walls Test Database and Modeling ParametersMohamed Yasser Mohamed El TahlawiPas encore d'évaluation

- Chapter 6 - Elasticity and OscillationDocument20 pagesChapter 6 - Elasticity and OscillationKenny Jay LabianoPas encore d'évaluation

- Mechanical Properties of MaterialsDocument33 pagesMechanical Properties of MaterialsAaron Dela CruzPas encore d'évaluation

- 1-1 Normal Stress and StrainDocument4 pages1-1 Normal Stress and StrainRonee PangilinanPas encore d'évaluation

- Mechanics of Materials CH 3Document12 pagesMechanics of Materials CH 3Adrian MackPas encore d'évaluation

- 68406-Ch 02Document28 pages68406-Ch 02Kirat Kamboz100% (1)