Académique Documents

Professionnel Documents

Culture Documents

Experimental Investigation On Halloysite Nano Tubes & Clay An Infilled Composite Steel Tube

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Experimental Investigation On Halloysite Nano Tubes & Clay An Infilled Composite Steel Tube

Droits d'auteur :

Formats disponibles

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 195

EXPERIMENTAL INVESTIGATION ON HALLOYSITE NANO TUBES &

CLAY AN INFILLED COMPOSITE STEEL TUBE

Vindhya C.R

1

, Hafeez Khan

2

, N.S Kumar

3

1

Master of Technology (Structural Engineering) student, Department of Civil Engineering, GCE Ramanagaram,

Karnataka India

2

Master of Technology (Structural Engineering) student, Department of Civil Engineering, GCE Ramanagaram,

Karnataka India

3

Professor & Director (R&D-Civil Engg) GCE Ramanagaram, Karnataka India

Abstract

This research aims at Comparative experimental behavior of Halloysite Nano Tubes& Clay as an in fill to Composite Steel tubes.

Both materials are of Nano category and one is in the tubular form and the other amorphous. Naturally formed in the Earth over

millions of years, Halloysite Nano Clay are unique and versatile Nano materials that composed of aluminum, silicon, hydrogen and

oxygen and are mined from natural deposits in countries like China, New Zealand, America, Brazil, and France. The effects of the

diameter, length of steel tube, grade of concrete & volume fractions of HNCs to concrete (0%,0.5%,1%,1.5%,&2%) on the behavior

of Halloysite Nano Clay(HNCs) concrete filled steel tube columns under axial compression are presented and compared with that of

Nano tubes. Also, Studies are carried out to know the effect of Diameter (D), Change in steel tube length (l), and Strength of infill (f

CK

)

and to determine the ultimate load (P

ult

) & defection (

axial

) in HNCs composite steel hollow tubes under monotonic loading and SEM

(scanning electron microscope) image are taken during mixing, before testing and after testing and Fracture Analysis will be carried

out for the buckled steel tubes using Radiographic Testing.

Keywords: Halloysite Nano Clay1, SEM2, Fracture Analysis3.

-----------------------------------------------------------------------***-----------------------------------------------------------------------

1. INTRODUCTION

Concrete filled steel tubes have been extensively used in the

modern Structure mainly due to the combination of the

advantage of Steel tube & Concrete core. The in-fill material

inside Steel tubes is required to be of the quality as to increase

the ductility, but not the strength of composite columns, many

kind of in-fill materials were used to improve ductility of

composite columns. Among the various in fill materials, we

are using Halloysite Nano Clay (HNCs).

Recent developments in nanoscience and nanotechnology

opened fundamental and applied new frontiers in science and

materials engineering. Advanced materials are being

developed with enhanced chemical and physical properties

with unique characteristics. The properties of these materials

are determined not only by their composition and chemical

bonds, but also by size and morphology. The nanotube (NT)

term is recent; the idea of a small tubular structure is not new.

In 1930, Linus Pauling (1930) proposed the existence of

cylindrical structures formed by minerals in nature.

Naturally formed in the Earth over millions of years,

Halloysite Nano Clay are unique and versatile Nano materials

that composed of aluminum, silicon, hydrogen and oxygen

and are mined from natural deposits in countries like China,

New Zealand, America, Brazil, and France. HNCs are

chemically similar to kaolinite and they used in the

manufacture of high quality ceramic white-ware. HNTs have

high mechanical strength and modulus and these features

make it an ideal material preparing for different composites.

The formation of halloysite is due to hydrothermal alteration,

and it is often found near carbonate. For example, halloysite

samples found in Wagon Wheel Gap, Colorado and United are

suspected to be the weathering product of rhyolite by

downward moving waters. In general the formation of clay

minerals is highly favored in tropical and sub-tropical climates

due to the immense amounts of water flow. Halloysite has also

been found overlaying basaltic rock, showing no gradual

changes from rock to mineral formation. Halloysite occurs

primarily in recently exposed volcanic-derived soils, but it

also forms from primary minerals in tropical soils or pre-

glacially weathered materials. Igneous rocks, especially glassy

basaltic rocks are more susceptible to weathering and

alteration forming halloysite.

1.1 Advantages of Halloysite Nanotubes

Fine particle size, high surface area and dispersion.

Implementable in many forms such as powders, creams, gels,

Superior loading rates to other carriers, Fast adsorption rate

High aspect ratio, high porosity and non swelling

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 196

Regeneration ability and increased efficacy

2. EXPERIMENTAL

Experiment were carried out on four different specimens with

four variations in each specimen, which varies in length

50mm, 75mm, 100mm, 125mm, 150mm and 200mm with

constant diameter 25mm. And mixed with Cement, Sand &

HNCs (0.5%, 1%, 1.5% and 2%).

Sample1- 1:2:3 (Cement: HNC: Sand)

Sample2- 1:1.5:3 (Cement: HNC: Sand)

Sample3- 1:2 (Cement: HNC)

Sample4- 2:3 (HNC: Sand)

Sample5- 1:1.5 (Cement: HNC)

Sample6- 1.5:3 (HNC: Sand)

Sample7- Cement

Sample8- HNCs

Sample9- Sand

Sample10- After compression testing

2.1 Halloysite Nanotubes

Source: Sigma Aldrich (manufacturer)-New Zealand [1]

Physical and chemical properties (provide by the supplier)

Synonyms: Kaolin clay

Appearance Form: powder

Colour: White to Tan

Relative density 2, 53 g/cm3

Formula: H4Al2O9Si2 2 H2O

Molecular Weight: 294, 19 g/mol

P

H

Value 6.5-6.9

Pore volume 1.26-1.34 ml/gm

Diameter 30-70nm (nanometers)

Length 0.25-4 microns.

2.2 Characterization

2.2 1 Scanning Electron Microscopy (SEM)

A Scanning electron microscopy [2] imaging was obtained to

investigate the microstructures and the fracture surfaces of

composites. The samples were mounted on aluminum stubs

using carbon tape. The samples were then coated with a thin

layer of gold to prevent charging before the observation by

SEM.

Sample preparation before SEM testing [2]

Gold coating after sample preparation before SEM testing[2]

Ultra high resolution scanning electron imaging coupled with

material spectroscopy tools

The ULTRA 55 represents the latest development in GEMINI

technology. Based on the SUPRA 55, the ULTRA 55 now

comprises a fully integrated Energy and angle selective

Backscattered electron (EsB) detector. The ULTRA 55 offers

ultra high resolution for both SE to image surface information

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 197

and BSE to present compositional information. The new EsB

detector features an integrated filtering grid to enhance image

quality and requires no additional adjustments. The EsB

detector is less sensitive for edge contrast and charging effects

which enables precise imaging and measurement of

boundaries, particles, and features. Combined with the large

multi-port analytical chamber, the fully motorised 5-axes

motorised eucentric stage and the GEMINI high current mode

the ULTRA 55 also offers superb analytical capabilities.

2.2.2 Fracture Analysis

Radiographic Testing were examined using Iridium-192

diameter 2.7*1.2mm, Strength 30 Ci Gamma Ray machine

View of a Gamma Ray machine [3]

2.2.2 Energy-Dispersive X-ray Spectroscopy (EDX)

Analysis

EDX is an analytical technique used for the elemental analysis

or chemical characterization of a sample. It relies on an

interaction of some source of X-ray excitation and a sample.

Its characterization capabilities are due in large part to the

fundamental principle that each element has a unique atomic

structure allowing unique set of peaks on its X-ray spectrum

Another way to use SEM/EDX is to make a quantitative

chemical analysis of materials.

2.2.3 200 Ton Cyclic Loading Machine

Hydraulic press for testing load comprising Press frame;

hydraulic cylinder (dia320Xdia 250X250mm stroke).

Hydraulic power pack 100 it with electric motor 5hp X

1440rpm,electrical control panel operating with PLC SCADA

software, strain gauge SI -30 & strain indicator. To conduct

the compression tests on all the specimens.

Concrete filled steel tube subjected to monotonic loading [4]

Composite steel tube under testing [4]

3. RESULTS & DISCUSSIONS

3.1 Scanning electron microscopy (SEM)

Sample1- 1:2:3(Cement: HNC: Sand)

a) b)

c) d)

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 198

e) f)

Fig1. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample1- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

Sample2- 1:1.5:3 (Cement: HNC: Sand)

a) b)

c) d)

e) f)

Fig2. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample2- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

Sample3- 1:2 (Cement: HNC)

a) b)

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 199

c) d)

e) f)

Fig3. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample3- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

Sample4- 2:3 (HNC: Sand)

a) b)

c) d)

e) f)

Fig4. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample4- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 200

Sample5- 1:1.5 (Cement: HNC)

a) b)

c) d)

e) f)

Fig5. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample5- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

Sample6- 1.5:3 (HNC: Sand)

a) b)

c) d)

e) f)

Fig6. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample6- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 201

Sample7- Cement

a) b)

c) d)

e) f)

Fig7. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample7- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

Sample8- HNCs

a) b)

c) d)

e) f)

Fig8. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample8- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 202

Sample9- Sand

a) b)

c) d)

Fig9. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample9- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

Sample10- After compression testing

a) b)

c) d)

e) f)

Fig10. SEM Images of fracture surface morphology from low

to high magnification (a-f)

Sample10- Energy-dispersive X-ray spectroscopy

(EDX) Analysis

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 203

3.2 Fracture Analysis

Radiographic Testing were examined for the samples

1) Length 300mm, c/s3*3mm -stainless steel

2) Length 300mm, diameter 23mm-middle steel

3) Length 280mm, diameter 22mm- middle steel

4) Length 30mm, diameter 30mm -middle steel

Fig 11 radiographic film

When the Tube was monotonically loaded it was observed that

crack patters as shown in the fig1 & were obtained from the

radiographic testing and further work is being carried out by

the author for modeling the future using facture analysis

approach and for further developing the mathematical

modeling for facture.

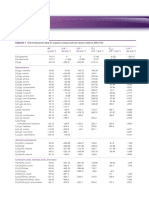

3.3 Experimental Results

Length 300mm, diameter 22mm, thickness 5mm & M20

(1:2:3) concrete.

Ultimate load (P

ult

) in KN

Without

HNCs

With

HNCs

HNCs

in %

84 85.68 0.5

86.10 88.25 1.0

86.52 89.11 1.5

87.36 82.32 2.0

Fig 12- Result Table

78

80

82

84

86

88

90

0

.

5

%

1

.

0

%

1

.

5

%

2

.

0

%

u

l

t

i

m

a

d

e

l

o

a

d

(

P

u

l

t

)

i

n

K

N

HNC's in %

Without HNCs

With HNCs

Fig 13- Ultimate load (P

ult

) vs. HNCs graph

4. CONCLUSIONS

Physical and chemical properties of the HNCs tested were

founded to be very positive for civil engineering applications.

Especially it has light weight and is in the powder form which

can mix well with the cement & sand. Tests are being

conducted for the compressive strength of HNCs. When

mixed with only cement, only sand & all the three. SEM &

EDX analysis are shows that HNCs can lead to homogenous

mixture which in turns enhances load caring capacity of

composite steel column.

As shown in the fig 2 as percent of HNCs increase load also

increase observed and ultimate load (P

ult

) is increased but

reached optimum and started deceasing between 1.5 to 2.0%.

ACKNOWLEDGEMENTS

Authors are highly indebted to Dr Girish Kunte, Micro &

Nano Characterization Facility (MNCF) Center for Nano

Science and Engineering (CENSE) IISc, Bangalore. Dr. Sudha

Joseph, Dept of Material Engineering, IISc, Bangalore. Mr.

Gadhadar, NoPo Nanotechnologies India Pvt Ltd, Bangalore.

Sigma Aldrich-New Zealand. Pallakki NDT Excellence

Center, Peenya, Bangalore.

REFERENCES

[1]. Sigma Aldrich Bommasandra, Bangalore.

[2]. Micro & Nano Characterization Facility (MNCF) Center

for Nano Science and Engineering (CENSE) IISc, Bangalore

[3]. Pallakki NDT Excellence Center, Peenya, Bangalore

[4]. R&D Lab, Dept of Civil Engineering, GCE,

Ramanagaram.

[5]. Alamri H, Low IM. Microstructural, mechanical, and

thermal characteristics of recycled cellulose .ber-halloysite-

epoxy hybrid nanocomposites. Polym Compos

2012;33(4):589600.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 06 | May-2014 | RRDCE - 2014, Available @ http://www.ijret.org 204

[6]. Churchman GJ, Davy TJ, Aylmore LAG, Gilkes RJ, Self

PG. Characteristics of .nepores in some halloysites. Clay

Miner 1995;30:8998.

[7]. Joussein E, Petit S, Churchman J, Theng B, Right D,

Delvaux B. Halloysite clay minerals a review. Clay Miner

2005;40:383426.

[8]. Smith ME, Neal G, Trigg MB, Drennan J. Structural

characterization of the thermal transformation of halloysite by

solid-state NMR. Appl Magn Reson 1993;4:15770.Cer

[9]. Fix, D., Andreeva, D.V., Lvov, Y.M., Shchukin, D.G.,

Mhwald, H., 2009.

[10]. Application of inhibitor-loaded halloysite nanotubes in

active anti-corrosive coatings. Advanced

[11]. Functional Materials 19 (11), 17201727.2006. Layer-

by-layer assembled nanocontainers for self-healing corrosion

protection. Advanced Materials 18 (13), 16721678.

[12] Prashantha K, Lacrampe MF, Krawczak P. Processing

and characterisation of halloysite nanotubes filled

polypropylene nanocomposites based on a master batch route:

effect of halloysites treatment on structural and mechanical

properties. Express Polym Lett 2011;5(4):295307.

[13]. Handge UA, Hedicke-Hchsttter K, Altstdt V.

Composites of polyamide-6 and silicate nanotubes of the

mineral halloysite: in.uence of molecular weight on thermal,

mechanical and rheological properties. Polymer

2010;51(12):26909.

[14]. Lin Y, Ng KM, Chan C-M, Sun G, Wud J. High-impact

polystyrene/halloysite nanocomposites prepared by emulsion

polymerization using sodium dodecyl sulfate as surfactant. J

Colloid Interface Sci 2011;358:4239.

[15]. Yuan Q, Misra RDK. Polymer nanocomposites: current

understanding and issues. Mater Sci Technol 2006;22:74255.

[16]. Friedrich K, Fakirov S, Zhang Z. Polymer composites:

from nano-to-macro-scale. (USA): Springer Science &

Business Media, Inc.; 2005.

[17]. Deng S, Zhang J, Ye L. Halloysite-epoxy

nanocomposites with improved particle dispersion through

ball mill homogenisation and chemical treatments. Compos

Sci Technol 2009;69:2497505.

[18]. Morote-Martinez V, Pascual-Sanchez V, Martin-

Martinez JM. Improvement in mechanical and structural

integrity of natural stone by applying unsaturated polyester

resin-nanosilica hybrid thin coating. Eur Polym J

2008;44:314655.

BIOGRAPHIES

Graduated in the year 2011 from VTU,

Belgaum Presently perusing Master of

Technology in Structural Engineering at

Ghousia College of Engineering,

Ramanagaram Also working on this topic for

the dissertation under the guidance of Dr. N S

Kumar

Graduated in the year 2012 from VTU,

Belgaum. Presently perusing Master of

Technology in Structural Engineering at

Ghousia College of Engineering, Ramanagaram

Also working on this topic for the dissertation

under the guidance of Dr. N S Kumar

Involved in the Research field related to

behavior of Composite Steel Column since a

decade Presently guiding four Ph.D Scholars,

including one M.Sc Engineering (Research

under VTU, Belgaum) Has more than 25 years

of teaching experience & 6 years of Research

experience at Ghousia College of Engineering, Ramanagaram.

Vous aimerez peut-être aussi

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- MasterSpec Consolidated TOCDocument39 pagesMasterSpec Consolidated TOCsheevesPas encore d'évaluation

- CHM1 Structure & Bonding QDocument115 pagesCHM1 Structure & Bonding QGoutham SivagnanamPas encore d'évaluation

- Atkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Document7 pagesAtkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Roselle Mea EderPas encore d'évaluation

- TWM 3178 PDSDocument2 pagesTWM 3178 PDSsunnyooiPas encore d'évaluation

- Types of Chemical ReactionsDocument7 pagesTypes of Chemical ReactionsAirene PalerPas encore d'évaluation

- Multiparticulate Delayed Release Drug Delivery SystemDocument24 pagesMultiparticulate Delayed Release Drug Delivery SystemAarti koramPas encore d'évaluation

- Boas Práticas para Produção de ADBlueDocument27 pagesBoas Práticas para Produção de ADBluewelyson_henriquePas encore d'évaluation

- EagleBurgmann MG1 enDocument4 pagesEagleBurgmann MG1 ensanjeevvangePas encore d'évaluation

- 3rd Quarter Science 8Document50 pages3rd Quarter Science 8John Ryan PiolPas encore d'évaluation

- 531 (1999) T. R. Golub: Science Et AlDocument8 pages531 (1999) T. R. Golub: Science Et AlBair PuigPas encore d'évaluation

- Who We Are: Case Study-Mahindra ChlorisDocument25 pagesWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMAPas encore d'évaluation

- Part A: Multiple - Choice QuestionsDocument14 pagesPart A: Multiple - Choice QuestionsGora PostingPas encore d'évaluation

- Benzocaine Synthesis PDFDocument2 pagesBenzocaine Synthesis PDFLive FlightsPas encore d'évaluation

- Auditor or ManagerDocument7 pagesAuditor or Managerapi-79118648Pas encore d'évaluation

- ETT Seminar - Isotopes in MedicineDocument71 pagesETT Seminar - Isotopes in MedicineisocenterPas encore d'évaluation

- SANDVIK - Steel Designation and Markings - STA-02-030EDocument4 pagesSANDVIK - Steel Designation and Markings - STA-02-030EPetr HavelPas encore d'évaluation

- Determination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Document11 pagesDetermination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Irvine MupambaPas encore d'évaluation

- Waste Management AustriaDocument34 pagesWaste Management AustriaregiapursofPas encore d'évaluation

- Unit 5.12 PrecipitationDocument16 pagesUnit 5.12 PrecipitationMutale InongePas encore d'évaluation

- 409 Data BulletinDocument12 pages409 Data BulletinWilliam PaivaPas encore d'évaluation

- Spesifikasi Material Finishing Unit ApartemenDocument34 pagesSpesifikasi Material Finishing Unit ApartemenArif GumelarPas encore d'évaluation

- Tsubaki ChainDocument8 pagesTsubaki Chainbmihaiela100% (1)

- Totalenergies PaperDocument2 pagesTotalenergies PaperJulian Dario Galarza InsfranPas encore d'évaluation

- Cambridge International Examinations Cambridge International Advanced Subsidiary and Advanced LevelDocument20 pagesCambridge International Examinations Cambridge International Advanced Subsidiary and Advanced LevelharshanauocPas encore d'évaluation

- McQuay WHS ChillerDocument28 pagesMcQuay WHS ChillerYorkist100% (1)

- Detailed Storage Tank SizingDocument18 pagesDetailed Storage Tank SizingBooLat Johorean100% (3)

- Plumbing Notes 1 PDFDocument57 pagesPlumbing Notes 1 PDFhoneyvie53% (15)

- Different Manicure Equipment, Materials and CosmeticsDocument36 pagesDifferent Manicure Equipment, Materials and CosmeticsRenlen EstevesPas encore d'évaluation

- Regents Homeostasis and EnzymesDocument5 pagesRegents Homeostasis and Enzymesapi-3031203990% (1)