Académique Documents

Professionnel Documents

Culture Documents

Fixed Cutter Bits - IADC Dull Grading: Security Dbs Drill Bits

Transféré par

Ed CalheDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fixed Cutter Bits - IADC Dull Grading: Security Dbs Drill Bits

Transféré par

Ed CalheDroits d'auteur :

Formats disponibles

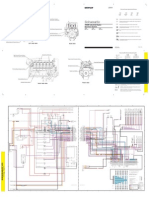

Fixed Cutter Bits - IADC Dull Grading

Cutting Structure

Inner Rows Outer Rows Dull Char. Location Bearings/Seals X Gauge Other Dull Char. Reason Pulled

8 7 6 3 4 2 1 X

H

A

L

9

0

8

6

Gauge

Shoulder

Taper

Nose

Cone

H

A

L

9

0

8

5

No Wear Worn Cutter

H

A

L

9

0

4

5

Lost Cutter Delaminated

H

A

L

9

0

4

5

Inner Cutting Structure

Outer Cutting Structure

A measure of lost, worn and/or

broken cutting structure.

Linear Scale: 0-8

0 - No lost, worn and/or broken

cutting structure

8 - All of cutting structure lost,

worn and/or broken

Dull Characteristics

BF - Bond Failure

BT - Broken Teeth/Cutters

BU - Balled Up

CR - Cored

CT - Chipped Teeth/Cutters

ER - Erosion

FC - Flat Crested Wear

HC - Heat Checking

JD - Junk Damage

LN - Lost Nozzle

LT - Lost Teeth/Cutters

NO - No Dull Characteristic

NR - Not Rerunnable

OC - Off Center Wear

PN - Plugged Nozzle/Flow Passage

RG - Rounded Gauge

RO - Ring Out

RR - Rerunnable

TR - Tracking (and Spalling)

WO- Washed Out

WT - Worn Teeth/Cutters

Location

A - All Areas

C - Cone

G - Gauge

N - Nose

S - Shoulder

T - Taper

X

Gauge

I - In Gauge

1 - 1/16-in. Out of Gauge

2 - 1/8-in. Out of Gauge

4 - 1/4-in. Out of Gauge

Other Dull Characteristics

(Refer to column 3 codes)

Reason Pulled or Run Terminated

BHA - Change Bottomhole Assembly

CM - Condition Mud

CP - Core Point

DMF - Downhole Motor Failure

DP - Drill Plug

DSF - Drill String Failure

DST - Drill Stem Test

DTF - Downhole Tool Failure

FM - Formation Change

HP - Hole Problems

HR - Hours on Bit

LIH - Left in Hole

LOG - Run Logs

PP - Pump Pressure

PR - Penetration Rate

RIG - Rig Repair

TD - Total Depth/Casing Depth

TQ - Torque

TW - Twist Off

WC - Weather Conditions

WO - Washout - Drill String

6

7

8

2

3

5

1

Inner Area

2/3 Radius

Outer Area

1/3 Radius

HALLIBURTON

SECURITY DBS DRILL BITS

Security DBS fixed cutter bits are

tip ground to exacting tolerances at

gauge O.D. per API spec 7.

Depending on the specific design

and application as much as .080 of

an inch of the cutter diameter may

be ground flat. This can be mistaken

for gauge wear if unfamiliar with

our products. Please ensure that dull

bits are in gauge with a calibrated

PDC No Go ring gauge.

4

Fixed Cutter Bits - Ring Gauging

Any fixed cutter bit should be ring gauged prior to running

in the hole. Stabilizers should also be calipered or gauged to

verify they meet API-approved outside dimension

tolerances as shown in the following table. Fixed cutter bits

should not be larger than the nominal diameter.

A no go gauge is used to ensure a bit is not smaller than

allowed and, as the name implies, it should not go or slip

down the entire length of the bit. A go gauge ensures

a bit is not larger than allowed and should slip down the

entire bit.

API Fixed Cutter Bit Tolerances

Bit Size In. Fixed Cutter Bit

O.D. Tolerance In.

6-3/4 and Smaller -0.015 to +0.00

6-25/32 to 9 -0.020 to +0.00

9-1/32 to 13-3/4 -0.030 to +0.00

13-25/32 to 17-1/2 -0.045 to +0.00

17-17/32 and Larger -0.063 to +0.00

HALLIBURTON

www.halliburton.com

Sales of Halliburton products and services will

be in accord solely with the terms and conditions

contained in the contract between Halliburton and

the customer that is applicable to the sale.

H03086 05/08

2008 Halliburton

All Rights Reserved

Printed in U.S.A.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Volvo Prosis 2013 VMDocument2 pagesVolvo Prosis 2013 VMEd CalhePas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 3500B Industrial Engine Electrical System: Left Side View Rear ViewDocument2 pages3500B Industrial Engine Electrical System: Left Side View Rear ViewEd Calhe0% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalhePas encore d'évaluation

- WOMA Technical Data All Pumps en MedidasDocument11 pagesWOMA Technical Data All Pumps en MedidasEd CalhePas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Calibrating Pressure GaugesDocument4 pagesCalibrating Pressure GaugesRonny AndalasPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Whitepaper Fuel SystemsDocument8 pagesWhitepaper Fuel SystemsQaiser Iqbal100% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hammer Master JCBDocument1 pageHammer Master JCBEd CalhePas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- CompetitorsDocument4 pagesCompetitorsEd CalhePas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- WarrenCATDynoReport2 3508Document11 pagesWarrenCATDynoReport2 3508Ed CalhePas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- 3406Document2 pages3406Ed CalhePas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- CompetitorsDocument4 pagesCompetitorsEd CalhePas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Melco Type F and FC Manual Valve PartsDocument4 pagesMelco Type F and FC Manual Valve PartsEd CalhePas encore d'évaluation

- Datasheet 2494Document1 pageDatasheet 2494Ed CalhePas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Iadc Bit GradingDocument1 pageIadc Bit GradinganarkasisPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- BJ Pacemaker Spare Parts RQDocument1 pageBJ Pacemaker Spare Parts RQEd Calhe100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- System Operation Mechanical Cat 3306 SN EpsDocument37 pagesSystem Operation Mechanical Cat 3306 SN EpsEd Calhe94% (18)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- !rex Roller To Part Book TableDocument1 page!rex Roller To Part Book TableEd Calhe0% (1)

- 3 Way Direct Acting Solenoid Valve SV83Document4 pages3 Way Direct Acting Solenoid Valve SV83Ed CalhePas encore d'évaluation

- Grooy D9Awiñg'S: Cam LineDocument1 pageGrooy D9Awiñg'S: Cam LineEd CalhePas encore d'évaluation

- 261 267Document7 pages261 267Ed CalhePas encore d'évaluation

- Power Swivel Torque ReactionDocument6 pagesPower Swivel Torque ReactionEd CalhePas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Top Driven Bowen BarcoDocument65 pagesTop Driven Bowen BarcoingcalderonPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Oteco Shear Pin ChartDocument1 pageOteco Shear Pin ChartEd Calhe100% (1)

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalhePas encore d'évaluation

- KG Act 3121269Document24 pagesKG Act 3121269Gustavo KemeñyPas encore d'évaluation

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalhePas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalhePas encore d'évaluation

- Injector Cut-Out Test ProcedureDocument9 pagesInjector Cut-Out Test ProcedureEd CalhePas encore d'évaluation

- Strippers JU y JU HDocument5 pagesStrippers JU y JU HEd CalhePas encore d'évaluation

- Lugeon TestDocument59 pagesLugeon TestakhtarasrarPas encore d'évaluation

- Master Vocabulary List For 8th Grade ScienceDocument6 pagesMaster Vocabulary List For 8th Grade Scienceapi-257039711Pas encore d'évaluation

- Dam Engineering PDFDocument30 pagesDam Engineering PDFMen Keo RathaPas encore d'évaluation

- PEC2601 Report GuideDocument44 pagesPEC2601 Report GuideVeronica MulaudziPas encore d'évaluation

- Pre-Feasibity Report of Deuchuli Panighat MHPDocument11 pagesPre-Feasibity Report of Deuchuli Panighat MHPsunilPas encore d'évaluation

- EarthandLifeSci12 Q1 Mod3 Rock Metamorphism and Different Types of Stress Version2Document40 pagesEarthandLifeSci12 Q1 Mod3 Rock Metamorphism and Different Types of Stress Version2Arthur LaurelPas encore d'évaluation

- Sieve Analysis: - Wet Sieve - Dry Sieve - Hydrometer TestDocument20 pagesSieve Analysis: - Wet Sieve - Dry Sieve - Hydrometer TestfarahaidasabriPas encore d'évaluation

- M.SC Applied GeologyDocument11 pagesM.SC Applied GeologySatyam MehtaPas encore d'évaluation

- Engineering Geological Environment of AthensDocument10 pagesEngineering Geological Environment of Athensbilal afzalPas encore d'évaluation

- Proses Pelapukan Batuan Dan MineralDocument31 pagesProses Pelapukan Batuan Dan MineralOla CaesarPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Mineral Handbook by Sudarshan GurjarDocument48 pagesMineral Handbook by Sudarshan GurjarKhushwant Bhadana0% (1)

- Volcanic Succession Modern & Ancient PDFDocument531 pagesVolcanic Succession Modern & Ancient PDFRobin Ruban100% (6)

- Rehabilitation Cost Calculation ToolDocument75 pagesRehabilitation Cost Calculation ToolYudhi HuseinPas encore d'évaluation

- P-752 Unit 2 FundamentalsDocument88 pagesP-752 Unit 2 FundamentalsIfsyahestiPas encore d'évaluation

- Types of Faults 3Document3 pagesTypes of Faults 3blood lustPas encore d'évaluation

- Petroleum DictionaryDocument360 pagesPetroleum DictionaryAnonymous rey6aU3ZPas encore d'évaluation

- PETROLEUM GEOLOGY The Petroleum SystemDocument27 pagesPETROLEUM GEOLOGY The Petroleum Systemfergot2010100% (1)

- Grade 10 First Quarter SummaryDocument3 pagesGrade 10 First Quarter SummaryAdrian Tastar100% (1)

- ES Chapter 18Document69 pagesES Chapter 18Mark Sherwin MangarinPas encore d'évaluation

- Chapter 10 - NSCP 2015) Base Shear - Introduction-1Document14 pagesChapter 10 - NSCP 2015) Base Shear - Introduction-1ysaapparelphPas encore d'évaluation

- Academic Olympics CompilationDocument9 pagesAcademic Olympics CompilationlianPas encore d'évaluation

- Reference: Chapter 7: Fossen Chapter 10 Marshak & Mitra Chapter 8: Twiss & MooreDocument35 pagesReference: Chapter 7: Fossen Chapter 10 Marshak & Mitra Chapter 8: Twiss & MooreRiddhi Archon MandalPas encore d'évaluation

- EIA Guideline For Oil and GasDocument15 pagesEIA Guideline For Oil and GasMark Temitope BrownPas encore d'évaluation

- When Did Life Begin?: The Origin and Evolutionary Processes of Life On EarthDocument5 pagesWhen Did Life Begin?: The Origin and Evolutionary Processes of Life On EarthKaten KyoukotsuPas encore d'évaluation

- Forces That Shape The EarthDocument48 pagesForces That Shape The EarthdantePas encore d'évaluation

- A. Introduction Lesson1Document34 pagesA. Introduction Lesson1SeptianPas encore d'évaluation

- Subdivisions of The Field of Geotechnical EngineeringDocument2 pagesSubdivisions of The Field of Geotechnical EngineeringParikshit BhujbalPas encore d'évaluation

- Shortcrete Technology by Anuj Chaudhary & Abdul QadirDocument3 pagesShortcrete Technology by Anuj Chaudhary & Abdul QadirAnuj ChaudharyPas encore d'évaluation

- General HydrologyDocument78 pagesGeneral HydrologySunil KumarPas encore d'évaluation

- Erosion Risk Evaluation Van Zuidam 1986Document3 pagesErosion Risk Evaluation Van Zuidam 1986videsousaPas encore d'évaluation