Académique Documents

Professionnel Documents

Culture Documents

SAP - Info - Terp10 - 1

Transféré par

BlalGhali50%(2)50% ont trouvé ce document utile (2 votes)

1K vues5 pagesMPS and MRP are two planning processes used to ensure material availability. MPS focuses on critical items and plans them separately before a detailed MRP run. MRP then explodes BOMs, adjusts for inventory, and offsets requirements to generate time-phased material needs. MRP runs generate planned orders, purchase requisitions, and production orders.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMPS and MRP are two planning processes used to ensure material availability. MPS focuses on critical items and plans them separately before a detailed MRP run. MRP then explodes BOMs, adjusts for inventory, and offsets requirements to generate time-phased material needs. MRP runs generate planned orders, purchase requisitions, and production orders.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

50%(2)50% ont trouvé ce document utile (2 votes)

1K vues5 pagesSAP - Info - Terp10 - 1

Transféré par

BlalGhaliMPS and MRP are two planning processes used to ensure material availability. MPS focuses on critical items and plans them separately before a detailed MRP run. MRP then explodes BOMs, adjusts for inventory, and offsets requirements to generate time-phased material needs. MRP runs generate planned orders, purchase requisitions, and production orders.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

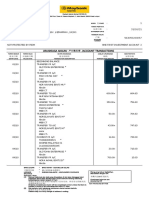

The purpose of MPS (Master Prod. Sched) and MRP (Material Req.

Planning) is to guarantee material availability on a 2 step planning process

SOP

Sales & Operation

Planning

Material

Product

Group

Cost

Center

Activity

Types

Routing

Work

Center

Demand

Management

(Admin of Ind Req.)

MPS

MRP

Material Requirements Planning

Planned Orders

Purchase

Requisition

Production Order

Items

Items

Items

Goods

Receipt

Sales Info

Syst

CO-PA

OP

OP

Items

Goods

Issue

C.O.T

Costs debited

to Prod.Order

MATERIAL PLANNING

Product

Group

Forecast

Manual

Disaggregation

and transfer to

Sales Order

(Created in SD)

Header

+Items

Mvt 101

Variances

settled

FI CO

FI CO MM

E

(inhouse production)

F

(Externally procured)

Release

Not normally part of MRP because MRP doesnt consider

capacities unless scheduling parameter is set in MRP.

Areas of

responsibilities

Assembly painting

engineering

Who does the work?

Stock Final Good

3000

Plant

Activity

3000

Raw

Consum

3000

Stock Raw

3000

Controlling

Profitable

Analisys

Use to derive a future demand program from the demand figures in the past

SOP: planning and forecasting module with the

logistic area. It provides a method for :

Sales plan: (data from the SIS, data from

CO-PA, from past sales to forecast future

sales, from another P.group, or manually)

Is a Product family.

It groups together

products with similar

plann. charact.

Product

Group 1

Prod.

Group A

Prod.

Group B

Mat.

A1

Mat.

A2

Mat.

B1

Mat.

B2

P.Groups require a

proportion factor. A higher

level is disaggregated to a

lower level

Production plan (based on sales plan) can

be created several ways:

= to sales plan, target stock level, days

supply, inventory to zero, manually)

Feasibility estimates

To create a Sales or Prod.

Plan at one level we must

disaggregate.

For ex. disaggregate the sales

plans of all the product groups

down to the materials, and

develop production plans at

that level.

The plan that is sent to

demand manag. is used to

manage the Ind. Req.

D

i

s

a

g

g

r

e

g

a

t

i

o

n

Forcasting =Warehouse Req.

=Planned Ind. Req.

=Customer

Ind. Req.

MAKE TO STOCK PROD: Plan consump. are forecast,

then procur. and prod. takes place without Sales Orders.

Requirements covered by warehouse stock (=>shorter

delivery time).

SUBASSEMBLY PLANNING: M.to.Stock Prod for

assemblies. The finished products are not produced to

stock, rather the necessary assemblies are procured.

MAKE TO ORDER PROD: products are procured and

produce once a Sales Order arrives.

PLANNING STRATEGY controlls the diff. mode of action of

Planned Ind. Req.

STRATEGY 40 Planning with

Final Asembly =>fast reaction to customer demand

Proc. and Prod. of all comp. and assemblies is triggered by

Plnnd. Ind. Req. in Demand Mgt before a Sales Order arrives.

Incoming Sales Orders consume these Plnnd. Ind. Req.

If Sales Ord. exceed Pl. Ind. Req, a new Plnnd Order for the

unplanned quantity is trigger for the next MRP run (thus Sales

Ord. affect requirements).

M1. BACKWARD CONS: the Sales Ord. consumes Pln. Ind.

Req. that lie before this sale.

M3. FORWARD CONS: the Sales Ord. consumes Pln. Ind.

Req. that lie after this sale.

M2. BACK/FORW CONS: uses both.

By default Backwards consumption. The mode and the periods

can be defined in the Material master or in each MRP group.

CONSUMPTION

Determines the direction on the time axis in which the arriving sales orders

are to consume the Plnnd. Ind. Req.

(MPS) - Master production scheduling is a

form of MRP that concentrates planning on the

parts or products that have the great influence

on company profits or which dominate the entire

production process by taking critical resources.

These items are marked as A parts (MPS

items) and are planned with extra attention.

These items are selected for a separate MPS

run that takes place before the MRP run. The

MPS run is conducted without a BOM explosion

so that the MRP controller can ensure that the

Master schedule items (MSI) are correctly

planned before the detailed MRP run takes

place.

MPS operates within only one level of the BOM,

While MRP can be utilized throughout all levels

of a materials BOM.

MRP is set of techniques that uses BOM data,

inventory data, and the MPS to calculate

requir. for materials. Time-phased MRP begins

with the items listed on the MPS and determines

1. The quantity of all components and mat.

required to fabricate those items and

2. the date that the components and material

are required.

Time-phased MRP is accomplished by

exploding the BOM, adjusting for inventory

quant, and offsetting the net requirements

MRP TYPES (how materials should be planned)

MRP

NO PLANING

CONSUMPTION BASED:

_Based on historical rates of consumption (past cons)

_Appropriate for low value mat (b,c parts)

_No ref. to master plan (not triggered by ind. req)

_Net req. cons. is triggered when:

*stock levels fall below a reorder point (safety stock) or

*by forecast req. (frompast cons. data).

_Appropriate for mat. with demand consistent

_Ind-Dep. Req and sales order dont affect them.

Purchase

Order

Schedule

Lines

Planned

Orders

Stock +fixed receipts that exists (PR, PO,Pln.O, PrO)

VS

Safety Stock +Requirements (Pln Ind. Req, Sales O)

=quantity available for planning.

BOM

Bill Of Material

Multilevel Backward Scheduling

The systemcalculates the start dates based on

a end date.

MRP RUN

Planning run can be done in 2 levels:

1. Total planning (planning of all materials of

one or several plants.(online or in the background).

2. Single-item planning:

2.1. Multilevel. Planning of all BOMs materials

2.2 Single-level. Planning of a specific material

2.2 Interactive. Interactive single-level planning

Scope of the Planning Run

Processing key field specify the type of planning:

NEUPL: Regenerative planning (plann of all MRP

relevant materials). (first time, errors)

NETCH: Net change for total horizon (plann all

mat. we made changes).

NETPL: Net change for planning horizon

Control parameters for MRP

Processing key

Create Purchase Requisit (mat. procured ext.)

Create Schedules lines (bis)

Create MRP list (always, never, only except.

Planning mode (if existing data simply be

adjusted, whether BOM and routings should be

re-exploded or whether the plann. Should be

started fromthe beginning again.

MD04: Stock/Req.list: info current status of stocks

MRP list: info latest plann run

Only in the opening period

1 1

1

2

2 2

MRP Net Requirements calculation

Is executed in the planning run to determine if there is

a shortage for a certain material.

Item Category:

Stock

Non Stock

Variable size

Documents

Text

Class

Intra material

Material type:

Raw materials

Operating supplies

Semi-finished products

Finished products

controls:

Business process .

Views (Screens)

Department-specific data

Material # assignment

Procurement types

GL- general ledger accounts

MRP Control Parameters

(required for planning run)

1. Processing key

2. Create Purchase Req.

3. Schedule lines

4. Create MRP list

5. Planning mode

contain the list the sequence of steps

for producing a material:

Operations,

Operation Sequences

Usage

Time elements

Work Centers.

Component allocations

www.sap-terp10.com.ar

SOP

Sales &

Operation

Planning

Material

Product

Group

Cost

Center

Activity

Types

Routing

Work

Center

Demand

Management

(Admin of Ind Req.)

MPS

MRP

Material

Requirements

Planning

Planned

Orders

Purchase

Requisition

Production Order

Items

Items

Items

Goods

Receipt

Sales Info

Syst

CO-PA

OP

OP

Items

Goods

Issue

C.O.T

Costs debited

to Prod.Order

MANUFACTURING EXECUTION

Product

Group

Forecast

Manual

`

Disaggregation

and transfer to

Sales Order

(Created in

SD)

Header +

Items

Mvt 101

Variances

settled

FI CO

FI CO MM

E

(inhouse

production)

F

(Externally

procured)

Release

Areas of

responsibilities

Assembly painting

engineering

Who does the

work?

Controlling

Profitable

Analisys

Forcasting =Warehouse

Req. =Planned Ind. Req.

=Customer

Ind. Req.

Purchase

Order

Schedule

Lines

Planned

Orders

BOM

MD04: Stock/Req.list: info current status of stocks

MRP list: info latest plann run

Only in the opening

period

Raw

Consumption

Raw Stock

Finished

Goods stock

Plant Activity

5000

5000 10000

10000

Cost

Elem

ent

Elements of a Prod. Order:

Order Header

Settlement rule

Costs

Operations

Operation sequences

Material components

PRTs

Trigger points

Documents links

Order Creation Options:

Without BOM Routing

With BOM Routing

With Routing

With Planned Order

Availability Check: Checks for:

(from Rout+BOM or manually)

-Material components

-Capacities

-PRTs

contain the list the sequence of steps

for producing a material, that is:

Operations,

Operation Sequences

Usage

Time elements

Work Centers.

Component allocations

If a BOM is changed after a Pln Order is created but before is converted into

a Prod. Order: BOM is not re-read and the Prod. Order uses the old BOM

Releasing orders: levels

_Individual operation

_Whole order

_Several orders together

Production Order: GI - Goods Issue Posting:

Is executed for a consumption of a material component for a prod. order.

MM - Material document: describe the g. movt. from the MM (stock) point of view.

FI - Accounting document: describes the goods movt. from the FI point of view.

CO - Cost accounting document: serve various cost analysis purposes

_ Account affected:

.Consumption is debited

.Raw material Stock is credited

. NON Finished goods stock, Plant activity

Q + $ (value) in Material master data is updated

Reservations is Reduced (for planned withdrawal)

Determination of actual costs (evaluation) and update of order

When you display the material document, you can branch to the other documents

GI doc. can be printed.

The GI posting is controlled via a movement type 261.

List the application modules that integrate with Manufacturing Execution:

Inventory Management

Quality Management

FI - Financial Accounting

CO -Controlling

SD - Sales and Distribution

Order

PS -Project Systems

HCM -Human Capital Management

Production Order: GR - Goods Receipt Posting

Realizes the stock receipt of a product produced using a production order.

MM - Material document:

FI - Accounting document:

CO - Cost accounting document: serve various cost analysis purposes

_ Account affected:

.Finished good stock is debited

.Plant activity is credited

. NON consump, raw mat.

When you display the material document, you can branch to the other doc.

GR doc. can be printed

Delivery quantity in an order is Updated

lant activity is Updated

Evaluation of the receipt

Credit to order

The GR posting is controlled via a movement type 101.

Basic data

Default values

Cost center

Capacities

Scheduling

HR assignment

Cost Object Controlling (COC):

Order settlement:

_Debits the stock account

_Credits the order

Order related

.flexible production environment

.flexible product range

.Cost mgt of ind. production lots

.if controlling is required for each order

.High setup costs

.Manufacture o co-products

Product related

Status Prod. Order:

CRTD

1 1

1

2 2

2

www.sap-terp10.com.ar

Vendor

Info

record

Material

Conditio

n

Output

Account

group

Material type

Industry sector

Condition

types

Output

types

Manually by the

Dep. Respons.

Automatically

by MRP

Is an Internal document

20

10 Stock item

Non-stock item

Item Category

Purchase

order

Source of

supply

Info record

Quotation

Contract

Source list

Goods Receipt

MM

Doc

Movement type: determines the kind of goods movements. What happens to

the items, how they are handledkey to differentiate between goods

movements (ex: GR, GI or transfer postings). (Inv. Mgt)

Determines which stock or consumption accounts are updated (posted) in

Financial Accounting.

Determines the structure of the screen when entering documents and updating

quantity fields.

1

Storage location

F - Unrestricted

Q Quality Insp.

X Blocked Stock

Goods

receipt

area

105

103

101

Invoice/

Billing

2

Pay

3

FI

Doc

Consumption Raw Stock Raw Bank GR / IR

Reconciliation

Vendor

Subledger

Vendor

P / L - Balance sheet G / L:

300 3000 3300

1

1

3300 3300 3300 3300

3300 3300

1 3 2 2 3 2 3

Cost

element

PROCUREMENT PROCESS

Purchase

Requisition

20

10

Consumable Material:

Are materials or services that are procured specifically for an account

assignment object. (EX: office supplies; computer systems)

Value is recorded in the cost element or asset accounts.

When a material is procured directly for consumption, no material master

record is necessary.

In the case of consumable material with a master record:

o Not subject to inventory management (on either quantity or value basis)

o Subject to inventory management on a quantity, but not a value basis

Account Assign. Objects

A Asset

C Cost Center

P Project

P Prod. Order

S Sales Order

with / without

reference

Item category: defines the process used to procure a material

or service.

S Standard: material procured externally

S Stock transport order: mat. is transf. from 1 plant to another

S Subcontracting: vendor manufacture a component

C Consignment: Liability only when mat. is withdrawn from

consg. stock, no when the stock is placed in the consg. store

T Third-party order: material order from a vendor with the

instruction to deliver the goods directly to a 3er party (customer)

Header Data:

Doc. #

Date

Vendor

Terms of payment

Currency

Item:

Material #

Delivery date

Q, $, Text

Posting a Goods Receipt by referencing to a Purchase Order has a 3 advantages:

The goods receiving department can check whether the goods delivered are what was actually ordered.

Data from PO is copied automatically to the GR transaction.

PO history is updated upon GR creation.

When goods receipt to the warehouse is posted:

A MM doc. is created: with info such as material delivered

and quantity delivered; storage location and associated plant.

An FI doc. is created: which record the effects the material

movement has on the value of the stock.

Goods movements: A transaction that causes a stock change. Include both external and internal

movements. You can distinguish between:

Goods receipt (GR): is a goods movement in which the receipt of goods from both an external vendor

and from production is posted. A GR leads to an increase of warehouse stock.

Goods issue (GI): is a goods movement in which a material withdrawal, goods issue, material

consumption, or goods shipment is posted to a customer. A GI leads to a decrease of warehouse stock.

Stock trasfer: is removal of materials from particular storage location and placement into another

storage location. Stock transfers can take place both within the same plant and between two plants.

Transer posting: changes the stock identification or qualification of a material regardless of its a

physical movement or not. (EX: release of the stock for quality inspection).

Stock type

you enter goods receipt against

production and purchase orders

Effects of Goods Receipt:

MM - Material document is created (quantity)

FI - Accounting document is created (value)

CO Cost Accounting document cost analysis purpose

Material master is updated (here not in the inv. verif)

_ Account affected:

.Stock raw (+ Consumption Raw) is debited

.Provision in the GR/IR is credited

. NON Bank, Reconc. Vendor, Subdledger Vendor

PO History for a PO items is updated (when a GR is

entered with reference to this item)

Quality Management (Inspection lot is created)

Warehouse Management (Transfer Requir. is created)

Output may be generated (GR slip)

Material Mgt, manages the procurement process until Invoice verif.

Other Dpt (account) manage the payment and evaluation of invoices.

Therefore, Inv. Verif. creates a link between Mat. Mgt and external (FI) or Internal account. (CO)

Invoice Verification and Vendor Payment

If there are variances between the PO or GR vs INVOICE, the system warns the user and blocks the invoice for payment.

Posting the invoice completes the process of Invoice Verification.

Types of Invoice Verification:

Invoice items can be posted with reference to:

Goods receipt based Invoice verification: invoices for quantities greater

than the goods receipt cannot be posted.

Purchase order based Invoice verification: you can settle all items,

irrespective of whether there have been partial deliveries.

The postings are automatically made to the corresponding G/L accounts.

When an Invoice is posted, an open item is credited on the vendor account.

Logistics: Invoice Verification: Effects

FI - Accounting document is created

PO History is updated

Open Itemis created in the vendors account

If invoice $ differs from the PO $, the stock value and the current moving price is

recalculated and updated in the material master, for a material valuated with mov. aver. $.

_ Account affected:

.Provision in the GR/IR clearing account are reversed - debited

.Reconc. Vendor is credited

.Subledger Vendor is credited

. NON Stock raw-consum. raw, Bank

Material Management Integration:

(FI) Financial Accounting: Purchasing and FI maintains data on the VENDOR master data (is a creditor account in FI) that contains account.+ procur. info

(SD) Sales and Distribution: requirements that arrives to Sales can be passed on to Purchasing. when a P.Req. is created, it can be directly assigned to a Sales Order.

Production Planning: and MM are linked through inventory needs. Inv. Mgt is responsible for assuring all components required for production.

Plant Maintenance and MM are linked by BOM. Its possible to post a GR with ref to an equipment BOM and to withdraw part for maintenance orders too.

Integration in Logistics: the Inv. Mgt system (manages Stock (Q) quantity + ($) value) can be extended by the WMS which manages storage (also Storage Bins)

Process of GR with Transfer Order

GR posting is subject to WMS: checks for each PO item and

generates:

MM + FI docs for goods movt.:

_MM doc.: Header + Item (q, descrip, stor.loc., plant), is

identified by material document number and year.

_FI doc.: Header + Item (G/L acc. #, $) records the effects of

material movements on the accounts. Is identified by CC (of the

plant); acc doc. #, fiscal year.

Transfer requirement doc

Incoming quantity of materials into the goods receiving area

An Interim storage area in the receiving warehouse number

A transfer order is used to move the items from the receiving

area

(in a put away process) the destination storage type, the storage

section, storage bin are determined

Org. level needed for a PO

Plant

Purch. Org.

Vendor

Storage loc not nec. until good

are not received.

Account Posting

Good Receipt : Debit Stock, Credit GR/IR

Invoice Receipt: Debit GR/IR, Credit Vendor (Recon.+Subledger) (=> acc. payable)

Pay Vendor: Debit Vendor (Recon.+Subledger), Credit Bank/Cash

FI

Doc

MM

Doc

MM

Doc

FI

Doc

CO

Doc

Documents generated

Account payable

Vendor (Recon.+Subledger) are debited,

Bank/Cash is credited

www.sap-terp10.com.ar

Inquiry Quote

Sales

Order

Delivery/

Shipping

10

Warehouse

Goods

Issue

Invoice

/ Billing

Receive

Payment

Revenue

Inventory

Change

Bank

Customer Receiv/

Reconciliation

Customer

Sub-Ledger

1

2

3

1

4000

Inventory/Stock

4000 10000 10000 10000 10000 10000 10000

1 2

2 3

3 2 3

Auto

MM

Doc

FI

Doc

CO

Doc

Documents generated

TO

Pick Quantity

Confirm

Pick

Quantity

Transfer Request

Transfer Order

MM

Doc

FI

Doc

CO-

PA

Doc

FI

Doc

Customer

Info

record

Material Condition Output

Material type

Industry sector

Condition

types

Output

types

SALES ORDER MANAGEMENT

Pre sales activities: establishing and maintaining

customer relationships

Creating and tracking customer contacts

Mailing campaigns

Answering customer ques. received by email, fax etc

Inquiries

Quotations

Sales order processing:

Contains all info.(Inquiries and quotations

docs) to process the customers request

during sales order processing. Sales process

data from master records.

1 quotation can = multiple sales orders.

Multiple quotation can = 1 sales orders.

A Sales document is created in a sales area.

It references from Inquiry + Quote

Sales documents structure: is grouped into 3 levels:

header customer related data)

items data about the material / quantities ordered, $, conditions

schedule lines delivery q. + dates. schedule line =1 item, expect for partial

deliveries => multiple schedule lines.

Backward scheduling:

The customers requested delivery date is used to calculate the pick/pack time

and the transportation lead time. The delivery must be created on the earliest

of the two dates (selection date for the outbound delivery).

Incompletion log:

Each SD document contains data required for the documents and for further

processing.

The system determines which fields are displayed in the incompletion log when

the user does not fill them during sales order processing.

The incompletion log will be displayed:

Automatically when you save your entries.

Or by choosing edit-incompletion log

In customizing you can decide which fields should be part of the incompl. log

The incompl. log functions are available in the sales order and in the delivery.

Transfer of requirements:

Communication between SD and Procurement is carried out via requirements.

The material for the order can come from in-house production or external

procurement.

If there is insufficient material available, purchase orders can be made via

material planning.

Availability check in the sales order:

Can be required via customizing

Can be required via the material master record

The system can check other plants for a material

Backward scheduling is used to determine whether a material will be available

Shipping processing in SD begins when you create the

delivery document (Header and item)(copying information

from the sales order, such as the materials and quant). The

deliv. doc. controls, supports and monitors numerous sub

processes for shipping processing such as:

(Optional) picking and confirming (transfer req. orders)

(Optional) Packing

(Optional) Planning and monitoring of transport

(shipment docs)

Posting the goods issue GI (goods issue documents).

Creating a transfer order includes copying data

from the delivery document to the transfer order

for processing within the warehouse. The

transfer order is essential for controlling the

movement of goods within the warehouse.

The transfer order is based on a simple principle:

where you are taking goods from and to, within

your warehouse. There is a source location and a

destination location for every transfer order.

Creating outbound delivery:

You can create an outbound delivery in a shipping point for

orders that are due for delivery. The relevant data is copied

from the order to the outbound delivery.

1 Sales Order can = 1 or several outbound deliveries

Several Sales Orders can = 1 outbound delivery.

The orders must all have the same characteristics that are

essential for the shipping process:

Shipping point

Due date

Ship-to address

Picking:

You create transfer order for an outbound delivery

A transfer order is generated for a warehouse number. The

system copies the relevant data from the delivery.

Picking in shipping processing:

You can control an item in an outbound delivery so that

picking is required.

Picking is carried out by creating transfer requests with

which you trigger and survey warehouse movements.

Packing:

When packing you can combine delivery items and pack

them in different shipping units.

GI - goods issue posting: effects

MM - Material doc: describe the g. movt. from

the MM (stock) point of view.

FI - Accounting doc: describes the goods movt.

from the FI point of view.

CO - Cost accounting document: serve various

cost analysis purposes

_ Account affected:

.Inventory/stock is credited

.Inventory change (cost of goods) is debited

. NON Banked, Revenue, Customer.

Q in Inventory Mgt and the Delivery req. in

material planning are updated.

Further documents for FI are created.

(document flow updated)

Billing due list is generated.

The status in all relevant sales doc is updated

Customer requirement deleted

Billing:

Billing supports:

Creating invoices for products and services

Creating credit and debit memos

Cancelling previously posted billing documents

Automatically transferring billing document data to

accounting

When you create a billing document, data is copied from the

sales order and the delivery docs to the billing document.

Functions:

It is SD document that helps you to generate invoices.

The billing document serves as a data source for FI to help

you monitor and process customer payments.

When you create a billing doc., the G/L accounts will

normally be updated automatically. During this process, the

system carries out:

o Customer Receivables account is debited (bis)

o Revenue account is credited (bis)

Creating a billing document:

You can create an invoice for a delivery or sales order.

You can group invoices using selection criteria, such as

customer, billing date and destination country.

The SAP system can combine deliveries into a billing document,

provided these deliveries share some essential characteristics:

Payer Billing date Destination country

Billing document structure: two levels:

Header (Payer, Billing date)

Item (Details about the material,Billing quant, items Net value)

Billing document posting: effects

Customer credit account is updated

Status in all related sales, delivery and billing documents, is updated

Sales statistics in the SIS are updated

_ Account affected:

Customer Receivables account is debited

Customer Subledger account is debited

Revenue account is credited

Further documents for accounting can be automatically generated by

the system, for example:

For the components controlling (CO) accounting

Profitability analysis (CO-PA) posted

Market segment analysis (CO-PA)

Consolidation (FI-LC)

Payment:

process part of the application module FI

Payment supports:

Posting payments against invoices

Reviewing differences

Incoming payment posting: effects

Cash/Bank account is debited

Customer Receivables account is

credited

Customer Subledger account is credited

Document flow in the SAP system: docs in sales process

are linked to each other using the doc. flow.

This let you access the history and current status of

your sales process at any time

1.Standard order

2.Delivery

3.WMS transfer order

4.GI- goods issue

5.Invoice

6.Accounting document

Sales and distribution integration:

Integrates with Materials Management for availability checking

Integrates with Production Planning for make to order product

Integrate with Project Systems for delivery and billing processing

Integrate with Warehouse Management module, where the product is picked and print shipping document

Integrate with Materials Management, Financial Accounting and Controlling when posting a goods issue

Integrates with Profitability Analysis for sales order

Integrates with Sales Information System

We know that payment has been

received from the customer for a

particular invoice, because the overall

processing status of the accounting

documents changes to cleared.

ORDER TO CASH PROCESS

Pre-sales activities -> Sales order processing -> Inventory sourcing -> Shipping-> Billing ->Payment receipt

and posting

Account Posting

1. Goods Issue : Credit Inventory, Debit Cost of goods sold (Inv. Change)

2. Billing a customer : Credit Revenue, Debit customer (Reconc+Subdledger)

3. incoming Payment: Credit Customer(Reconc+Subdledger), Debit bank account

Open item posted on

cust.s account

www.sap-terp10.com.ar

PROCUREMENT

MATERIAL

PLANNING

MANUFACTURI

NG EXECUTION

SALES ORDER FI CO

INVENTORY AND

WAREHOUSE MGT

Client Client Client Client CC Controlling Area Client Client

CC CC CC CC

Plant Operating Concern

CC CC

Plant Plant Plant

Sales Area (Sales

Org - Dist. Ch-

Profit Centers

CC Transport. Pln. Point

Plant

Subdiv. Of CC

Storage Location

Storage

Location Storage Location

Plant

Credit Control

Area

Business Area

Plant Maintenance Plant Default values

Purch. Org. Storage Location

Plant

Shipping Point Location Selection for reporting

Purch. Group Shipping Point

Purch. Org.

Storage Location

Maintenance Work

Center Authoriz. Checks

Sales Org.

Warehouse Number

Maintenance

Planning Plant

Wage structures, Work

schedules

Maintenance

Planner Groups Country groupings

Legal person

Time management

Payscales

Public holiday calendar

Active employees

Retirees

Contractors

Deffault values

Reporting

Authorization

Trainee

Hourly

Salaried

Payroll Area

Organizational Unit

Position (specific)

Job (general)

Person (ass.to position)

Material Material Material Customer GL Account

Vendor BOM BOM Infor Record Vendor

Info Record Routing Work Center Material Customber

Conditions

Task Lists

(routings,etc) Output Credit Mgt

PRTs Condition

MASTER

DATA

Personnel Area

Personnel Subarea

ORG. LEVELS

General

Location-

Based

Planning-

Based

Organizationa

l

ENTERPRISE ASSEST

MGT/CUST. SERVICE

Employee Group

Employee Subgroup

Enterprise

Personnel

HR MANAGEMENT

CC

Client

Vous aimerez peut-être aussi

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesD'EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesPas encore d'évaluation

- Warehouse Management Systems A Complete Guide - 2019 EditionD'EverandWarehouse Management Systems A Complete Guide - 2019 EditionPas encore d'évaluation

- MRP Process FlowDocument10 pagesMRP Process FlowjdrockoPas encore d'évaluation

- Executing MRP: MRP Can Be Run atDocument2 pagesExecuting MRP: MRP Can Be Run atEndah PutrihadiaPas encore d'évaluation

- SAP PO ConfirmationsDocument18 pagesSAP PO Confirmationsarrowxen8396100% (1)

- 1 Material Planning Process WWW - Sap Terp10.Com .Ar 1Document1 page1 Material Planning Process WWW - Sap Terp10.Com .Ar 1prashantitankarPas encore d'évaluation

- P25 Img Consumption Based PlanningDocument23 pagesP25 Img Consumption Based PlanninglymacsauokPas encore d'évaluation

- Decoding MRP and MRP ViewsDocument15 pagesDecoding MRP and MRP ViewsBalanathan Virupasan100% (1)

- SAP MRP What Is SAP MRP - Material Requirement PlanningDocument2 pagesSAP MRP What Is SAP MRP - Material Requirement Planningswayam100% (1)

- MRP Run Net Requirement Lotsize CalculationDocument7 pagesMRP Run Net Requirement Lotsize CalculationSilva SilvaPas encore d'évaluation

- SAP MRP ConfigurationDocument32 pagesSAP MRP ConfigurationJames BondPas encore d'évaluation

- What Is A Planned IndependentDocument8 pagesWhat Is A Planned IndependentRizwan SiddiquiPas encore d'évaluation

- MASS BOM Maintenance Using CEWBDocument10 pagesMASS BOM Maintenance Using CEWBbestbay100% (1)

- WM Interface To Inventory ManagementDocument5 pagesWM Interface To Inventory ManagementPhilip BurrowPas encore d'évaluation

- 3 - 9 - Material Master Data - Sap WM ViewsDocument4 pages3 - 9 - Material Master Data - Sap WM Viewsrajesh98765100% (1)

- Cycle Counting Configuration, Process Flow and Implementation by Rajen Patel in SAP ERP Logistics Materials Management (SAP MM)Document6 pagesCycle Counting Configuration, Process Flow and Implementation by Rajen Patel in SAP ERP Logistics Materials Management (SAP MM)gong688665Pas encore d'évaluation

- 35 Lot Size CalculationDocument9 pages35 Lot Size CalculationlymacsauokPas encore d'évaluation

- 1g2 S4hana2020 BPD en UsDocument75 pages1g2 S4hana2020 BPD en UsMAYANK JAINPas encore d'évaluation

- I. Creation of Unit of MeasureDocument7 pagesI. Creation of Unit of MeasureRahul JainPas encore d'évaluation

- Batch Determination in SapDocument13 pagesBatch Determination in SapVivek KalchuriPas encore d'évaluation

- Sap MM Master DataDocument19 pagesSap MM Master DataImran PatelPas encore d'évaluation

- User StatusDocument12 pagesUser StatusMarco Antônio Claret TeixeiraPas encore d'évaluation

- Sap Master Data in Materials ManagementDocument13 pagesSap Master Data in Materials Managementedmondo77Pas encore d'évaluation

- Sap WMDocument15 pagesSap WMAnbu SaravananPas encore d'évaluation

- Sap MM Inbound Delivery Process PDFDocument7 pagesSap MM Inbound Delivery Process PDFమనోహర్ రెడ్డిPas encore d'évaluation

- SAP Warehouse Management Process CycleDocument39 pagesSAP Warehouse Management Process CycleSAPAPOOnlinetrainingPas encore d'évaluation

- KANBAN Process Steps - Inhouse ProductionDocument20 pagesKANBAN Process Steps - Inhouse ProductionSagar GoliwarPas encore d'évaluation

- Expertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsDocument6 pagesExpertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsArun PadhiPas encore d'évaluation

- Erp Sop SapDocument69 pagesErp Sop Sapmuhammad romliPas encore d'évaluation

- Hazardous Material Treatment in SAP WMDocument15 pagesHazardous Material Treatment in SAP WMsumitjain_25100% (1)

- SAP WMS ConfigDocument11 pagesSAP WMS ConfigVishal SathePas encore d'évaluation

- SAP WM - Uploading Opening Balances To Storage BinDocument3 pagesSAP WM - Uploading Opening Balances To Storage BinIlmoyetePas encore d'évaluation

- SAP WM SyllabusDocument7 pagesSAP WM Syllabuskurrysuchit50% (2)

- Key Questions Topic For Sap Terp10 CourseDocument4 pagesKey Questions Topic For Sap Terp10 CoursepbtgPas encore d'évaluation

- Carrying Out The Planning Run Using MRP LiveDocument3 pagesCarrying Out The Planning Run Using MRP LiveAmar ReddyPas encore d'évaluation

- How To Configure of Quality Management in Embedded EWMDocument37 pagesHow To Configure of Quality Management in Embedded EWMGhassan SharafPas encore d'évaluation

- Group of StrategyDocument12 pagesGroup of StrategyMangeshPas encore d'évaluation

- Batch Specific Units of MeasureDocument10 pagesBatch Specific Units of MeasureRavi SubramanianPas encore d'évaluation

- HFC Sap s4 Hana Gs1 Product HierarchyDocument14 pagesHFC Sap s4 Hana Gs1 Product HierarchyChokchai AunhavichaiPas encore d'évaluation

- Configuration For Automatic Packing in Outbound DeliveryDocument10 pagesConfiguration For Automatic Packing in Outbound DeliveryShwetha SPas encore d'évaluation

- Steps For The Batch Determination in The Production OrderDocument23 pagesSteps For The Batch Determination in The Production Orderajithkbalan100% (1)

- Configuring The Purchase Order Release StrategyDocument2 pagesConfiguring The Purchase Order Release StrategySoumen DuttaPas encore d'évaluation

- Handling Unit ManagementDocument4 pagesHandling Unit ManagementchiranjeeviPas encore d'évaluation

- SAP-WM Training: Introduction To Warehouse ManagementDocument4 pagesSAP-WM Training: Introduction To Warehouse Managementrajkumaraei40% (5)

- WM TcodesDocument15 pagesWM TcodesbtbsapmmPas encore d'évaluation

- MRP 1 ViewDocument13 pagesMRP 1 ViewaheraskPas encore d'évaluation

- Release StrategyDocument18 pagesRelease StrategyEl Hag Shalata100% (1)

- SAP WM StrategiesDocument3 pagesSAP WM StrategiesSarosh100% (3)

- Vendor Return Process in SAP EWMDocument15 pagesVendor Return Process in SAP EWMjanipashaPas encore d'évaluation

- What Is Batch Management in Sap MMDocument1 pageWhat Is Batch Management in Sap MMRahul pawadePas encore d'évaluation

- Sap Mmphysical InventoryDocument9 pagesSap Mmphysical Inventorykumarranjit228Pas encore d'évaluation

- STO Stock Transport Order: BY Manikumar PLVDocument5 pagesSTO Stock Transport Order: BY Manikumar PLVpmanikumar0% (1)

- Sap MM Configuration Transaction CodesDocument17 pagesSap MM Configuration Transaction CodesGadigota Suresh ReddyPas encore d'évaluation

- Lo531 PDFDocument173 pagesLo531 PDFannasunilkumar3437Pas encore d'évaluation

- Consignment Stock in TransiteDocument6 pagesConsignment Stock in TransiteManish GangwalPas encore d'évaluation

- Warehouse Management Systems A Complete Guide - 2021 EditionD'EverandWarehouse Management Systems A Complete Guide - 2021 EditionPas encore d'évaluation

- SAP MRP (Material Requirement Planning)Document8 pagesSAP MRP (Material Requirement Planning)niranjan100% (2)

- Sap PP SCM 240Document19 pagesSap PP SCM 240Camran KhanPas encore d'évaluation

- MRP RunDocument12 pagesMRP RunNethajiSathpathe NethuPas encore d'évaluation

- SAP BW Transactions PDFDocument6 pagesSAP BW Transactions PDFBlalGhaliPas encore d'évaluation

- SAP - Info - Terp10 - 10Document5 pagesSAP - Info - Terp10 - 10BlalGhali50% (2)

- SAP - Info - Terp10 - 8Document5 pagesSAP - Info - Terp10 - 8BlalGhaliPas encore d'évaluation

- SAP - Info - Terp10 - 9Document5 pagesSAP - Info - Terp10 - 9BlalGhaliPas encore d'évaluation

- SAP - Info - Terp10 - 6Document5 pagesSAP - Info - Terp10 - 6BlalGhaliPas encore d'évaluation

- SAP - Info - Terp10 - 7Document5 pagesSAP - Info - Terp10 - 7BlalGhali100% (1)

- SAP - Info - Terp10 - 5Document5 pagesSAP - Info - Terp10 - 5BlalGhali100% (1)

- SAP - Info - Terp10 - 3Document5 pagesSAP - Info - Terp10 - 3BlalGhali100% (1)

- SAP - Info - Terp10 - 4Document5 pagesSAP - Info - Terp10 - 4BlalGhaliPas encore d'évaluation

- SAP BW Transactions PDFDocument6 pagesSAP BW Transactions PDFBlalGhaliPas encore d'évaluation

- SAP - Info - Terp10 - 2Document5 pagesSAP - Info - Terp10 - 2BlalGhaliPas encore d'évaluation

- August Pay SlipDocument5 pagesAugust Pay SlipperesandraphcPas encore d'évaluation

- Full Download Contemporary Project Management 2nd Edition Kloppenborg Test BankDocument35 pagesFull Download Contemporary Project Management 2nd Edition Kloppenborg Test Bankalojlyhol3100% (29)

- S 1Document100 pagesS 1Sachin BansalPas encore d'évaluation

- Midas Safety PPT Procurement and Inventory ManagementDocument20 pagesMidas Safety PPT Procurement and Inventory ManagementChaudhary Hassan Arain0% (1)

- 0124 - Review of Accounting ProcessDocument42 pages0124 - Review of Accounting ProcessKhayceePadilla76% (17)

- Financial Accounting Questions and Solutions Chapter 3Document7 pagesFinancial Accounting Questions and Solutions Chapter 3bazil360Pas encore d'évaluation

- ACC 121 Chapter 1 Exercise SolutionsDocument12 pagesACC 121 Chapter 1 Exercise SolutionsDarrianAustinPas encore d'évaluation

- Basic Accounting ExamDocument8 pagesBasic Accounting ExamJollibee JollibeeePas encore d'évaluation

- Praktikum Akuntansi-BiayaDocument27 pagesPraktikum Akuntansi-BiayaK-AnggunYulianaPas encore d'évaluation

- Relational ALgebra (Summer+Spring-2021)Document19 pagesRelational ALgebra (Summer+Spring-2021)Imrul HasanPas encore d'évaluation

- Final Asian Paints SCMDocument25 pagesFinal Asian Paints SCMsanju0789Pas encore d'évaluation

- 3-The Accounting Information SystemDocument98 pages3-The Accounting Information Systemtibip12345100% (1)

- Master Production Scheduling: The Master Production Schedule The Rough-Cut Capacity PlanDocument19 pagesMaster Production Scheduling: The Master Production Schedule The Rough-Cut Capacity Plannino1901Pas encore d'évaluation

- 2018 List of Lending Companies With CADocument70 pages2018 List of Lending Companies With CARadee King CorpuzPas encore d'évaluation

- Linc Digital Systems PVT Ltd. (MEP) MERGEDocument2 pagesLinc Digital Systems PVT Ltd. (MEP) MERGEkunjal mistryPas encore d'évaluation

- Posting Journal Entries To The LedgerDocument14 pagesPosting Journal Entries To The LedgerJeanlyn Vallejos DomingoPas encore d'évaluation

- 1Document23 pages1Dalip YadavPas encore d'évaluation

- Supply Chain Management of Big BazaarDocument49 pagesSupply Chain Management of Big Bazaarnilma pais67% (3)

- Modul OSPM-6 (SCM)Document20 pagesModul OSPM-6 (SCM)Fajar Aditya Putra0% (1)

- Accounting Handbook For Regional Controllers PDFDocument66 pagesAccounting Handbook For Regional Controllers PDFAntara DeyPas encore d'évaluation

- Supply Chain and Logistics KPI Dashboard - Someka V2Document10 pagesSupply Chain and Logistics KPI Dashboard - Someka V2Ismael Guamani Mena100% (1)

- VP Director Supply Chain Logistics in United States Resume David StonichDocument2 pagesVP Director Supply Chain Logistics in United States Resume David StonichDavid StonichPas encore d'évaluation

- Level Out The WorkloadDocument5 pagesLevel Out The WorkloadJuan PabloPas encore d'évaluation

- DFA5058 Tutorial Chapter 3 SolutionDocument9 pagesDFA5058 Tutorial Chapter 3 SolutionArabella Summer100% (1)

- London Police StateDocument2 pagesLondon Police StateChamille ZuePas encore d'évaluation

- Laikipia UniversityDocument2 pagesLaikipia UniversityWilson KindaPas encore d'évaluation

- Som Projects PVT LTD (DDA-NP) : Particulars Credit Debit Opening Balance 3,30,604.00Document2 pagesSom Projects PVT LTD (DDA-NP) : Particulars Credit Debit Opening Balance 3,30,604.00umesh KumarPas encore d'évaluation

- 5.0 Variable and Absorption Costing 2018Document7 pages5.0 Variable and Absorption Costing 2018Margo SongPas encore d'évaluation

- Conversion of A Sole Proprietorship Into A PartnershipDocument5 pagesConversion of A Sole Proprietorship Into A PartnershipABCPas encore d'évaluation

- Ibs Kerteh 1 31/10/21Document6 pagesIbs Kerteh 1 31/10/21ain faqierahPas encore d'évaluation