Académique Documents

Professionnel Documents

Culture Documents

Astm A319.370238-1

Transféré par

Fabio Augusto Hincapie Henao100%(1)100% ont trouvé ce document utile (1 vote)

1K vues2 pagesThis specification covers three classes of gray iron suitable for castings exposed to temperatures as high as 1400degF (760degC) Some are suitable for long service at the lower temperatures only unless low stresses are involved. Some of the gray cast irons described in this specification are ductile iron.

Description originale:

Titre original

ASTM A319.370238-1

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis specification covers three classes of gray iron suitable for castings exposed to temperatures as high as 1400degF (760degC) Some are suitable for long service at the lower temperatures only unless low stresses are involved. Some of the gray cast irons described in this specification are ductile iron.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

1K vues2 pagesAstm A319.370238-1

Transféré par

Fabio Augusto Hincapie HenaoThis specification covers three classes of gray iron suitable for castings exposed to temperatures as high as 1400degF (760degC) Some are suitable for long service at the lower temperatures only unless low stresses are involved. Some of the gray cast irons described in this specification are ductile iron.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Designation: A319 71 (Reapproved 2011)

Standard Specication for

Gray Iron Castings for Elevated Temperatures for Non-

Pressure Containing Parts

1

This standard is issued under the xed designation A319; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specication covers three classes of gray iron

suitable for castings exposed to temperatures encountered in

such service as grate bars, stoker links, stoker parts, oil still

furnace parts, rebox parts, ingot molds, glass molds, caustic

pots, and metal melting pots.

NOTE 1This specication is general, covering cast irons normally

used for the above types of service, at temperatures as high as 1400F

(760C). It is not intended to imply that all three classes are suitable

throughout this entire temperature range without regard to actual service

stresses. Some are suitable for long service at the lower temperatures only,

unless low stresses are involved.

1.2 The three classes of gray iron covered by this speci-

cation are as follows:

1.2.1 Class I, possessing superior resistance to thermal

shock,

1.2.2 Class II, possessing average resistance to thermal

shock and a moderately good tensile strength (tensile strengths

above 30 000 psi (207 MPa) may be expected), and

1.2.3 Class III, possessing a higher tensile strength than

either Classes I or II (tensile strengths as high as 40 000 psi

(276 MPa) may be expected).

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

2

A48/A48M Specication for Gray Iron Castings

3. Manufacture

3.1 The melting procedure shall be optional with the

foundry.

4. Physical Requirements

4.1 Some of the gray cast irons described in this specica-

tion are deliberately made of a soft, low-strength iron for

resistance to thermal shock, and strength requirements are

unnecessary. For applications in which a strength requirement

is essential, room temperature tensile strengths may be speci-

ed up to those prescribed for Class 40 in Specication

A48/A48M.

5. Machinability

5.1 All machinable castings shall be limited in hardness at

such locations on the castings as designated by the purchaser.

The maximum hardness at the locations on castings that are to

be machined shall be a matter of agreement between the

manufacturer and the purchaser.

6. Chemical Composition

6.1 It is the intention of this specication to classify these

irons in accordance with their carbon content equivalent

calculated as follows:

Carbon content equivalent 5 C10.3 ~Si1P! (1)

where:

C = carbon content, %,

Si = silicon content, %, and

P = phosphorus content, %,

6.2 The carbon content equivalent and the minimum carbon

content for the various classes shall be as prescribed in Table 1.

Table 2 prescribes the allowable silicon ranges predicated on

the basis of various permissible carbon contents. It is recom-

mended that embrittling impurities be held to the following

maximum limits:

Phosphorus, max, %

Sulfur, max, %

0.60

0.15

6.3 The three basic classes may be alloyed with chromium.

When chromium is present as an alloying element, each class

shall be subdivided into types designated as follows:

Type Chromium, %

A 0.200.40

B 0.410.65

C 0.660.95

D 0.961.20

1

This specication is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.01 on Grey and White

Iron Castings.

Current edition approved March 1, 2011. Published September 2011. Originally

approved in 1948. Last previous edition approved in 2006 as A31971 (2006). DOI:

10.1520/A0319-71R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

Copyright by ASTM Int'l (all rights reserved); Wed Jun 11 10:00:22 EDT 2014

Downloaded/printed by

Universidad Del Valle pursuant to License Agreement. No further reproductions authorized.

6.4 All irons may be alloyed to increase the strength and to

improve and stabilize the structure for elevated-temperature

service. The alloying elements, which, in addition to chro-

mium, are commonly added to improve these properties, are

copper, molybdenum, nickel, and vanadium. Any combination

of these alloying elements that assists in resisting oxidation or

surface deterioration or in stabilizing the structure or retaining

strength at elevated temperatures, may be used.

NOTE 2The provisions of this specication permit the purchaser to

select a grade of cast iron suitable for his service and to dene the product

as, for example:

Castings Class II, Type B, plus |Cz|Cz alloys. All surfaces marked f

(for nish) with HBN 250, max.

7. Product Analysis

7.1 When alloying elements are agreed upon between the

manufacturer and the purchaser, the purchaser may make check

analyses from any casting, test bar, or lot of castings delivered

under this specication. Results of such analyses shall be in

accordance with the limits agreed upon.

8. Workmanship, Finish, and Appearance

8.1 The castings shall conform substantially to the dimen-

sions on drawings furnished by the purchaser or to the

dimensions predicated by the pattern supplied by the purchaser,

if no drawing has been provided. The castings shall be free

from injurious defects. Surfaces of the castings shall be free

from burnt-on sand and shall be reasonably smooth. Runners,

risers, ns, and other cast-on pieces shall be removed. In other

respects the castings shall conform to whatever points may be

specially agreed upon between the manufacturer and the

purchaser.

9. Inspection

9.1 The inspector representing the purchaser shall have free

entry, at all times while work on the contract of the purchaser

is being performed, to all parts of the manufacturers works

that concern the manufacture of the material ordered. The

manufacturer shall afford the inspector, without charge, all

reasonable facilities to satisfy him that the material is being

furnished in accordance with this specication. All tests and

inspection shall be made at the place of manufacture prior to

shipment, unless otherwise specied, and shall be so conducted

as not to interfere unnecessarily with the operation of the

works.

10. Rejection

10.1 Failure to meet the requirements of Section 7 or of

physical tests, when required, shall be sufficient cause for

rejection as defective castings.

11. Certication

11.1 Upon request of the purchaser, the manufacturer shall

furnish a statement that the inspection and all of the tests have

been made as specied; this statement shall contain the results

of all specied tests.

12. Keywords

12.1 chemical composition; elevated temperature; gray

iron; iron castings; non-pressure containing; tensile strength

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

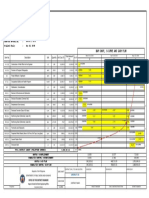

TABLE 1 Chemical Requirements

Class Carbon Content Equivalent Carbon, min, %

I 3.814.40 3.50

II 3.514.10 3.20

III 3.203.80 2.80

TABLE 2 Variations in Carbon and Silicon Contents

Class Carbon, % Silicon, %

I 3.50 0.902.70

3.70 0.902.10

3.90 0.901.50

II 3.20 0.902.70

3.40 0.902.10

3.50 1.80 max

III 2.80 1.202.70

3.00 0.602.40

3.20 0.601.80

A319 71 (2011)

2

Copyright by ASTM Int'l (all rights reserved); Wed Jun 11 10:00:22 EDT 2014

Downloaded/printed by

Universidad Del Valle pursuant to License Agreement. No further reproductions authorized.

Vous aimerez peut-être aussi

- A319Document2 pagesA319malika_000% (1)

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarPas encore d'évaluation

- IBR 73-80 Steel CastingsDocument5 pagesIBR 73-80 Steel CastingsRajivharolikarPas encore d'évaluation

- A367-11 Standard Test Methods of Chill Testing of Cast Iron PDFDocument4 pagesA367-11 Standard Test Methods of Chill Testing of Cast Iron PDFCarlos Guillermo Somoza Alvarenga100% (1)

- Feeding Risering For Steel Casting Design PDFDocument10 pagesFeeding Risering For Steel Casting Design PDFHusen TaufiqPas encore d'évaluation

- B917B917M - CAST - Heat Treatment of Aluminum-Alloy Castings From All ProcessesDocument14 pagesB917B917M - CAST - Heat Treatment of Aluminum-Alloy Castings From All ProcessesYirlany Mesén MejíasPas encore d'évaluation

- Grey Cast IronDocument43 pagesGrey Cast IronVasanth PrasadPas encore d'évaluation

- Non Metallic Inclusions in SteelsDocument17 pagesNon Metallic Inclusions in SteelsUlises Quintana Carhuancho0% (1)

- Astm e 112 Ebook - enDocument46 pagesAstm e 112 Ebook - enyostar 232Pas encore d'évaluation

- The Current State of Worldwide Standards of Ductile IronDocument8 pagesThe Current State of Worldwide Standards of Ductile IronN.PalaniappanPas encore d'évaluation

- Sand Molding Processes: Thanuj Kumar MDocument47 pagesSand Molding Processes: Thanuj Kumar MVDPas encore d'évaluation

- AISI 4340 NitridingDocument8 pagesAISI 4340 NitridingVlad Craciun100% (1)

- Astm 487Document6 pagesAstm 487JOSEPH REFUERZOPas encore d'évaluation

- A 958 - A 958M - 17Document5 pagesA 958 - A 958M - 17Eddie Michael67% (3)

- Aisi 4140 Alloy Steel (Uns g41400)Document3 pagesAisi 4140 Alloy Steel (Uns g41400)diogolabegPas encore d'évaluation

- Ams 2451 Rev. DDocument9 pagesAms 2451 Rev. DJorge Luis Gonzalez Gonzalez100% (1)

- Nomenclature and Applications of MetalsDocument38 pagesNomenclature and Applications of MetalsJaveed AkhtarPas encore d'évaluation

- Isothermal Heat Treatment PDFDocument6 pagesIsothermal Heat Treatment PDFsmani170Pas encore d'évaluation

- ASTM A536 Ductile Iron Castings Tensile RequirementsDocument1 pageASTM A536 Ductile Iron Castings Tensile RequirementsKhin Aung Shwe67% (3)

- Cast IronsDocument8 pagesCast IronsAlberto LunaPas encore d'évaluation

- Powder Components Heat Treatment PDFDocument47 pagesPowder Components Heat Treatment PDFsmani170Pas encore d'évaluation

- Norma Astm A255Document21 pagesNorma Astm A255Carlos Fernando Luna Carlosama100% (1)

- Cast Iron MicrostructuresDocument41 pagesCast Iron MicrostructuresNeo TarunPas encore d'évaluation

- Plasma Nitriding of Steels PDFDocument192 pagesPlasma Nitriding of Steels PDFRenè KubíkPas encore d'évaluation

- Steel CleanlinessDocument22 pagesSteel CleanlinessfondershellPas encore d'évaluation

- KB Alloys Foundrymans Guide To SR and TiBorDocument7 pagesKB Alloys Foundrymans Guide To SR and TiBorfoundryjoePas encore d'évaluation

- 1570 (Part II Sec I) Revised - Wrought Steeks For PlatesDocument20 pages1570 (Part II Sec I) Revised - Wrought Steeks For PlatesKaushik Sengupta67% (3)

- Cerium in Ductile IronDocument2 pagesCerium in Ductile Ironvivek1312100% (2)

- Filter NotesDocument46 pagesFilter Notestanzil10100% (1)

- Soft Annealing Heat Treatment PDFDocument6 pagesSoft Annealing Heat Treatment PDFsivajirao70Pas encore d'évaluation

- Hardenability of SteelDocument59 pagesHardenability of SteelKhaula M RausyanPas encore d'évaluation

- Alloy Process Data Sheet - 105-85Document3 pagesAlloy Process Data Sheet - 105-85Ugur KayaPas encore d'évaluation

- Nucor Steel ASTM A709 Plate Rolling ProcessDocument54 pagesNucor Steel ASTM A709 Plate Rolling ProcessDave MulvihillPas encore d'évaluation

- Aerospace Material SpecificationDocument6 pagesAerospace Material Specificationvsraju2Pas encore d'évaluation

- Astm A356 PDFDocument6 pagesAstm A356 PDFAndresInforBJPas encore d'évaluation

- Ductile Iron Casting Specfications and Details All StandardsDocument15 pagesDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- ASTM E 140 FOR Standard Hardness Conversioin Table PDFDocument21 pagesASTM E 140 FOR Standard Hardness Conversioin Table PDFFabian Armando Barragan RamirezPas encore d'évaluation

- Colour Metallography of Cast IronDocument9 pagesColour Metallography of Cast IronJoaquim Pedroso SilvaPas encore d'évaluation

- Heat Treatment Grossmann Hardenability PDFDocument11 pagesHeat Treatment Grossmann Hardenability PDFsivajirao70100% (2)

- Aluminium Casting Alloys EnglishVersionDocument102 pagesAluminium Casting Alloys EnglishVersionmythos1976Pas encore d'évaluation

- Astm A802Document3 pagesAstm A802Srinivasan KrishnamoorthyPas encore d'évaluation

- Manufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesDocument5 pagesManufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesMiguel Rodriguez100% (1)

- Determine The Moisture and Volatile Content in The Green SandDocument3 pagesDetermine The Moisture and Volatile Content in The Green SandUsman Raza100% (2)

- Effects of MN Content and Heat TreatmentDocument5 pagesEffects of MN Content and Heat TreatmentTrần Xuân VịnhPas encore d'évaluation

- Astm A792 PDFDocument6 pagesAstm A792 PDFOswaldo Enrique Adame67% (3)

- Cast Iron StandardsDocument2 pagesCast Iron StandardsBao Duy NguyenPas encore d'évaluation

- Astm A1008.a1008m Rev A 2012 PDFDocument9 pagesAstm A1008.a1008m Rev A 2012 PDFjoao carlos protzPas encore d'évaluation

- Microstructure-Property Relationships in High Chromium White Iron Alloys PDFDocument24 pagesMicrostructure-Property Relationships in High Chromium White Iron Alloys PDFLuis AcevedoPas encore d'évaluation

- ASTM B208 - Norma de Ensaio de Tensão Bronze PDFDocument11 pagesASTM B208 - Norma de Ensaio de Tensão Bronze PDFFred Duarte CaldeiraPas encore d'évaluation

- Astm A 148Document4 pagesAstm A 148orqh007Pas encore d'évaluation

- A 607 PDFDocument4 pagesA 607 PDFGustavo Suarez100% (1)

- A737Document2 pagesA737doshi78Pas encore d'évaluation

- High-Strength Low-Alloy Structural Steel Plate With Atmospheric Corrosion ResistanceDocument2 pagesHigh-Strength Low-Alloy Structural Steel Plate With Atmospheric Corrosion ResistanceGustavo SuarezPas encore d'évaluation

- A204Document3 pagesA204doshi78Pas encore d'évaluation

- Pressure Vessel Plates, High-Strength, Low-Alloy Steel: Standard Specification ForDocument2 pagesPressure Vessel Plates, High-Strength, Low-Alloy Steel: Standard Specification ForGustavo SuarezPas encore d'évaluation

- Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsDocument2 pagesPressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsGustavo SuarezPas encore d'évaluation

- Alloy/Steel Bolting Materials For Low-Temperature ServiceDocument7 pagesAlloy/Steel Bolting Materials For Low-Temperature ServiceJosé Ramón GutierrezPas encore d'évaluation

- A 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFDocument8 pagesA 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFMung Duong XuanPas encore d'évaluation

- A575Document2 pagesA575Demetrio Rodriguez100% (1)

- Control de Nivel Mcdonnell Miller 259Document12 pagesControl de Nivel Mcdonnell Miller 259Appleuk SudarPas encore d'évaluation

- Metallurgical Microscope: Key FeaturesDocument1 pageMetallurgical Microscope: Key FeaturesFabio Augusto Hincapie HenaoPas encore d'évaluation

- FjugandofisicaDocument5 pagesFjugandofisicaFernanda VillalpandoPas encore d'évaluation

- Condensate Return Systems 10.11.12 PDFDocument53 pagesCondensate Return Systems 10.11.12 PDFarunyoga100% (2)

- Control de Nivel Mcdonnell Miller 259Document12 pagesControl de Nivel Mcdonnell Miller 259Appleuk SudarPas encore d'évaluation

- Pfi Es-24Document10 pagesPfi Es-24kingstonPas encore d'évaluation

- Torispherical Head TolvaDocument1 pageTorispherical Head TolvaFabio Augusto Hincapie HenaoPas encore d'évaluation

- Tolva Sand Blasting Shell1Document1 pageTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoPas encore d'évaluation

- Tolva Sand Blasting Shell1Document1 pageTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoPas encore d'évaluation

- Toriconical Head 87 PsiDocument2 pagesToriconical Head 87 PsiFabio Augusto Hincapie HenaoPas encore d'évaluation

- Tolva Sand Blasting Shell1Document1 pageTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoPas encore d'évaluation

- Miller TIG HandbookDocument20 pagesMiller TIG Handbookquiron2010Pas encore d'évaluation

- Tolva Sand Blasting Shell1Document1 pageTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoPas encore d'évaluation

- Toriconical Head 87 PsiDocument2 pagesToriconical Head 87 PsiFabio Augusto Hincapie HenaoPas encore d'évaluation

- ASME B16 20 Metallic Gaskets For Pipe Flanges PDFDocument2 pagesASME B16 20 Metallic Gaskets For Pipe Flanges PDFFabio Augusto Hincapie HenaoPas encore d'évaluation

- Tolva Sand Blasting Shell1Document1 pageTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoPas encore d'évaluation

- SSE QC CIV 402 Rev0 PDFDocument2 pagesSSE QC CIV 402 Rev0 PDFBhalsingh JangraPas encore d'évaluation

- Ce6506 Ctep NotesDocument183 pagesCe6506 Ctep NotesPriya ThangamuthuPas encore d'évaluation

- Daikin FCQG - F - Thin Body Round Flow Cassette 950 X 950Document32 pagesDaikin FCQG - F - Thin Body Round Flow Cassette 950 X 950PrestoneKPas encore d'évaluation

- Material Design of Aerated Concrete-An Optimum Performance DesignDocument6 pagesMaterial Design of Aerated Concrete-An Optimum Performance DesignYuliusRiefAlkhalyPas encore d'évaluation

- Ubstructure Esign: Bridge Design Manual - 2002 Substructure DesignDocument14 pagesUbstructure Esign: Bridge Design Manual - 2002 Substructure DesignHundeejireenyaPas encore d'évaluation

- Slickline Basics.11 20Document10 pagesSlickline Basics.11 20Rio de MarioPas encore d'évaluation

- 5.deflections Using Energy Methods PDFDocument47 pages5.deflections Using Energy Methods PDFking burgosPas encore d'évaluation

- N4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyDocument2 pagesN4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyRafael CastroPas encore d'évaluation

- Technical Data Sheet: Cable ConstructionDocument1 pageTechnical Data Sheet: Cable ConstructionYehude Guillen RomeroPas encore d'évaluation

- Fracture Mechanics of Delamination Buckling in Laminated CompositesDocument20 pagesFracture Mechanics of Delamination Buckling in Laminated CompositesShree BiradarPas encore d'évaluation

- Building PlanDocument1 pageBuilding Planshaik moizPas encore d'évaluation

- 1 Ndimuto Augustin Ingenieur en ConstructionDocument3 pages1 Ndimuto Augustin Ingenieur en ConstructionJosh UaPas encore d'évaluation

- 16 ConstructionDocument28 pages16 Constructionalcibiades romeroPas encore d'évaluation

- Cross Reference AWG To MM2 - Multi - Cable CorporationDocument1 pageCross Reference AWG To MM2 - Multi - Cable CorporationPankaj RawatPas encore d'évaluation

- CladdingDocument78 pagesCladdingRahul RaghavPas encore d'évaluation

- Ultrasonic Welding of ThermoplasticsDocument17 pagesUltrasonic Welding of ThermoplasticsSyed Farhan RazaPas encore d'évaluation

- Beam Column Joint IIT RoorkeeDocument109 pagesBeam Column Joint IIT RoorkeeMayank RajputPas encore d'évaluation

- Steel-Concrete Composite Slab Design Using ExcelDocument9 pagesSteel-Concrete Composite Slab Design Using ExcelTasnuva NazmulPas encore d'évaluation

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDocument55 pagesProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuidemithileshPas encore d'évaluation

- Monitoring Pekerjaan Dan MaterialDocument3 pagesMonitoring Pekerjaan Dan MaterialHarits Angga KusumaPas encore d'évaluation

- New Tools For Non-Linear Analysis of Masonry Buildings: August 2010Document9 pagesNew Tools For Non-Linear Analysis of Masonry Buildings: August 2010sher khanPas encore d'évaluation

- Bar Chart and S-Curve 17rg0113 - SampleDocument1 pageBar Chart and S-Curve 17rg0113 - SampleRyan Macayan100% (1)

- Catalouge For Lenton CouplersDocument18 pagesCatalouge For Lenton Couplerss.skumar1Pas encore d'évaluation

- Hardie Plank Installation GuideDocument1 pageHardie Plank Installation GuideBrandon VieceliPas encore d'évaluation

- Mold Advance Course BookDocument121 pagesMold Advance Course Bookshahzad afzal100% (6)

- Meyco Segment HR PDFDocument16 pagesMeyco Segment HR PDFFabioSoaresPas encore d'évaluation

- Modelling of Negative Skin Friction On Bored Piles in ClayDocument64 pagesModelling of Negative Skin Friction On Bored Piles in ClayLordM00nPas encore d'évaluation

- 1.toraflex Rubber Joints IomDocument8 pages1.toraflex Rubber Joints IomjacksonliPas encore d'évaluation

- DOWSIL™ 2-9034 Emulsion: Features & BenefitsDocument5 pagesDOWSIL™ 2-9034 Emulsion: Features & BenefitsLaban KantorPas encore d'évaluation

- Direct Tensile Test of ConcreteDocument7 pagesDirect Tensile Test of ConcreteBunkun15100% (1)