Académique Documents

Professionnel Documents

Culture Documents

unionGalvasteelPUpanelInstallationManual 20140704

Transféré par

Joseph Cloyd L. LamberteTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

unionGalvasteelPUpanelInstallationManual 20140704

Transféré par

Joseph Cloyd L. LamberteDroits d'auteur :

Formats disponibles

If'lyL.

JLt

Cold Room/ Storage Facility:

A room in which temperature is controlled to preserve goods

(e.g. Meat, fruits, vegetables...) in its original/fresh state.

Checklist in Designing.

1. Ask for Plan / lay-out.

2. Know the usage.

3. Ask for the designed room temperature of the Facility.

Cold Room! Storage Facility:

TYPICAL COLD ROOMCOMPONENTS

List of Materials:

1. PU Panels for Ceiling.

- -

-

Wailing & Slab

-

-

- 2. U-Track(0.6OmmPPGi)

3. ExterlorAngie

Wall.

- (0.60itmPP0i)

ij

J,

J

4. Interior Angle

1

PUSwng0wr

1%0.60mmPPGU

S. PU Door (Swing/Sliding)

6. Suspension

7. Concrete Skirt

8. PressureReiief Port (PRP)

A. MATERIAL STORAGE

Closed Storage Areas

rPU support

H e i d h t ( h )

E

!d i

Remarks.

1. Storage Height (H) should have a maximum dimension of 2.00m.

2. PU support(d) should have a maximum dear spacing equal to 1.00

meter.

3. Should be kept awayfrom dust, lime and direct sunlight.

4. Water should not be allowed to condense or enter between the

panels, since it can cause corrosion.

B. Walling

Materials needed

Utrack

2 -------- Interior Angie

S .---=-----' Exterior Angle

4------ 5f32%R,

Rivets sp @0.20m o.c.

5-------- 46 x 1 Screw

wf tox sp. i3) (}.30m G.C.

Note

BeTided Accessary thickness

should not be less than

0.50mm

PU Panel Height Capability

25-30 .1.50

50 300

75 400

100 500

125 500

150 220 6, 06.

What if PU wall panel exceeds to its height capabiiity

P0V1DEGR11NG...........

I/1JL.5JJT

A. Material Storage

* Open Areas

/Plastlo Cover

PU Palle t

- i

IA ,--- -- ,,,g

I

U ,-- - - -

Remad

I. Panels should have inclination so that rainwater could not

accumulate between the panels.

2. Stacked storage for long period of time must be avoided, (at least 2

weeks)

I /T5.1T

C Ceiling

\ ---

Z

/

--FP

c6Kng

-- ' j 1

sssd 5e st w----2 p

wal wafl

LJLL

Materials needed:

Note:

Exterior Angle Banded Accessory thickness

2 ---------- Interior Angle should not be less than

3 ------------- 5132 x % LI. 060mm

Rivets sp @0.20m o.c.

4 ------------- PU chemical (A &8)

PU Panel Length(L)Capability

15-30 120

50 350

15 4.00

100-125 500

156-220 600

What if PU Ceiling Panel exceeds to its length capability?

PROVIDE "Suspension"

D. Suspension

used as horizontal support for ceiling panels which exceeds from

its unsupported length capability.

Types:

1. A luminum Suspension

used for cut joints of two ceiling panels.

2. Mushroom Head Suspension

used for continues ceiling panels exceeding its

length capability.

Aluminum Suspension

Materials needed:

1------------- Alum. Flat Bar

2 ---'---'------- Alum, Cover

{0.40mm PPGI)

3 -------------- 6mm dia Stainless

stud bolt sp. @ 1.20m o.c

4--'------------ 2"x 3/16Angle

Cleats

S ---------------- PU Chemical

6 ------ Rubberized Ring

7 ---------------- Mg Turnbuckle

S -------- 8mm dia. Plain

Round Bar

9----- 2Sched 406.1.

Pipe

10 ----- 12mm dia Plain

Round Bar

11 ----------- M12 Turnbuckle

LUJ.T

Mushroom Head Suspension

Materialeneeded;

I --------- 3/8 dia Mushroom

Boltsp. 4) 1.20m oc.

2----- 2" x 3/16 Angle Cleats

3 PU Chemical

4 ---------- Rubberized Ring

S 8mm dia. Plain Round

Bar

6 Mg turnbuckle

7------2Y2Sched4OG.LPipe

8"--..-- M12 Turnbuckle

:1

E. flooring

Materials needed;

1 -----U-track

Z.""--46x1YScreww/toxsp.

V

4) 0.30m ox.

/

3 5/32x % B. Rivets sp. 4)

/

0.20m ox.

4 -------------- Moisture Barrier

S Insulation Tape

-,

4

Base Concrete

FA I

IJT/I...5JJ7T

F. PU Doors

Type s:

1. SlidlngDoor

* iJzfly used in processing areas which is using

forklifts, pallet trucks and the likes.

2. Swlnq000r

ideally used in walk-in freezers.

Post Installation A ctivities:

1 . Application of Sealant

1.

I ;

Sealant is applied in the th

1. Between the tongue and grove

2. Between the gaps of PU panels

3. in the edge of the installed mouldings.

LI

3. Installation of Pressure Relief Port (PRP)

is installed to relieve a

pressure within an enclosure.

U

d

*

iflerence

Eliminates the damage to

the vacuum compartment

as a result of pressure

between the

j

interior and exterior spaces

of the refrigerated facility

:.

t N

2. Removal of Laminated Film I Plastic

Recommended sealant '5ikafiex 221'S

-Approximate coverage per sausage . 40 meters.

Paintable

4 Resistant to aging and weathering exposure

Laminated film put on the panels

should be removed immediately

after mounting and it should not be

later than 2 weeks.

Long term removal of plastic

from the panel may damage the

paint coating.

M.

1/9/ LSJJ.'+

PU Roofing Tips

B. Joint Connection of Roof Panel

-provide double purlins at panel joint

provide 300mm minimum overlap of roof's top sheet

---Pand

/

Jo e l

1

_ s e

Pufinscut

--- _\

Trusses

PU Roofing Tips

A . Recommended maximumroofing length = 8 meters

PU Roofing with enormous length is prone to damage.

the under sheeting breaks easily especially if the back

skin is standard profile PPGI

C. Valley (utter Design

L

v ai i e y

gut t e r

D. I). Tackacrew Length

25. mm Pu#75 Trckscrew

SO mm PU # 100 Teckacrew

Legend:

t pu

Sb Std Height

A

t

Durable =2"

Rib Type =134"

Valley Gutter Design

tpUthickness of pu

7

Vous aimerez peut-être aussi

- Additional Handouts ScaffoldingDocument58 pagesAdditional Handouts ScaffoldingJoseph Cloyd L. Lamberte67% (3)

- Front ElevationDocument1 pageFront ElevationJoseph Cloyd L. LambertePas encore d'évaluation

- 05 - C-Purlin DesignDocument1 page05 - C-Purlin DesignJoseph Cloyd L. LambertePas encore d'évaluation

- Table of ContentsDocument2 pagesTable of ContentsJoseph Cloyd L. LambertePas encore d'évaluation

- Slab Design Parameters and Steel RequirementsDocument1 pageSlab Design Parameters and Steel RequirementsJoseph Cloyd L. LambertePas encore d'évaluation

- Katalog Techniczny ENG PDFDocument136 pagesKatalog Techniczny ENG PDFJoseph Cloyd L. LambertePas encore d'évaluation

- Terms of Reference For Civil EngineerDocument4 pagesTerms of Reference For Civil EngineerJoseph Cloyd L. LambertePas encore d'évaluation

- Sika RaintiteDocument5 pagesSika RaintiteJoseph Cloyd L. LambertePas encore d'évaluation

- 11 - Chapter 3 PDFDocument28 pages11 - Chapter 3 PDFRainielPas encore d'évaluation

- Standards and Tolerances GuideDocument74 pagesStandards and Tolerances GuideJoseph Cloyd L. LambertePas encore d'évaluation

- Footing Design Result-RcdcDocument360 pagesFooting Design Result-RcdcJoseph Cloyd L. LambertePas encore d'évaluation

- 04 - Arki02Document1 page04 - Arki02Joseph Cloyd L. LambertePas encore d'évaluation

- Roots of Polynomials NotesDocument11 pagesRoots of Polynomials NotesJoseph Cloyd L. LambertePas encore d'évaluation

- Staadfooting Design ResultDocument157 pagesStaadfooting Design ResultJoseph Cloyd L. LambertePas encore d'évaluation

- Handbook of Construction Estimate by Velasco PDFDocument74 pagesHandbook of Construction Estimate by Velasco PDFJoseph Cloyd L. Lamberte75% (4)

- Rear ElevationDocument1 pageRear ElevationJoseph Cloyd L. LambertePas encore d'évaluation

- Structural Analysis and Design CriteriaDocument4 pagesStructural Analysis and Design CriteriaJoseph Cloyd L. Lamberte78% (9)

- Typicaltruss Design ResultDocument6 pagesTypicaltruss Design ResultJoseph Cloyd L. LambertePas encore d'évaluation

- C-Purlin DesignDocument1 pageC-Purlin DesignJoseph Cloyd L. LambertePas encore d'évaluation

- Construction NotesDocument4 pagesConstruction NotesJoseph Cloyd L. LambertePas encore d'évaluation

- Electrical Model2Document1 pageElectrical Model2Joseph Cloyd L. LambertePas encore d'évaluation

- Stair DesignDocument1 pageStair DesignJoseph Cloyd L. LambertePas encore d'évaluation

- Plate Load Test Determines 154kPa Soil Bearing CapacityDocument5 pagesPlate Load Test Determines 154kPa Soil Bearing CapacityJoseph Cloyd L. LambertePas encore d'évaluation

- Test Report Revised - IR - 5-25-08Document37 pagesTest Report Revised - IR - 5-25-08Joseph Cloyd L. LambertePas encore d'évaluation

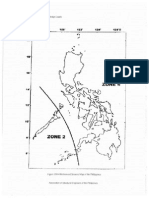

- 05 - Seismic Map of The Philippines PDFDocument1 page05 - Seismic Map of The Philippines PDFJoseph Cloyd L. LambertePas encore d'évaluation

- NCAE Type Exam - 2010-2011Document3 pagesNCAE Type Exam - 2010-2011Joseph Cloyd L. Lamberte69% (16)

- House Bill N0.2200 PDFDocument5 pagesHouse Bill N0.2200 PDFJoseph Cloyd L. LambertePas encore d'évaluation

- Reinforced Concrete Structure Design PDFDocument153 pagesReinforced Concrete Structure Design PDFJoseph Cloyd L. Lamberte100% (1)

- Moodle Seminar WorkshopDocument2 pagesMoodle Seminar WorkshopJoseph Cloyd L. LambertePas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 시멘트와 콘크리트 관련 ISO 표준Document5 pages시멘트와 콘크리트 관련 ISO 표준Jhonernest Berrios GallegoPas encore d'évaluation

- Tolo HouseDocument8 pagesTolo HouseIvan ElenaPas encore d'évaluation

- PASSIVE DESIGN-swathi Assignment 1Document16 pagesPASSIVE DESIGN-swathi Assignment 1swathikaPas encore d'évaluation

- Annex List For EurocodesDocument2 pagesAnnex List For EurocodesKha PhucPas encore d'évaluation

- Scaffolding: Scaffolding Is A Temporary Framework Used ToDocument38 pagesScaffolding: Scaffolding Is A Temporary Framework Used ToNagakrishna SamanasaPas encore d'évaluation

- Slab Material Specifications for Second to Fifth FloorsDocument4 pagesSlab Material Specifications for Second to Fifth Floorshhhh0% (1)

- DiaMassive 25 PIS EN SCREENDocument1 pageDiaMassive 25 PIS EN SCREENАлександар ГајићPas encore d'évaluation

- Building Construction Report Two Stories Building Design: Program InternasionalDocument34 pagesBuilding Construction Report Two Stories Building Design: Program InternasionalDian Ratri CPas encore d'évaluation

- Stud anchor technical specificationsDocument2 pagesStud anchor technical specificationsLe HanPas encore d'évaluation

- Kelken US Metric Chart ASTM A615 Grade 60 RebarDocument1 pageKelken US Metric Chart ASTM A615 Grade 60 RebarAvsin CevaPas encore d'évaluation

- QATAR CHARITY Shorkot Construction of WASH Category 1 Project: Abstract of Quantity and CostDocument2 pagesQATAR CHARITY Shorkot Construction of WASH Category 1 Project: Abstract of Quantity and Costmuhammad iqbal0% (1)

- Glass Unloading Tools Supply-Forklift SkewerDocument2 pagesGlass Unloading Tools Supply-Forklift SkewerHan JoePas encore d'évaluation

- CertainTeedGypsum 2315 Shaftliner 01 2007Document16 pagesCertainTeedGypsum 2315 Shaftliner 01 2007anhnguyenhaiPas encore d'évaluation

- Roof and Wall Flashing Architectural Detailing Design Guide PDFDocument24 pagesRoof and Wall Flashing Architectural Detailing Design Guide PDFTamo Talasasa100% (1)

- Fencing Project Lot 326-B-1 Materials ListDocument2 pagesFencing Project Lot 326-B-1 Materials ListRalf Francis SaraPas encore d'évaluation

- Roofing with Burlington slates design guideDocument20 pagesRoofing with Burlington slates design guideAFW111Pas encore d'évaluation

- SCC Mall Fit-Out GuidelineDocument68 pagesSCC Mall Fit-Out GuidelineGR Chandra SekharPas encore d'évaluation

- Monthly Progress Report - PK08: Time SpanDocument2 pagesMonthly Progress Report - PK08: Time SpanDalia FathyPas encore d'évaluation

- Module 2 Septic Tank and Rectangular Manhole ProblemsDocument9 pagesModule 2 Septic Tank and Rectangular Manhole ProblemsSyedPas encore d'évaluation

- Balance FCUs For CommissioningDocument6 pagesBalance FCUs For CommissioningAbdullahTitiPas encore d'évaluation

- Pre Construction Meeting InfoDocument23 pagesPre Construction Meeting InfoFeri_Ganteng_8294Pas encore d'évaluation

- Analysis and Design of Cantilever SlabDocument9 pagesAnalysis and Design of Cantilever SlabOscarKonzultPas encore d'évaluation

- Building Management Systems (BMS) for HVAC and Energy ControlDocument5 pagesBuilding Management Systems (BMS) for HVAC and Energy ControltemamPas encore d'évaluation

- ZenMar Solutions for Maritime Piping SystemsDocument17 pagesZenMar Solutions for Maritime Piping SystemsirfanPas encore d'évaluation

- Mist Cooling System: Plastic Misting NozzleDocument1 pageMist Cooling System: Plastic Misting NozzleMiftah FardPas encore d'évaluation

- Deep BeamDocument59 pagesDeep BeamNumair Ahmad FarjanPas encore d'évaluation

- Sika Fibre Selection ChartDocument2 pagesSika Fibre Selection ChartjeffPas encore d'évaluation

- Thermal and Economic Study on Improving Building Wall InsulationDocument10 pagesThermal and Economic Study on Improving Building Wall InsulationkrieymPas encore d'évaluation

- Architectural Design Sections and ElevationsDocument4 pagesArchitectural Design Sections and ElevationsRitikaPas encore d'évaluation

- Precast Stairs AucklandDocument43 pagesPrecast Stairs AucklandDave Robert HasibuanPas encore d'évaluation