Académique Documents

Professionnel Documents

Culture Documents

Atex Approved Oxygen Analyzer

Transféré par

Githu OommenCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Atex Approved Oxygen Analyzer

Transféré par

Githu OommenDroits d'auteur :

Formats disponibles

ATEX explosion

approved

InSitu Oxygen

Analysers

Fred Gumprecht

M.D. ENOTEC GmbH

For the safe use of analyser systems in areas with

explosion hazards, it is important to not only rely

on the ATEX certificate.

It is also important to realise where potential

ignition sources are formed and that the equipment

be ATEX tested under conditions similar to the

expected process conditions.

In the following presentation we will focus on InSitu

type analysers with heated sensors which are a

potential ignition risk.

ATEX explosion approved InSitu

analyser at work.

The film has shown that the measurement

of true flue gas values contribute to a safe

combustion process.

We will now focus on essential gas hazard area

related safety requirements for an InSitu

analyser itsself.

ATEX approved probes for dust hazard areas

are not dealt with here as they do require a

different test and certification process.

Fast flue gas response

Ignition protection for all gas conditions at the

probe

Essential safety related

requirements:

Safety relevant components are easily inspected for

functionality

Foreseeable process conditions must be considered for

ATEX certification

Fast flue gas response

Fast flue gas response

An OXITEC probe needs about 30 seconds in normal flue gas velocity.

The green line shows the required flue gas response for safe

combustion control

An example of a different probe construction principle

which causes a slow flue gas response

Test gas flow to a small sensor volume suggests fast

response

Flue gas slowly displaces the test gas volume

through two barriers, the probe filter and the flame

arrestor

Fast flue gas response

The sensor response to the flue gas composition is important for safe combustion control.

The blue line shows a fast test gas response but an extremely slow

flue gas response.

Fast flue gas response

Ignition protection for all

gas conditions at the

probe

Important! All types of oxide ceramic sensors are electrically heated

to 700C - 800C and present a potential ignition so urce!

CO

e

Sensor O

2

Sensor

T3 = Temperature class

surface temperature

below 200C

IIC = Explosion group (safe gap)

hydrogen / acetylene

Equipment category

1 = qualified for zone 0, 1 and 2

2 = qualified for zone 1 and 2

3 = qualified for zone 2

Kind of atmosphere

G = gas

D = dust

II d IIC T3

Device group

I = mining

II = others

2 G EEx

Corresponds to the European Ex-Standards

(EN-50...)

d = Flameproof enclosure

explosion only inside the enclosure

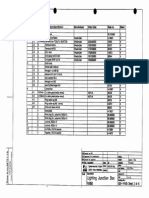

COMTEC

KEX6001

Ignition protection for all gas

conditions at the probe

ENOTEC probe - ATEX approved for all gas conditions

Hot corrosive flue duct Ambient air

Duct wall

Regular inspection of

safety relevant

components

Hot Corrosive Flue Gas Ambient Air

Duct Wall

Pressure tested 37 Bar

Hottest Surface area 200C (T3)

Visible filter & flame arrestor

Corrosion resistant material

Redundant probe thermocouple for failsafe probe

heater controller

Regular inspection of safety

relevant components

Easy disassembling for inspection purposes

Certified construction

Certified material

Certified production

Filter & flame

arrestor

Test gas port

Terminal box

ATEX approved ENOTEC construction principle

Mounting

flange

Zirconia cell Heater

Surface temperature 450C (T1)

Certified for two temperatures

T1 and T6?

Only 1 probe thermocouple

No failsafe probe heater controller

Non visible flame arrestors

Less corrosion resistant materials

Disassembling problematic

Toxic materials used

Reference air probe volume included for

flame proof tests?

Certified production and testing?

Typical construction principle found on the world market

Regular inspection of safety

relevant components

Hot Corrosive Flue Gas

Ambient Air

Foreseeable process

conditions must be

considered for ATEX

certification

The legal regulations demand that the testability and maintenance ability must be

considered during the certifying process (94/9/EG, Appendix II, 1.0.3).

All heated InSitu probes with non visible ignition protection relevant components do not allow the user

a regular check.

If hot corrosive flue gas is not considered by a test house as the normal operational ambient condition

when testing these products, these products are suitable for ambient air measurement only.

All heated InSitu probes with certificates, which do not specify foreseeable flue gas conditions have a

certificate for ambient air conditions only. This certificate is invalid if this product is used in hot

corrosive flue gas.

The legal regulations demand that the foreseeable process conditions have

to be considered during the certifying process (94/9/EG, Appendix II, 1.0.4).

Foreseeable process conditions must

be considered for ATEX certification

The legal regulations demand that the entire equipment (e.g. an O

2

measuring probe) is to be examined

and certified as one unit.

In each case an ATEX certificate must refer to the complete probe assembly.

All probes, which are certified for two different temperature classifications (e.g. T1/T6) and for two

different gas groups (e.g. EExd IIB/IIC), do not comply with the EU-Directives.

All manufacturers who assemble probes using some ATEX approved components, such as flame

arrestors or terminal boxes, do not comply with the EU-Directives.

These probes are not qualified for hazardous areas installations, even if some Ex-markings

remain on any components.

All certified probes where a temperature class is mentioned, do require a certified failsafe

temperature limitation.

Foreseeable process conditions must

be considered for ATEX certification

Responsibilities

The plant owner has the responsibility for safe operation of his plant.

It is his responsibility to judge the explosion risks and to divide areas into zones

accordingly.

He must ensure that all installed equipment is suitable for safe plant operation

under all foreseeable process conditions.

He must ensure that all installed equipment is certified according to the

regulations for all foreseeable process conditions before initial use.

The equipment must be kept in a safe status by means of regular inspection and

maintenance.

Responsibilities

Responsibilities

The plant owner has the responsibility for all arising damages.

The manufacturer of explosion protected equipment has the

responsibility for mandatory tests as close as possible to

foreseeable process conditions.

Certification and documentation of the construction, the material

and test procedures are required to ensure that each manufactured

device complies with the certified design.

Responsibilities

Do not put your trust only in certificates!

We thank you for paying attention

Look at all specifics of a product before using it!

Install proven product quality for your plant safety.

For more information, please contact us at the Multi Instruments booth

Appendix

Basic information for your safe

operation in Hazardous areas

Areas with risk of explosion are divided into zones, depending on frequency and

duration of the occurrence of combustible atmosphere (Directive 1999/92/EG).

Gases, Vapours, Mists Dusts (coal, flour, metal,

finely ground powder)

Zone 0 Zone 20

Zone 1 Zone 21

Zone 2 Zone 22

Equipment with relevant Ex-protection can be safely operated in each zone

according to its certification.

Category 1 G Category 1 D

Category 2 G Category 2 D

Category 3 G Category 3 D

Area, in which explosive atmosphere...

is continuously, long-term or frequently existent (Guiding value, not

standardised: more than 1000 h per year)

in normal operations occasionally occurs (Guiding value, not standardised:

10 1000 h per year)

in normal operations normally not or with only short-term occurrences

(Guiding value, not standardised: less than 10 h per year)

Devices of this category are to be designed and manufactured in such a way that...

ignition sources, even in case of equipment faults which seldom arise, are to be avoided. Also if two

faults arise within the equipment, it may not come to an ignition.

In the event of frequently arising or expected disturbances (defects of the equipment) retain the

necessary level of safety to ensure that no ignition source is created.

ignition sources which can be expected and which can occur with normal usage, are avoided.

S

o

u

r

c

e

:

E

U

-

D

i

r

e

c

t

i

v

e

9

4

/

9

/

E

G

a

n

d

1

9

9

9

/

9

2

/

E

G

Zone 0

Zone 1

Zone 2

Definition of Hazardous

Areas into Zones

An explosion is the sudden chemical reaction (oxidation) of a

flammable material with oxygen under release of high energy.

Flammable Material

O

x

y

g

e

n

I

g

n

i

t

i

o

n

S

o

u

r

c

e

Ignition

Triangle

Explosion Limit

An explosion can only occur, if the flammable material is present within a certain

concentration range. If the concentration is too small (too lean) or to high (too rich) no

explosion takes place, but a slow oxidation without a visible flame may happen.

Substance

Designation

Lower Explosion Limit in

Mixture with Air [Vol.%]

Upper Explosion Limit in

Mixture with Air [Vol.%]

Acetylene 1,5 82

Gasoline 0,6 8

Natural Gas 4,5 13,5

Carbon monoxide 12,5 75

Three factors must be met to induce an explosion :

The explosion limits depend on the

ambient pressure and the oxygen

content.

S

o

u

r

c

e

:

w

w

w

.

f

e

u

e

r

w

e

h

r

-

s

c

h

u

l

e

n

b

u

r

g

.

d

e

Definition of an Explosion

Device

Group

I Electrical apparatus for

mining

II Electrical apparatus for all

remaining potentially

explosive atmospheres

Equipment

Category

1 = qualified for zone 0, 1 and 2

2 = qualified for zone 1 and 2

3 = qualified for zone 2

G = gas

D = dust

Kind of

Atmosphere

Conformance

Marking

EEx The equipment corresponds to valid EN

standards and is certified from a recognized

European laboratory.

Method of

Protection

d flameproof enclosure

e increased safety

i intrinsic safety

m encapsulation

n type of protection

o oil immersion

p pressurized apparatus

q powder filling

Explosion

Group

I firedamp endangered mine workings

(methane)

IIA experimental safe gap > 0,9 mm

typical gas: propane, gasoline

IIB experimental safe gap 0,5 mm to 0,9 mm

typical gas: town gas, ethylene

IIC experimental safe gap < 0,5 mm

typical gas: acetylene, hydrogen

Max. surface

temperature of

equipment:

T1 450C

T2 300C

T3 200C

T4 135C

T5 100C

T6 85C

I

II

1

2

3

G

D

EEx

d

e

i

m

n

o

p

q

I

IIA

IIB

IIC

T1

T2

T3

T4

T5

T6

Type-exami-

nation tested

(Probe)

(Electronic Unit)

ATEX, the European Ex-Marking

Surface

Temperature

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Absorption of Gamma RaysDocument9 pagesAbsorption of Gamma RaysRachit KanchanPas encore d'évaluation

- Parker Fulflo Poly Mate Filter CartridgeDocument4 pagesParker Fulflo Poly Mate Filter CartridgeGithu OommenPas encore d'évaluation

- Rose Junction Box 4 Way PDFDocument4 pagesRose Junction Box 4 Way PDFGithu OommenPas encore d'évaluation

- rsg2100 Datasheet PDFDocument11 pagesrsg2100 Datasheet PDFEnzo Quintanilla YatacoPas encore d'évaluation

- Electrical Distribution Field Services Schneider Electric BrandsDocument25 pagesElectrical Distribution Field Services Schneider Electric BrandsGithu OommenPas encore d'évaluation

- Quanta Complete Offer ABA-QME-101-14 REV PDFDocument10 pagesQuanta Complete Offer ABA-QME-101-14 REV PDFGithu OommenPas encore d'évaluation

- Diester Based OilDocument4 pagesDiester Based OilGithu OommenPas encore d'évaluation

- TMI HEATER ChromaloxDocument2 pagesTMI HEATER ChromaloxGithu OommenPas encore d'évaluation

- Rupture DiscDocument1 pageRupture DiscGithu OommenPas encore d'évaluation

- 20100427761Tri-RatedPanelWire Draka CablesDocument4 pages20100427761Tri-RatedPanelWire Draka CablesGithu OommenPas encore d'évaluation

- STAHL Poster Safety RealityDocument1 pageSTAHL Poster Safety Realityedwardesjr100% (1)

- Air Cooled Heat ExchangerDocument26 pagesAir Cooled Heat ExchangerMagesh Kumar90% (10)

- 20100427761Tri-RatedPanelWire Draka CablesDocument4 pages20100427761Tri-RatedPanelWire Draka CablesGithu OommenPas encore d'évaluation

- Load Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbDocument8 pagesLoad Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbGithu OommenPas encore d'évaluation

- Regulations For The Installation of Electrical Wiring EleDocument121 pagesRegulations For The Installation of Electrical Wiring EleKrishna Sankar100% (1)

- Barnes en Bloor - NieuwDocument14 pagesBarnes en Bloor - NieuwpietpaaltjenPas encore d'évaluation

- More Than One Answer Is CorrectDocument182 pagesMore Than One Answer Is CorrectNikhil GandhiPas encore d'évaluation

- Wear and Corrosion Properties of AISI 420 Martensitic Stainless Steel Treated by Active Screen Plasma Nitriding PDFDocument9 pagesWear and Corrosion Properties of AISI 420 Martensitic Stainless Steel Treated by Active Screen Plasma Nitriding PDFsaltbathPas encore d'évaluation

- From External Alarm 17pli061 Asam - Asam - JorongDocument4 pagesFrom External Alarm 17pli061 Asam - Asam - JorongAMSARAH BR MUNTHEPas encore d'évaluation

- Linear ProgrammingDocument29 pagesLinear ProgrammingBrejohn McCrary100% (1)

- ST-2500FH: Part No. Description Part No. Description Part No. DescriptionDocument1 pageST-2500FH: Part No. Description Part No. Description Part No. DescriptionGergely IvánovicsPas encore d'évaluation

- 6 DZM 24Document1 page6 DZM 24Wai Phyoe AungPas encore d'évaluation

- Prelims Solution Ce18Document6 pagesPrelims Solution Ce18Mark Lester LualhatiPas encore d'évaluation

- Mounting Systems For Solar TechnologyDocument24 pagesMounting Systems For Solar TechnologyArianit ZeqiriPas encore d'évaluation

- Chem 152 Lab ReportDocument21 pagesChem 152 Lab Reportapi-643022375Pas encore d'évaluation

- Rohaizat JMCWM10.1007 - s10163 017 0672 7Document10 pagesRohaizat JMCWM10.1007 - s10163 017 0672 7Hadi Iz'aanPas encore d'évaluation

- Cummins 161110083846 PDFDocument18 pagesCummins 161110083846 PDFMuhammad IshfaqPas encore d'évaluation

- DD210-V 9604sb PDFDocument4 pagesDD210-V 9604sb PDFBrandon MoralesPas encore d'évaluation

- Multilevel Converters - Dual Two-Level Inverter SchemeDocument226 pagesMultilevel Converters - Dual Two-Level Inverter Schemejuancho2222Pas encore d'évaluation

- Steam / Power SystemDocument63 pagesSteam / Power SystemNabil SalimPas encore d'évaluation

- Drawing Free-Body DiagramsDocument5 pagesDrawing Free-Body DiagramsMahamadali DesaiPas encore d'évaluation

- Grade 7 MathDocument3 pagesGrade 7 MathMarie Antonette SandiegoPas encore d'évaluation

- Running Concurrent WorkflowsDocument10 pagesRunning Concurrent WorkflowsyprajuPas encore d'évaluation

- Dlesp Packer, Viton: A) DescriptionDocument10 pagesDlesp Packer, Viton: A) Descriptionaditya rastogiPas encore d'évaluation

- Lab Report Welding (SMAW) - FizaDocument13 pagesLab Report Welding (SMAW) - FizaCheng Yee71% (7)

- Engineering Materials CE-105: ConcreteDocument27 pagesEngineering Materials CE-105: Concretenasir khanPas encore d'évaluation

- Interpretations of The IMO Gas Code: International Association of Classification SocietiesDocument53 pagesInterpretations of The IMO Gas Code: International Association of Classification SocietiesAlkaPas encore d'évaluation

- Summative Test Gr7Document1 pageSummative Test Gr7Les Angelz100% (1)

- Metron PS-410 Patient SimulatorDocument2 pagesMetron PS-410 Patient SimulatorismailshajjiPas encore d'évaluation

- Handout 3 TMR4305 Lecture 13 09 2007Document5 pagesHandout 3 TMR4305 Lecture 13 09 2007sujaydsouza1987Pas encore d'évaluation

- Fan Laws: Table 1 Fan Laws Parameters Variable ‘n' Speed Variable ‘ρ' Density Variable ‘d' Impeller Diameter p Q PpowDocument3 pagesFan Laws: Table 1 Fan Laws Parameters Variable ‘n' Speed Variable ‘ρ' Density Variable ‘d' Impeller Diameter p Q Ppowgeetikag_23Pas encore d'évaluation

- Choking vs. Clutch Performance: A Study of Sport Performance Under PressureDocument19 pagesChoking vs. Clutch Performance: A Study of Sport Performance Under Pressuremensrea0Pas encore d'évaluation

- M and V-Issues-and-Examples 2019 - 02 - 04 - FINAL PDFDocument67 pagesM and V-Issues-and-Examples 2019 - 02 - 04 - FINAL PDFNeeraj Singhvi100% (2)

- Sequential Logic: Unit-IDocument86 pagesSequential Logic: Unit-IMonika RawatPas encore d'évaluation