Académique Documents

Professionnel Documents

Culture Documents

Static Loading of Welds: Workbook

Transféré par

musaismail8863Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Static Loading of Welds: Workbook

Transféré par

musaismail8863Droits d'auteur :

Formats disponibles

WELDING

WORKBOOK

Welds are sized for their ability to withstand static or cyclic

loading in accordance with AWS D1.1, Structural Welding Code

Steel, to ensure that a soundly welded joint is able to support

the applied load for the expected service life. Design strengths

of welds for various types of static loading are normally specified

in the applicable standard for the job. These are usually based

on a percentage of the tensile or yield strength of the filler or

base metal. The allowable stress range for cyclic loading is also

normally specified in the applicable standard for the job.

Static Loading

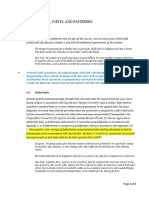

The various types of static loading are shown in Fig. 1. Com-

plete joint penetration (CJP) groove welds, illustrated in Fig.

1AD, are considered full-strength welds because they are capa-

ble of transferring the full strength of the connected elements.

Providing matching strength weld metal is used, the design

strength of such welds are the same as those in the base metal.

In CJP groove welds, the mechanical properties of the filler metal

selected must at least match those of the base metal. If two base

metals of different strengths are welded together, the selected

filler metal strength must match or exceed the strength of the

weaker base metal.

Partial joint penetration groove welds, which are shown in

Fig. 1B, C, E, and F, are widely used for the economical welding

of thick sections. These welds not only lead to savings in weld

metal and welding time, but they can also provide the required

joint strength. To avoid cracking in the weld or the heat-affected

zone, the minimum weld size should provide adequate process

heat input to counteract the quenching effect of the base metal.

Various factors should be considered in determining the de-

sign strength of the throat of partial joint penetration groove

welds. One factor is joint configuration. The effective throat of

a prequalified partial joint penetration groove weld is the depth

of the groove when the groove angle is 60 deg or greater at the

root of the weld. For groove angles of less than 60 deg, the ef-

fective throat depends upon the welding process, welding posi-

tion, and groove angle at the root. The provisions of AWS D1.1

should be consulted to determine if an allowance for uncertain

penetration is required for the conditions of a particular weld.

APRIL 2010 60

Datasheet 314

Excerpted from the Welding Handbook, Vol. 1, ninth edition.

Static Loading of Welds

Fig. 1 Examples of welds with various types of loading. A Complete joint penetration groove weld in tension; B compression normal to

the axis of weld; C tension or compression parallel to weld axis; D complete joint penetration groove weld in shear; E partial joint pen-

etration in groove welds; F shear parallel to weld axis; G fillet welds loaded in shear along weld throat.

A

B

C

D

E

F

G

Welding Workbook April 2010layout:Layout 1 3/10/10 4:05 PM Page 60

Vous aimerez peut-être aussi

- Steel DetailerDocument3 pagesSteel DetailerKooroshPas encore d'évaluation

- Welding ConnectionDocument46 pagesWelding ConnectionSabih Hashim AlzuhairyPas encore d'évaluation

- FastenalTechnicalReferenceGuide PDFDocument62 pagesFastenalTechnicalReferenceGuide PDFikirby77Pas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- A Technical Seminar On: Suspension SystemDocument24 pagesA Technical Seminar On: Suspension SystemRanjan suvarnaPas encore d'évaluation

- Article - Bolted Joint DesignDocument15 pagesArticle - Bolted Joint DesignPiyush YardiPas encore d'évaluation

- Determining Weld SizeDocument22 pagesDetermining Weld SizeJose Luis Olivares Lopez100% (1)

- Anchor Bolts Design of Headed Anchor BoltsDocument12 pagesAnchor Bolts Design of Headed Anchor BoltsDoug LambPas encore d'évaluation

- AS 1100 Part 301 Architectural DrawingDocument24 pagesAS 1100 Part 301 Architectural DrawingHao Much100% (2)

- Service Manual #41Document106 pagesService Manual #41GrindK0re73% (15)

- Pipe DesignDocument16 pagesPipe DesignManas KotruPas encore d'évaluation

- Honda CRZ 2011 2012 Service ManualDocument20 pagesHonda CRZ 2011 2012 Service Manualdonna100% (49)

- Welding SlidesDocument334 pagesWelding SlidesAsad Bin Ala Qatari100% (13)

- Steel Interchange: Cold Weather Welding Plate Girder StiffenersDocument2 pagesSteel Interchange: Cold Weather Welding Plate Girder Stiffenershector diazPas encore d'évaluation

- Extended End-Plate Stiffener PDFDocument2 pagesExtended End-Plate Stiffener PDFaams_sPas encore d'évaluation

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863Pas encore d'évaluation

- Solar Refrigeration ReportDocument64 pagesSolar Refrigeration ReportSakshi JoshiPas encore d'évaluation

- What Every Fabricator Wants You To Know About WeldingDocument3 pagesWhat Every Fabricator Wants You To Know About WeldingAhmed GamalPas encore d'évaluation

- Galvanized Slip-Critical ConnectionsDocument2 pagesGalvanized Slip-Critical Connectionsaams_sPas encore d'évaluation

- 3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFDocument199 pages3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFJoselyn LiraPas encore d'évaluation

- API 570 - Mockup OP - Paper 2 + MDocument13 pagesAPI 570 - Mockup OP - Paper 2 + MShanawas Abdul Razak80% (5)

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863Pas encore d'évaluation

- API 570 Day 2 Book (1 To 51)Document65 pagesAPI 570 Day 2 Book (1 To 51)AbdulQuddus100% (3)

- Eto na-Uniform-Accelerated-Motion-lessonDocument22 pagesEto na-Uniform-Accelerated-Motion-lessonJackiequeencess TentadoPas encore d'évaluation

- WPQ FormDocument1 pageWPQ Formudaysrp100% (1)

- 120 1224 001 - F03 - 0010Document8 pages120 1224 001 - F03 - 0010musaismail8863100% (1)

- TGN-D-02 Fatigue Improvement of Welded StructuresDocument10 pagesTGN-D-02 Fatigue Improvement of Welded StructuresakuntayPas encore d'évaluation

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyD'EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyPas encore d'évaluation

- HSS Steel AvailabilityDocument2 pagesHSS Steel Availabilityaams_sPas encore d'évaluation

- QuizDocument2 pagesQuizMamu ToothPas encore d'évaluation

- Forces in WeldsDocument8 pagesForces in WeldsBun KunPas encore d'évaluation

- HSS Article DesignFilletWelds RectangularHSS 0615 060120Document4 pagesHSS Article DesignFilletWelds RectangularHSS 0615 060120John Cesar NacionalesPas encore d'évaluation

- Joining Steel MembersDocument1 pageJoining Steel MemberstierradiegoyahooesPas encore d'évaluation

- Steelwise PDFDocument3 pagesSteelwise PDFYan Naung KoPas encore d'évaluation

- Clase Dise o Anclajes PDFDocument59 pagesClase Dise o Anclajes PDFFran Barrera AlbornozPas encore d'évaluation

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 pagesSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazPas encore d'évaluation

- General Provisions: Chapeer ADocument9 pagesGeneral Provisions: Chapeer AJerry M. Davila MartelPas encore d'évaluation

- Penetration Into The Base Metal: If You'Ve Ever Asked Yourself "Why?"Document2 pagesPenetration Into The Base Metal: If You'Ve Ever Asked Yourself "Why?"Ganesh AdityaPas encore d'évaluation

- Steel Structure InformationDocument1 pageSteel Structure InformationsirnassarPas encore d'évaluation

- Chapter 1Document8 pagesChapter 1Saker MohamedPas encore d'évaluation

- Modern Steel Construction's MonthlyDocument2 pagesModern Steel Construction's MonthlyircivilcivilPas encore d'évaluation

- Steel Interchange: Tension-Only OCBFDocument2 pagesSteel Interchange: Tension-Only OCBFhector diazPas encore d'évaluation

- RCD ObjectivesDocument3 pagesRCD ObjectivesiamcerbzjrPas encore d'évaluation

- MSN612215/MSN616218 Elemen Mesin I: Welding JointsDocument36 pagesMSN612215/MSN616218 Elemen Mesin I: Welding JointsDavid TaradePas encore d'évaluation

- Article: Connecting Hollow Structural Section Members With Through-BoltsDocument4 pagesArticle: Connecting Hollow Structural Section Members With Through-BoltsRoPas encore d'évaluation

- ArtigoDocument8 pagesArtigoIgor HenriquePas encore d'évaluation

- Extended End-Plate Stiffener Torsional and Flexural-Torsional BucklingDocument2 pagesExtended End-Plate Stiffener Torsional and Flexural-Torsional BucklingsteelagePas encore d'évaluation

- Filler Weld DesignDocument2 pagesFiller Weld Designaams_sPas encore d'évaluation

- AWS D1.1 D1.1M 2020 - Unlocked 541 664Document124 pagesAWS D1.1 D1.1M 2020 - Unlocked 541 664Jorge Andy Arce CaricariPas encore d'évaluation

- Dec11 Si PDFDocument2 pagesDec11 Si PDFspaceheaterPas encore d'évaluation

- Si 12 2011 PDFDocument2 pagesSi 12 2011 PDFHectorPas encore d'évaluation

- Figure 3-2. Direct Tension Indicators and Feeler GagesDocument1 pageFigure 3-2. Direct Tension Indicators and Feeler GagestierradiegoyahooesPas encore d'évaluation

- MemorandumDocument5 pagesMemorandumpio.mirandaPas encore d'évaluation

- Connections, Joints, and Fasteners: 7.1. ScopeDocument4 pagesConnections, Joints, and Fasteners: 7.1. ScopeQuốc KhánhPas encore d'évaluation

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document8 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!JitendraPas encore d'évaluation

- Teh 2007Document9 pagesTeh 2007Mithil DarpePas encore d'évaluation

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoPas encore d'évaluation

- Bantog - Finals HW 1Document4 pagesBantog - Finals HW 1Penuel G. BantogPas encore d'évaluation

- 09A Steel Structure-174142-16188512242230Document90 pages09A Steel Structure-174142-16188512242230NamPas encore d'évaluation

- Jurnal StudiDocument10 pagesJurnal Studiyuri251292Pas encore d'évaluation

- SQ 17Document2 pagesSQ 17Alparslan GurePas encore d'évaluation

- An Experimental Study of Welded Splices of Reinforcing Bars: Camille A. Issa, Antoine NasrDocument12 pagesAn Experimental Study of Welded Splices of Reinforcing Bars: Camille A. Issa, Antoine NasrRajesh SinghPas encore d'évaluation

- TECHNICAL PAPER03 2015 Design of Fillet Welds To Rectangular HSS June2015Document5 pagesTECHNICAL PAPER03 2015 Design of Fillet Welds To Rectangular HSS June2015ZebPas encore d'évaluation

- Tee L Nterc A G: Ses Evio SDocument2 pagesTee L Nterc A G: Ses Evio Sfarhadmrt6923Pas encore d'évaluation

- Steel Interchange: Fillet Weld Terminations Built-Up Column DesignDocument2 pagesSteel Interchange: Fillet Weld Terminations Built-Up Column Designhector diazPas encore d'évaluation

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoPas encore d'évaluation

- Structural Steel Design Cie 552: Hopeson Kasumba M.Eng, B.Eng, Macez, Meiz, PR - Eng, R.EngDocument30 pagesStructural Steel Design Cie 552: Hopeson Kasumba M.Eng, B.Eng, Macez, Meiz, PR - Eng, R.EngPenelope MalilwePas encore d'évaluation

- Structural Connections - Scia5203: Unit - IDocument77 pagesStructural Connections - Scia5203: Unit - IVignesh DhuruvanPas encore d'évaluation

- Steel Interchange: How To Specify AESS Gusset Plate DesignDocument2 pagesSteel Interchange: How To Specify AESS Gusset Plate Designhector diazPas encore d'évaluation

- Connections 1Document26 pagesConnections 1Jeiel ValenciaPas encore d'évaluation

- Types of Welding JointDocument6 pagesTypes of Welding JointTesema TeshomePas encore d'évaluation

- Design of Fillet Welds To Rectangular HSS - TECHNICAL-PAPER03-2015 - June2015Document5 pagesDesign of Fillet Welds To Rectangular HSS - TECHNICAL-PAPER03-2015 - June2015David ArndtPas encore d'évaluation

- Bristle BlasterDocument6 pagesBristle Blastermusaismail8863Pas encore d'évaluation

- C1 13jgfjdfgDocument25 pagesC1 13jgfjdfgmusaismail8863Pas encore d'évaluation

- Ags 10 PDFDocument33 pagesAgs 10 PDFmusaismail8863Pas encore d'évaluation

- AWS PricelistDocument1 pageAWS Pricelistmusaismail8863Pas encore d'évaluation

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Document1 pageFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- MDR NDT Drawing Tembikai As of 08.11.2014Document1 pageMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- Material Specification Sheet Saarstahl - C40E (Ck40)Document2 pagesMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863Pas encore d'évaluation

- Part 1 eDocument70 pagesPart 1 emusaismail8863Pas encore d'évaluation

- Guide To ColorsDocument1 pageGuide To ColorsMardiSantosoPas encore d'évaluation

- D Internet Myiemorgmy Iemms Assets Doc Alldoc Document 5431 Brochure-RevisedDocument2 pagesD Internet Myiemorgmy Iemms Assets Doc Alldoc Document 5431 Brochure-Revisedmusaismail8863Pas encore d'évaluation

- Steel Vessels 2008: Rules For Building and ClassingDocument18 pagesSteel Vessels 2008: Rules For Building and Classingmusaismail8863Pas encore d'évaluation

- Abs Guide Rules For Fpso ConversionDocument1 pageAbs Guide Rules For Fpso Conversionmusaismail8863Pas encore d'évaluation

- APPEA Guidelines For Lliting EquipmentDocument41 pagesAPPEA Guidelines For Lliting EquipmentJason RobertsPas encore d'évaluation

- ASTM A105 Flange Heat TreatmentDocument16 pagesASTM A105 Flange Heat TreatmentpuffdPas encore d'évaluation

- 2009FDocument26 pages2009FdaimaheshPas encore d'évaluation

- Anchor Bolt Chair Weld Map Cond N22Document1 pageAnchor Bolt Chair Weld Map Cond N22sharif339Pas encore d'évaluation

- 232 50Document2 pages232 50musaismail8863Pas encore d'évaluation

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocument6 pagesInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863Pas encore d'évaluation

- Cidb Green CardDocument1 pageCidb Green CardMuhammad Adzim Azizi67% (3)

- YeldDocument2 pagesYeldmusaismail8863Pas encore d'évaluation

- Agf' R Pack: With S IserDocument4 pagesAgf' R Pack: With S IseralbertoPas encore d'évaluation

- Atb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesDocument4 pagesAtb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesAlePas encore d'évaluation

- Simple Harmonic Motion Multiple Choice 2013 07 11 PDFDocument4 pagesSimple Harmonic Motion Multiple Choice 2013 07 11 PDFYuusuf AhmedPas encore d'évaluation

- Process Flow SheetDocument22 pagesProcess Flow Sheetranger cleetusPas encore d'évaluation

- Changanyikeni Apartments PadFtgDocument25 pagesChanganyikeni Apartments PadFtgAnonymous Xb3zHioPas encore d'évaluation

- Briggs and Stratton 133412 - 0059 01 PartsMan (EN)Document31 pagesBriggs and Stratton 133412 - 0059 01 PartsMan (EN)Gisell ZapataPas encore d'évaluation

- Manual Taladro RadialDocument39 pagesManual Taladro RadialMartin Rodriguez RamirezPas encore d'évaluation

- High Torque Drive Rod (SLHT) Rod Introduction-HUAMINGDocument18 pagesHigh Torque Drive Rod (SLHT) Rod Introduction-HUAMINGKevin XuPas encore d'évaluation

- Testing & Adjusting The Patriot Metering System: Magnum Venus PlastechDocument26 pagesTesting & Adjusting The Patriot Metering System: Magnum Venus PlastechCamilo Correa100% (1)

- Insight NDT Equipment LTD - ..Document2 pagesInsight NDT Equipment LTD - ..aoxoxzPas encore d'évaluation

- Basic of ThermodynamicsDocument12 pagesBasic of ThermodynamicsTeeranun NakyaiPas encore d'évaluation

- UPTO-DATE Daily Progress Report 07-02-2024-DIDocument1 pageUPTO-DATE Daily Progress Report 07-02-2024-DIMobin Thomas AbrahamPas encore d'évaluation

- Shell and Tube Heat ExchangersDocument11 pagesShell and Tube Heat ExchangersSuresh SjPas encore d'évaluation

- Potter Air Relief Valve - 5401165 - PavDocument3 pagesPotter Air Relief Valve - 5401165 - PavFrancisco AlarconPas encore d'évaluation

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanPas encore d'évaluation

- Prestressed Concrete Assignment TU DelftDocument4 pagesPrestressed Concrete Assignment TU DelfttimsykiPas encore d'évaluation

- GuyhirnDocument4 pagesGuyhirnTyburnPas encore d'évaluation

- Cylinder Head - Install: Desarmado y ArmadoDocument4 pagesCylinder Head - Install: Desarmado y ArmadoDavid Apaza HurtadoPas encore d'évaluation

- Cataloque Torc-Tensionador-TentecDocument11 pagesCataloque Torc-Tensionador-TentecDeividas BPas encore d'évaluation

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsDocument8 pagesDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesPas encore d'évaluation

- Ceng60 A2021 Module 1aDocument5 pagesCeng60 A2021 Module 1aKurt Francis AcostaPas encore d'évaluation

- CH 3 Review Load and Stress AnalysisDocument33 pagesCH 3 Review Load and Stress AnalysisAnas TubailPas encore d'évaluation

- Grand Vitara 2010Document191 pagesGrand Vitara 2010Fernando OrtizPas encore d'évaluation

- Introduction and TheoryDocument2 pagesIntroduction and TheoryAhmad NajibPas encore d'évaluation