Académique Documents

Professionnel Documents

Culture Documents

Load Chart-Wire Rope

Transféré par

Rajmohan BabuDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Load Chart-Wire Rope

Transféré par

Rajmohan BabuDroits d'auteur :

Formats disponibles

Load Chart

Working Load

Limits Tonnes

Angle to

the

vertical

Nominal rope

Diameter mm

8

9

10

11

12

13

14

16

18

20

22

24

26

28

32

36

40

44

48

52

56

60

leg factor KL

One Leg Sling

0

Tensile

n/mm2

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1960

1770

1770

1770

1770

1770

1770

Fibre

Core

0.76

0.96

1.19

1.44

1.71

2

2.33

3.05

3.85

4.75

5.75

6.85

8.02

9.31

12.15

15.38

19.09

22.94

27.35

32.12

37.26

42.77

Steel

Core

0.82

1.04

1.28

1.55

1.84

2.17

2.51

3.29

4.15

5.12

6.2

7.38

8.66

10.04

13.12

16.59

20.56

24.78

29.55

34.69

40.2

46.07

1

Two Leg Sling

0 - 45

>45 - 60

Fibre Steel

Core Core

1.06

1.15

1.35

1.45

1.66

1.79

2.01

2.17

2.39

2.57

2.8

3.03

3.26

3.52

4.27

4.6

5.4

5.81

6.66

7.17

8.04

8.69

9.58 10.33

11.23 12.13

13.03 14.06

17.01 18.37

21.53 23.23

26.72 28.78

32.12 34.69

38.29 41.37

44.97 48.57

52.16 56.28

59.87 64.5

1.4

Fibre

Core

0.76

0.96

1.19

1.44

1.71

2

2.33

3.05

3.85

4.75

5.75

6.85

8.02

9.31

12.15

15.38

19.09

22.94

27.35

32.12

37.26

42.77

Steel

Core

0.82

1.04

1.28

1.55

1.84

2.17

2.51

3.29

4.15

5.12

6.2

7.38

8.66

10.04

13.12

16.59

20.56

24.78

29.55

34.69

40.2

46.07

1

Three and Four Leg Sling

0 - 45

>45 - 60

Fibre Steel

Core

Core

1.6

1.72

2.02

2.18

2.49

2.69

3.02

3.25

3.59

3.85

4.2

4.55

4.9

5.28

6.4

6.9

8.09

8.71

9.98 10.75

12.06 13.03

14.38 15.5

16.84 18.19

19.54 21.08

25.52 27.56

32.3 34.84

40.09 43.17

48.18 52.04

57.43 62.06

67.45 72.85

78.25 84.41

89.81 96.75

2.1

Fibre Steel

Core

Core

1.14

1.23

1.44

1.56

1.78

1.92

2.16

2.32

2.56

2.75

3

3.25

3.5

3.77

4.57

4.93

5.78

6.22

7.13

7.68

8.62

9.31

10.27 11.07

12.03

13

13.96 15.06

18.23 19.69

23.07 24.89

28.63 30.84

34.42 37.17

41.02 44.33

48.18 52.04

55.89 60.3

64.15 69.11

1.5

Endless Sling Choke Hitch

0

Fibre

Core

1.22

1.54

1.9

2.3

2.73

3.2

3.73

4.88

6.17

7.61

9.19

10.95

12.83

14.89

19.44

24.61

30.54

36.71

43.76

51.39

59.62

68.43

Safety Recommendations

Safety Recommendations

When using multi=leg sling assemblies remember that increasing the angles between the legs will increase the

load in each leg. Examine all slings before use and discard any that are defective. Slings which are found to be

unfit for use should be destroyed by cutting them up - not put on a refuse dump. "Hooking back" to the leg is not

recommended. The Working Load Limit of slings is effected by the method of usage. Check that the crane hook

is positioned over the loads centre of gravity to prevent swinging when the load is being raised. Correct signals,

according to the recognised code, should be given to the crane driver. The signals must be given by the person

responsible for the lift and nobody else.

Keep wire rope slings away from welding and flame cutting operations. The Law requires that all lifting equipment

must be examined by a competent person at regular intervals. This includes wire rope slings.

Certex can manufacture slings to DNV 2-7.1 in their approved facility in Montrose.

Steel

Core

1.31

1.66

2.05

2.48

2.94

3.47

4.02

5.26

6.64

8.19

9.93

11.81

13.86

16.06

21

26.55

32.89

39.65

47.28

55.51

64.32

73.71

1.6

Typical Sling Arrangements

Cradle Sling

Lifting coils, steel strip, etc. Basket Hitch

SWL = 1.4 x WLL of sling Protect Rope from sharp corners.

Cradle Slings

Lifting boilers and packaging cases, etc. Double Basket Hitch SWL = 2.1 x WLL of single sling.

Halshing Slings

Method using a single sling in place of an endless sling where a bight is required. A stirrup fitted temporarily

in the bight will minimise damage to the sling. Double and Choked.

SWL = 1.6 x WLL of sling.

Double Wrap Slings

Note how the double wrap grips the load and helps to prevent it from slipping sideways out of the slings.

Double Wrap Basket Hitch

SWL = 2.1 x WLL of single sling

Combination Slings

Timber steel sheets and packing cases, etc. N.B. Maximum angle from vertical is 45

Reeving Slings

Lifting tubes, bars and rods, etc. Double Choke Hitch SWL = 1.1 x WLL of single sling

Vous aimerez peut-être aussi

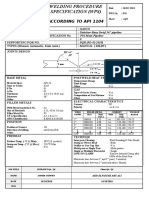

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- DIGIPRO 1000s REV2.0.pdf Manuel Pancho PDFDocument5 pagesDIGIPRO 1000s REV2.0.pdf Manuel Pancho PDFJohnny Tenezaca Duarte50% (2)

- Pad Eye Puller DesignDocument5 pagesPad Eye Puller DesignbudygmoodPas encore d'évaluation

- Service Manual Trucks: Wiring Diagram FM9, FM12, FH12, FH16, NH12 VERSION2Document184 pagesService Manual Trucks: Wiring Diagram FM9, FM12, FH12, FH16, NH12 VERSION2Jonathan Eduardo Torres100% (7)

- Pipe & Tube of NSSMCDocument0 pagePipe & Tube of NSSMCLim DongseopPas encore d'évaluation

- DIN 11864-3 Aseptic Clamp Unions For BS 4825 / ISO 2037 & ASME BPE 2002Document7 pagesDIN 11864-3 Aseptic Clamp Unions For BS 4825 / ISO 2037 & ASME BPE 2002hari.suryanto8417Pas encore d'évaluation

- QMS System References PDFDocument2 pagesQMS System References PDFAbdhel X-Meta100% (1)

- STF HRSGDocument20 pagesSTF HRSGDaniellzhangPas encore d'évaluation

- Ufc 4 152 01Document167 pagesUfc 4 152 01bhavdip_shahPas encore d'évaluation

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiPas encore d'évaluation

- Mangalore Refinery and Petrochemicals Limited Mangalore Karnataka 2632018104557516Document76 pagesMangalore Refinery and Petrochemicals Limited Mangalore Karnataka 2632018104557516Veena NageshPas encore d'évaluation

- GTM-COM-SA-DS-0004-08 - Fire Water PumpDocument4 pagesGTM-COM-SA-DS-0004-08 - Fire Water PumpFranscois Van RooyenPas encore d'évaluation

- Boiler Tube Products Sa-178Document25 pagesBoiler Tube Products Sa-178Sai Prasath100% (1)

- Tank Roof Lifting TechniqueDocument19 pagesTank Roof Lifting TechniquesadiqalikmPas encore d'évaluation

- Coastal Ocean Observing SystemsD'EverandCoastal Ocean Observing SystemsYonggang LiuPas encore d'évaluation

- Lineshaft and Submersible Turbine PumpsDocument16 pagesLineshaft and Submersible Turbine PumpsRheoservePas encore d'évaluation

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesPas encore d'évaluation

- Mobile Reverse Osmosis Units: For Purified Water NeedsDocument4 pagesMobile Reverse Osmosis Units: For Purified Water NeedsVeera SekarPas encore d'évaluation

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 pagesPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Conversion Table Hardness To UTSDocument2 pagesConversion Table Hardness To UTSSendi LuciverPas encore d'évaluation

- Ventilation FansDocument39 pagesVentilation FanskalaiPas encore d'évaluation

- Seawater Reverse Osmosis Swro PresentationDocument34 pagesSeawater Reverse Osmosis Swro PresentationYang SunmanPas encore d'évaluation

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCOPas encore d'évaluation

- TechnipDocument36 pagesTechnipShashwat Nigam0% (1)

- Cathodic Protection: Jump To Navigationjump To SearchDocument7 pagesCathodic Protection: Jump To Navigationjump To SearchfayasPas encore d'évaluation

- General Information G-0002: Description On Material JIS-ASTMDocument4 pagesGeneral Information G-0002: Description On Material JIS-ASTMEko Indra SaputraPas encore d'évaluation

- Nalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSDocument2 pagesNalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSAlok NayakPas encore d'évaluation

- Corrosion Data GuideDocument8 pagesCorrosion Data GuideLê Tuấn Asia ValvesPas encore d'évaluation

- Pre Feasibility PDFDocument90 pagesPre Feasibility PDFSulaksha WimalasenaPas encore d'évaluation

- DRG 5 StorageTankDocument2 pagesDRG 5 StorageTankbharathpePas encore d'évaluation

- Pumps OnboardDocument31 pagesPumps OnboardTamal MukherjeePas encore d'évaluation

- Basalt RockDocument25 pagesBasalt Rocksaqib mujtabaPas encore d'évaluation

- How To Order Alfa ValveDocument0 pageHow To Order Alfa ValveZoebairPas encore d'évaluation

- JIS JFE Pipe and TubeDocument25 pagesJIS JFE Pipe and Tubedavorp1402Pas encore d'évaluation

- Balance Quality GradesDocument1 pageBalance Quality GradesVijay SainiPas encore d'évaluation

- Notes: PT Unilever Oleochemical Indonesia Sunshine Project Piping, Insulation & Mecahnical Tender - Osbl & IsblDocument14 pagesNotes: PT Unilever Oleochemical Indonesia Sunshine Project Piping, Insulation & Mecahnical Tender - Osbl & Isblrizky youlandaPas encore d'évaluation

- Role of ContainersDocument39 pagesRole of ContainersEliza PopaPas encore d'évaluation

- Basics of Shell and Tube Heat Exchangers With PDFDocument12 pagesBasics of Shell and Tube Heat Exchangers With PDFtruong cong truc100% (1)

- CV-Amit SinhaDocument6 pagesCV-Amit Sinharanjan sahooPas encore d'évaluation

- Painting ReportDocument29 pagesPainting ReportDimas Afiefan AmirPas encore d'évaluation

- Boiler 2 Boiler1 Ro Plant: Steam Line 2" Wall StackDocument1 pageBoiler 2 Boiler1 Ro Plant: Steam Line 2" Wall StackZubair NawazPas encore d'évaluation

- Pumps: Pacifico Ortaliza Pme 828Document32 pagesPumps: Pacifico Ortaliza Pme 828Angel Silva VicentePas encore d'évaluation

- Feedwater HeaterDocument6 pagesFeedwater HeaterIzzat AzmanPas encore d'évaluation

- LT26G PDFDocument4 pagesLT26G PDFraul gonzalezPas encore d'évaluation

- Saipem 3000Document8 pagesSaipem 3000del3333Pas encore d'évaluation

- Hydrotest Welding and NDTDocument11 pagesHydrotest Welding and NDTALFA ENGINEERINGPas encore d'évaluation

- Pipes CATALOGUE PDFDocument3 pagesPipes CATALOGUE PDFYusma NurPas encore d'évaluation

- Checklist Wcom 626 Vibration & Tention Belt Record PPL 2 2016Document2 pagesChecklist Wcom 626 Vibration & Tention Belt Record PPL 2 2016email100% (1)

- 135 TPH Boiler-2. Erection ReportDocument12 pages135 TPH Boiler-2. Erection ReportVijay RajPas encore d'évaluation

- Corrosion ChartDocument15 pagesCorrosion ChartAnup MathewPas encore d'évaluation

- Standards MapsDocument7 pagesStandards MapsRoelf MostertPas encore d'évaluation

- Procedure Painting Mps Epoxcy - Final - PT KhiDocument12 pagesProcedure Painting Mps Epoxcy - Final - PT KhisinambeladavidPas encore d'évaluation

- CES Business PresentationDocument50 pagesCES Business PresentationGary David CrowhurstPas encore d'évaluation

- Landfall and Shore Approach PDFDocument7 pagesLandfall and Shore Approach PDFvpandya1981100% (1)

- Clyde Bergemann Biomass Solutions ENGLISHDocument6 pagesClyde Bergemann Biomass Solutions ENGLISHErickPas encore d'évaluation

- Mineral Wool Pipe Insulation DatasheetDocument2 pagesMineral Wool Pipe Insulation DatasheetDenny Akbar Nur Hadyansyah100% (1)

- Progress Piping PDFDocument1 pageProgress Piping PDFebsmsartPas encore d'évaluation

- Comparison of Two FEA Models For Calculating Stresses in Shell-And-tube Heat ExchangerDocument5 pagesComparison of Two FEA Models For Calculating Stresses in Shell-And-tube Heat ExchangerDevang DesaiPas encore d'évaluation

- Wire RopesDocument7 pagesWire RopesZednanreh JessiePas encore d'évaluation

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaPas encore d'évaluation

- Awwa c153 (Dimension Details)Document7 pagesAwwa c153 (Dimension Details)aroratsPas encore d'évaluation

- Fender Accessories (Panels, Chains, Brackets) Catalogue en V1.3Document10 pagesFender Accessories (Panels, Chains, Brackets) Catalogue en V1.3loicdertyPas encore d'évaluation

- Purlins C30024Document2 pagesPurlins C30024Gatot WisnubrataPas encore d'évaluation

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingD'EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingPas encore d'évaluation

- ITPM01 Rev.1 NPS CT Inspection and Test PlanDocument32 pagesITPM01 Rev.1 NPS CT Inspection and Test PlanRajmohan BabuPas encore d'évaluation

- Procrastination Article HWO Fall 2012Document3 pagesProcrastination Article HWO Fall 2012Rajmohan BabuPas encore d'évaluation

- Self Reliance: Text)Document2 pagesSelf Reliance: Text)Rajmohan BabuPas encore d'évaluation

- Load Chart Learning Guide: Folding Boom CraneDocument7 pagesLoad Chart Learning Guide: Folding Boom CraneRajmohan Babu100% (1)

- Container Marks and NumbersDocument31 pagesContainer Marks and NumbersRajmohan BabuPas encore d'évaluation

- SPDC - Hse: Bayelsa State NigeriaDocument7 pagesSPDC - Hse: Bayelsa State NigeriaRajmohan BabuPas encore d'évaluation

- AathichudiDocument16 pagesAathichudiமுரளி கிருஷ்ணன் alias முகி100% (9)

- Crane Wire RopeDocument32 pagesCrane Wire RopeRajmohan Babu100% (3)

- Opinion Op-Ed: Gandhiji Shot Dead - The Hindu (January 31, 1948)Document2 pagesOpinion Op-Ed: Gandhiji Shot Dead - The Hindu (January 31, 1948)Rajmohan BabuPas encore d'évaluation

- Guidance On The Safe Use of TelehandlersDocument86 pagesGuidance On The Safe Use of TelehandlersAlbaTraining100% (1)

- DOE StandardsDocument213 pagesDOE StandardsRajmohan BabuPas encore d'évaluation

- API Casing Color CodesDocument2 pagesAPI Casing Color CodesRajmohan BabuPas encore d'évaluation

- Lightweight Concrete Made From Waste Polystyrene and Fly Ash PDFDocument5 pagesLightweight Concrete Made From Waste Polystyrene and Fly Ash PDFFederico ArqueroPas encore d'évaluation

- Bilder: Alle Bilder Für Aqualock Fitting AnzeigenDocument1 pageBilder: Alle Bilder Für Aqualock Fitting AnzeigenDirk HofmannPas encore d'évaluation

- Savage Hydraulic Presses Are Application-Specific and Job-EngineeredDocument1 pageSavage Hydraulic Presses Are Application-Specific and Job-EngineeredRajiv GandhiPas encore d'évaluation

- Laboratory 2 MRPFDocument27 pagesLaboratory 2 MRPFsopan saPas encore d'évaluation

- K-Flex Insul-SheetDocument2 pagesK-Flex Insul-SheetJuan SantosPas encore d'évaluation

- Unit 3 Assignment AnswersDocument0 pageUnit 3 Assignment AnswersRosanna LombresPas encore d'évaluation

- SWD Aci 530 11Document57 pagesSWD Aci 530 11Stephanie Miyata100% (2)

- Comment Resolution Sheet (Qap Review) : Authorized byDocument1 pageComment Resolution Sheet (Qap Review) : Authorized byHarsh KumarPas encore d'évaluation

- Mouser ToolsectionDocument26 pagesMouser ToolsectionalltheloveintheworldPas encore d'évaluation

- AIR TECH Complete ManualDocument33 pagesAIR TECH Complete ManualEvandro OliveiraPas encore d'évaluation

- Developing Advanced Biorefinery Schemes For Integration Into ExistingDocument89 pagesDeveloping Advanced Biorefinery Schemes For Integration Into ExistingamirPas encore d'évaluation

- Polyamino AcidsDocument2 pagesPolyamino AcidsRichard J. GrayPas encore d'évaluation

- Eso2 MechanismsDocument3 pagesEso2 MechanismsGregorio Caballero RosalesPas encore d'évaluation

- Roboze ArgoDocument12 pagesRoboze ArgoGregorio PisaneschiPas encore d'évaluation

- Marshall Stability and Flow of Asphalt ConcreteDocument2 pagesMarshall Stability and Flow of Asphalt ConcreteadePas encore d'évaluation

- CableDocument42 pagesCableMochamad Irfan MaulanaPas encore d'évaluation

- BS EN 00003-3-1996 ScanDocument16 pagesBS EN 00003-3-1996 ScanRinu RavikumarPas encore d'évaluation

- Project Report On Analysis of A Solar Heter by Ansys.Document61 pagesProject Report On Analysis of A Solar Heter by Ansys.chanki chhangani100% (1)

- Unica - Svi Uredjaji Ramovi Unica Basic, Colors, Allegro, PLDocument24 pagesUnica - Svi Uredjaji Ramovi Unica Basic, Colors, Allegro, PLurcoadPas encore d'évaluation

- 520CJ CK CL - Wob L - 3297 - 11 14Document3 pages520CJ CK CL - Wob L - 3297 - 11 14zayerirezaPas encore d'évaluation

- HELIAX Coaxial CableDocument8 pagesHELIAX Coaxial CablehernanoygPas encore d'évaluation

- STSQuad Threadkorr 5Document48 pagesSTSQuad Threadkorr 5Parminder SinghPas encore d'évaluation

- Defogger: SectionDocument72 pagesDefogger: SectionJavier SiñaniPas encore d'évaluation

- High-Voltage Vacuum ContactorsDocument9 pagesHigh-Voltage Vacuum ContactorstanujaayerPas encore d'évaluation

- FS Indocement Plant 11 (Final)Document1 pageFS Indocement Plant 11 (Final)yohanes agungPas encore d'évaluation

- AP Chem CalorimetryDocument19 pagesAP Chem Calorimetrysumire shiny dartokPas encore d'évaluation