Académique Documents

Professionnel Documents

Culture Documents

The Overall Heat Transfer Characteristics of A Double Pipe Heat Exchanger: Comparison of Experimental Data With Predictions of Standard Correlations

Transféré par

Engr. AbdullahTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Overall Heat Transfer Characteristics of A Double Pipe Heat Exchanger: Comparison of Experimental Data With Predictions of Standard Correlations

Transféré par

Engr. AbdullahDroits d'auteur :

Formats disponibles

IJE Transactions B: Applications Vol. 15, No.

4, December 2002 - 395

THE OVERALL HEAT TRANSFER CHARACTERISTICS OF A DOUBLE

PIPE HEAT EXCHANGER: COMPARISON OF EXPERIMENTAL DATA

WITH PREDICTIONS OF STANDARD CORRELATIONS

M A Mehrabian, S H Mansouri and G A Sheikhzadeh

Department of Mechanical Engineering, Shahid Bahonar University of Kerman

P.O. Box 76175-133, Kerman, Iran, ma_mehrabian@yahoo.com

(Received: September 24, 2001 Accepted in Revised Form: October 7, 2002)

Abstract The single-phase flow and thermal performance of a double pipe heat exchanger are

examined by experimental methods. The working fluid is water at atmospheric pressure. Temperature

measurements at the inlet and outlet of the two streams and also at an intermediate point half way

between the inlet and outlet is made, using copper-constantan thermocouple wires. Mass flow rates

for each stream are also measured using calibrated rotameters. Heat is supplied to the inner tube

stream by an immersion heater. The overall heat transfer coefficients are inferred from the measured

data. The heat transfer coefficient of the inner tube flow (circular cross section) is calculated using the

standard correlations. The heat transfer coefficient of the outer tube flow (annular cross section) is

then deduced. Higher heat transfer coefficients are reported in the laminar flow regime in comparison

to the predictions of standard correlations for straight and smooth tubes. The reasons for this

discrepancy are identified and discussed. Experimental errors in measuring temperatures and mass

flow rates are studied and their effects on the heat transfer coefficients are estimated. Experimental

results for the range of operating conditions used in this work show that the outer tube side heat

transfer coefficients are smaller than the inner side heat transfer coefficients by a factor of almost 1.5

and 3.4 in counter flow and parallel flow arrangements, respectively. The agreement with predictions

is very good for the counter flow arrangement, but not very good for the parallel flow arrangement.

Key Words Double Pipe Heat Exchanger-Heat Transfer Coefficient-Inner Tube Flow-Outer Tube

Flow

!"#$%& !"#$%& !"#$%& !"#$%& '( )* +'*,$- . /012 34,56 7'89:0 .; !/'<=>; '4 7; ?@1@ :/ 360;,A B"C2 )* 360;,A /,%DEF :

32 0;,G 3$>0,4 /,#H . 0'I( 0/ JK L2'F B'#> ; M>; 7,<NE6 . : 7/:0: OP'Q2 0/ R0;,A ?-0/ 7,#H !.;"S;

T#4 3S'#2 ?UQS )* : 3-:,V W2 LX1Y 12,6 7'8E#> .; !/'<=>; '4 3-:,V : 7/:0: OP'Q2 - Z'5S; +'=S'=N[Y

3$2 /1$9 . 7,#H !.;"S; !"9 \0"2 7'],=2'6:0 .; !/'<=>; '4 ^#$S B'#$> :/ .; )$* ,$] 3$2,- +'*,$- R"$9

3$2 /1$9 . 32 ?C>'_2 34,56 7'] !/;/ 7:0 .; 3DY R0;,A B'Q=S; `*,$a /19 . +'*,- R0;,A B'Q=S; `*,a

?@1@ 3DV;/ ) !,*;/ OUQ2 ( 32 M>"4 /0;"S'=>; b4;:0 .; !/'<=>; '4 "*K . 3-0'V ?@1@ +'*,- R0;,A B'Q=S; `*,a

) 71$QDA O$UQ2 ( 32 Lc'A 7; ?S;1=>; `Y,2 0;"- )* 0/ '8=$2:'Q2 T$#4 ?$U4;0 .; .; Lc'A ,*/'Q2 '4 : /19

32 ?N*'Q2 /0;"S'=>; b4;:0 //,H . 32 ?dAe2 ,A B'Q=S; `*;,a ?Y /19 .; 7; ?dAe2 L4'G +;^#2 ?4 34,56 R0;

32 3[#4 f#X Z,S : g#Q=N2 ?@1@ )* 7;,4 /0;"S'=>; b4;:0 ?Y ?hSK M>; ,=I#4 "[[Y . 3*'>'[9 ie=V; T*; LDF

32 0;,$G j$_4 /01$2 : /,#H . : '860;,A ?-0/ 7,#H !.;"S; 0/ 'UV L2;1F '8S'*,- 7 : ?k@'U2 B'#> :/ 32,-

Q=$S; `*;,$a ,$4 +K ,#$l'6 32 !/. T#Em6 R0;,$A B' /19 . : '860;,A ?-0/ !/:"_2 0/ 34,56 n*'=S '8S'*,- 7

32 +'IS f]:oX T*; 0/ !/'<=>; /012 3$2,- b>1=2 01U4 3-0'V ?@1@ +'*,- R0;,A B'Q=S; `*;,a ?Y "[]/

MCNS ?$4 p / q : M8- g] ,#r 7'8S'*,- '4 B"C2 7;,4 s / t `*;,a .; M8- g] 7'8S'*,- '4 B"C2 7;,4 B'Q=S;

M>; ,=%&1Y 3DV;/ ?@$1@ +'*,$- R0;,$A . 7;,4 /0;"S'=>; b4;:0 b>16 3[#4 f#X L4'G 7'8=CNS '4 '8=CNS T*;

: )*/^S MQ4'U2 M8- g] ,#r 7'8S'*,- '4 B"C2 /0;/ "*"9 i;,_S; M8- g] 7'8S'*,- '4 B"C2 7;,4 .

1. INTRODUCTION

Double pipe heat exchangers are the simplest

recuperators in which heat is transferred from the

hot fluid to the cold fluid through a separating

cylindrical wall. It consists of concentric pipes

separated by mechanical closures. Inexpensive,

rugged and easily maintained, they are primarily

adapted to high-temperature, high-pressure applications

due to their relatively small diameters.

Archive of SID

www.SID.ir

396 Vol. 15, No. 4, December 2002 IJE Transactions B: Applications

Double pipe heat exchangers have a simple

construction. They are fairly cheap, but the amount

of space they occupy is generally high compared

with the other types. The amount of heat transfer

per section is small, that makes the double pipe

heat exchangers a suitable heat transfer device in

applications where a large heat transfer surface is

not required.

Although the performance and analysis of

double pipe heat exchangers have been established

long time ago, Abdelmessih and Bell [1] have

taken a closer look to these exchangers recently.

They have summarized some of the existing

laminar flow heat transfer correlations in circular,

horizontal, straight tubes. They have studied the

effects of natural convection upstream of the bend

and also the effects of secondary flow downstream

the bend.

For a fully (or almost fully) developed velocity

profile in the straight tube (upstream of the bend),

where the thermal profile is not fully developed

under any conditions, Abdelmessih and Bell [1]

found that both forced and natural convection

contribute to the heat transfer process according to

the following correlation:

14 . 0 4 / 1

) ]( Pr) ( 327 . 0 36 . 4 [

w

b

Gr Nu

+ = (1)

where all physical properties (except

w

) are

evaluated at the local bulk temperature. Nu is the

local peripheral average Nussult number. The term

representing the forced convection effect (4.36)

will be recognized as the analytical result for fully

developed laminar flow with constant properties

and constant wall heat flux. The data used to

generate Equation.1 covered the following ranges:

120 2500 Re

39 110 . Pr

1130000 2500 Gr (2)

27 171

X

d

i

Downstream from the bend, in addition to the

forced and natural convection contributions, there

is a secondary flow contribution. Adding the term

correlating this effect gives the final Equation [5]:

14 . 0 ) / ( 07259 . 0 8 . 0 6 . 1

6 4 / 1

) ( ] Re

10 955 . 1 Pr) ( 327 . 0 36 . 4 [

w

b d X

i

e De

Gr Nu

+ + =

(3)

The data covered the following ranges:

120 2500 Re

40 110 Pr

50000 2500 Gr (4)

195 145 .

X

d

i

4 8 254 . .

R

r

c

i

Equation 3 has three limiting cases, as the

curvature tends to zero, the Dean number tends to

zero and Equation 3 reduces to Equation 1. The

second case is the absence of natural convection, i.

e., the Grashof number reduces to zero. The third

case is for the fully developed velocity and

temperature profiles in a straight tube and the

absence of natural convection, i. e., both the

Grashof number and the Dean number tend to zero,

then Equation 3 reduces to:

14 . 0

) ( 36 . 4

w

b

Nu

= (5)

For a nearly uniform wall heat flux, there will

always be a natural convection contribution; i. e.

Grashof number will not approach zero, unless

gravity approaches zero.

The natural convection upstream of the bend

(second term in Equation 1), the natural convection

downstream of the bend (second term in Equation

3) and the secondary flow downstream of the bend

(third term in Equation 3) contribute to the heat

transfer process [1], [2], [3] and [4]. The present

study is aimed to investigate the effect of these

phenomena quantitatively by measuring the heat

transfer coefficients and estimating their deviation

from the predictions of standard correlations for

straight tubes. It should be mentioned that, some of

this deviation could be because of surface

roughness of the tubes, as the standard correlations

are generally for the smooth tubes. The question

that what fraction of this deviation is because of

Archive of SID

www.SID.ir

IJE Transactions B: Applications Vol. 15, No. 4, December 2002 - 397

natural convection, secondary flows, and surface

roughness is still unanswered.

2. EXPERIMENTAL SETUP

The experiments, on which this work is based,

were performed for the case of nearly uniform heat

flux at the surface. This condition of uniform heat

flux is probably closer to present the practical

condition of operating double pipe heat exchangers

in concurrent flow, where the outside fluid heats

the fluid in the pipe, or vice versa. Constant heat

flux should not be confused with constant surface

temperature, where the latter is closely

approximated when there is a phase change in one

of the fluids, or when the fluids are in co-current

flow.

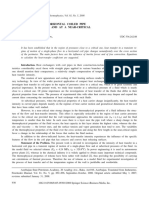

The experimental rig was designed and

constructed in the Heat Transfer Laboratory,

Department of Mechanical Engineering, Kerman

University. A schematic diagram of the rig circuit

is shown in Figure. 1. The double pipe heat

exchanger is in the vertical position; it is bent 90

degrees twice.

Some geometrical data about the exchanger are

listed in Table 1.

An immersion heater heats water. A constant

speed pump is used to pump the hot water from the

tank into the inner tube. Water returns to the tank

through valve 5. The cold water is supplied

through the mains and drains through valves 2 and

3 in the counterflow and parallel flow conditions

respectively. Shutting the valves 1 and 3 and

opening the valves 2 and 4 achieve the counterflow

conditions, while the parallel flow shutting the

valves 2 and 4 and opening the valves 1 and 3

obtain these conditions.

Temperatures are measured at the inlet and

outlet regions of the exchanger using copper-

constantan thermocouple wires. The locations of

thermocouples are so designed that the cold and

hot stream temperatures at each terminal are

measured at the same cross section. The insulating

material covering the outer tube is 1.5 cm thick. It

can be assumed that no heat from the hot stream

dissipates into the atmosphere.

3. EXPERIMENTAL PROCEDURE,

RESULTS AND ERRORS

Experimental Procedure The overall

characteristics of the exchanger unit are

investigated experimentally. The steps taken are as

follows:

1. Measuring the temperatures of water at the

inlet and outlet sections and also at an

intermediate point half way between the inlet

TABLE 1. The Exchanger Geometrical Data.

The inner tube inner diameter 16.5 mm

The inner tube outer diameter 21.5 mm

The outer tube inner diameter 27.5 mm

The inner tube height 650 mm

The outer tube height 600 mm

Total exchanger length 1500 mm

External tube area 0.101316 m

2

The tube material steel

Heater

Pump

T

c1

T

c2

T

h2

Flowmeter

T

h

Tank

T

h1

1

2 3

4

5

T

c

Figure1. Schematic diagram of the rig circuit.

Archive of SID

www.SID.ir

398 Vol. 15, No. 4, December 2002 IJE Transactions B: Applications

and outlet for each stream, using copper-

constantan thermocouple wires.

2. Measuring the water flow rate for each stream

using calibrated rotameters. Rotameters have

been tested manually by measuring the amount

of fluid collected in a vessel in a certain

amount of time at room temperature.

Rotameters have stainless steel floats.

3. Calculating the overall rate of heat transfer in

the exchanger assuming heat losses from the

outer tube stream to be negligible. Therefore

the overall rate of heat transfer is equal to

either the heat released from the hot stream or

the heat absorbed by the cold stream, namely:

h c

T WC T WC Q ) ( ) ( = =

(6)

4. Calculating the log-mean temperature

difference between the two streams. The total

heat transfer rate from the hot fluid to the cold

fluid in the exchanger is expressed as:

) (LMTD UA Q =

(7)

5. Calculating the overall heat transfer coefficient

at different operating conditions assuming to

be constant throughout the exchanger, using

Equation 7.

6. Calculating the film heat transfer coefficient

for the inner tube side flow, using the Dittus-

Boelter [6] correlation:

n

Nu Pr Re 023 . 0

8 . 0

=

(8)

The value of n is 0.3 if the inner tube side fluid

is being cooled and 0.4 if the inner tube side

fluid is being heated. The Dittus-Boelter

correlation is valid for fully developed

turbulent flow (Re>10000) in smooth tubes for

fluids with Prandtl numbers ranging from

about 0.6 to 100 and with moderate

temperature differences between the wall and

the fluid conditions. The other restriction for

Equation 8 is that it is used when constant heat

flux boundary condition is applied.

7. Calculating the film heat transfer coefficient

for the outer tube side from Equation 17.

Experimental Results The experimental

procedure for each run was to set a pre-defined

temperature and flow rate for the hot water stream,

set the cold water flow rate and then wait for the

steady state conditions to be reached. Following

steps 1 to 7 for each run provides a value for the

heat transfer coefficient of the outer tube flow.

Repeating the experiment for different operating

conditions, results in a set of tabulated data. Table

2 contains a range of 8 operating conditions

measured as described in steps 1 and 2. The first 4

rows correspond to counterflow conditions while

the second 4 rows correspond to parallel flow

conditions.

Tabl e 3 cont ai ns t he heat t ransfer

characteristics calculated as described in steps 3 to

5. Table 3 corresponds to the data listed in Table 2.

Calculating the film heat transfer coefficient for

the tube side flows as mentioned in step 6, requires

one to know viscosity, Reynolds number, Prandtl

TABLE 2. Temperature and Flow Rate Measurements.

T

h1

[C] T

h2

[C] T

hm

[C]

W

h

[kg/s]

T

c1

[C] T

c2

[C] T

cm

[C]

W

c

[kg/s]

1 71.4 61.6 66.4 0.072 25.1 41.3 32.4 0.041

2 69.5 60.4 64.1 0.072 25.9 34.8 26.6 0.067

3 65.6 57.3 61.2 0.072 23.2 33.4 26.3 0.055

4 61.5 54.4 58.3 0.072 24.0 32.5 26.7 0.059

5 63.7 57.3 60.1 0.072 22.3 32.2 27.2 0.042

6 64.4 57.5 60.4 0.072 21.7 33.6 27.8 0.037

7 68.4 62.6 66.3 0.072 26.9 35.7 30.1 0.042

8 66.1 58.9 62.2 0.072 21.5 31.6 26.9 0.049

Archive of SID

www.SID.ir

IJE Transactions B: Applications Vol. 15, No. 4, December 2002 - 399

number, Nusselt number, and conductivity of

water. These data for operating conditions

corresponding to Table 2 are listed in Table 4. The

inner tube side heat transfer coefficients based on

Equation 8 and the outer tube side heat transfer

coefficients based on Equation 17 are listed in

Tables 4 and 6 respectively.

Experimental Errors The accuracy for

measured heat transfer coefficients is affected by

the effectiveness of thermal insulation, the amount

of heat lost to the ambient, the accuracy of

the thermocouple system, and the accuracy of

rotameters. Simple one-dimensional calculations

clearly indicate that 99% of the heat transferred

from the inner tube flow goes to the outer tube

flow and only 1% is lost into the insulation

material. It is estimated that the thermocouple

syst em i ncl udi ng t he t hermocoupl e wi re

variations, digital voltmeter characteristics and

all associated measurements, communications

and transformation procedure is able to give

readings of 0.1

o

C about the true temperature.

The rotameters used to measure the inner tube

and outer tube flow rates were quoted by the

manufacturer as being able to measure to 2%

of the readings. Thus for a typical run, where

the stream temperature difference is about

18

o

C, an error of about:

% 5 . 1 ) 02 . 0 ( )

18

2 . 0

( ) 01 . 0 (

2 2 2

= + +

TABLE 3. Heat Transfer Characteristics of the Exchanger.

Q

h

[kW]

LMTD[C]

U W m C

[ / ]

2

c

Q [kW]

1-Q

c

/Q

h

1 2.956 33.20 879 2.755 6.8%

2 2.745 34.60 783 2.512 8.5%

3 2.504 33.14 746 2.366 5.5%

4 2.142 29.69 712 2.093 2.3%

5 1.931 32.40 588 1.761 8.8%

6 2.082 32.40 634 1.851 11.1%

7 1.750 33.67 513 1.544 11.8%

8 2.172 35.25 608 2.094 3.6%

TABLE 4. Inner Tube Side Heat Transfer Coefficient Deductions.

[ / . ] kg m s

Re Pr Nu

k[W/m.C]

h W m C

i

[ / ]

2

1 0.000439 12585 2.802 59.67 0.658 2380

2 0.000453 12196 2.896 58.75 0.657 2344

3 0.000473 11681 3.037 57.58 0.654 2283

4 0.000493 11207 3.178 56.48 0.651 2229

5 0.000480 11510 3.084 57.19 0.653 2263

6 0.000480 11510 3.084 57.19 0.653 2263

7 0.000439 12585 2.802 59.67 0.658 2380

8 0.000466 11856 2.990 58.02 0.655 2303

Archive of SID

www.SID.ir

400 Vol. 15, No. 4, December 2002 IJE Transactions B: Applications

is expected for the evaluated heat transfer

coefficients. The errors are much greater when the

stream temperature differences are lower. For

example, for the stream temperature difference of

3

o

C, the estimated error in the evaluated heat

transfer coefficients is:

% 7 ) 02 . 0 ( )

3

2 . 0

( ) 01 . 0 (

2 2 2

= + +

The mean heat transfer coefficient, the variance,

the standard deviation and the coefficient of

variation for both counter-flow and parallel-flow

arrangements are listed in Table 7. It can be seen

that for counter-flow arrangement, 75% of the data

are within one standard deviation from the mean

and 100% of the data are within two standard

deviations from the mean. For parallel-flow

arrangement, 50% of the data are within one

standard deviation from the mean and 100% of the

data are within two standard deviations from the

mean.

4. COMPARISON OF DATA WITH

STANDARD CORRELATIONS

The Hausen Correlation The Hausen correlation

[7] may be used for the outer tube flow, in this case

the hydraulic diameter is:

o i e

D D D = (9)

where D

i

is the outer tube inner diameter and D

o

is the inner tube outer diameter, for the case at

hand D

e

is 6 mm. The Hausen correlation reads as

follows:

3

2

04 . 0 1

0668 . 0

66 . 3

Gz

Gz

Nu

+

+ = (10)

where Gz is the Graetz number defined as follows:

L D Gz

e

/ Pr Re = (11)

The results appeared in Table 6 have been

multiplied by 1.2 to take care of the uniform heat

TABLE 5. Outer Tube Heat Transfer Properties.

] . / [ s m kg

Re Pr k

[W/mC]

1 0.000795 1339 5.414 0.6174

2 0.000863 2016 5.93 0.6101

3 0.000877 1629 6.034 0.6087

4 0.000863 1776 5.93 0.6101

5 0.000863 1265 5.93 0.6107

6 0.000850 1131 5.827 0.6116

7 0.000822 1326 5.621 0.6145

8 0.000863 1475 5.93 0.6107

TABLE 6. Comparison between the Experimental Data and the Standard Correlations for Laminar Flow in the Outer Tube.

h W m C

o

[ / . ]

2

experimental data,

Equation (A.5)

Gz=RePrD

e

/L

Graetz number

h W m C

o

[ / . ]

2

Equation 10

h W m C

o

[ / . ]

2

Equation 12

Kays [14] and Sellars

et al [12]

1 1861 29.00 625.2 705.6 473

2 1496 47.82 702 823.2 549

3 1395 39.33 664.8 770.4 507

4 1303 42.13 678 789.6 519

5 933 30.00 624 705.6 489

6 1054 26.36 607.2 676.8 459

7 741 29.81 626.4 709.2 481

8 974 35 646.8 742.8 499

Archive of SID

www.SID.ir

IJE Transactions B: Applications Vol. 15, No. 4, December 2002 - 401

flux boundary condition at the surface of the

existing heat exchanger. This is because the

Hausen correlation is for isothermal wall.

Table 5 includes viscosity, Reynolds number,

Prandtl number, Nusselt number and conductivity

of the outer tube stream corresponding to the

operating conditions listed in Table 2.

The experimental heat transfer coefficients are

then calculated using Equation 17 and inserted in

Table 6.

The outer tube heat transfer coefficients

evaluated according to the Hausen correlation and

using the data listed in Table 5 are included in

Table 6. The outer tube heat transfer coefficients

can now be compared with those evaluated

experimentally. The comparison is illustrated in

Figures 2 and 3 for the counterflow and parallel

flow conditions respectively. The points indicated

by symbol ! are predictions of the Hausen

correlation, while the points indicated by symbol !

are the experimental results.

It should be mentioned that some different

combinations of standard correlations have been

recommended to predict the film heat transfer

coefficients of inner tube flow and outer tube flow

by different workers. For example the ESDU [5]

and the Kern [10] correlations are used to predict

the inner tube side and the outer tube side heat

transfer coefficients, respectively in the TASC [11]

computer program.

It is evident that the results obtained by the

independent workers are different from each other.

Figure2. The outer tube side heat transfer coefficients-Counterflow.

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

1000 1200 1400 1600 1800 2000 2200

Re

h

Test

Eq. 10

Eq. 12

Fig. 4

Table7. Statistical Analysis of Experimental Data

for Heat Transfer Coefficient of Flow in the Outer Tube

Mean Heat Transfer

Coefficient

Variance Standard Deviation Coefficient of

Variation

Counter-flow 1514 44854 212 0.14

Parallel-flow 926 13240 115 0.124

Archive of SID

www.SID.ir

402 Vol. 15, No. 4, December 2002 IJE Transactions B: Applications

The Dittus-Boelter [6] and Hausen [7] correlations

have been used to predict the film heat transfer

coefficients of inner tube flow and outer tube flow,

respectively, and the results have been compared

with those deduced experimentally in Table 6. Two

other correlations are used to predict the film heat

transfer coefficients of the outer tube side in the

same manner as the Hausen correlation was

applied and the results will be compared with those

deduced experimentally in Table 6. In these two

cases the Dittus-Boelter [6] correlation is

monotonically used to predict the film heat transfer

coefficients of the inner tube side.

The Sieder-Tate correlation The Sieder-Tate

[12] correlations have been used to design the

double pipe heat exchangers since 1950 and they

are strongly recommended by Kern [10] in his old

but reliable text. The Sieder-Tate correlations can

be used for predicting the film coefficients of flow

in both the inner tube side and the outer tube side

of a double pipe heat exchanger. They can be used

for both heating and cooling of a number of fluids,

principally petroleum fractions, in horizontal and

vertical tubes:

14 . 0

3

1

3

1

3

1

) ( ) ( Pr Re 86 . 1

w

L

D

Nu

= (12)

The results appeared in Table 6 have been

multiplied by 1.2 to take care of the uniform heat

flux boundary condition at the surface of the

existing heat exchanger. This is because the

Sieder-Tate correlation is for isothermal wall.

Equation 12 applies for laminar flow (Re<2100). L

is the total heat transfer length. The outer tube heat

transfer coefficients are recalculated based on

Equation 12. The results are included in Table 6

and the comparison is shown in Figures 2 and 3 for

the counterflow and parallel flow conditions

respectively. The points indicated by the symbol !

are predictions of the Sieder-Tate correlation,

while the points indicated by the symbol ! are the

experimental results.

The Heat Exchanger Design Handbook, HEDH

[13], has also recommended the Sieder-Tate

correlations to be used for predicting the film

coefficients of single-phase flow in both the inner

tube and the outer tube of a double pipe heat

exchanger.

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

Re

h

Test

Eq. 10

Eq. 12

Fig. 4

Figure 3. The outer tube side heat transfer coefficients-Parallel flow.

Archive of SID

www.SID.ir

IJE Transactions B: Applications Vol. 15, No. 4, December 2002 - 403

The Kays and Sellars, Tribus and Klein

Predictions Kays [8] and Sellars, Tribus, and

Klein [9] calculated the total and average

Nusselt numbers for laminar entrance regions of

circular tubes for the case of a fully developed

velocity profile. The results of their analyses

are shown as the variation of average Nusselt

number in terms of the inverse of Graetz number

[14]. Figure 4 is a graphical presentation of the

average Nusselt numbers for circular tube

thermal entrance region in fully developed

laminar flow, deduced by Kays, and Sallars

[14], introduced here as a source of comparison.

The outer tube heat transfer coefficients are

recalculated based on the above predictions. The

results are included in Table 6 and the comparison

is shown in Figures 2 and 3 for the counterflow

and parallel flow conditions respectively. The

points indicated by the symbol in Figures 2

and 3 are predictions of the Kays and Sellars et

al (extracted from Figure 4), while the points

indicated by the symbol ! are the experimental

results.

5. CONCLUSIONS

The outer tube side heat transfer coefficients

deduced from experimental data are compared with

those evaluated based on standard correlations.

The comparison is illustrated schematically in

Figures 2 and 3 for counterflow and parallel flow

conditions, respectively.

In both the counterflow and parallel flow

conditions, all three standard correlations predict

lower heat transfer coefficients compared with the

experimental results. The Sieder-Tate [12]

correlation predicts the highest values among the

three standard correlations; they are still lower by a

factor of 1.04 to 2.64. That means, the standard

correlations for laminar flow in the outer tube side

in which the Nusselt numbers are proportional to

Re

0.33

underestimate the heat transfer coefficients.

The differences between the predictions of

standard correlations (Equation 10, Equation 12

and Figure 4) as shown in Figures 2 and 3 are not

considerable. This close agreement for empirical

correlations is rather strange. In fact a simple or

0

2

4

6

8

0

2

4

0.0001 0.001 0.01 0.1 1

Inverse Graetz numbe

A

v

e

r

a

g

e

N

u

s

s

e

l

t

n

u

m

b

e

r

Inverse Graetz number

Figure 4. Average Nusselt numbers for circular tube thermal entrance regions in fully developed laminar flow [11].

Archive of SID

www.SID.ir

404 Vol. 15, No. 4, December 2002 IJE Transactions B: Applications

minor error could have brought the results

together.

The outer tube side Reynolds numbers are

lower by a factor of 6 to 10 (third column in Tables

5 and 6), but the hydraulic diameter is lower by a

factor of nearly 3 (Table 1). Therefore, if a Dittus-

Boelter type of correlation (Equation 8) is valid for

both the outer and inner tube side streams, the

outer tube side heat transfer coefficients would be

expected to be smaller than the inner tube side heat

transfer coefficients by a factor of:

7 . 1 )

3

1

( ) 8 ( ) ( )

Re

Re

(

8 . 0 8 . 0

=

i

o

o

i

o

i

D

D

h

h

The above ratio for the experimental results ranges

between 1.28 and 1.71 for the counterflow

arrangement, and between 2.15 and 4.62 for the

parallel flow arrangement. The agreement with

predictions is very good for the counterflow

arrangement, but not very good for the parallel

flow arrangement. The discrepancy may be

because of four reasons. Firstly, there was

probably heat transfer in regions between the

thermocouple wires and the exchanger terminals,

so that the actual heat transfer area was larger than

calculated. Secondly, there was probably a higher

coefficient in certain regions, such as in turnaround

region, than predicted by straight pipe equation.

Thirdly, the effect of natural convection in internal

flows, especially when the forced and free

convection currents are in the same direction

(aiding flow), can enhance the heat transfer

coefficients by a factor of 1.41compared with the

case when the heat transfer mechanism is assumed

strictly on the basis of laminar forced convection

[solved example in 14]. Fourthly, the standard

correlations are generally presented for the smooth

heat transfer surfaces, while in a real exchanger the

heat transfer surfaces are not smooth and those

results in higher heat transfer coeffficiets.

Temperatures have been rounded to the nearest

decimal. Stream temperature differences ranged

from 3 to 18 degrees. Stream flow rates are likely

to be in error by 2 percent. The heat loss through

the thermal insulation is about 1%. With this error

analysis, the error in the measured heat transfer

coefficients is 1.5-7 percent.

Hewitt et al [15] and also HEDH [13] have

recommended that the Dittus-Boelter correlation

(Equation 8) with n=0.4 to be used for predicting

the film coefficients of both the inner tube side and

the outer tube side flows for both laminar and

turbulent flows. Using the Dittus-Boelter

correlation with Re

0.8

for the laminar flow in the

outer tube side increases the heat transfer

coefficients by a factor 2 to 3. That makes us

believe that Hewitt et al [15] and also HEDH [13]

are correct.

The experimental heat transfer coefficients do

not have a direct relationship with the outer tube

side Reynolds numbers. This behaviour is not

repeated by any of the standard correlations. This

is because the experimental heat transfer

coefficients are governed by the overall heat

transfer coefficients (Equation. 17), rather than by

the Reynolds number.

The purpose of this article is to recognise the

mechanisms of heat transfer that occur in double

pipe heat exchangers and to report higher heat

transfer coefficients in the laminar flow regime.

The phenomena that contribute to the heat transfer

enhancement are mainly natural convection,

secondary flows, and surface roughness. There are

of course other reasons for this enhancement that

need to be studied experimentally. The question

that what fraction of this enhancement is because

of natural convection, secondary flows, and surface

roughness is still unanswered.

6. NOMENCLATURE

A Tube area exposed to heat transfer, m

2

C Stream specific heat, J kg C / .

d

i

Inner tube inner diameter, m

D

i

Outer tube inner diameter, m

D

o

Inner tube outer diameter, m

De Dean number =

c i

R r / Re

Gr Grashof number

Gz Graetz number

h Film heat transfer coefficient,

W m C / .

2

k Thermal conductivity, W m C / .

L Total length exposed to heat transfer, m

LMTD Logarithmic Mean Temperature

Archive of SID

www.SID.ir

IJE Transactions B: Applications Vol. 15, No. 4, December 2002 - 405

Difference, C

n Exponent in Equation. 8

Nu Nusselt number

Pr Prandtl number

Q Heat transfer rate, W

r

i

Inner tube inner radius, m

r

o

Inner tube outer radius, m

R

c

Bend radius measured to

centerline of U-tube, m

Re Reynolds number

T Stream temperature, C

U Overall heat transfer

coefficient, W m C / .

2

W Stream mass flow rate, kg/s

Dynamic viscosity, kg/m.s

7. SUBSCRIPTS

c Cold

e Equivalent

i Inner

h Hot

o Outer

w Wall

8. APPENDIX

The heat transfer rate in a composite cylindrical

wall is expressed in terms of the total temperature

difference and the resistance of different layers:

( )

( ) ( ) ( )

o o i o i i

c h

A h kL r r A h

T T Q

/ 1 2 / / ln / 1

/

+ +

=

(13)

The overall heat transfer coefficient is defined as

the inverse of the sum of resistances to heat flow,

so that Equation 13 reduces to:

) (

c h

T T UA Q = (14)

where U can be defined in terms of either the

internal or external tube areas. In each case

Equation 14 applies:

) ( ) (

c h o o c h i i

T T A U T T A U Q = = (15)

The values of U

i

and U

o

are as follows:

( ) ( ) ( )

o o i i o i i

i

A h A kL r r A h

U

/ 2 / / ln / 1

/ 1

+ +

=

(16)

and

( ) ( ) ( )

o i o o i i o

o

h kL r r A h A A

U

/ 1 2 / / ln /

/ 1

+ +

=

(17)

T T

h c

is the temperature difference between the

hot and cold fluids at a local point. This

temperature difference varies with position along

the path of flow. To determine the rate of heat

transfer between the hot and cold fluids is therefore

a complicated matter. In practice it is convenient to

use an average effective temperature difference for

the entire heat exchanger. Only if the overall heat

transfer coefficient, U, is constant, this average

effective temperature difference turns out to be the

logarithmic mean temperature difference, LMTD,

defined as:

( )

( ( ) ( ) )

1 1 2 2

1 1 2 2

/ ln

/ ) ( ) (

c h c h

c h c h

T T T T

T T T T LMTD

=

(18)

The subscripts used in Equation 18 are consistent

with those used in Table 2 and therefore apply for

parallel flow conditions only. In counterflow

conditions, however, the subscripts 1 and 2 for the

cold fluid temperatures must be replaced.

9. REFERENCES

1. Abdelmessih, A. N., and Bell, K. J., Effect of Mixed

Convection and U-Bends on the Design of Double Pipe

Heat Exchangers, Heat Transfer Engineering, Vol. 20,

No. 3, (1999), 25-36.

2. Abdelmessih, A. N., and Bell, K. J., Laminar Flow Heat

Archive of SID

www.SID.ir

406 Vol. 15, No. 4, December 2002 IJE Transactions B: Applications

Transfer Downstream from U-Bends, Proc. Second U.

K. Natl. Conf. Heat Transfer, Vol. II, (1988), 1087-1100.

3. Abdelmessih, A. N., Laminar Flow Heat Transfer

Downstream from U-Bends, Ph. D. Thesis, Oklahoma

State University, Stillwater, OK, (1987).

4. Shome, B. and Jensen, M. K., Mixed Convection

Laminar Flow and Heat Transfer of Liquids in Isothermal

Horizontal Circular Ducts, I nt. J . Heat Mass Transfer,

Vol. 38, No. 11, (1995), 1945-1956.

5. Engineering Science Data Unit, Paper 67016, 1967; Paper

68007, 1968; Paper 68006 with amendment A, (1970), 4,

Hamilton Place, London.

6. Dittus, F. W., and Boelter, L. M. K., Univ. Calif.

(Berkeley) Pub. Eng., Vol. 2, (1930), 443-450.

7. Hausen, H., Darstellung des Warmeuberganges in

Rohren Durch Verallgemeinerte Potenzbeziehungen,

VDI Z., No. 4, (1943), 91-99.

8. Kays, W. M., Convective Heat and Mass Transfer,

McGraw-Hill, New York, (1966), 187-190.

9. Sellars, J. R., Tribus, M. and Klein J. S., Heat Transfer

to Laminar Flows in a Round Tube or Flat Conduit: The

Graetz Problem Extended, Trans. ASME, Vol. 78,

(1956), 441-451.

10. Kern, D. Q., Process Heat Transfer, McGraw-Hill, New

York, (1950).

11. Heat Transfer and Fluid Flow Services News Sheet, No.

6, (December 1985), 12-21.

12. Sieder, E. N., and Tate, F. E. Heat Transfer and Pressure

Drop in Tubes, I nd. Eng. Chem., Vol. 28, (1936), 1429-

1436.

13. Schlunder, E. U., Editor-in-Chief, Heat Exchanger

Design Handbook, Section 3.2, Hemisphere Publishing

Corporation, New York, (1989).

14. Holman, J.P., Heat Transfer, Eighth Edition, McGraw-

Hill, New York, (1996).

15. Hewitt, G. F., Shires, G. L. and Bott, T. R., Process Heat

Transfer, CRC Press, London, ISBN 0-8493-9918-1,

(1994).

Archive of SID

www.SID.ir

Vous aimerez peut-être aussi

- CMEM01060FUDocument12 pagesCMEM01060FUAbeje AlemnewPas encore d'évaluation

- Review B InggrisDocument10 pagesReview B InggrisWillyam PrizkiabiPas encore d'évaluation

- Heat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersDocument5 pagesHeat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersShalehAhmad100% (1)

- Thermal Analysis of A Commercial Plate Fin Heat Exchanger With Non-Uniform Inlet Flow ConditionsDocument47 pagesThermal Analysis of A Commercial Plate Fin Heat Exchanger With Non-Uniform Inlet Flow ConditionsdondiPas encore d'évaluation

- Heat Transfer Augmentation Using Twisted Wire Mesh InsertsDocument5 pagesHeat Transfer Augmentation Using Twisted Wire Mesh InsertsVeeresh FuskelePas encore d'évaluation

- Heat Transfer in a Horizontal Coiled Pipe at Near-Critical PressureDocument5 pagesHeat Transfer in a Horizontal Coiled Pipe at Near-Critical PressureM. SukarmanPas encore d'évaluation

- Double Pipe Heat ExchangerDocument21 pagesDouble Pipe Heat ExchangerIsabel GarciaPas encore d'évaluation

- Thermal Analysis of Multi-Row Cross-Flow Heat ExchangersDocument6 pagesThermal Analysis of Multi-Row Cross-Flow Heat ExchangersnaveenPas encore d'évaluation

- PressurenDrop in Double Pipe Heat ExchangersDocument5 pagesPressurenDrop in Double Pipe Heat ExchangersdikimPas encore d'évaluation

- Fahad Sauod Opt.Document23 pagesFahad Sauod Opt.Haitham AliPas encore d'évaluation

- 5Document8 pages5Anwar ALkurayshiPas encore d'évaluation

- Double Pipe Heat Exchanger Heat Transfer CoefficientsDocument12 pagesDouble Pipe Heat Exchanger Heat Transfer CoefficientsParthibanPas encore d'évaluation

- Two-Phase Condensation Heat Transfer ModelsDocument14 pagesTwo-Phase Condensation Heat Transfer ModelsaldaadrinaPas encore d'évaluation

- Chapter 5 - Heat ExchangerDocument48 pagesChapter 5 - Heat ExchangerHoneydaa FitraPas encore d'évaluation

- Research Inventy: International Journal of Engineering and ScienceDocument5 pagesResearch Inventy: International Journal of Engineering and ScienceinventyPas encore d'évaluation

- Performance Analysis of Shell and Tube Heat ExchangersDocument5 pagesPerformance Analysis of Shell and Tube Heat ExchangersMichał KisielewskiPas encore d'évaluation

- Heat Transfer in Staggered Tube BanksDocument9 pagesHeat Transfer in Staggered Tube BanksMohammed Bate'ePas encore d'évaluation

- Forced ConvectionDocument9 pagesForced ConvectionAmeer ShPas encore d'évaluation

- Direq/CorDocument64 pagesDireq/CorMohamed Ben MansourPas encore d'évaluation

- Lab 2 Full Reprt HEx DoaaDocument22 pagesLab 2 Full Reprt HEx DoaaDoaa BadarnehPas encore d'évaluation

- Analysis of flow and heat transfer characteristics of an asymmetrical flat plate heat pipeDocument13 pagesAnalysis of flow and heat transfer characteristics of an asymmetrical flat plate heat pipe李品賢Pas encore d'évaluation

- Shell and Tube Heat ExchangerDocument12 pagesShell and Tube Heat ExchangerZi ChingPas encore d'évaluation

- Transient Simulation of Vapor LiqDocument5 pagesTransient Simulation of Vapor LiqsantoshkumarvenuPas encore d'évaluation

- CFD Analysis of Shell-and-Tube Heat Exchanger DesignDocument15 pagesCFD Analysis of Shell-and-Tube Heat Exchanger DesignHari SimhaPas encore d'évaluation

- Mal Distribution in PCHEDocument13 pagesMal Distribution in PCHEVinayak AgarwalPas encore d'évaluation

- Theoretical Solution For The CrossflowDocument17 pagesTheoretical Solution For The CrossflowAndriano Suryawan UtamaPas encore d'évaluation

- Heat Transfer Final PaperDocument14 pagesHeat Transfer Final PaperGilbert RacinesPas encore d'évaluation

- An Engineering Model of Coils and Heat Exchangers For HVAC System Simulation and OptimizationDocument6 pagesAn Engineering Model of Coils and Heat Exchangers For HVAC System Simulation and Optimizationsilentsoldier781344Pas encore d'évaluation

- HEDocument10 pagesHEMohamed BelallPas encore d'évaluation

- Exhaust ManifoldDocument5 pagesExhaust ManifoldDeepak Chachra100% (1)

- Parametric Study Concentric048Document6 pagesParametric Study Concentric048Narayana Swamy GPas encore d'évaluation

- Applied Energy: Junye WangDocument8 pagesApplied Energy: Junye WangResearcherzPas encore d'évaluation

- Lab 5 Heat ExchangerDocument13 pagesLab 5 Heat ExchangerNur Syuhaidah100% (1)

- Eteiac1411 (Heat Exchanger)Document6 pagesEteiac1411 (Heat Exchanger)Evans IraborPas encore d'évaluation

- Numerical Analysis of Heat Transfer Enhancement in Pipe-inPipe Helical Coiled Heat ExchangersDocument6 pagesNumerical Analysis of Heat Transfer Enhancement in Pipe-inPipe Helical Coiled Heat ExchangersIOSRjournalPas encore d'évaluation

- 5316ijmech02 PDFDocument8 pages5316ijmech02 PDFNickPas encore d'évaluation

- Heat Transfer and CombustionDocument9 pagesHeat Transfer and CombustionmihailmiPas encore d'évaluation

- ENCH607-F2012-L07-Heat Transfer and Heat Transfer EquipmentDocument113 pagesENCH607-F2012-L07-Heat Transfer and Heat Transfer EquipmentmadithakPas encore d'évaluation

- Enhancement of Heat Transfer Rate of Tube in Tube Helical Coil Heat ExchangerDocument7 pagesEnhancement of Heat Transfer Rate of Tube in Tube Helical Coil Heat ExchangerInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Analysis of Helical Coil Heat Exchangers: by V.Swapna Priya Guide R S MauryaDocument23 pagesAnalysis of Helical Coil Heat Exchangers: by V.Swapna Priya Guide R S MauryaSwapna Priya VattemPas encore d'évaluation

- Heat Exchanger PDFDocument9 pagesHeat Exchanger PDFsunita45Pas encore d'évaluation

- Heat Transfer in Internal Combustion EnginesDocument7 pagesHeat Transfer in Internal Combustion EnginesMishelPas encore d'évaluation

- Heat ExchangerDocument25 pagesHeat ExchangerFarisRazzak67% (3)

- Heat Transfer Processes in Detergent IndustryDocument17 pagesHeat Transfer Processes in Detergent Industryعبدالمحسن علي EPas encore d'évaluation

- Accepted ManuscriptDocument38 pagesAccepted ManuscriptNaveen KumarPas encore d'évaluation

- Experimental Determination of Fouling Factor On Plate Heat Exchangers in District Heating System PDFDocument8 pagesExperimental Determination of Fouling Factor On Plate Heat Exchangers in District Heating System PDFarianaseriPas encore d'évaluation

- Analysis of Counter Flow Heat ExchangerDocument5 pagesAnalysis of Counter Flow Heat ExchangerSantiKhamtreePas encore d'évaluation

- Thermal Resistance of Steam Condensation in Horizontal Tube BundlesDocument8 pagesThermal Resistance of Steam Condensation in Horizontal Tube BundlesRavinder SinghPas encore d'évaluation

- CFD Studies in The Prediction of Thermal Striping in An LMFBRDocument12 pagesCFD Studies in The Prediction of Thermal Striping in An LMFBRjofredjosephPas encore d'évaluation

- Thermal Analysis of Various Duct Cross S PDFDocument10 pagesThermal Analysis of Various Duct Cross S PDFRajesh SamalPas encore d'évaluation

- Models - Heat.turbulent Heat ExchangerDocument18 pagesModels - Heat.turbulent Heat ExchangerMaximiliano FaríaPas encore d'évaluation

- Fall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFDocument68 pagesFall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFMashaelPas encore d'évaluation

- General Steady State Model for Fin-and-Tube Heat ExchangersDocument9 pagesGeneral Steady State Model for Fin-and-Tube Heat ExchangersLỢI NGUYỄN CÔNGPas encore d'évaluation

- Ts-3 Thermal Performance and Pressure Drop of The Helical-Coil Heat Ex Changers With and Without Helically Crimped FinsDocument10 pagesTs-3 Thermal Performance and Pressure Drop of The Helical-Coil Heat Ex Changers With and Without Helically Crimped FinsSoham PatilPas encore d'évaluation

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringD'EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringPas encore d'évaluation

- A Modern Course in Statistical PhysicsD'EverandA Modern Course in Statistical PhysicsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- HPL HowTo PDFDocument9 pagesHPL HowTo PDFAndrew FongPas encore d'évaluation

- 106 BDocument11 pages106 BEngr. AbdullahPas encore d'évaluation

- 106 BDocument11 pages106 BEngr. AbdullahPas encore d'évaluation

- SyllabusDocument2 pagesSyllabusEngr. AbdullahPas encore d'évaluation

- A10541191S19Document5 pagesA10541191S19Engr. AbdullahPas encore d'évaluation

- Thesis3 Low Cost Monitoring System For Solar SystemDocument125 pagesThesis3 Low Cost Monitoring System For Solar SystemEngr. AbdullahPas encore d'évaluation

- Thesis3 Low Cost Monitoring System For Solar SystemDocument125 pagesThesis3 Low Cost Monitoring System For Solar SystemEngr. AbdullahPas encore d'évaluation

- A10541191S19Document5 pagesA10541191S19Engr. AbdullahPas encore d'évaluation

- L Ccompxe 2011 Sp1.11.339 Release Notes en USDocument39 pagesL Ccompxe 2011 Sp1.11.339 Release Notes en USEngr. AbdullahPas encore d'évaluation

- Ref - 2 Dorin Bica PDFDocument7 pagesRef - 2 Dorin Bica PDFEngr. AbdullahPas encore d'évaluation

- Sys Design Course ContentsDocument4 pagesSys Design Course ContentsEngr. AbdullahPas encore d'évaluation

- Ref - 1 IEEE Committee Report PDFDocument12 pagesRef - 1 IEEE Committee Report PDFEngr. AbdullahPas encore d'évaluation

- Fault DiagnisisDocument8 pagesFault DiagnisisEngr. AbdullahPas encore d'évaluation

- SyllabusDocument2 pagesSyllabusEngr. AbdullahPas encore d'évaluation

- TORQUE Administrators Guide PDFDocument238 pagesTORQUE Administrators Guide PDFEngr. AbdullahPas encore d'évaluation

- Roll Torque UsersguideDocument13 pagesRoll Torque UsersguideEngr. AbdullahPas encore d'évaluation

- Friction Factor CalDocument13 pagesFriction Factor CalEngr. AbdullahPas encore d'évaluation

- Friction Factor ExperimentDocument3 pagesFriction Factor ExperimentEngr. AbdullahPas encore d'évaluation

- StanfordHPCConf Rocks PresoDocument59 pagesStanfordHPCConf Rocks PresoEngr. AbdullahPas encore d'évaluation

- Quickspecs: Microsoft Windows Server 2012 R2 Microsoft Windows Server 2012 R2Document18 pagesQuickspecs: Microsoft Windows Server 2012 R2 Microsoft Windows Server 2012 R2Engr. AbdullahPas encore d'évaluation

- Defined and Described: Figure 2. Transformer-Coupled SSR Figure 1. Hybrid SSRDocument5 pagesDefined and Described: Figure 2. Transformer-Coupled SSR Figure 1. Hybrid SSRpidmap2Pas encore d'évaluation

- Cyber Essentials Requirements PDFDocument17 pagesCyber Essentials Requirements PDFEngr. AbdullahPas encore d'évaluation

- RCI QuestionDocument4 pagesRCI QuestionEngr. AbdullahPas encore d'évaluation

- Experiences Setting Up A Rocks Based Linux Cluster: Tomas Lind en Helsinki Institute of Physics CMS Programme 08.12.2003Document29 pagesExperiences Setting Up A Rocks Based Linux Cluster: Tomas Lind en Helsinki Institute of Physics CMS Programme 08.12.2003Engr. AbdullahPas encore d'évaluation

- Cyber Essentials Requirements PDFDocument17 pagesCyber Essentials Requirements PDFEngr. AbdullahPas encore d'évaluation

- Friction Factor ExperimentDocument3 pagesFriction Factor ExperimentEngr. AbdullahPas encore d'évaluation

- FF Lab ReportDocument3 pagesFF Lab ReportEngr. AbdullahPas encore d'évaluation

- Computing Fourier Series and Power Spectrum With MATLAB: TEX PaperDocument15 pagesComputing Fourier Series and Power Spectrum With MATLAB: TEX PaperekhadhanaPas encore d'évaluation

- Verification of BernoulliDocument2 pagesVerification of BernoulliEngr. AbdullahPas encore d'évaluation

- DPHX Report G5Document13 pagesDPHX Report G5Engr. AbdullahPas encore d'évaluation

- Cau Truc To HopDocument1 258 pagesCau Truc To Hopkhôi trươngPas encore d'évaluation

- Abm Trial Balance ActivityDocument3 pagesAbm Trial Balance ActivityRoxanne RoldanPas encore d'évaluation

- ABE College Manila. 2578 Legarda Avenue Sampaloc, ManilaDocument11 pagesABE College Manila. 2578 Legarda Avenue Sampaloc, ManilaRonalie SustuedoPas encore d'évaluation

- Theory of Elinor OstromDocument5 pagesTheory of Elinor OstromSanjana KrishnakumarPas encore d'évaluation

- Delivering Large-Scale IT Projects On Time, On Budget, and On ValueDocument5 pagesDelivering Large-Scale IT Projects On Time, On Budget, and On ValueMirel IonutPas encore d'évaluation

- Office of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)Document44 pagesOffice of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)T.O. Nature & DevelopmentPas encore d'évaluation

- Compound Interest Factor PDFDocument32 pagesCompound Interest Factor PDFFelicia TayPas encore d'évaluation

- List of Family Outing EpisodesDocument7 pagesList of Family Outing EpisodesFanny KesumaliaPas encore d'évaluation

- Install MATV Distribution SystemDocument7 pagesInstall MATV Distribution SystemDong VanraPas encore d'évaluation

- Memorandum of AgreementDocument4 pagesMemorandum of AgreementMarvel FelicityPas encore d'évaluation

- Understanding ProbabilityDocument14 pagesUnderstanding ProbabilityKajaraiPas encore d'évaluation

- Ciphertext-Policy Attribute-Based EncryptionDocument15 pagesCiphertext-Policy Attribute-Based EncryptionJ_RameshPas encore d'évaluation

- Visual Basic Is Initiated by Using The Programs OptionDocument141 pagesVisual Basic Is Initiated by Using The Programs Optionsaroj786Pas encore d'évaluation

- Bigdata 2016 Hands On 2891109Document96 pagesBigdata 2016 Hands On 2891109cesmarscribdPas encore d'évaluation

- Why The Bollard Pull Calculation Method For A Barge Won't Work For A Ship - TheNavalArchDocument17 pagesWhy The Bollard Pull Calculation Method For A Barge Won't Work For A Ship - TheNavalArchFederico BabichPas encore d'évaluation

- Focus ManualDocument597 pagesFocus ManualSabareesan SundarPas encore d'évaluation

- Lab 8 Introduction To XML: Exercise 1Document4 pagesLab 8 Introduction To XML: Exercise 1HasanPas encore d'évaluation

- Netflix AccountsDocument2 pagesNetflix AccountsjzefjbjePas encore d'évaluation

- Nca Lahore Nca Lahore Nca LahoreDocument1 pageNca Lahore Nca Lahore Nca LahoreSalman QaiserPas encore d'évaluation

- Case Study ExamplesDocument18 pagesCase Study ExamplesSujeet Singh BaghelPas encore d'évaluation

- Time Division Muliple AccessDocument4 pagesTime Division Muliple AccessAbhishek RanaPas encore d'évaluation

- American Civil War, WikipediaDocument32 pagesAmerican Civil War, WikipediaMariko100% (1)

- Data Sheet 3VA2225-5HL32-0AA0: ModelDocument7 pagesData Sheet 3VA2225-5HL32-0AA0: ModelJENNYPas encore d'évaluation

- Philippine Constitutional Commissions Powers and FunctionsDocument36 pagesPhilippine Constitutional Commissions Powers and Functionssharlica1990Pas encore d'évaluation

- Cement Lined Piping SpecificationDocument167 pagesCement Lined Piping SpecificationvenkateshwaranPas encore d'évaluation

- DowerDocument7 pagesDowerabrash111Pas encore d'évaluation

- Princeton Review GRE ScheduleDocument1 pagePrinceton Review GRE ScheduleNishant PanigrahiPas encore d'évaluation

- Chapter 3 Views in ASP - NET CoreDocument23 pagesChapter 3 Views in ASP - NET Coremohammadabusaleh628Pas encore d'évaluation

- Development Approach PlanDocument15 pagesDevelopment Approach PlanGaurav UpretiPas encore d'évaluation

- Zelio Plug-In Relays: RPM Power RangeDocument16 pagesZelio Plug-In Relays: RPM Power RangeSimon MounePas encore d'évaluation