Académique Documents

Professionnel Documents

Culture Documents

FM Lab Manual 2014

Transféré par

Karthik Perumal SwamyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FM Lab Manual 2014

Transféré par

Karthik Perumal SwamyDroits d'auteur :

Formats disponibles

AL - AMEEN ENGINEERINGCOLLEGE

Erode - 638 104

DEPARTMENT OF MECHANICAL ENGINEERING

Fluid Mec!"ic# !"d M!ci"er$

L!%or!&or$ Record

A LIST OF BASIC SAFETY RULES

1. When you handle chemicals wear eye protection (chemical splash goggles or full

face shield).

2. When you work with furnaces for heat treatment procedures or other thermally

activated equipment you should use special gloves to protect your hands.

3. Students should wear durale clothing that covers the arms! legs! torso and feet.

("ote# sandals! shorts! tank tops etc. have no place in the la. Students

inappropriately dressed for la! at the instructors discretion! e denied access)

$. %o protect clothing from chemical damage or other dirt! wear a la apron or la coat.

&ong hair should e tied ack to keep it from coming into contact with la chemicals

or flames.

'. (n case of in)ury (cut! urn! fire etc.) notify the instructor immediately.

*. (n case of a fire or imminently dangerous situation! notify everyone who may e

affected immediately+ e sure the la instructor is also notified.

,. (f chemicals splash into someone-s eyes act quickly and get them into the eye wash

station! do not wait for the instructor.

.. (n case of a serious cut! stop lood flow using direct pressure using a clean towel!

notify the la instructor immediately.

/. 0ating! drinking and smoking are prohiited in the laoratory at all times.

11. "ever work in the laoratory without proper supervision y an instructor.

11. "ever carry out unauthori2ed e3periments. 4ome to the laoratory prepared. (f you

are unsure aout what to do! please ask the instructor.

12. 5lways rememer that 67% metal or ceramic pieces look e3actly the same as 47&8

pieces are careful what you touch.

13. 9now the location and operation of #

:ire 5larm ;o3es

03it 8oors

%elephones

INDEX

S.No DATE NAME OF THE EXPERIMENT MARK SIGNATURE

1

2

3

4

5

6

7

!

1"

11

12

Co#$%&'&( ()'&*

A+&,)-& M),.* S')// 0 12 0 34),-&

FLUID MECHANICS AND MACHINERY LAB

1. 8etermination of the coefficient of discharge of given 7rifice meter.

2. 8etermination of the coefficient of discharge of given <enturi meter.

3. 4alculation of the rate of flow using =ota meter.

$. 8etermination of friction factor of given set of pipes.

'. 4onducting e3periments and drawing the characteristics curves of centrifugal pump.

*. 4onducting e3periments and drawing the characteristics curves of reciprocating

pump.

,. 4onducting e3periments and drawing the characteristics curves of >ear pump.

.. 4onducting e3periments and drawing the characteristics curves of ?elton wheel.

/. 4onducting e3periments and drawing the characteristics curves of :rancis turine.

11. 4onducting e3periments and drawing the characteristics curves of 9aplan turine.

5ENTURIMETER6 ORIFICEMETER AND ROTAMETER TEST RIG

1 2

DETERMINATION OF THE CO0EFFICIENT OF

DISCHARGE OF GI5EN ORIFICE METER

AIM*

%o determine the co@efficient discharge through orifice meter

APPARATUS RE7UIRED*

1. 7rifice meter

2. 8ifferential A tue

3. 4ollecting tank

$. Stop watch

'. Scale

FORMULAE*

1. ACTUAL DISCHARGE#

B

act

C 5 3 h D t (m

3

D s)

2. THEORTICAL DISCHARGE#

Where#

B

th

C a

1

3 a

2

3 2 g h D a

2

E a

2

(m

3

D s)

Where#

5 C 5rea of collecting tank in m

2

h C 6eight of collected water in tank C 11 cm

a

1

C 5rea of inlet pipe in! m

2

a

2

C 5rea of the throat in m

2

g C Specify gravity in m D s

2

t C %ime taken for h cm rise of water

6 C 7rifice head in terms of flowing liquid

C (6

1

F 6

2

) (s

m D

s

1 @

1)

61 C Ganometric head in first lim

62 C Ganometric head in second lim

s

m

C Specific gravity of Ganometric liquid

81.&.9 L1:;1( #&,3;,< H- = 13.6

s

1

C Specific gravity of flowing liquid water C 1

S.No

D1)#&'&,

12 ##

M)2o#&',13

,&)(12-

M)2o#&',13

4&)(

H=8H1>H29

? 12.6 ? 1"

02

T1#& ').&2 /o,

4 3# ,1@&

o/

A)'&,

'

S&3

A3';)%

(1@34),-&

03

7 )3' ? 1"

#

3

B @

T4&o,&'13)%

(1@34),-& 7'4

03

? 1"

#

3

B @

Co0&//131&2' o/

(1@34),-& C(

82o ;21'9

H1 3#

o/ H-

H2 3#

o/ H-

M&)2 C( =

3. CO EFFICENT OF DISCHARGE*

4o@ efficient of discharge C B act D B th (no units)

DESCRIPTION*

7rifice meter has two sections. :irst one is of area a

1

! and second one of area a

2!

it

does not have throat like venturimeter ut a small holes on a plate fi3ed along the diameter

of pipe. %he mercury level should not fluctuate ecause it would come out of manometer.

PROCEDURE*

1. %he pipe is selected for doing e3periments

2. %he motor is switched on! as a result water will flow

3. 5ccording to the flow! the mercury level fluctuates in the A@tue manometer

$. %he reading of 6

1

and 6

2

are noted

'. %he time taken for 11 cm rise of water in the collecting tank is noted

*. %he e3periment is repeated for various flow in the same pipe

,. %he co@efficient of discharge is calculated

MODEL CALCULATION*

RESULT*

%he co efficient of discharge through orifice meter is HHH ("o unit)

5ENTURIMETER6 ORIFICEMETER AND ROTAMETER TEST RIG

1 2

DETERMINATION OF THE CO EFFICIENT OF

DISCHARGE OF GI5EN 5ENTURIMETER

AIM*

%o determine the coefficient of discharge for liquid flowing through venturimeter.

APPARATUS RE7UIRED*

1. <enturimeter

2. Stop watch

3. 4ollecting tank

$. 8ifferential A@tue

'. Ganometer

*. Scale

FORMULAE*

1. ACTUAL DISCHARGE*

2.

B

act

C 5 3 h D t

THEORTICAL DISCHARGE*

(m

3

D s)

Where#

B

th

C a

1

3 a

2

3 2 g h D a

2

E a

2

(m

3

D s)

Where#

5 C 5rea of collecting tank in m

2

h C 6eight of collected water in tank C 11 cm

a

1

C 5rea of inlet pipe in m

2

a

2

C 5rea of the throat in m

2

g C Specify gravity in m D s

2

t C %ime taken for h cm rise of water

6 C 7rifice head in terms of flowing liquid

C (6

1

F 6

2

) (s

m

Ds

1 @

1)

61 C Ganometric head in first lim

62 C Ganometric head in second lim

s

m

C Specific gravity of Ganometric liquid

81.&.9 L1:;1( #&,3;,< H- = 13.6

s

1

C Specific gravity of flowing liquid water C 1

S.No

D1)#&'&,

12 ##

M)2o#&',13

,&)(12-

M)2o#&',13

4&)(

H = 8H1>H29

? 12.6 ? 1"

02

T1#& ').&2 /o,

4 3# ,1@&

o/

A)'&,

'

S&3

A3';)%

(1@34),-&

03

7 )3' ? 1"

#

3

B @

T4&o,&'13)%

(1@34),-& 7'4

03

? 1"

#

3

B @

Co0&//131&2' o/

(1@34),-& C(

82o ;21'9

H1 3#

o/ H-

H2 3#

o/ H-

M&)2 C( =

3. CO EFFICENT OF DISCHARGE*

4o@ efficient of discharge C B act D B th (no units)

DESCRIPTION*

<enturimeter has two sections. 7ne divergent area and the other throat area. %he

former is represented as a

1

and the later is a

2

water or any other liquid flows through

the <enturimeter and it passes to the throat area the value of discharge is same at a

1

and a

2

.

PROCEDURE*

1. %he pipe is selected for doing e3periments

2. %he motor is switched on! as a result water will flow

3. 5ccording to the flow! the mercury level fluctuates in the A@tue manometer

$. %he reading of 6

1

and 6

2

are noted

'. %he time taken for 11 cm rise of water in the collecting tank is noted

*. %he e3periment is repeated for various flow in the same pipe

,. %he co@efficient of discharge is calculated

MODEL CALCULATION*

RESULT*

%he co efficient of discharge through <enturimeter is HHH ("o unit)

5ENTURIMETER6 ORIFICEMETER AND ROTAMETER TEST RIG

CALCULATION OF THE RATE OF FLOC USING ROTOMETER

AIM*

%o determine the percentage error in =otometer with the actual flow rate.

APPARATUS RE7UIRED*

1. =otometer setup

2. Geasuring scale

3. Stopwatch.

FORMULAE*

1. ACTUAL DISCHARGE*

B

act

C 5 3 hD t (m

3

D s)

Where#

5 C 5rea of the collecting tank (m

2

)

hC 11 cm rise of water level in the collecting tank (11

@2

m).

t C %ime taken for 11 cm rise of water level in collecting tank.

CON5ERSION*

5ctual flow rate (lit D min)! B

act

C Bact 3 1111 3 *1 lit Dmin

?ercentage error of =otometer C

=otometer reading F 5ctual 3 111 I

=otometer reading

PROCEDURE*

C = F Bact D = 3 111 I

1. Switch on the motor and the delivery valve is opened

2. 5d)ust the delivery valve to control the rate in the pipe

3. Set the flow rate in the =otometer! for e3ample say '1 liters per minute

$. "ote down the time taken for 11 cm rise in collecting tank

'. =epeat the e3periment for different set of =otometer readings

*. %aular column is drawn and readings are noted

,. >raph is drawn y plotting =otometer reading <s percentage error of the

=otometer

S.No

Ro'o#&'&,

R&)(12-

8%$#9

A3';)%

D1@34),-&

7

)3'

8#

3

B@&39

T1#& ').&2 /o, 1"3#

,1@& o/ A)'&,

I2 ')2. 8' @&39

A3';)% (1@34),-&

7

)3'

8%$#9

P&,3&2')-&

E,,o, o/

Ro'o#&'&, 8D9

A+&,)-& =

MODEL CALCULATION*

RESULT*

%he percentage error of the =otometer was found to eHHHH.H. I

FRICTION LOSSES TEST RIG

DETERMINATION OF FRICTION FACTOR OF

GI5EN SET OF PIPES

AIM*

%o find the friction JfK for the given pipe.

APPARATUS RE7UIRED*

1. 5 pipe provided with inlet and outlet and pressure tapping

2. 8ifferential u@tue manometer

3. 4ollecting tank with pie2ometer

$. Stopwatch

'. Scale

FORMULAE*

1. FRICTION FACTOR 8 F 9*

Where!

Where

f C 2 3 g 3 d 3 h

f

D l 3 v

2

(no unit)

g C 5cceleration due to gravity (m D sec

2

)

d C 8iameter of the pipe (m)

l C &ength of the pipe (m)

v C <elocity of liquid following in the pipe (m D s)

h

f

C &oss of head due to friction (m)

C h

1

F h

2

h

1

C Ganometric head in the first lims

h

2

C Ganometric head in the second lims

2. ACTUAL DISCHARGE*

Where

B C 5 3 h D t (m

3

D sec)

5 C 5rea of the collecting tank (m

2

)

h C =ise of water for ' cm (m)

t C %ime taken for ' cm rise (sec)

S.No

D1)#&'&, o/

$1$& ##

M)2o#&'&, ,&)(12-@

T1#& /o,

53#

,1@& o/

A)'&,

' @&3

A3';)% (1@34),-&

03

7

act

? 1"

#

3

B @

5&%o31'<

5

#B@

2

5

2 2

# B @

F,13'1o2

/)3'o,

/ ? 1"

02

4

1

?

1"

02

4

2

?

1"

02

4

f

= 8410429

? 1"

02

M&)2 / =

3. 5ELOCITY*

Where

DESCRIPTION*

< C B D a (m D sec)

B C 5ctual discharge (m

3

D sec)

5 C 5rea of the pipe (m

2

)

When liquid flows through a pipeline it is su)ected to frictional resistance. %he

frictional resistance depends upon the roughness of the pipe. Gore the roughness of the

pipe will e more the frictional resistance. %he loss of head etween selected lengths of the

pipe is oserved.

PROCEDURE*

1. %he diameter of the pipe is measured and the internal dimensions of the

collecting tank and the length of the pipe line is measured

2. 9eeping the outlet valve closed and the inlet valve opened

3. %he outlet valve is slightly opened and the manometer head on the lims h

1

and

h

2

are noted

$. %he aove procedure is repeated y gradually increasing the flow rate and then

the corresponding readings are noted.

MODEL CALCULATION*

RESULT*

1. %he frictional factor Jf J for given pipe C 3 11

@2

(no unit)

2. %he friction factor for given pipe y graphical method C HH 3 11

@2

( no unit )

CENTRIFUGAL PUMP TEST RIG

CONDUCTING EXPERIMENTS AND DRACING THE

CHARACTERISTICS CUR5ES OF CENTRIFUGAL PUMP

AIM*

%o study the performance characteristics of a centrifugal pump and to determine the

characteristic with ma3imum efficiency.

APPARATUS RE7UIRED*

1. 4entrifugal pump setup

2. Geter scale

3. Stop watch

FORMULAE*

1. ACTUAL DISCHARGE*

B

act

C 5 3 y D t (m

3

D s)

Where#

5 C 5rea of the collecting tank (m

2

)

y C 11 cm rise of water level in the collecting tank

t C %ime taken for 11 cm rise of water level in collecting tank.

2. TOTAL HEAD*

Where#

6 C 6

d

L 6

s

L M

6

d

C 8ischarge head! meter

6

s

C Suction head! meter

M C 8atum head! meter

3. INPUT POCER*

Where#

(D? C (3*11 " 1111) D (0 %) (watts)

" C "umer of revolutions of energy meter disc

0 C 0nergy meter constant (rev D 9w hr)

% C time taken for J"rK revolutions (seconds)

S.No

S;3'1o2

-);-&

H@ #

o/ A)'&,

S;3'1o2

4&)( H@

E# o/ A)'&,

D&%1+&,<

G);-&

R&)(12-

84(9 # o/

A)'&,

D&%1+&,<

H&)(

8H(9 # o/

A)'&,

To')%

H&)(

8H9 # o/

A)'&,

T1#& ').&2

for h

rise

o/ A)'&,

8'9 S

T1#&

').&2 /o,

N,

,&+o%;'1o

2 ' S

A3';)%

D1@34),-&

87)3'9 ?1"

03

3

# E@&3

I2$;'

PoA&,

8P1 9

A)''

O;'$;'

PoA&,

8Po9

A)''

D

A+&,)-& =

4. OUTPUT POCER*

?o C N 3 g 3 B 3 6 D 1111 (watts)

Where!

N C 8ensity of water (kg D mO)

g C 5cceleration due to gravity (m D s

2

)

6 C %otal head of water (m)

5. EFFICIENCY*

o

C (7utput power oDp D input power (Dp) 111 I

Where!

7Dp C 7utput power kW

(D p C (nput power kW

DESCRIPTION*

PRIMING*

%he operation of filling water in the suction pipe casing and a portion delivery pipe

for the removal of air efore starting is called priming.

5fter priming the impeller is rotated y a prime mover. %he rotating vane gives a

centrifugal head to the pump. When the pump attains a constant speed! the delivery valve is

gradually opened. %he water flows in a radially outward direction. %hen! it leaves the vanes

at the outer circumference with a high velocity and pressure. "ow kinetic energy is gradually

converted in to pressure energy. %he high@pressure water is through the delivery pipe to the

required height.

PROCEDURE*

1. ?rime the pump close the delivery valve and switch on the unit

2. 7pen the delivery valve and maintain the required delivery head

3. "ote down the reading and note the corresponding suction head reading

$. 4lose the drain valve and note down the time taken for 11 cm rise of water level

in collecting tank

'. Geasure the area of collecting tank

*. :or different delivery tues! repeat the e3periment

,. :or every set reading note down the time taken for ' revolutions of energy

meter disc.

GRAPHS*

1. 5ctual discharge <s %otal head

2. 5ctual discharge <s 0fficiency

3. 5ctual discharge <s (nput power

$. 5ctual discharge <s 7utput power

MODEL CALCULATION*

RESULT*

%hus the performance characteristics of centrifugal pump was studied and

the ma3imum efficiency was found to e

RECIPROCATING PUMP TEST RIG

CONDUCTING EXPERIMENTS AND DRACING THE

CHARACTERISTICS CUR5ES OF RECIPROCATING PUMP

AIM*

%o study the performance characteristics of a reciprocating pump and to determine

the characteristic with ma3imum efficiency.

APPARATUS RE7UIRED*

1. =eciprocating pump

2. Geter scale

3. Stop watch

FORMULAE*

1. ACTUAL DISCHARGE*

B

act

C 5 3 y D t (m

3

D s)

Where#

5 C 5rea of the collecting tank (m

2

)

y C 11 cm rise of water level in the collecting tank

t C %ime taken for 11 cm rise of water level in collecting tank

2. TOTAL HEAD*

Where#

6 C 6d L 6s L M

6d C 8ischarge head+ 6d C ?d 3 11! m

6s C Suction head+ ?d C ?s 3 1.113*! m

M C 8atum head! m

?d C ?ressure gauge reading! kg D cm

2

?s C Suction pressure gauge reading! mm of 6g

3. INPUT POCER*

?

i

C (3*11 ") D (0 %) (9w)

Where!

" C "umer of revolutions of energy meter disc

0 C 0nergy meter constant (rev D 9w hr)

% C time taken for J"K revolutions (seconds)

S.No

D&%1+&,<

$,&@@;,&

,&)(12-

P(

.- B 3#

2

S;3'1o2

$,&@@;,&

,&)(12-

P@ ##

o/ H-

D&%1+&,<

4&)( H(

=

P(?1"."

S;3'1o2

4&)( H@

= P@ ?

"."136

D)';#

4&)( F

#

To')%

4&)(

H

T1#& ').&2

/o, 1" 3# o/

,1@& o/ A)'&,

12 ')2. ' @&3

A3';)%

(1@34),-&

7

)3'

#GB@

T1#& ').&2

/o, N ,&+ o/

&2&,-<

#&'&, (1@3

' @&3

I2$;'

$oA&,

P1 .A

O;'$;'

$oA&,

Po .A

D

M&)2 =

$. OUTPUT POCER*

?o C N 3 g 3 B 3 6 D 1111 (9w)

Where!

N C 8ensity of water (kg D mO)

g C 5cceleration due to gravity (m D s

2

)

6 C %otal head of water (m)

B C 8ischarge (m

3

D sec)

5. EFFICIENCY*

Where!

PROCEDURE*

o

C (7utput power po D input power pi) 111 I

?o C 7utput power 9W

?i C (nput power 9W

1. 4lose the delivery valve and switch on the unit

2. 7pen the delivery valve and maintain the required delivery head

3. "ote down the reading and note the corresponding suction head reading

$. 4lose the drain valve and note down the time taken for 11 cm rise of water level

in collecting tank

'. Geasure the area of collecting tank

*. :or different delivery tues! repeat the e3periment

,. :or every set reading note down the time taken for ' revolutions of energy

meter disc.

GRAPHS*

1. 5ctual discharge <s %otal head

2. 5ctual discharge <s 0fficiency

3. 5ctual discharge <s (nput power

$. 5ctual discharge <s 7utput power

MODEL CALCULATION*

RESULT*

%he performance characteristic of the reciprocating pump is studied and the

efficiency is calculated HHHHH I

G

E

A

R

P

U

M

P

T

E

S

T

R

I

G

CONDUCTING EXPERIMENTS AND DRACING THE

CHARACTERISTICS CUR5ES OF GEAR OIL PUMP

AIM*

%o draw the characteristics curves of gear oil pump and also to determine efficiency

of given gear oil pump.

APPARATUS RE7UIRED*

1. >ear oil pump setup

2. Geter scale

3. Stop watch

FORMULAE*

1. ACTUAL DISCHARGE*

Where!

Bact C 5 3 y D t (mO D sec)

5 C 5rea of the collecting tank (mP)

y C =ise of oil level in collecting tank (cm)

t C %ime taken for JhK rise of oil in collecting tank (s)

2. TOTAL HEAD*

Where

6 C 6d L 6s L M

6d C 8ischarge head+ 6d C ?d 3 12.'! m

6s C Suction head+ ?d C ?s 3 1.113*! m

M C 8atum head! m

?d C ?ressure gauge reading! kg D cm

2

?s C Suction pressure gauge reading! mm of 6g

3. INPUT POCER*

Where!

?i C (3*11 ") D (0 %) (kw)

"r C "umer of revolutions of energy meter disc

"e C 0nergy meter constant (rev D 9w hr)

te C %ime taken for J"rK revolutions (seconds)

S.No

D&%1+&,<

$,&@@;,&

,&)(12-

P(

.- B 3#

2

S;3'1o2

$,&@@;,&

,&)(12-

P@ ## o/

H-

D&%1+&,<

4&)( H(

=

P(?12.5

#

S;3'1o2

4&)( H@

= P@ ?

"."136

#

D)';#

4&)( F

#

To')%

4&)(

H #

T1#& ').&2 /o,

1" 3# o/ ,1@&

o/ A)'&, 12

')2. ' @&3

A3';)%

(1@34),-&

7

#GB@

T1#& ').&2

/o, N ,&+ o/

&2&,-<

#&'&, (1@3

' @&3

I2$;'

$oA&, P1

.A

O;'$;'

$oA&,

Po .A

D

M&)2 =

)3'

4. OUTPUT POCER*

Where!

5. EFFICIENCY*

?o C W Bact 6 D1111 (watts)

W C Specific weight of oil (" D mO)

B

act

C 5ctual discharge (mO D s)

h C %otal head of oil (m)

I C (7utput power ?o D input power ?i) 111

DESCRIPTION*

%he gear oil pump consists of two identical intermeshing spur wheels working with

a fine clearance inside the casing. %he wheels are so designed that they form a fluid tight

)oint at the point of contact. 7ne of the wheels is keyed to driving shaft and the other

revolves as the driven wheel.

%he pump is first filled with the oil efore it starts. 5s the gear rotates! the oil is

trapped in etween their teeth and is flown to the discharge end round the casing. %he

rotating gears uild@up sufficient pressure to force the oil in to the delivery pipe.

PROCEDURE*

1. %he gear oil pump is stated.

2. %he delivery gauge reading is ad)usted for the required value.

3. %he corresponding suction gauge reading is noted.

$. %he time taken for J"K revolutions in the energy meter is noted with the help of a

stopwatch.

'. %he time taken for JhK rise in oil level is also noted down after closing the gate

valve.

*. With the help of the meter scale the distance etween the suction and delivery

gauge is noted.

,. :or calculating the area of the collecting tank its dimensions are noted down.

.. %he e3periment is repeated for different delivery gauge readings.

/. :inally the readings are taulated.

GRAPH*

1. 5ctual discharge <s %otal head

2. 5ctual discharge <s 0fficiency

3. 5ctual discharge <s (nput power

$. 5ctual discharge <s 7utput power

MODEL CALCULATION*

RESULT*

%hus the performance characteristic of gear oil pump was studied and ma3imum

efficiency was found to e. HHHI.

PELTON CHEEL TURBINE TEST RIG

CONDUCTING EXPERIMENTS AND DRACING THE

CHARACTERISTICS CUR5ES OF PELTON CHEEL TEST RIG

AIM*

%o conduct load test on pelton wheel turine and to study the characteristics of pelton

wheel turine.

APPARATUS RE7UIRED*

FORMULAE*

1. <enturimeter

2. Stopwatch

3. %achometer

$. 8ead weight

1. 5ENTURIMETER READING*

Where!

h C (?1 F ?2) 11 (m of water)

?1! ?2 @ <enturimeter reading in 9g Dcm

2

2. DISCHARGE*

B C 1.11'' h (m

3

D s)

3. BRAKE HORSE POCER*

Where!

;6? C ( 3 8 3 " 3 %) D (*1 ,') (hp)

" C Speed of the turine in (rpm)

8 C 0ffective diameter of rake drum C 1.31' m

% C %orsion in %o L %1 E %2 (9g)

$. INDICATED HORSE POCER*

Where!

(6? C (1111 B 6) D ,' (hp)

6 C %otal head (m)

'. PERCENTAGE EFFICIENCY*

I C (;.6.? D (.6.? 3 111) (I)

S.No

P,&@@;,&

G);-&

R&)(12-

HH$I

K-E3#

2

To')%

H&)(

HHI

# o/

A)'&,

5&2';,1#&

'&, ,&)(12-

K-B3#

2

H =

8P10P29

? 1"

# o/

A)'&,

C&1-4'

o/

4)2-&,

To

K-

S$&&(

o/

';,J12&

N

R$#

C&1-4

o/

4)2-&,

HT1I

.-

S$,12-

B)%)23&

T2

K-

T&2@1o2

HTI

K-

D1@34),-&

03

7 ?1"

#

3

B@&3

B.H.P

4$

I.H.P

4$

D

P1 P2

M&)2 =

DESCRIPTION*

?elton wheel turine is an impulse turine! which is used to act on high loads and

for generating electricity. 5ll the availale heads are classified in to velocity energy y means

of spear and no22le arrangement. ?osition of the )et strikes the knife@edge of the uckets

with least relative resistances and shocks. While passing along the uckets the velocity of

the water is reduced and hence an impulse force is supplied to the cups which in turn are

moved and hence shaft is rotated.

PROCEDURE*

GRAPHS*

1. %he ?elton wheel turine is started.

2. 5ll the weight in the hanger is removed.

3. %he pressure gauge reading is noted down and it is to e maintained

constant for different loads.

$. %he <enturimeter readings are noted down.

'. %he spring alance reading and speed of the turine are also noted down.

*. 5 '9g load is put on the hanger! similarly all the corresponding readings are

noted down.

,. %he e3periment is repeated for different loads and the readings are

taulated.

%he following graphs are drawn.

1. ;6? <s (6?

2. ;6? <s speed

3. ;6? <s 0fficiency

MODEL CALCULATION*

RESULT*

%hus the performance characteristic of the ?elton Wheel %urine is done and the

ma3imum efficiency of the turine is HHH. I

FRANCIS TURBINE TEST RIG

CONDUCTING EXPERIMENTS AND DRACING THE

CHARACTERISTICS CUR5ES OF FRANCIS TURBINE TEST RIG

AIM*

%o conduct load test on :rancis turine and to study the characteristics of :rancis

turine.

APPARATUS RE7UIRED*

1. Stop watch

2. %achometer

FORMULAE*

1. 5ENTURIMETER READING*

Where

h C (p1 @ p2) 3 11 (m)

?1! ?2@ <enturimeter readings in kg Dcm

2

2. DISCHARGE*

B C 1.111 3 h (m

3

D s)

3. BRAKE HORSEPOCER*

;6? C 3 8 3 " 3 % D *1 3 ,' (hp)

Where

" C Speed of turine in (rpm)

8 C 0ffective diameter of rake drum C 1.31' m

% C torsion in QkgR

$. INDICATED HORSEPOCER*

Where

6? C 1111 3 B 3 6 D ,' (hp)

6 C %otal head in (m)

'. PERCENTAGE EFFICIENCY*

I C ;.6.? 3 111 D (.6.? (I)

S.No

P,&@@;,&

G);-&

R&)(12-

HH$I

2

K-B3#

To')%

H&)(

HHI

# o/

A)'&,

5&2';,1#

&'&,

,&)(12-

K-E3#

2

H = 8P10

P29 ?

1"

# o/ A)'&,

C&1-4' o/

4)2-&, To

K-

S$&&( o/

';,J12& N

R$#

C&1-4 o/

4)2-&,

HT1I

.-

S$,12-

B)%)23&

T2

K-

T&2@1o2

HTI

K-

D1@34),-&

7 ?1"

03

#

3

E@&3

B.H.P

4$

I.H.P

4$

D

H1 H2 P1 P2

M&)2 =

DESCRIPTION*

Godern :rancis turine in an inward mi3ed flow reaction turine it is a medium head

turine. 6ence it required medium quantity of water. %he water under pressure from the

penstock enters the squirrel casing. %he casing completely surrounds the series of fi3ed

vanes. %he guidesK vanes direct the water on to the runner. %he water enters the runner of

the turine in the dial direction at outlet and leaves in the a3ial direction at the inlet of the

runner. %hus it is a mi3ed flow turine.

PROCEDURE*

1. %he :rancis turine is started

2. 5ll the weights in the hanger are removed

3. %he pressure gauge reading is noted down and this is to e

Gaintained constant for different loads

$. ?ressure gauge reading is ascended down

'. %he <enturimeter reading and speed of turine are noted down

*. %he e3periment is repeated for different loads and the readings are taulated.

GRAPHS*

%he following graphs are drawn

1. ;6? (vs.) (6?

2. ;6? (vs.) speed

3. ;6? (vs.) I efficiency

MODEL CALCULATION*

RESULT*%hus the performance characteristic of the :rancis wheel turine is done and

thema3imum efficiency of the turine is HHHH. I

KAPLAN TURBINE TEST RIG

CONDUCTING EXPERIMENTS AND DRACING THE

CHARACTERISTICS CUR5ES OF KAPLAN TURBINE TEST RIG

AIM*

%o study the characteristics of a 9aplan turine

APPARATUS RE7UIRED*

1. <enturimeter

2. Stopwatch

3. %achometer

$. 8ead weight

FORMULAE*

1. 5ENTURIMETER READING*

Where!

h C (?1 F ?2) 11 (m of water)

?1! ?2 @ <enturimeter reading in 9g Dcm

2

2. DISCHARGE*

B C 1.11'' h (m

3

D s)

3. BRAKE HORSE POCER*

Where!

;6? C ( 3 8 3 " 3 %) D (*1 ,') (hp)

" C Speed of the turine in (rpm)

8 C 0ffective diameter of rake drum C 1.31' m

% C %orsion in %o L %1 E %2 (9g)

$. INDICATED HORSE POCER*

Where!

(6? C (1111 B 6) D ,' (hp)

6 C %otal head (m)

'. PERCENTAGE EFFICIENCY*

I C (;.6.? D (.6.? 3 111) (I)

S.No

P,&@@;,&

G);-&

R&)(12-

HH$I

K-E3#

2

To')%

H&)(

HHI

# o/

A)'&,

5&2';,1#&

'&, ,&)(12-

K-B3#

2

H =

8P10P29

? 1"

# o/

A)'&,

C&1-4'

o/

4)2-&,

To

K-

S$&&(

o/

';,J12&

N

R$#

C&1-4

o/

4)2-&,

HT1I

.-

S$,12-

B)%)23&

T2

K-

T&2@1o2

HTI

K-

D1@34),-&

03

7 ?1"

#

3

B@&3

B.H.P

4$

I.H.P

4$

D

P1 P2

M&)2 =

DESCRIPTION*

9aplan turine is an a3ial flow reaction turine used in dams and reservoirs of low

height to convert hydraulic energy into mechanical and electrical energy. %hey are est

suited for low heads say from 11m to ' m. the specific speed ranges from 211 to 1111

%he flow through the pipelines into the turine is measured with the office meter fitted

in the pipeline. 5 mercury manometer is used to measure the pressure difference across the

orifice meter. %he net pressure difference across the turine output torque is measured with

a pressure gauge and vacuum gauge. %he turine output torque is determined with the rope

rake drum. 5 tachometer is used to measure the rpm.

EXPERIMENTAL PROCEDURE*

1. 9eep the runner vane at require opening

2. 9eep the guide vanes at required opening

3. ?rime the pump if necessary

$. 4lose the main sluice valve and they start the pump.

'. 7pen the sluice valve for the required discharge when the pump motor switches

from star to delta mode.

*. &oad the turine y adding weights in the weight hanger. 7pen the rake drum

cooling water gate valve for cooling the rake drum.

,. Geasure the turine rpm with tachometer

.. "ote the pressure gauge and vacuum gauge readings

/. "ote the orifice meter pressure readings.

=epeat the e3periments for other loads

GRAPHS*

%he following graphs are drawn.

1. ;6? <s (6?

2. ;6? <s speed

3. ;6? <s 0fficiency

MODEL CALCULATION*

RESULT*

%hus the performance characteristic of the 9aplan %urine is done and

the

ma3imum efficiency of the turine is HHH. I

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Rsi r2 Super Rsi FaqDocument14 pagesRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- PDS DeltaV SimulateDocument9 pagesPDS DeltaV SimulateJesus JuarezPas encore d'évaluation

- Waves and Ocean Structures Journal of Marine Science and EngineeringDocument292 pagesWaves and Ocean Structures Journal of Marine Science and Engineeringheinz billPas encore d'évaluation

- Metrology and MeasurementDocument79 pagesMetrology and MeasurementVasanth Kumar100% (1)

- Metrology and MeasurementDocument79 pagesMetrology and MeasurementVasanth Kumar100% (1)

- Scrum Exam SampleDocument8 pagesScrum Exam SampleUdhayaPas encore d'évaluation

- Intro To NDTDocument34 pagesIntro To NDTkbldamPas encore d'évaluation

- Hindusthan College of Engineering and Technology: Student Details Personal DetailsDocument2 pagesHindusthan College of Engineering and Technology: Student Details Personal DetailsKarthik Perumal SwamyPas encore d'évaluation

- Chapter 1thermodynamicsDocument10 pagesChapter 1thermodynamicsMatthew SmithPas encore d'évaluation

- Unit 5 NTMTDocument22 pagesUnit 5 NTMTKarthik Perumal SwamyPas encore d'évaluation

- S. No Date Experiments No. Marks SignDocument3 pagesS. No Date Experiments No. Marks SignKarthik Perumal SwamyPas encore d'évaluation

- Unit-I Vehicle Structure and Engines: ContentsDocument26 pagesUnit-I Vehicle Structure and Engines: ContentsKarthik Perumal Swamy100% (1)

- ME2308 Lab Manual ModifiedDocument39 pagesME2308 Lab Manual ModifiedKarthik Perumal SwamyPas encore d'évaluation

- ME2354Document6 pagesME2354Karthik Perumal SwamyPas encore d'évaluation

- ME2308 Lab Manual ModifiedDocument39 pagesME2308 Lab Manual ModifiedKarthik Perumal SwamyPas encore d'évaluation

- Model-1 Question Paper EgDocument2 pagesModel-1 Question Paper EgKarthik Perumal SwamyPas encore d'évaluation

- Mechatronics QBDocument25 pagesMechatronics QBKarthik Perumal SwamyPas encore d'évaluation

- Cam Lab ManualDocument55 pagesCam Lab ManualKarthik Perumal SwamyPas encore d'évaluation

- ME1304 - 2 Mark Q&ADocument12 pagesME1304 - 2 Mark Q&Aanon-993307Pas encore d'évaluation

- Mechtronics QBDocument8 pagesMechtronics QBKarthik Perumal SwamyPas encore d'évaluation

- Regu2009 ChennaiDocument17 pagesRegu2009 ChennaipsnasabariPas encore d'évaluation

- CAD&CAMDocument26 pagesCAD&CAMnvasirajaPas encore d'évaluation

- CAD&CAMDocument26 pagesCAD&CAMnvasirajaPas encore d'évaluation

- ME 1304-Engg. Metrology & MeasurementDocument5 pagesME 1304-Engg. Metrology & MeasurementKarthik Perumal SwamyPas encore d'évaluation

- Civil Enng Code BookDocument2 pagesCivil Enng Code BookKarthik Perumal SwamyPas encore d'évaluation

- Logistic RegressionDocument7 pagesLogistic RegressionShashank JainPas encore d'évaluation

- Problem Solving No. 123Document5 pagesProblem Solving No. 123Christy Joy BarboPas encore d'évaluation

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocument13 pagesStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorPas encore d'évaluation

- Aditya Academy Syllabus-II 2020Document7 pagesAditya Academy Syllabus-II 2020Tarun MajumdarPas encore d'évaluation

- My BaboogDocument1 pageMy BaboogMaral Habeshian VieiraPas encore d'évaluation

- Meta100 AP Brochure WebDocument15 pagesMeta100 AP Brochure WebFirman RamdhaniPas encore d'évaluation

- AMS ANALITICA-AIRFLOW TSP-HVS BrochureDocument1 pageAMS ANALITICA-AIRFLOW TSP-HVS BrochureShady HellaPas encore d'évaluation

- Homework 9Document1 pageHomework 9Nat Dabuét0% (1)

- FT2020Document7 pagesFT2020Sam SparksPas encore d'évaluation

- Naval TV SystemDocument24 pagesNaval TV Systemsharmasandeep0010Pas encore d'évaluation

- 5.1 Behaviour of Water in Rocks and SoilsDocument5 pages5.1 Behaviour of Water in Rocks and SoilsHernandez, Mark Jyssie M.Pas encore d'évaluation

- Spanish Greeting Card Lesson PlanDocument5 pagesSpanish Greeting Card Lesson Planrobert_gentil4528Pas encore d'évaluation

- (EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing SteelDocument24 pages(EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing Steelbagusu_6Pas encore d'évaluation

- Gas Compressor SizingDocument1 pageGas Compressor SizingNohemigdeliaLucenaPas encore d'évaluation

- D E S C R I P T I O N: Acknowledgement Receipt For EquipmentDocument2 pagesD E S C R I P T I O N: Acknowledgement Receipt For EquipmentTindusNiobetoPas encore d'évaluation

- Analisis Kebutuhan Bahan Ajar Berbasis EDocument9 pagesAnalisis Kebutuhan Bahan Ajar Berbasis ENur Hanisah AiniPas encore d'évaluation

- Chapter 11 AssignmentDocument2 pagesChapter 11 AssignmentsainothegamerPas encore d'évaluation

- 5.0008786 Aluminum GrapheneDocument11 pages5.0008786 Aluminum GrapheneBensinghdhasPas encore d'évaluation

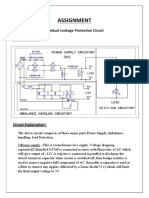

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaPas encore d'évaluation

- Sheet-Metal Forming Processes: Group 9 PresentationDocument90 pagesSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyPas encore d'évaluation

- Exploring-Engineering-And-Technology-Grade-6 1Document5 pagesExploring-Engineering-And-Technology-Grade-6 1api-349870595Pas encore d'évaluation

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDocument16 pagesJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarPas encore d'évaluation

- Log and Antilog TableDocument3 pagesLog and Antilog TableDeboshri BhattacharjeePas encore d'évaluation

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDocument3 pagesEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunPas encore d'évaluation

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineDocument8 pages7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkePas encore d'évaluation

- Static Electrification: Standard Test Method ForDocument10 pagesStatic Electrification: Standard Test Method Forastewayb_964354182Pas encore d'évaluation