Académique Documents

Professionnel Documents

Culture Documents

ISA Saint Louis Exceptional Opportunities Short Course Day 1

Transféré par

anuj1166Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ISA Saint Louis Exceptional Opportunities Short Course Day 1

Transféré par

anuj1166Droits d'auteur :

Formats disponibles

Standards

Certification

Education & Training

Publishing

Conferences & Exhibits

ISA Saint Louis Short Course Dec 6-8, 2010

Exceptional Process Control

Opportunities - An Interactive

Exploration of Process Control

Improvements - Day 1

Welcome

Gregory K. McMillan

Greg is a retired Senior Fellow from Solutia/Monsanto and an ISA Fellow.

Presently, Greg contracts as a consultant in DeltaV R&D via CDI Process &

Industrial. Greg received the ISA Kermit Fischer Environmental Award for pH

control in 1991, the Control Magazine Engineer of the Year Award for the

Process Industry in 1994, was inducted into the Control Process Automation

Hall of Fame in 2001, was honored by InTech Magazine in 2003 as one of the

most influential innovators in automation, and received the ISA Life

Achievement Award in 2010. Greg is the author of numerous books on process

control, his most recent being Essentials of Modern Measurements and Final

Elements for the Process Industry. Greg has been the monthly Control Talk

columnist for Control magazine since 2002. Gregs expertise is available on the

web site: http://www.modelingandcontrol.com/

Top Ten Things You Dont Want to Hear

in a Project Definition Meeting

(10) I dont want any smart instrumentation talking back to me

(9) Lets study each loop to see if the valve really needs a positioner

(8) Lets slap an actuator on our piping valves and use them for control

valves

(7) We just need to make sure the control valve spec requires the

tightest shutoff

(6) What is the big deal about process control, we just have to set the

flow per the PFD

(5) Cascade control seems awfully complex

(4) The operators can tune the loops

(3) Lets do the project for half the money in half the time

(2) Lets go with packaged equipment and let the equipment supplier

select and design the automation system

(1) Lets go out for bids and have purchasing pick the best deal

Without deadtime I would be out of a job

Fundamentals

A more descriptive name would be total loop deadtime. The loop deadtime is the amount

of time for the start of a change to completely circle the control loop and end up at the

point of origin. For example, an unmeasured disturbance cannot be corrected until the

change is seen and the correction arrives in the process at the same point as the

disturbance.

Process deadtime offers a continuous train of values whereas digital devices and

analyzers offer non continuous data values at discrete intervals, these delays add a phase

shift and increase the ultimate period (decrease natural frequency) like process deadtime.

Goals

Minimize delay (the loop cannot do anything until it sees and enacts change)

Sources

Pure delay from process deadtimes and discontinuous updates

Piping, duct, plug flow reactor, conveyor, extruder, spin-line, and sheet transportation delays (process

deadtimes set by mechanical design - remaining delays set by automation system design)

Digital device scan, update, reporting, and execution times (0.5T)

Analyzer sample processing and analysis cycle time (1.5T)

Sensitivity-resolution limits

Backlash-deadband

Equivalent delay from lags

Mixing, column trays, dip tube size and location, heat transfer surfaces, and volumes in series (process

lags set by mechanical design - remaining lags set by automation system design)

Thermowells

Electrodes

Transmitter damping

Signal filters

(1) - Delay

Top Ten Concepts

Speed kills - (high speed processes and disturbances and low

speed control systems can kill performance)

Fundamentals

The rate of change in 4 deadtime intervals is most important. By the end of 4 deadtimes,

the control loop should have completed most of its correction. Thus, the short cut tuning

method (near-integrator) is consistent with performance objectives.

Goals

Make control systems faster and make processes and disturbances slower

Sources

Control system

PID tuning settings (gain, reset, and rate)

Slewing rate of control valves and velocity limits of variable speed drives

Disturbances

Steps - Batch operations, on-off control, manual actions, SIS, startups, and shutdowns

Oscillations - limit cycles, interactions, and excessively fast PID tuning

Ramps - reset action in PID

Process

Degree of mixing in volumes due to agitation, boiling, mass transfer, diffusion, and migration

(2)- Speed

Top Ten Concepts

All is lost if nothing is gained

Fundamentals

Gain is the change in output for a change in input to any part of the control system. Thus

there is a gain for the PID, valve, disturbance, process, and measurement. Knowing the

disturbance gain (e.g. change in manipulated flow per change in disturbance) is important

for sizing valves and feedforward control.

Goals

Maximize control system gains (maximize control system reaction to change) and

minimize process and disturbance gains (minimize process reaction to change).

Sources

PID controller gain

Inferential measurements (e.g. temperature change for composition change in distillation

column)

Slope of control valve or variable speed drive installed characteristic (inherent

characteristic & system loss curve)

Measurement calibration (100% / span). Important where accuracy is % of span

Process design

Attenuation by upstream volumes (can be estimated)

Attenuation by upstream PID loops (transfer of PV variability to controller output)

For a discussion of unifying concepts check out Deminar #9

Process Control Improvement Primer Sept 8, 2010 Recording:

http://modelingandcontrol.com/

(3) - Gain

Top Ten Concepts

(4) - Resonance

Dont make things worse than they already are

Fundamentals

Oscillation period close to ultimate period can be amplified by feedback control

Goals

Make oscillation period slower or control loop faster

Sources

Control loops in series with similar loop deadtimes (e.g. multiple stage pH

control)

Control loops in series with similar tuning and valve sticktion and backlash

Day to night ambient changes to slow loops (e.g. column temperature control)

Top Ten Concepts

(4) - Resonance

Top Ten Concepts

1

Ultimate

Period

1

1

Faster

Tuning

Log of Ratio of

closed loop amplitude

to open loop amplitude

Log of ratio of

disturbance period

to ultimate period

no attenuation

of disturbances

resonance (amplification)

of disturbances

amplitude ratio is

proportional to ratio of

break frequency lag to

disturbance period

1

no better than manual worse than manual improving control

For all of you frequency response and Bode Plot Fans

(5) Attenuation

If you had a blend tank big enough you would not need control

Fundamentals

Attenuation increases as the volume of the blend tank increases and the

ultimate period of the control loop decreases.

Goals

Maximize attenuation by increasing volume and mixing and making loops faster

Sources

Mixed volume size and degree of mixing

Control loop speed

Top Ten Concepts

f

o

o f

t

A A

=

2

*

The attenuation of oscillations can be estimated from the expression of the Bode plot

equation for the attenuation of oscillations slower than the break frequency where (

f

) is

the filter time constant, electrode or thermowell lag, or a mixed volume residence time

Equation is also useful for estimating original process oscillation amplitude

from filtered oscillation amplitude to better know actual process variability

(measurement lags and filters provide a attenuated view of real world)

(5) Attenuation

Top Ten Concepts

(6) Sensitivity- Resolution

You cannot control what you cannot see

Fundamentals

Minimum change measured or manipulated - once past sensitivity limit full

change is seen or used but resolution limit will quantize the change (stair step

where the step size is the resolution limit). Both will cause a limit cycle if there is

an integrator in the process or control system.

Goals

Improve sensitivity and resolution

Sources

In measurements, minimum change detected and communicated (e.g. sensor

threshold and wireless update trigger level) and quantized change (A/D & D/A)

Minimum change that can be manipulated (e.g. valve stick-slip sensitivity and

speed resolution)

Top Ten Concepts

(6) Sensitivity- Resolution

Top Ten Concepts

o

x

x

o

x

o

o

o

o

o

o

o

o

ox

x

x

x

x

x x

x

Actual

Transmitter

Response

True

Process

Variable

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Digital Updates

0 1 2 3 4 5 6 7 8 9 10

0.00%

0.09%

0.08%

0.07%

0.06%

0.05%

0.04%

0.03%

0.02%

0.01%

1.00%

Sensitivity

(6) Sensitivity- Resolution

Top Ten Concepts

Digital Updates

o

o

o

o

o

o

o

o

o

o

x

x

x

x

x

x

x

x

x

x

o

x

Actual

Transmitter

Response

True

Process

Variable

0 1 2 3 4 5 6 7 8 9 10

0.00%

0.09%

0.08%

0.07%

0.06%

0.05%

0.04%

0.03%

0.02%

0.01%

1.00%

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Resolution

(7) Hysteresis-Backlash

No problem if you dont ever change direction

Fundamentals

Hysteresis is the bow in a response curve between full scale traverses in both

directions. Normally much smaller and less disruptive than backlash

Backlash (deadband) is minimum change measured or manipulated once the

direction is changed - once past backlash-deadband limit you get full change

Both Hysteresis and backlash will cause a limit cycle if there are 2 or more

integrators in the process or control system.

Goals

Minimize backlash and deadband

Sources

Pneumatic instrument flappers, links, and levers (hopefully these are long gone)

Rotary valve and damper links, connections, and shaft windup

Variable speed drive setup parameter to eliminate hunting and chasing noise

Top Ten Concepts

(7) Hysteresis-Backlash

Top Ten Concepts

Digital Updates

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Actual

Transmitter

Response

True

Process

Variable

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

0

0

0

0

0

0

0

0

0

0

0 1 2 3 4 5 6 7 8 9 10

0

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Hysteresis

Hysteresis

(7) Hysteresis-Backlash

Top Ten Concepts

Backlash (Deadband)

Deadband is 5% - 50%

without a positioner !

Deadband

Signal

(%)

0

Stroke

(%)

Digital positioner

will force valve

shut at 0% signal

Pneumatic positioner

requires a negative %

signal to close valve

(8) Repeatability-Noise

The best thing you can do is not react to noise

Fundamentals

Noise is extraneous fluctuations in measured or manipulated variables

Repeatability is difference in readings for same true value in same direction

Often repeatability is confused with noise

Goals

Minimize size and frequency of noise and do not transfer noise to process

Sources

Noise

Bubbles

Concentration and temperature non-uniformity from imperfect mixing

Electromagnetic interference (EMI)

Ground loops

Interferences (e.g. sodium ion on pH electrode)

Velocity profile non-uniformity

Velocity impact on pressure sensors

Repeatability

Sensitivity and resolution

Top Ten Concepts

(8) Repeatability-Noise

Top Ten Concepts

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Digital Updates

0 1 2 3 4 5 6 7 8 9 10

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

0

Repeatability

0

0

0

0

0

0

0

0

0

0

Actual

Transmitter

Response

True

Process

Variable

Official definition of repeatability

obtained from calibration tests

(8) Repeatability-Noise

Top Ten Concepts

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Digital Updates

0 1 2 3 4 5 6 7 8 9 10

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

Repeatability

0

x

0 0 0 0 0 0 0 0 0 0

x

x

x

x

x

x

x

x

x

x

Actual

Transmitter

Response

True

Process

Variable

Practical definition of repeatability

as seen on trend charts

(8) Repeatability-Noise

Top Ten Concepts

Noise as seen on trend charts

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Digital Updates

0 1 2 3 4 5 6 7 8 9 10

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

0 0 0 0 0 0 0 0 0 0 0

x

x

x

x

x

x

x

x

x

x

x

Noise

Actual

Transmitter

Response

True

Process

Variable

There is always an offset and drift, it is matter of size and consequence

Fundamentals

The deviation of the peak in the distribution of actual values from true value

Drift shows up as a slowly changing offset

Goals

Minimize offset and nonlinearity by smart transmitters and sensor matching and

smart tuned digital positioners with accurate internal closure member feedback

Sources

Manufacturing tolerance, degradation, de-calibration, and installation effects

(process and ambient conditions and installation methods and location)

(9) Offset-Drift

Top Ten Concepts

(9) Offset-Drift

Top Ten Concepts

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

0

0

0

0

0

0

0

0

0

0

Digital Updates

0 1 2 3 4 5 6 7 8 9 10

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Bias

Actual

Transmitter

Response

True

Process

Variable

x

x

x

x

x

x

x

x

x

x

0

Offset (Bias)

(9) Offset-Drift

Top Ten Concepts

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Months

0 1 2 3 4 5 6 7 8 9 10

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

0 0 0 0 0 0 0 0 0 0 0

Actual

Transmitter

Response

True

Process

Variable

x

Drift =1% per month

x

x

x

x

x

x

x

x

x

x

Drift (Shifting Bias)

(10) Nonlinearity

Not a problem if the process is constant, but then again if the process is

constant, you do not need a control system

Fundamentals

While normally associated with a process gain that is not constant, in a broader

concept, a nonlinear system occurs if a gain, time constant, or delay changes

anywhere in the loop. All process control systems are nonlinear to some degree.

Goals

Minimize nonlinearity by process and equipment design (e.g. reagents and heat

transfer coefficients), smart transmitters and sensor matching, valve selection,

signal characterization, and adaptive control

Sources

Control valve and variable speed drive installed characteristics (flat at high flows)

Process transportation delays (inversely proportional to flow)

Digital and analyzer delays (loop delay depends upon when change arrives in

discontinuous data value update interval)

Inferred measurement (conductivity or temperature vs. composition plot is a curve)

Logarithmic relationship (glass pH electrode and zirconium oxide oxygen probe)

Process time constants (proportional to volume and density)

Top Ten Concepts

(10) Nonlinearity

Top Ten Concepts

0%

90%

80%

70%

60%

50%

40%

30%

20%

10%

100%

0

0

0

0

0

0

0

0

0

0

Digital Updates

0 1 2 3 4 5 6 7 8 9 10

P

r

o

c

e

s

s

V

a

r

i

a

b

l

e

a

n

d

M

e

a

s

u

r

e

m

e

n

t

s

Nonlinearity

Actual

Transmitter

Response

True

Process

Variable

x

x

x

x

x

x

x

x

x

x

x

0

Good Accuracy and Good Precision

2-Sigma

Bias

2-Sigma

True and

Measured

Values

F

r

e

q

u

e

n

c

y

o

f

M

e

a

s

u

r

e

m

e

n

t

s

True

Value

Measured

Values

Good Accuracy and Poor Precision

2-Sigma 2-Sigma

Bias

True and

Measured

Values

True

Value

Measured

Values

F

r

e

q

u

e

n

c

y

o

f

M

e

a

s

u

r

e

m

e

n

t

s

Poor Accuracy and Good Precision

2-Sigma

Bias

2-Sigma

True and

Measured

Values

True

Value Measured

Values

F

r

e

q

u

e

n

c

y

o

f

M

e

a

s

u

r

e

m

e

n

t

s

Poor Accuracy and Poor Precision

2-Sigma 2-Sigma

Bias

True and

Measured

Values

True

Value

Measured

Values

F

r

e

q

u

e

n

c

y

o

f

M

e

a

s

u

r

e

m

e

n

t

s

Accuracy and Precision

Top Ten Concepts

Time (seconds)

% Controlled Variable (CV)

or

% Controller Output (CO)

CO

CV

p2

K

p

= CV / CO

0.63CV

CO

CV

Self-regulating process

open loop

negative feedback time constant

Self-regulating process gain (%/%)

Response to change in controller output with controller in manual

observed

total loop

deadtime

o

or

Maximum speed

in 4 deadtimes

is critical speed

Self-Regulating Process Open Loop Response

Improving Dynamics

Time (seconds)

o

K

i

= { [ CV

2

/ t

2

] [ CV

1

/ t

1

] } / CO

CO

ramp rate is

CV

1

/ t

1

ramp rate is

CV

2

/ t

2

CO

CV

Integrating process gain (%/sec/%)

Response to change in controller output with controller in manual

% Controlled Variable (CV)

or

% Controller Output (CO)

observed

total loop

deadtime

Maximum speed

in 4 deadtimes

is critical speed

Integrating Process Open Loop Response

Improving Dynamics

Response to change in controller output with controller in manual

p2

Noise Band

Acceleration

CV

CO

1.72CV

K

p

= CV / CO

Runaway process gain (%/%)

% Controlled Variable (CV)

or

% Controller Output (CO)

Time (seconds)

observed

total loop

deadtime

runaway process

open loop

positive feedback time constant

For safety reasons, tests are

terminated after 4 deadtimes

o

or

Maximum speed

in 4 deadtimes

is critical speed

Runaway Process Open Loop Response

Improving Dynamics

CV = change in controlled variable (%)

CO = change in controller output (%)

K

c

= controller gain (dimensionless)

K

i

= integrating process gain (%/sec/% or 1/sec)

K

p

= process gain (dimensionless) also known as open loop gain

DV = disturbance variable (engineering units)

MV = manipulated variable (engineering units)

PV = process variable (engineering units)

t = change in time (sec)

t

x

= execution or update time (sec)

o

= total loop dead time (sec)

f

= filter time constant or well mixed volume residence time (sec)

m

= measurement time constant (sec)

p2

= primary (large) self-regulating process time constant (sec)

p2

= primary (large) runaway process time constant (sec)

p1

= secondary (small) process time constant (sec)

T

i

= integral (reset) time setting (sec/repeat)

T

d

= derivative (rate) time setting (sec)

t

o

= oscillation period (sec)

= Lambda (closed loop time constant or arrest time) (sec)

f

= Lambda factor (ratio of closed to open loop time constant or arrest time)

Nomenclature

Improving Dynamics

Phase Shift () and Amplitude Ratio (B/A)

A

B

time

phase

shift

oscillation

period T

o

If the phase shift is -180

o

between the process input Aand output B, then the total shift

for a control loop is -360

o

and the output is in phase with the input (resonance) since

there is a -180

o

from negative feedback (control error = set point process variable).

This point sets the ultimate gain and period that is important for controller tuning.

Improving Dynamics

For frequency response and Bode plot fans

Basis of First Order Approximation

= Tan

-1

( ) negative phase shift

(as approaches infinity, approaches -90

o

phase shift)

t = (-360 / ) T

o

time shift

B 1

AR = ---- = ----------------------- amplitude ratio

A [1 + ( )

2

]

1/2

Amplitude ratios are multiplicative (AR = AR

1

AR

2

) and phase shifts are additive ( =

1

+

2

)

asis of first order approx method where gains are multiplicative and dead times are additive

Improving Dynamics

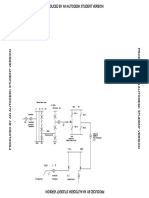

For a self-regulating process

p1

p2

p2

K

pv

p1

c1

m2

m2

m1

m1

K

cv

c2

K

c

T

i

T

d

Valve Process

Controller

Measurement

K

mv

v

K

L

L

Load Upset

CV

CO

MV

PV

PID

Delay

Lag

Delay Delay

Delay

Delay

Delay

Delay

Lag Lag

Lag

Lag Lag Lag

Lag

Gain

Gain

Gain

Gain

Local

Set Point

DV

First Order Approximation:

o

v

+

p1

+

p2

+

m1

+

m2

+

c

+

v

+

p1

+

m1

+

m2

+

c1

+

c2

(set by automation system design for flow, pressure, level, speed, surge, and static mixer pH control)

%

%

%

Delay <=> Dead Time

Lag <=>Time Constant

For integrating processes: K

i

= K

mv

(K

pv

/

p2

) K

cv

100% / span

Loop Block Diagram (First Order Approximation)

Hopefully

p2

is the largest lag in the loop

Improving Dynamics

CV = change in controlled variable (%)

CO = change in controller output (%)

K

c

= controller gain (dimensionless)

K

i

= integrating process gain (%/sec/% or 1/sec)

K

p

= process gain (dimensionless) also known as open loop gain

DV = disturbance variable (engineering units)

MV = manipulated variable (engineering units)

PV = process variable (engineering units)

t = change in time (sec)

t

x

= execution or update time (sec)

o

= total loop dead time (sec)

f

= filter time constant or well mixed volume residence time (sec)

m

= measurement time constant (sec)

p2

= primary (large) self-regulating process time constant (sec)

p2

= primary (large) runaway process time constant (sec)

p1

= secondary (small) process time constant (sec)

T

i

= integral (reset) time setting (sec/repeat)

T

d

= derivative (rate) time setting (sec)

t

o

= oscillation period (sec)

= Lambda (closed loop time constant or arrest time) (sec)

f

= Lambda factor (ratio of closed to open loop time constant or arrest time)

Nomenclature

Improving Dynamics

o

p o

o

x

E E

+

=

) (

o

p o

o

i

E E

+

=

) (

2

Peak error is proportional to the ratio of loop deadtime to 63% response time

(Important to prevent SIS trips, relief device activation, surge prevention, and RCRA pH violations)

Integrated error is proportional to the ratio of loop deadtime squared to 63% response time

(Important to minimize quantity of product off-spec and total energy and raw material use)

For a sensor lag (e.g. electrode or thermowell lag) or signal filter that is much larger

than the process time constant, the unfiltered actual process variable error can be

found from the equation for attenuation

Ultimate Limit to Loop Performance

Total loop deadtime

that is often set by

automation design

Largest lag in loop

that is ideally set by

large process volume

Improving Dynamics

o L

E e E

L o

=

) 1 (

/

Effect of load disturbance lag (

L

) on peak error can be estimated by replacing the

open loop error with the exponential response of the disturbance during the loop deadtime

Disturbance Speed and Attenuation

For E

i

(integrated error), use closed loop time constant instead of deadtime

Improving Dynamics

Effect of Disturbance Lag on Integrating Process

Periodic load disturbance time constant

increased by factor of 10

Adaptive loop

Baseline loop

Adaptive loop

Baseline loop

Primary reason why bioreactor control loop

tuning and performance for load upsets is a

non issue!

Improving Dynamics

Accessing On-Demand and Adaptive Tuning

Click on magnifying glass to get

detail view of limits and tuning

Click on Duncan to get DeltaV Insight for

On-Demand and Adaptive tuning

Improving Dynamics

Effect of Dynamics Lab

Objective Show the effect of deadtime on ultimate period and tuning

Activities:

1. Go to Main Display, select Single Loop Lab01,

2. Click on AC1-1 PID Faceplate and Click on magnifying glass icon to get Detail display

3. Click on Duncan icon for Tune with Insight and click on top tab On Demand Tuning

4. Verify expert option is checked and click on Test for On Demand Tuning

5. Note ultimate period and Ziegler-Nichols - PI tuning settings

6. Update PID tuning settings and change mode from Explore to Run

7. After run is finished, note metrics, and then click on any block in block diagram of loop

8. Click on top tab for Process detail and increase Primary Delay from 1 to 5 sec

9. Click on Test for On Demand Tuning

10. Note ultimate period and Ziegler-Nichols - PI tuning settings

11. Update PID tuning settings and change mode from Explore to Run

12. After run is finished, note metrics, and decrease Primary Delay from 5 to 1 sec

13. Click on top tab for Measurements detail and increase Delay from 0 to 4 sec

14. Click on Test for On Demand Tuning

15. Note ultimate period and Ziegler-Nichols - PI tuning settings

16. Update PID tuning settings and change mode from Explore to Run

17. After run is finished, note metrics, and decrease Measurement Delay from 4 to 0 sec

18. Restore PID gain to 1.0 and reset time to 10 sec

Improving Dynamics

Top Ten Things Missing in University

Courses on Process Control

(10) Control valves with stick-slip and deadband

(9) Measurements with repeatability errors and turndown limits

(8) Volumes with variable mixing and transportation delays

(7) Process input load disturbance

(6) Control action (direct & reverse) & valve action (inc-open & inc-close)

(5) PID algorithms using percent

(4) PID structure, anti-reset windup, output limits, and dynamic reset

(3) Industry standards for function blocks and communication

(2) Control Talk

(1) My books

Improving Tuning - Part 1

Contribution of Each PID Mode

Improving Tuning - Part 1

Proportional (P mode) - increase in gain increases P mode contribution

Provides an immediate reaction to magnitude of measurement change to minimize

peak error and integrated error for a disturbance

Too much gain action causes fast oscillations (close to ultimate period) and can make

noise and interactions worse

Provides an immediate reaction to magnitude of setpoint change for P action on Error

to minimize rise time (time to reach setpoint)

Too much gain causes falter in approach to setpoint

Integral (I mode) - increase in reset time decreases I mode contribution

Provides a ramping reaction to error (SP-PV) to minimize integrated error if stable (since

error is hardly ever exactly zero, integral action is always ramping the controller output)

Too much integral action causes slow oscillations (slower than ultimate period)

Too much integral action causes an overshoot of setpoint (no sense of direction)

Derivative (D mode) - increase in rate time increases D mode contribution

Provides an immediate reaction to rate of change of measurement change to minimize

peak error and integrated error for a disturbance

Too much rate action causes fast oscillations (faster than ultimate period) and can make

noise and interactions worse

Provides an immediate reaction to rate of change of setpoint change for D action on

Error to minimize rise time (time to reach setpoint)

Too much rate causes oscillation in approach to setpoint

Contribution of Each PID Mode

Improving Tuning - Part 1

CO

2

= CO

1

SP

seconds/repeat

CO

1

Time

(seconds)

Signal

(%)

0

kick from

proportional

mode

bump from

filtered

derivative

mode

repeat from

integral

mode

Contribution of Each PID Mode for a Step

Change in the Set Point

(=1 and =1)

SP PV IVP

52 48 ?

TC-100

Reactor Temperature

steam

valve

opens

water

valve

opens

50%

set point

temperature

time

PV

Should steam or water valve be open ?

Reset Gives Operations What They Want

Improving Tuning - Part 1

Open Loop Time Constant (controller in manual)

CO

Time

(seconds)

Signal

(%)

0

o

Dead Time

(Time Delay)

p

Open Loop

(process)

Time Constant

(Time Lag)

CV

SP

Controller is in Manual

Open Loop

Error E

o

(%)

0.63E

o

Improving Tuning - Part 1

Closed Loop Time Constant (controller in auto)

CO

Time

(seconds)

Signal

(%)

0

o

Dead Time

(Time Delay)

c

Closed Loop

Time Constant

(Time Lag)

Lambda ()

CV

SP

Controller is in Automatic

SP (%)

0.63SP

Improving Tuning - Part 1

Conversion of Signals for PID Algorithm

Sensing

Element

Control

Valve

AO PID

SCLR

AI

SCLR

SCLR

%

% %

SUB

CV

SP

%

CO OUT

(e.u.)

Process

Equipment

Smart

Transmitter

PV - Primary Variable

SV - Second Variable*

TV - Third Variable*

FV - Fourth Variable*

PV

(e.u.)

PID

DCS

MV

(e.u.)

The scaler block (SCLR) that convert between engineering units of application and % of scale

used in PID algorithm is embedded hidden part of the Proportional-Integral-Derivative block (PID)

Final Element

Measurement

* - additional HART variables

PV

(e.u.)

To compute controller tuning settings, the process variable and controller output

must be converted to % of scale and time units of deadtimes and time constants

must be same as time units of reset time and rate time settings!

Improving Tuning - Part 1

o

c p

x

E

K K

E

+

=

) 1 (

1

o

c p

f x i

i

E

K K

t T

E

+ +

=

Peak error decreases as the controller gain increases but is essentially the

open loop error for systems when total deadtime >> process time constant

Integrated error decreases as the controller gain increases and reset time decreases

but is essentially the open loop error multiplied by the reset time plus signal

delays and lags for systems when total deadtime >> process time constant

Peak and integrated errors cannot be better than ultimate limit - The errors predicted

by these equations for the PIDPlus and deadtime compensators cannot be better

than the ultimate limit set by the loop deadtime and process time constant

Practical Limit to Loop Performance

Open loop error for

fastest and largest

load disturbance

Improving Tuning - Part 1

) ( 5 . 0

o i

+ =

Slow tuning (large Lambda) creates an implied deadtime where the loop performs

about the same as a loop with fast tuning and an actual deadtime equal to the

implied deadtime (

i

)

Implied Deadtime from Slow Tuning

For most aggressive tuning Lambda is set equal to observed deadtime

(implied deadtime is equal to observed deadtime)

Money spent on improving measurement and process dynamics

(e.g. reducing measurement delays and process deadtimes)

will be wasted if the controller is not tuned faster to take

advantage of the faster dynamics

You can prove most any point you want to make in a comparison

of control system performance, by how you tune the PID.

Inventors of special algorithms as alternatives to the PID

naturally tend to tune the PID to prove their case. For example

Ziegler-Nichols tuning is often used to show excessive

oscillations that could have be eliminated by cutting gain in half

Improving Tuning - Part 1

In this self-regulating process the original process delay (dead time) was 10 sec.

Lambda was 20 sec and the sample time was set at 0, 5, 10, 20, 30, and 80 sec (Loops 1 - 6)

The loop integrated error increased slightly by 1%*sec for a sample time of 10 sec which corresponded to a

total deadtime (original process deadtime + 1/2 sample time) equal to the implied deadtime of 15 seconds.

http://www.modelingandcontrol.com/repository/AdvancedApplicationNote005.pdf

sample time = 0 sec

sample time = 5 sec

sample time = 10 sec

sample time = 20 sec

sample time = 30 sec

sample time = 80 sec

Effect depends on tuning, which leads to miss-guided generalities based on process dynamics

Effect of Implied Deadtime on

Allowable Digital or Analyzer Delay

Improving Tuning - Part 1

Lambda Tuning for Self-Regulating Processes

CO

CV

K

p

=

) (

o p f p

i

c

K

T

K

+

=

p i

T =

Self-Regulation Process Gain:

Controller Gain

Controller Integral Time

p f

=

Lambda (Closed Loop Time Constant)

Lambda tuning excels at coordinating loops for blending,

fixing lower loop dynamics for model predictive control,

and reducing loop interaction and resonance

Improving Tuning - Part 1

Lambda Tuning for Integrating Processes

Integrating Process Gain:

Controller Gain:

Controller Integral (Reset) Time:

Lambda (closed loop arrest time) is defined in terms of a Lambda factor (

f

):

i f

K / =

Closed loop arrest time

for load disturbance

CO

t CV t CV

K

i

%

/ % / %

1 1 2 2

=

2

] ) / [(

o i f i

i

c

K K

T

K

+

=

o i f i

K T + = ) / ( 2

Controller Derivative (Rate) Time:

p d

T =

To prevent slow rolling oscillations:

i

i c

K

T K

2

* >

secondary lag

Improving Tuning - Part 1

Fastest Possible Tuning (Lambda Tuning Method)

o i

c

K

K

=

1

5 . 0

o p f

= =

For max load rejection set lambda equal to deadtime

p i

T =

o

=

p

p

i

K

K

=

Substitute

) (

o p

i

c

K

T

K

+

=

Into

Tuning for max disturbance rejection

(Ziegler Nichols reaction curve method gain factor would be 1.0 instead of 0.5)

o i

T = 4

o i

T =10

For setpoint response to minimize overshoot

Improving Tuning - Part 1

Near Integrator Approximation (Short Cut Tuning Method)

CO t CV Max

K

K

p

p

i

/ ) / ( = =

For Near Integrating gain approximation use maximum

ramp rate divided by change in controller output

The above equation can be solved for the process time constant by

taking the process gain to be 1.0 or for more sophistication as the

average ratio of the controlled variable to controller output

Tuning test can be done for a setpoint change

if the PID gain is > 2 and the PID structure is

PI on Error D on PV so you see a step change

in controller output from the proportional mode

Improving Tuning - Part 1

Fastest Controller Tuning (ultimate oscillation method*)

K

c

= 0.25 K

u

T

i

= 1.0 *

u

T

d

= 0.1

u

For integrating processes or for self-regulating processes where

p

>>

o

,

double the factor for reset time (0.5 => 1.0) and add rate time if the process

noise is negligible.

The oscillations associated with quarter amplitude decay is about the ultimate gain.

Thus if we use quarter amplitude decaying oscillations for the test, we take of the

controller gain that caused these oscillations to get of the ultimate gain

These tuning equations provide maximum

disturbance rejection but will cause

some overshoot of setpoint response

Improving Tuning - Part 1

* - Ziegler Nichols method closed loop modified

to be more robust and less oscillatory

o p

p

c

K

K

=

2

4 . 0

o i

T = 4

1 d p

T =

For runaway processes:

For self-regulating processes:

o i

c

K

K

=

1

5 . 0

o i

T = 4

1 d p

T =

o i

c

K

K

=

1

6 . 0

o i

T = 40

1 d

2

p

T =

For integrating processes:

o p

p

c

K

K

=

2

'

6 . 0

o i

c

K

K

=

1

4 . 0

Near integrator (

p2

>>

o

):

o i

T = 5 . 0

Near integrator (

p2

>>

o

):

Deadtime dominant (

p2

<<

o

):

0

d

= T

p

c

K

K

1

4 . 0 =

Improving Tuning - Part 1

Fastest Controller Tuning (reaction curve method*)

These tuning equations provide maximum

disturbance rejection but will cause

some overshoot of setpoint response

* - Ziegler Nichols method closed loop modified

to be more robust and less oscillatory

Ultimate Period and Ultimate Gain

Time

(min)

Measurement

(%)

Ultimate Gain is Controller Gain that Caused

these Nearly Equal Amplitude Oscillations (K

u

)

Set Point

Ultimate Period

T

u

0

If

p

>>

o

then T

u

= 4

If

p

<<

o

then

u

= 2

Improving Tuning - Part 1

Set Point

Time

(min)

Measurement

(%)

Offset

110%

of

o

Quarter Amplitude

Period T

q

0

Damped Oscillation - (Proportional Only Control)

Improving Tuning - Part 1

1. Put the controller in auto at normal setpoint.

2. Choose largest step change in controller setpoint that is safe. Increase the reset

time by a factor of 10x for test.

3. Add a PV filter to keep the controller output fluctuations from noise within the valve

deadband.

4. Step the controller setpoint. If the response is non-oscillatory, increase the

controller gain and step the controller setpoint in opposite direction. Repeat until

you get a slight oscillation (ideally amplitude decay). Make sure the controller

output is not hitting the controller output limits and is on the sensitive part of the

control valves installed characteristic.

5. Estimate the period of the oscillation. Reduce the controller gain until the oscillation

disappears ( current gain), set the reset time equal to the period, and the rate

time equal to of the reset time. If the oscillation is noisy or resembles a square

wave or the controller gain is high (e.g. > 10), set the rate time to zero. The factors

are the ultimate period and twice the ultimate gain factors because the controller

gain that triggered the amplitude oscillation is about the ultimate gain and the

amplitude period is larger than the ultimate period.

6. If a high controller gain is used (e.g. > 10) use setpoint rate of change (velocity)

limits if a big kick in the controller output for setpoint changes from proportional

action on error ( > 0) is disruptive to operations.

7. Make setpoint changes across the range of operation to make sure an operating

point with a higher controller gain or larger process deadtime does not cause

oscillations. Monitor the loop closely over several days of operation.

Damped Oscillation Tuning Method

Improving Tuning - Part 1

Traditional Open Loop Tuning Method

1. Choose largest step change in controller output that is safe.

2. Add a PV filter to keep the controller output fluctuations from noise within the valve

deadband.

3. Make a change in controller output in manual.

4. Note the time it take for the process variable to get out of the noise band as the

loop deadtime.

5. Estimate the process time constant as the time to reach 63% of the final value.

6. Estimate the process gain as final change in the process variable (%) after it

reaches a steady state divided by change in the controller output (%).

7. To use reaction curve tuning, set the controller gain equal to the process time

constant divided by the product of the process gain and deadtime.

8. If the process lag is much larger than the loop deadtime, set the reset time setting

equal to 4x the deadtime and set the rate time setting equal to the deadtime. If

process lag is much smaller than the loop deadtime, set the reset time to 0.5x the

loop deadtime and the rate time to zero.

9. If a high controller gain is used (e.g. > 10) use setpoint rate of change (velocity)

limits if a big kick in the controller output for setpoint changes is disruptive to

operations (for PID structures with > 0).

10. Make setpoint changes across the range of operation to make sure an operating

point with a higher controller gain or larger process deadtime does not cause

oscillations. Monitor the loop closely over several days of operation.

Improving Tuning - Part 1

Short Cut Ramp Rate Tuning Method

1. Choose largest step change in controller output and setpoint that is safe. If the test is

to be made in auto, increase the reset time by factor of 10x for test.

2. Add a PV filter to keep the controller output fluctuations from noise within the valve

deadband. Measure the initial rate of change of the process variable (PV

1

/t).

3. Make a either a change in controller output in manual or change in set point in auto

4. Note the time it take for the for the process variable to get out of the noise band as

the loop deadtime.

5. Estimate the rate of change of the process variable (PV

2

/t) over successive

deadtime intervals (at least two). Choose the largest rate of change. Subtract this

from initial rate of change of the process variable and divide the result by the step

change in controller output to get the integrating process gain.

6. To use reaction curve tuning, set the controller gain equal to 0.4 the inverse of the

product of integrating process gain and loop deadtime (Equation 7).

If the inverse of the integrating gain is much larger than the loop deadtime, set the reset time

setting equal to 4x the process deadtime and set the rate time setting equal to the process

deadtime, otherwise set the reset time to 0.5x the process deadtime and the rate time to zero

7. If a high controller gain is used (e.g. > 10) use setpoint rate of change (velocity) limits

if a big kick in the controller output for setpoint changes is disruptive to operations

(for PID structures with > 0)

8. Make setpoint changes across the range of operation to make sure an operating

point with a higher controller gain or larger process deadtime does not cause

oscillations. Monitor the loop closely over several days of operation.

Improving Tuning - Part 1

Manual Tuning Lab

Objective Gain experience with manual tuning methods to appreciate auto tuning

Activities:

1. Go to Main Display, and select Single Loop Lab01

2. Click on any block in block diagram

3. In Process detail, set Primary Process Lag 2 = 30 sec for Inc and Dec

4. Click on AC1-1 PID Faceplate and Click on magnifying glass icon to get Detail display

5. Tune PID with damped oscillation method and note tuning settings

6. Tune PID with traditional open loop method and note tuning settings

7. Tune PID with short cut tuning method and note tuning settings

Improving Tuning - Part 1

On-Demand Tuning Algorithm

Time

(min)

Ultimate Period

T

u

0

Set Point

d

a

Ultimate Gain

4 d

K

u

=

e

n

e = sq rt (a

2

- n

2

) If n = 0, then e = a

alternative to n is a filter to smooth PV

Signal

(%)

Improving Tuning - Part 2

Adaptive Tuning Algorithm

Improving Tuning - Part 2

Improving Tuning - Part 2

Pensacola Reactor Adaptive Control Beta Test

Improving Tuning - Part 2

Pensacola Reactor Adaptive Control Beta Test

pH

Level

Temperature

Slurry Feed

Reactor Control After

Broadley-James Corporation Bioreactor Setup

Improving Tuning - Part 2

Hyclone 100 liter

Single Use

Bioreactor (SUB)

Rosemount

WirelessHART

gateway and

transmitters for

measurement

and control of pH

and temperature.

(pressure

monitored)

BioNet lab

optimized control

system based on

DeltaV

Bioreactor Adaptive Control Performance

Improving Tuning - Part 2

Bioreactor Adaptive Tuning Setup

Improving Tuning - Part 2

Bioreactor Adaptive Model Viewing

Improving Tuning - Part 2

Bioreactor Adaptive Learning Setup

Improving Tuning - Part 2

Output comes off high limit at 36.8

o

C

0.30

o

C overshoot

Bioreactor Adaptive Tuning Gain 40 Reset 500

Improving Tuning - Part 2

Output comes off high limit at 35.9

o

C

0.12

o

C overshoot

Bioreactor Adaptive Tuning Gain 40 Reset 5,000

Improving Tuning - Part 2

0.13

o

C overshoot

Output comes off high limit at 36.1

o

C

Bioreactor Adaptive Tuning Gain 40 Reset 10,000

Improving Tuning - Part 2

0.20

o

C overshoot

Output comes off high limit at 36.4

o

C

Bioreactor Adaptive Tuning Gain 40 Reset 15,000

Improving Tuning - Part 2

0.11

o

C overshoot

Output comes off high limit at 36.1

o

C

Bioreactor Adaptive Tuning Gain 80 Reset 15,000

Improving Tuning - Part 2

Integrating and Runaway Process Tuning

It is difficult to prevent overshoot in processes without self-regulation

Controller gain adds self-regulation via closed loop response

Examples of integrating processes (ramping response) are

Liquid and solids level

furnace, column, or vessel pressure

batch composition, pH, or temperature

Examples of runaway processes (accelerating response) are

exothermic reactor temperature

strong acid - strong base pH

exponential growth phase biomass

compressor speed during surge

An overdrive of the controller output beyond its resting value is needed to reach a

set point or compensate for a disturbance (achieved by high controller gain)

The maximum allowable controller gain for many integrating processes is well

beyond the comfort level of most users. Measurement noise and resolution often

sets the practical high limit to the controller gain rather than process dynamics

Too much reset action (too small of a reset time) cause severe overshoot

A higher controller gain creates more overdrive for small setpoint changes and gets

controller off its output limit sooner for large setpoint changes

There is a window of allowable controller gains.

Instability from too high of a controller gain (not likely for industrial processes)

Slow rolling oscillations from too low of a controller gain (common case) that slowly decay for

integrating processes but can grow for runaway processes till it hits physical limits

Improving Tuning - Part 2

MIT Anna India University Lab Setup

Improving Tuning - Part 2

http://www.controlglobal.com/articles/2010/LevelControl1002.html

Improving Tuning - Part 2

Gravity discharge flow makes the level response self-regulating

(increase in level head increases flow through discharge valve)

Increase in cross sectional area with level

increases process time constant

making process response slower

Conical Tank Detail

Improving Tuning - Part 2

Conical Tank Linear Level Controller Performance

Improving Tuning - Part 2

Conical Tank Adaptive Level Controller Models

Improving Tuning - Part 2

Conical Tank Adaptive Level Controller Performance

Nonlinear Control Valve Lab

Improving Tuning - Part 2

Equal Percentage

Flow Characteristic

Nonlinear Control Valve Lab

Improving Tuning - Part 2

click on PID tag

and then Tune

Nonlinear Control Valve Lab

Improving Tuning - Part 2

click on PID tag

and then Tune

Nonlinear Control Valve Lab

Improving Tuning - Part 2

Process gain is

approximately

proportional

to flow for

equal percentage

flow characteristic

Nonlinear Control Valve Lab

Improving Tuning - Part 2

Identification

Out Limit that

sets deadzone

should be set

approximately

equal to valve

deadband and

stick-slip near

closed position

Nonlinear Control Valve Lab

Improving Tuning - Part 2

Objective - Show adaptive control of fast nonlinear self-

regulating processes (fast loop with equal percentage valve)

Activities:

1. Go to Main Display, select Cascade Loop Lab02

2. Click on any block, in Control Valve detail set Equal % Characteristic in Table

3. Click on secondary loop AC1-2 PID Faceplate and put PID in Auto

4. Click on magnifying glass icon to get Detail display

5. Click on Duncan icon for Tune with Insight

6. Run On-Demand Tuner (set Ziegler-Nichols - PI factors: 0.2*Ku and 0.6*Tu)

7. In Models Viewing , set number of regions = 5 and state parameter as OUT

8. Go to settings, and set boundaries for each region

1. Region 1 0 => 35%

2. Region 2 35 => 60%

3. Region 3 60 => 75%

4. Region 3 75 => 90%

5. Region 3 90 => 100%

9. In Adaptive Tuner, set Lambda time = reset time

10.With Adaptive Mode Off make 2 setpoint changes in each region

11.Review Adaptive Control screen

12.Review Model Viewing screen

13.Review Simulate screen

14.With Adaptive Mode Partial make same setpoint changes in each region

Nonlinear Control Valve Lab

Improving Tuning - Part 2

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- MEMVT006Document1 pageMEMVT006anuj1166Pas encore d'évaluation

- Swinburne - An Empirical Testing of Autonomous VehicleDocument7 pagesSwinburne - An Empirical Testing of Autonomous Vehicleanuj1166Pas encore d'évaluation

- Discovering New Ways To Apply AI - ML in Communication Networks - Meet The Winning Teams in The ITU AI - ML in 5G Challenge - AI For GoodDocument3 pagesDiscovering New Ways To Apply AI - ML in Communication Networks - Meet The Winning Teams in The ITU AI - ML in 5G Challenge - AI For Goodanuj1166Pas encore d'évaluation

- VerifAI UCBDocument7 pagesVerifAI UCBanuj1166Pas encore d'évaluation

- Addressing The IEEE AV Test Challenge With Scenic and VerifAIDocument7 pagesAddressing The IEEE AV Test Challenge With Scenic and VerifAIanuj1166Pas encore d'évaluation

- Hybrid Model Predictive Control of Public Trans-Port OperationsDocument20 pagesHybrid Model Predictive Control of Public Trans-Port Operationsanuj1166Pas encore d'évaluation

- Electro Dynamometer TypeDocument5 pagesElectro Dynamometer Typeanuj1166Pas encore d'évaluation

- 1 " (T: : 2 3 4 5 6 P... Il ? """."." 8 9 10 Yt"t 11 12 13 14 19:9:T 79 2A If 1)Document3 pages1 " (T: : 2 3 4 5 6 P... Il ? """."." 8 9 10 Yt"t 11 12 13 14 19:9:T 79 2A If 1)anuj1166Pas encore d'évaluation

- Ip Lab ManualDocument52 pagesIp Lab Manualanuj1166Pas encore d'évaluation

- List of Tables: NO Particulars Page NoDocument4 pagesList of Tables: NO Particulars Page Noanuj1166Pas encore d'évaluation

- 5three PDFDocument5 pages5three PDFanuj1166Pas encore d'évaluation

- PX7301-Power Electronics For Renewable Energy SystemsDocument11 pagesPX7301-Power Electronics For Renewable Energy Systemsanuj1166Pas encore d'évaluation

- T tn003Document8 pagesT tn003anuj1166Pas encore d'évaluation

- Jansons Institute of Technology: Jit0141 Power Plant EngineeringDocument45 pagesJansons Institute of Technology: Jit0141 Power Plant Engineeringanuj1166Pas encore d'évaluation

- ISO Forms - For Various Activities: Department AdministrationDocument1 pageISO Forms - For Various Activities: Department Administrationanuj1166Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- UntitledDocument32 pagesUntitledAnimeFreak930901Pas encore d'évaluation

- Relationship Between Organisations and Information SystemsDocument16 pagesRelationship Between Organisations and Information SystemsJoan KuriaPas encore d'évaluation

- Abbbaileyinfi 90Document17 pagesAbbbaileyinfi 90Vipper80Pas encore d'évaluation

- Installation of Water HeatersDocument5 pagesInstallation of Water HeatersLaura KurniawanPas encore d'évaluation

- Nueva Ecija University of Science and Technology Gapan Academic Extension CampusDocument4 pagesNueva Ecija University of Science and Technology Gapan Academic Extension CampusErmercadoPas encore d'évaluation

- Zeal High Precision Wet Test Gas Flow Meters 2022Document5 pagesZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaPas encore d'évaluation

- MP Interconnection StandardsDocument54 pagesMP Interconnection StandardsAnonymous utxGVB5VyPas encore d'évaluation

- HydroAir™ Variable Radius Turbine - Dresser-RandDocument2 pagesHydroAir™ Variable Radius Turbine - Dresser-RandLeoPérezPas encore d'évaluation

- Toshiba Multi Split and Single Split Systems BrochureDocument32 pagesToshiba Multi Split and Single Split Systems Brochurethanhlong2005Pas encore d'évaluation

- Resolume Arena DMX Auto Map SheetDocument8 pagesResolume Arena DMX Auto Map SheetAdolfo GonzalezPas encore d'évaluation

- Tesco, PLC "From Mouse To House"Document13 pagesTesco, PLC "From Mouse To House"Md IrfanPas encore d'évaluation

- Database AssignmentDocument29 pagesDatabase AssignmentAdasa EdwardsPas encore d'évaluation

- Teacher Evaluation in A Blended Learning EnviornmentDocument11 pagesTeacher Evaluation in A Blended Learning Enviornmentapi-287748301Pas encore d'évaluation

- 88 Numerical Series BASED TECHNOLOGY AWARENESS Grigory GRABOVOIJADocument5 pages88 Numerical Series BASED TECHNOLOGY AWARENESS Grigory GRABOVOIJAStellaEstel93% (15)

- Pillars OF Digital Marketing by Anuj TanwarDocument13 pagesPillars OF Digital Marketing by Anuj TanwarAnuj TanwarPas encore d'évaluation

- Unist MQL Article - ShopCleansUpAct CTEDocument2 pagesUnist MQL Article - ShopCleansUpAct CTEMann Sales & MarketingPas encore d'évaluation

- KSLCDocument52 pagesKSLCzacklawsPas encore d'évaluation

- Process Simulation in Refineries SamplerDocument30 pagesProcess Simulation in Refineries SamplerNagendra HPas encore d'évaluation

- Brady Lecture 6Document32 pagesBrady Lecture 6TygerGoose0% (1)

- Java - Informatica Scenario Based Interview Questions (Convert Columns Into Rows)Document6 pagesJava - Informatica Scenario Based Interview Questions (Convert Columns Into Rows)Sri Kanth SriPas encore d'évaluation

- 11kv BB1Document1 page11kv BB1Hammadiqbal12Pas encore d'évaluation

- Last - kmsg-2016-11-17 10 29 34Document588 pagesLast - kmsg-2016-11-17 10 29 34Anonymous HpW3UcqPas encore d'évaluation

- Redundant Power Supply Installation Guide EP-DCX205Document38 pagesRedundant Power Supply Installation Guide EP-DCX205Anonymous zLwP4FjLPas encore d'évaluation

- Database Upgrade 10g To 11gDocument28 pagesDatabase Upgrade 10g To 11gSubhasis1928Pas encore d'évaluation

- Bombillas LedDocument1 pageBombillas LedElviore PeruPas encore d'évaluation

- 300Mbps/150Mbps Wireless LAN Broadband Router: Quick Installation GuideDocument2 pages300Mbps/150Mbps Wireless LAN Broadband Router: Quick Installation GuideLuis AngelPas encore d'évaluation

- Fault and Alarm Indicators: Planning and Installation Guide For Trident v2 SystemsDocument27 pagesFault and Alarm Indicators: Planning and Installation Guide For Trident v2 SystemsDeepikaPas encore d'évaluation

- Infile StatementDocument21 pagesInfile StatementNagarjuna Parvatala100% (1)

- BOB SO Information HandoutDocument5 pagesBOB SO Information HandoutKabya SrivastavaPas encore d'évaluation