Académique Documents

Professionnel Documents

Culture Documents

3 High Speed OHE of Indian Railways Issues, Challenges and Options - N.N.lal (RDSO)

Transféré par

devidattairsme0 évaluation0% ont trouvé ce document utile (0 vote)

627 vues11 pagesThe document discusses high speed rail travel as a low cost solution for mass transportation in India. It provides the following key points:

- Electric traction is the mainstay of mass transport as it offers freedom from primary energy sources and makes railways future-proof.

- Indian Railways first introduced electric traction in 1925 in Mumbai and has since expanded electrification across its network, currently using the 25kV AC system.

- Demand for rail transport has increased rapidly, requiring upgrades to the existing infrastructure to meet higher power needs and allow for higher train speeds and frequencies on core routes.

- Justification for investing in high speed rail lines includes time savings, increased capacity and reliability, reduced congestion and

Description originale:

high speed rail

Titre original

3 High Speed OHE of Indian Railways Issues, Challenges and Options_N.N.lal(RDSO)

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document discusses high speed rail travel as a low cost solution for mass transportation in India. It provides the following key points:

- Electric traction is the mainstay of mass transport as it offers freedom from primary energy sources and makes railways future-proof.

- Indian Railways first introduced electric traction in 1925 in Mumbai and has since expanded electrification across its network, currently using the 25kV AC system.

- Demand for rail transport has increased rapidly, requiring upgrades to the existing infrastructure to meet higher power needs and allow for higher train speeds and frequencies on core routes.

- Justification for investing in high speed rail lines includes time savings, increased capacity and reliability, reduced congestion and

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

627 vues11 pages3 High Speed OHE of Indian Railways Issues, Challenges and Options - N.N.lal (RDSO)

Transféré par

devidattairsmeThe document discusses high speed rail travel as a low cost solution for mass transportation in India. It provides the following key points:

- Electric traction is the mainstay of mass transport as it offers freedom from primary energy sources and makes railways future-proof.

- Indian Railways first introduced electric traction in 1925 in Mumbai and has since expanded electrification across its network, currently using the 25kV AC system.

- Demand for rail transport has increased rapidly, requiring upgrades to the existing infrastructure to meet higher power needs and allow for higher train speeds and frequencies on core routes.

- Justification for investing in high speed rail lines includes time savings, increased capacity and reliability, reduced congestion and

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 11

H I G H S P E E D R A I L T R A V E L : L OW C OS T S OL U T I ON S

Jayendra Nath Lal

Senior Executive Director

Traction Installations Directorate

Research Designs and Standards Organisation

Ministry of Railways

1. INTRODUCTION

Electric traction is mainstay of mass transport. Electricity offers

freedom from primary source of energy. Hence, it is in essence free

from obsolescence. This feature makes electricity based Railways,

not just an investment in economic mode of transport, but also

makes it future proof as we move from one source of energy to

another. Use of petroleum derived energy is being discouraged

actively world over in favour of practical alternatives offered by

Electric Railways.

Indian Railways came about in its present shape post

independence, when various Railways were amalgamated. The

electric traction was introduced in erstwhile Bombay (now Mumbai)

in 1925 for Suburban Railway and permitted emergence of Mumbai

as the financial capital of India. This 1500 Volts DC system of

unregulated electrification served Mumbai well over 87 years before

being phased out in favour of 25 kV, 50 Hz, running rail return

system of electrification-which is currently in progress.

Erstwhile Calcutta (now Kolkata) also saw electrification, albeit at

3 kV DC during 1957, a well adopted European system with

unregulated overhead conductors.

However, with 25 kV AC as electrification showing promise,

Indian Railways decided during 1957 to adopt this SNCF pioneered

system. This system proposed a simple polygonal overhead

electrification system with regulated conductors, for all weather

maintenance free consistent performance. It was a landmark decision

that just electrified 3 kV system of Howrah - Bardhman Section and

meter gauge Chennai Beach - Tambaram Section was changed over

to 25 kV, 50 Hz, electrification, retaining unregulated over head

conductor system. 25 kV, 50 Hz, single phase supply was obtained

from the utilities which owned the Traction sub-stations and the

protection of feeders. However, with passage of time, Traction Sub-

stations are being constructed by Railways themselves. Where the

Traction Sub-station is not with Indian Railways, the protection is

provided at the Feeding post as it was felt that utilities were more

concerned for HV side trippings and Transformer protection rather

than Feeder protection, which is of interest to Railways.

Overhead conductor system using simple polygonal type of

conductor arrangement has stood test of time and vagaries of

extreme climate seen in the country. Kolkatas overhead conductor

system also is being converted to regulated. Proposal to regulate

Mumbai sub-urban overhead conductor system is on cards. It is seen

that well thermally compensated conductor system has given

maintenance free consistent performance. The predominant

construction uses 1000 kgf force in each Catenary and Contact wire,

with common tensioning device. The tensioning device used on

Indian Railways is principally Pulley type.

Efforts are underway to convert conventional running rail return

system to 2x25 kV AT system. Challenge is to get conversion done

with minimal traffic disruptions.

Further, it was explored to procure power directly from the Power

producers and bring to Indian Railways own 132 kV Transmission

lines. The two points of tap on countrys 220 kV network exist

presently and the major arterial flow between Delhi-Allahabad

section is supported by one such 132 kV transmission line. With

another Grid Sub-station coming up at Allahabad, the 132 kV

backbone is being extended further. With provision of open access

enabled by the Electricity Act, 2003 being operationalised, Indian

Railways is in process of setting up 3,020 MW of captive generation

capacity at Nabinagar (Bihar), which will be wheeled to various

Traction substations.

2. NEED & JUSTIFICATION FOR HIGH SPEED

Greater speed implied lower generalised costs of travel and

lower costs implied reduced impedance of distance, which would

raise accessibility and the economic potential of the major centers

served.

Building high speed rail infrastructure depends on its capacity

to generate social benefits which compensate for the constructions,

maintenance and operation costs.

High Speed Rail investment is, in general socially profitable

depending on the local conditions, which determine the magnitude of

costs, demand levels and external benefits such as reduced

congestion or pollution from other modes.

High Speed Rail investment does not only save time but also

increases capacity for passengers as well as for freight, both by

providing capacity itself and by releasing capacity on existing routes.

Investment could be justified by a combination of factors: the

existence of network benefits arising from serving a variety of traffic

flow and the presence of congestion in competing transport modes.

The development of high speed rail has been accelerated in

many European countries and become a key element in the priority.

High Speed Rail is not only simply an updating of the rail system to

deal with problems of capacity and, thus, help maintain rails market

share, whether it is a means of competing with the rapid growth of

air travel or medium distance journeys in the 400 to 600 Kms range

or it is a more fundamental agent of economic change and territorial

balance with impacts on both competitiveness and cohesion. Whilst

the wider economic effects of high speed rail can be significant, they

are not always obvious or predictable.

High speed rail infrastructure compete with road and air

transport.

High speed rail generates social benefits, which come from

time savings, increase in reliability, comfort, safety, reduction of

congestion and accidents.

The key question is whether the social benefits are greater

than the costs the society incurs to carry on the

construction/conversion and operation of high speed lines. In other

words, the question is not whether we like high speed rail or not, but

whether we are willing to pay its costs.

The high speed rail network can be built/converted gradually.

The economic appraisal has to look carefully to the diverted and

generated traffic, the time savings, any additional benefit and the

users willingness to pay.

3. INITIAL DEVELOPMENTS

The first Section (Rajkharsan Kendposi on South Eastern

Railway) was commissioned on 25 kV AC on 15.12.1959. Since then

due to continuous increase of Passenger as well as Freight traffic the

Traction Power density of all the route of Golden Quadrilateral (and

Diagonals) i.e. MVA/RKM has increased manifold which is evident

from the following Table. It has been prepared by collecting the data

of each Traction Sub-station situated over the Golden Quadrilateral

(and Diagonals).

Sl.

No.

Section Power Density

During initial

Commissioning

(MVA/RKM)

Present Power

Density

(MVA/RKM)

1. Howrah-New Delhi 0.18 0.53/0.57*

2. New Delhi- Igatpuri- Mumbai

CST

0.24 0.48/0.56*

3. New Delhi- Kota-Mumbai

Central

0.19 0.47/0.49*

4. Howrah-Vishakhapatnam-

Chennai

0.32 0.46/0.63*

5. Mumbai CST- Pune-Chennai Section under Electrification.

6. Howrah-Nagpur-Mumbai CST 0.28 0.51/0.66*

7. New Delhi-Nagpur-Chennai 0.29 0.46/0.56*

* While Traction Transformer are operating in Oil natural, Air

forced mode.

Further increase in Traction Power requirement has other

contributors too viz:

(i) Increased number of Mail/Express trains at higher speed are

expected to draw higher Electrical energy,

(ii) Increase number of Mail/Express trains leading to

precedences,

(iii) Increase number and length of EMU/MEMU trains,

(iv) Increased number of Freight trains to transport more goods

and

(v) Line capacity Utilisation has gone up to a very high level,

resulting in congestion and frequent stops & starts.

4. MEETING INCREASED DEMAND

The increase in power demand has been met by increasing the

number of Traction sub-stations in the section.

With this, it is evident that at present the average Traction Power

requirement has increased in the range of 2.94 to 3.17 times

compared to early electrification days.

Depending upon the Traction Power requirement, either

existing Traction Sub-stations has been augmented (from 10 MVA

to 21.6/30.24 MVA and further to 30/40 MVA) or additional

Traction Sub-Station has been added thereby the spacing between

two Traction Sub-station has been reduced from 70 Kms to 19

Kms (approx.).

Further, reduction of Traction Sub-station spacing will have

adverse effect on the performance of Electric locomotive and

thereby on train operation. Thus, there is a need for augmentation

and refurbishment in the existing infrastructure to meet the

increased demand/traffic, which the high speed routes have to

carry.

The upgradation of OHE and PSI Assets are essential and early

warranted.

5. INPUT PROPOSED

The following inputs are immediately required:

5.1 Input for OHE

The inputs in the OHE may be made to ensure smooth train

operation:

5.1.1 Planning of higher cross section Contact Wire (150 Sq. mm)

during age cum replacement stage/OHE rehabilitation Works.

Use of Silver bearing Contact Wire for higher steady state

thermal rating of contact wire to take care of increase in

frequency and higher electrical load requirement of traffic.

5.1.2 Adopting higher tension 1200 kgf for 65 Sq. mm Catenary Wire

and 1200 kgf. for 150 Sq. mm Contact Wire and use of Five

Pulley type Regulating Equipment. Use of Balance Weight to

480 kg (from 665 kg), wherever existing 107 Sq. mm Contact

Wire to be replaced by 150 Sq. mm Contact Wire.

5.2 Input for Power Supply

5.2.1 Adoption of 2x 25 kV AT System with the spacing of Traction

Sub-station as 50 - 60 kms.

5.2.2 Conversion of existing Switching Stations to suit 2 x 25 kV AT

System.

5.2.3 Use of latest Traction Sub-station Automation System (IEC-

61850).

5.2.4 Upgradation of SCADA system with provision of IP based

SCADA with latest Remote Control Protocol (RC-103) along

with linking the Traction Sub-station/SCADA with the Cable

Hut by OFC Cable (instead of Copper Quad Cable).

5.2.5 Provision of 3 Zone Protection Scheme (in heavy loaded

Section, in addition to high speed route).

5.2.6 Use of higher conductor i.e. PANTHER for 132 kV Transmission

line to transmit more Electrical Power through existing

Transmission Lines.

5.2.7 Conversion of two phase to three phase (Double Circuit)

Transmission line from Power utility to Railways Traction Sub-

station.

5.3 IMPROVED MAINTENANCE AND DIAGNOSTIC TOOLS

In order to improve the productivity and optimum

utilisation of Power/Traffic Blocks, the modern Intelligent 8

Wheeler Tower Car, Mobile Instrumentation Car, modern

Diagnostic and measuring Tools/Gadgets/Instruments,

including Pneumatic/Power Tools, are to be provided in the

Tower Car and at OHE Maintenance Depots.

6. 2X25 KV AT SYSTEM OF ELECTRIFICATION

Incidentally, 2 x 25 kV AT system is in use world over for

high speed and/or high haul routes. A Pilot Project over Indian

Railways has already been commissioned in Bina-Katni Section

of West Central Railway on 16.01.1995 as well as in Katni

Anuppur - Bishrampur/Chirimiri Section of South East Central

Railway.

Need for conversion /up gradation to 2x25 kV AT System

over Indian Railways was expressed and deliberated in

Electrical Standards Committee meeting held at Jaipur on 28

th

& 29

th

September, 2012. The committee has unanimous view

that it is imperative to switch over to 2x25 kV AT System which

can support higher traction power delivery with longer spacing

of Traction Sub-Station.

7. HIGH SPEED RAIL TRAVEL

For train journeys lasting less than 4 hours, high speed

trains are the best alternative among all available forms of

transport. Assuming equal journey times, the quality of the

service provided by high speed trains is markedly greater than

that of other modes of transport. The threshold of four hours is

because air transport is penalised by the time required to reach

airports, longer periods to board and leave the aircraft,

heightened security controls and the constraints of baggage

handling, not to mention the saturation of the airspace around

metropolitan airports.

Indian Railways is planning to have a fairly big slice of

this lucrative business segment by providing high speed

corridors. But, this type of operation, which will be a first for

our country, will require detailed study of dynamics, hitherto

neglected. Further, a robust design shall have to be evolved

based upon the best engineering practices in the other Railway

systems.

7.1 HIGH SPEED LINE (UIC DEFINITION)

As per the definition of International Union of Railways (Union

Internationale des Chemins de fer), a line is described as a

"high speed line":-

(a) When it is a new one designed to enable trains to operate

at speeds above 250 km/h throughout the whole journey,

or at least over a significant part of the journey.

Or,

(b) It is an upgraded conventional line, suitable for carrying

traffic over 200 km/h

7.2 HIGH SPEED LINE (EUROPEAN COUNCIL DEFINITION)

European Council directives (No.96/48), published during

1996 states that high speed infrastructure comprised three

different types of lines:

(i) Purposely built high speed lines equipped for speed

generally equal to or greater than 250 kmph.

(ii) Upgraded conventional lines, equipped for speed of the

order of 200 kmph and

(iii) Other upgraded conventional lines, which have special

features as a result of topographical or land planning

constraints, on which the speed must be adapted to each

case.

In theory, these technical definitions are broad enough to

encompass the entire rail infrastructure capable of providing

high speed services.

In practice, however, speed has not always been the best

indicator, since commercial speed in many services is often

limited due to, for example, proximity to densely urbanised

areas or the existence of viaducts or tunnels (where speed

must be reduced for safety reasons).

The average commercial speed in several (supposedly)

high speed services over the densest areas in North Europe is

often below the average speed of some conventional lines,

running between distant stops through sparsely populated plain

areas.

More than the speed factor, what actually plays a more

relevant role in the economic definition of high speed services

are both the relationship of High Speed Rail with existing

conventional services and the way in which the use of

infrastructure is organised.

For India Mixed High Speed Model high speed trains run

either on specifically built new lines or on conventional lines.

This corresponds to the French model, whose TGV (Train a

Grande Vitesse) has been operating since 1981, mostly on new

tracks but also on re-electrified tracks of conventional lines in

areas where duplication was impractical.

Fully Mixed Model which allows for the maximum

flexibility, since this is the case where both high speed and

conventional services can run (at their corresponding speeds)

on each type of infrastructure. This is the case of German

Intercity Trains (ICE) AND THE Rome-Florence line in Italy,

where high speed trains occasionally use conventional lines and

freight services use the spare capacity of high speed lines

during the night.

7.3 PRESENT SCENARIO OF INDIAN RAILWAYS

Though many modifications were introduced over the

years in the form of

(i) Forged fittings,

(ii) BFB Steady Arm with 25 mm Drop Bracket,

(iii) Winch type/3 Pulley type Auto Tensioning Device, and

(iv) Removal of Crossed type OHE, etc.

But the basic designed speed has always been declared

at 160 km/h. Further improvement in the design was never

attempted because barring few high speed passenger trains

operating at 140 km/h, rest runs at 110 km/h. The freight

traffic operates well below this speed (75 km/h).

But to improve the performance of this OHE, which runs

for more than 23,541 Route Kilometer over IR (42.07% of IR

BG network), Indian Railways have identified certain inputs for

better current collection which are yet to be implemented like -

o Increased tension to 1200 kg from 1000 kg

o Reduced Contact wire gradient

o Reduced presage to 50 mm from 100 mm

o Use of Flexible Droppers.

These modifications will result in an OHE system on

which it will be possible to run trains at 200 km/h.

8. DESIGN PRINCIPLES FOR HIGH SPEED OVERHEAD LINE

EQUIPMENT ON IRS EXISTING OHE

The overhead equipment has to comply with

sophisticated quality criteria for successful power transfer from

contact wire to the locomotive through the pantograph. There

are static quality criteria such as elasticity and its uniformity

along the span and contact wire uplift.

The dynamic quality criteria include speed of wave

propagation, the Doppler coefficient, the Reflection coefficient

and Amplification coefficient.

The Contact force as a function of the running speed and

its standard derivation are also a significant quality features as

well.

8.1 OVERHEAD EQUIPMENT REQUIREMENT

The permissible range of contact wire uplift in a span is

maximum 100 mm upto 200 km/hour speed for single

Pantograph and leading Pantograph of a multi-Pantograph

train and 120 mm for trailing Pantograph of dual Pantograph

trains. This should be verified by measurement according to

EN 50317 and simulation validation according to EN 50318.

In case of several pantographs the minimum spacing

between two pantographs should be 200 m. For lower spacing

the running speed has to be reduced accordingly.Cantilevers

should have space for maximum uplift of the Steady Arm

equal to twice the uplift value.

In order to upgrade OHE for 200 kmph, the differential

Elasticity between Support and mid span should be less. To

achieve this, the Elasticity at support should be increased

along with the reduction in elasticity at mid span.Elasticity at

mid span is being reduced by increasing the tension from

1000 kgf to 1200 kgf in Contact Wire & Catenary Wire.To

reduce rigidity at support, the existing Cantilever Assembly

shall be replaced by light weight modular Cantilever assembly

and the existing Rigid (loop) Droppers shall have to be

replaced by stranded wire crimped Dropper and current

carrying Droppers, also known as Flexible Droppers.

8.2 CHALLENGES

Replacement of 107 Sq. mm Contact Wire with 150 Sq.

mm silver bearing contact wire will have following challenges:-

8.2.1 Replacement of existing 107 Sq. mm HDGC Contact wire by

150 Sq. mm silver bearing HDGC Contact wire, change of

Dropper Schedule with 50 mm Presag in OHE.

8.2.2 Contact Wire Gradient (Variation in Contact wire height)

Gradient of Contact wire (Absolute Gradient) and change of

gradient (Relative Gradient) are function of Speed.

During maintenance, efforts shall be made to upgrade the

Contact wire Absolute gradient as 2 mm/metre and Relative

gradient (maximum change of gradient) as 1mm/metre to

achieve the sectional speed of 200 kmph at the later date

following EN-50119:2009.

8.2.3 For Sectional Speed of 160 kmph, the Contact wire Absolute

gradient as 3 mm/metre and Relative gradient (maximum

change of gradient) of 1.5 mm/metre is sufficient.The Contact

wire Absolute gradient & Relative gradient shall be adjusted to

2 mm/ metre & 1 mm/metre respectively, while replacing the

107 Sq. mm Contact wire with 150 Sq. mm Contact wire, if not

changed earlier.

8.2.4 Wiring train of latest type, having the simulataneous facilities

for Unrolling (the existing conductor) and Rolling (the new

conductor) as well as with simultaneous Droppering &

adjustment facilities (to the maximum extent) is essential for

each Zonal Railway.

8.3 Minimum Dropper Length

8.3.1 At maximum permissible span length, the minimum Dropper

length shall not be less than 300 mm for the Speed less than

120 kmph. But according to Para 9.3 of ACTM (Volume-II, Part

II), IR maintains minimum distance of 150 mm between

Catenary wire & Contact wire. It is recommended to adhere it

for 160 kmph.

8.3.2 Minimum Dropper length of 500 mm shall have to be

maintained for 200 kmph.

9. Steps to be taken for introducing trains at 160 & 200 kmph

9.1 Now Indian Railways are planning towards high speed.

Facilities may be planned & developed at the Traction

Installation Directorate to validate the Dynamic behavior of

Overhead Equipment to correlate with the theoretical

approach. This should be verified by measurement according to

EN-50317 and simulation validation according to EN 50318.

System level reviews of interaction between Pantograph

& Overhead Equipment is essential at high speed, following EN-

50367, for optimal & efficient functioning of Electric Traction.

9.2 Overhead Equipment Requirement for 200 kmph

9.2.1 The Contact Wire near the support, is much harder than either

the German or British design.

The Bracket Assembly of Indian design is heavier thus

elasticity is less at support.

Modular Cantilever Assembly (i.e. lighter Bracket

Assembly) has to be adopted having light weight, minimum

number of components (including Stainless Steel Steady Arm)

and better Pushup allowance characteristic.

10. OBJECTIVES OF WORKS PLANNED

The following are main objectives while making the existing

OHE (of Conventional Lines) fit for running high speed trains (up to

200 kmph):

(i) Validation of existing OHE, Foundation & Mast

(Overlap & Anchor)

(ii) Validation of existing OHE Components like Cantilever

Assembly, Tensioning Device.

(iii) Increasing Tension of OHE Conductors.

(iv) Suitable OHE Conductors (Catenary/Contact Wires).

(v) Reducing Rigidity at support.

(vi) Reducing Elasticity at mid span.

(vii) Increasing Wave Propogation Velocity.

(viii) Maintaining Reflection co-efficient, Doppler co-efficient &

Amplification co-efficient within range.

(ix) Maintaining satisfactory Dynamic behaviour of current

collection.

(x) Upgrading Power Supply System.

(xi) Upgrading Protection System.

(xii) Condition Monitoring & Maintenance Vehicle &

Equipments.

11. COST OF CONSTRUCTION

In Japan, the cost per kilometer (excluding land costs) in the

Tokyo Osaka Shinkansen (started in 1964) was relatively low (

5.4 million in 2005 values i.e. Rs. 43 Cr./RKM), but in all the projects

carried out during following years, this figure was tripled or

quadrupled.

In France, each Kilometer built for the TGV Sud - Est between

Paris and Lyon, inaugurated in 1981, required as investment of 4.7

million (in construction costs) (i.e. Rs. 37.6 Cr./RKM), whereas cost

per kilometer of the TGV Mediterranee, inaugurated in 2001 was

12.9 million (Rs. 103 Cr./RKM). These differences is due to intrinsic

characteristics of each project.

The estimated project cost of construction of Mumbai

Ahmedabad High Speed Rail link (526 KM) is Rs. 91,283 Cr. &

completion cost of Rs. 1,18,050 Cr. The average cost per kilometer

comes in the order of Rs. 174 Cr. To 224 Cr.

12. COST OF CONVERSION OF EXISTING OHE TO HIGH SPEED

OHE (PER RKM)

The following Table gives the approximate cost for conversion

of existing Conventional Main Lines to High Speed line, in concurrent

with, running of regular traffic over the sections, which have already

saturated line capacity:-

Sl.No. Item Works involved Cost/RKM

(Rs. lakh)

(i) Replacment of Foundation,

Mast at the selected

Overlap & Anchor locations

(10% of the Route length)

(Excluding the cost of light

weight Bracket Assemblies)

2 Overlap Masts

&

2 Anchor Masts

Per Route Kms.

4

Sl.No. Item Works involved Cost/RKM

(Rs. lakh)

(ii) Cost of Light Weight

Bracket Assembly

40 Nos. 18.40

(iii) Cost of 150 sq.mm Contact

Wire including Dropper Wire

3.1 Tonne 17.11

(iv) 25 kV Feeder Wire

(For 2x25 kV AT System)

Per RKM 14.25

(v) Power Supply Installations Per RKM 36

(vi) Cost of Stringing 3

rd

Phase

from Grid Sub-station to

Traction Sub-Station

Per

Transmission

Line Kilometer

12

(vii) Cost of Construction Vehicle Proportionate

cost

8

(viii) Cost of Monitoring Vehicle Proportionate

cost

17

(ix) Miscellaneous Tools &

Plants

Proportionate

cost

5

(x) Construction Establishment

& other charges

- 16.9

Total 148.66

Rounded off to Rs. 1.50 Cr. Per Route Kilometer of Double Line

13. CONCLUSION

With the commissioning of Dedicated Freight Corridors, the

freight traffic would gradually shift from the existing IR conventional

Howrah New Delhi & New Delhi Mumbai (via Western Railway)

routes.

Simultaneous planning of conversion of existing conventional

route to high speed route gradually would help Indian Railways in

building up spare capacity for haulage of additional Passenger

Services.

Critical factors are line length, the number of trains needed to

respond to demand, train capacity, average distance and the

corresponding Unit Cost. It is interesting to note that neither the

increase in train capacity nor the commercial speed have a large

impact reducing the total costs of the project.

*************

Vous aimerez peut-être aussi

- OHE Manual Volume-IDocument404 pagesOHE Manual Volume-Isahoobd75% (4)

- Presentation On: 2 X 25 KV SystemDocument28 pagesPresentation On: 2 X 25 KV SystemAkhilesh kumar Srivastava100% (4)

- Study - OHE DescriptionDocument8 pagesStudy - OHE DescriptionTanweer AlamPas encore d'évaluation

- Actm 1Document169 pagesActm 1TPC 7850% (2)

- Bonding & EarthingDocument75 pagesBonding & EarthingPrachir Shrivastava0% (1)

- INECO Comparative Study 1x25 - 2x25Document16 pagesINECO Comparative Study 1x25 - 2x25manualvazPas encore d'évaluation

- Panto EntanglementDocument16 pagesPanto EntanglementAnonymous bau06xStT100% (1)

- OHE Manual Volume-IDocument404 pagesOHE Manual Volume-Ibsunanda010% (1)

- UIC Leaflet 406Document56 pagesUIC Leaflet 406devidattairsme100% (1)

- 02 MSS Final ElectricalDocument31 pages02 MSS Final ElectricalNima MahmoudpourPas encore d'évaluation

- AC DC InterfaceDocument28 pagesAC DC InterfaceLaurence MichaelPas encore d'évaluation

- Reminiscences of A Railwayman by NatarajanDocument145 pagesReminiscences of A Railwayman by NatarajanJoydeep Patra0% (1)

- ACTMDocument823 pagesACTMdc12dc86% (7)

- Power System Installation 2x25kv Traction SystemDocument28 pagesPower System Installation 2x25kv Traction Systemmott macPas encore d'évaluation

- Rdso Summer ReportDocument22 pagesRdso Summer ReportPRADEEP KUMARPas encore d'évaluation

- 9.10.17aluminium Cantilever FinalDocument16 pages9.10.17aluminium Cantilever Finalgkapoorg@gmail.com100% (1)

- Data Bank of Important Guidelines, Letters, Instructions, Circulars Etc For OHE PDFDocument129 pagesData Bank of Important Guidelines, Letters, Instructions, Circulars Etc For OHE PDFLakshmiVishwanathan0% (1)

- Principles For Layout Plans and Sectioning Diagrams For 25 KV Ac TractionDocument4 pagesPrinciples For Layout Plans and Sectioning Diagrams For 25 KV Ac TractionPragati SrivastavaPas encore d'évaluation

- Navi Mumbai Metro Line 1: Mast Calculation - Panchanand DepotDocument3 pagesNavi Mumbai Metro Line 1: Mast Calculation - Panchanand DepotAnkit Agarwal100% (1)

- Unit Types: History of Indian RailwayDocument5 pagesUnit Types: History of Indian RailwaysukhadiadarshanPas encore d'évaluation

- Ti SPC Ohe Atd 0060Document16 pagesTi SPC Ohe Atd 0060pradeeepgarg100% (1)

- OHEDocument8 pagesOHEMohammad Zakir50% (2)

- Overhead Equipments (OHE) & Current Collection Equipments: Electric Traction - Unit-3 - Unit-4Document36 pagesOverhead Equipments (OHE) & Current Collection Equipments: Electric Traction - Unit-3 - Unit-4suvo dasPas encore d'évaluation

- Ohe Anti - Theft Charging 25 KVDocument25 pagesOhe Anti - Theft Charging 25 KVAmit KumarPas encore d'évaluation

- DRAFT OHE Layout and Plan - 05082020 - UploadingDocument68 pagesDRAFT OHE Layout and Plan - 05082020 - UploadingAQIBPas encore d'évaluation

- Mohan Bidkar: Retd. Adee / TRD / Manmad Central RailwayDocument90 pagesMohan Bidkar: Retd. Adee / TRD / Manmad Central RailwayUpendra kumar SinghPas encore d'évaluation

- Ohe IDocument41 pagesOhe IMandar GorhePas encore d'évaluation

- Ohe Fitting GuidelineDocument56 pagesOhe Fitting Guidelinepretha56Pas encore d'évaluation

- 2) - Basics of OHE DesignDocument13 pages2) - Basics of OHE Designanuragt_575% (4)

- Bending Moment Calculation - Anticreep Center, One Cantilever, Tangent TrackDocument7 pagesBending Moment Calculation - Anticreep Center, One Cantilever, Tangent TrackAnkit AgarwalPas encore d'évaluation

- Ir Ohe ParametersDocument2 pagesIr Ohe ParametersDHARMENDRAPas encore d'évaluation

- Cantiliver Allocation ChartDocument78 pagesCantiliver Allocation Chartarun kumar vermaPas encore d'évaluation

- Camtech Recommendations: Maharajpur, Gwalior - 474005Document20 pagesCamtech Recommendations: Maharajpur, Gwalior - 474005ashwaniPas encore d'évaluation

- Cantilever Cataloagh Final 06 Sep 2017 Low Size PDFDocument52 pagesCantilever Cataloagh Final 06 Sep 2017 Low Size PDFVIVEK KUMAR100% (1)

- 25kv AT Feeding System For HSR: Presented By: R.K.Jain & B.S. Bodh, GM/Electrical, DFCCILDocument49 pages25kv AT Feeding System For HSR: Presented By: R.K.Jain & B.S. Bodh, GM/Electrical, DFCCILPANKAJ KESHARWANIPas encore d'évaluation

- 2X25 KVDocument28 pages2X25 KVAnonymous sENwj8nwq100% (1)

- DFCCIL HistoryDocument50 pagesDFCCIL HistorySP NiralaPas encore d'évaluation

- 25 KV Traction SCADA SPECIFICATION No. TISPCRCCSCADA0130 (Rev-1) 1Document70 pages25 KV Traction SCADA SPECIFICATION No. TISPCRCCSCADA0130 (Rev-1) 1pradeeepgarg100% (1)

- Ohe IDocument41 pagesOhe IAnonymous sENwj8nwq100% (11)

- Ohe ParameterDocument8 pagesOhe ParameterAmit Chaturvedi100% (2)

- Technical Standards OCSDocument76 pagesTechnical Standards OCStaarak143Pas encore d'évaluation

- CMRL-Presentation On Procedure For Safety Clearances - IDocument29 pagesCMRL-Presentation On Procedure For Safety Clearances - Ibumeshrai2026Pas encore d'évaluation

- Ohe Manual IIDocument306 pagesOhe Manual IIpunit sarswat100% (4)

- OHE InterviewDocument36 pagesOHE InterviewAnindyaGuhaPas encore d'évaluation

- Re 30 Ohe 5 - 11 60Document3 pagesRe 30 Ohe 5 - 11 60Abhishek Pandey25% (4)

- Conductor ParametersDocument34 pagesConductor ParametersDHARMENDRAPas encore d'évaluation

- Ti-Spc-Psi-Protct-6070 (9 08) PDFDocument49 pagesTi-Spc-Psi-Protct-6070 (9 08) PDFsrdeetrdsbc100% (2)

- Lecture 5 Power Supply Substation ArrangmentDocument36 pagesLecture 5 Power Supply Substation ArrangmentMaalmalan KeekiyyaaPas encore d'évaluation

- PantografeDocument12 pagesPantografeAlex GeorgePas encore d'évaluation

- 1414670989548-TI MI 0029 REV 3 3 Puley Type ATDDocument11 pages1414670989548-TI MI 0029 REV 3 3 Puley Type ATDkhan11k100% (1)

- Ohe Manual-1Document19 pagesOhe Manual-1ankitPas encore d'évaluation

- Mast&sps Details For OheDocument22 pagesMast&sps Details For OheLokeswaraRaoPas encore d'évaluation

- 25 KV Equipment Sizing Calculationv5 - PDFDocument56 pages25 KV Equipment Sizing Calculationv5 - PDFAbhas Gupta100% (2)

- Psi FinalDocument162 pagesPsi FinalsselmtpdrPas encore d'évaluation

- 2 X 25 KvacDocument24 pages2 X 25 KvacShubham shuklaPas encore d'évaluation

- ATD (Katariya Sir)Document42 pagesATD (Katariya Sir)Guruswamy Anumula100% (1)

- BBR 016 RigidCatenaryDocument4 pagesBBR 016 RigidCatenarykunalkhubaniPas encore d'évaluation

- Report On Electric Loco Shed Vadodara in TRD DepartmentDocument9 pagesReport On Electric Loco Shed Vadodara in TRD DepartmentBiren PatelPas encore d'évaluation

- APPENDIX I PRINCIPLES FOR LAYOUT PLANS AND SECTIONING DIAGRAMS FOR 25 KV Ac TRACTION PDFDocument19 pagesAPPENDIX I PRINCIPLES FOR LAYOUT PLANS AND SECTIONING DIAGRAMS FOR 25 KV Ac TRACTION PDFankitPas encore d'évaluation

- STC TRD RE 10Document377 pagesSTC TRD RE 10PavanPas encore d'évaluation

- AC Traction Vs DC TractionDocument24 pagesAC Traction Vs DC Tractionરામ પ્રતાપPas encore d'évaluation

- Introduction to Electricity Supply and Regulation in IndiaD'EverandIntroduction to Electricity Supply and Regulation in IndiaPas encore d'évaluation

- Theory and Technology for Improving High-Speed Railway Transportation CapacityD'EverandTheory and Technology for Improving High-Speed Railway Transportation CapacityPas encore d'évaluation

- Rolling Stock For Metro Railway-2nd Draft 25-1-20 by DevidattaDocument46 pagesRolling Stock For Metro Railway-2nd Draft 25-1-20 by DevidattadevidattairsmePas encore d'évaluation

- Maintenance ThesisDocument76 pagesMaintenance ThesisdevidattairsmePas encore d'évaluation

- Fuel Cell Technology For Indian Railways: HKKJR LJDKJ Jsy Ea KyDocument11 pagesFuel Cell Technology For Indian Railways: HKKJR LJDKJ Jsy Ea KydevidattairsmePas encore d'évaluation

- Parallel Session 1Document1 pageParallel Session 1devidattairsmePas encore d'évaluation

- 7 High Speed - Turnout Actuation, Locking and Detection Devices-Cost Efficient Service Proven SolDocument28 pages7 High Speed - Turnout Actuation, Locking and Detection Devices-Cost Efficient Service Proven SoldevidattairsmePas encore d'évaluation

- 5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilityDocument12 pages5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilitydevidattairsmePas encore d'évaluation

- 2 A Study For Development of Low Cost Train Digital Communication Network For High Speed Rail TraDocument12 pages2 A Study For Development of Low Cost Train Digital Communication Network For High Speed Rail TradevidattairsmePas encore d'évaluation

- 4 Fastenings For High Speed Track - Vipul Kumar (RDSO)Document10 pages4 Fastenings For High Speed Track - Vipul Kumar (RDSO)devidattairsmePas encore d'évaluation

- 1 Alignment Design Criteria For Dedicated High Speed Railway Lines - Arbind Kumar, Amrendra Jha (RITEDocument12 pages1 Alignment Design Criteria For Dedicated High Speed Railway Lines - Arbind Kumar, Amrendra Jha (RITEdevidattairsmePas encore d'évaluation

- Brief History of Electric Traction in IndiaDocument6 pagesBrief History of Electric Traction in IndiaAmarYalavarthiPas encore d'évaluation

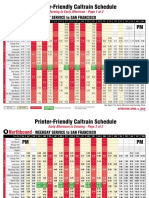

- Weekday Northbound Printer-Friendly Schedule 04042016Document2 pagesWeekday Northbound Printer-Friendly Schedule 04042016meniPas encore d'évaluation

- Electric Locomotive Workshop.Document38 pagesElectric Locomotive Workshop.Apurwa Patil100% (1)

- Chapter 3 - Rail Development PlanDocument116 pagesChapter 3 - Rail Development Planlolo buysPas encore d'évaluation

- Signalling in 25 KV Ac Electrified Section PDFDocument104 pagesSignalling in 25 KV Ac Electrified Section PDFpriyaranjan100% (1)

- Revised SOD 2004Document50 pagesRevised SOD 2004anilsahi@yahoo.co.in100% (3)

- Industrial Training Report Mechanical Workshop Gorakhpur Maintenance and OperationDocument47 pagesIndustrial Training Report Mechanical Workshop Gorakhpur Maintenance and OperationAkash KumarPas encore d'évaluation

- TractionDocument26 pagesTractionYogesh GurjarPas encore d'évaluation

- Summer Training at Indian Railways Electrical Genl. Department.Document32 pagesSummer Training at Indian Railways Electrical Genl. Department.Subhankar BosePas encore d'évaluation

- 48 TMSS 01 R0Document0 page48 TMSS 01 R0renjithas2005Pas encore d'évaluation

- EmiiDocument49 pagesEmiiŠãüřãbh PãthãkPas encore d'évaluation

- Ti SPC Ohe Ins 0070 FinalDocument38 pagesTi SPC Ohe Ins 0070 FinalAbhishek Pandey100% (1)

- Data Bank of Important Guidelines, Letters, Instructions, Circulars Etc For OHEDocument129 pagesData Bank of Important Guidelines, Letters, Instructions, Circulars Etc For OHEDHARMENDRAPas encore d'évaluation

- Static Model of A 2x25kV AC Traction SystemDocument6 pagesStatic Model of A 2x25kV AC Traction SystemnpfhPas encore d'évaluation

- In UK: Earthing and Bonding of Electrzfied RailwaysDocument7 pagesIn UK: Earthing and Bonding of Electrzfied RailwaysiaessackjeePas encore d'évaluation

- 17.5 MM DIN Rail Mounting MAR1 Part Number 88826115: Functions Timing Output Nominal Rating Connections Supply VoltageDocument3 pages17.5 MM DIN Rail Mounting MAR1 Part Number 88826115: Functions Timing Output Nominal Rating Connections Supply VoltageRoga29Pas encore d'évaluation

- STC TRD 01 PDFDocument162 pagesSTC TRD 01 PDFankitPas encore d'évaluation

- Shedule of Dimensions2Document4 pagesShedule of Dimensions2Gnanasekar SPas encore d'évaluation

- Jeffrey Russell - DR Stephen Goh - Aurecon Paper PDFDocument14 pagesJeffrey Russell - DR Stephen Goh - Aurecon Paper PDFAnubhav Hem Kumar JainPas encore d'évaluation

- HSR Rs Final enDocument150 pagesHSR Rs Final enSümeyye Kaya100% (1)

- Industrial Training Report Mechanical Workshop Gorakhpur Maintenance and OperationDocument47 pagesIndustrial Training Report Mechanical Workshop Gorakhpur Maintenance and OperationshivamPas encore d'évaluation

- Power Transfer From OHE To Traction Motor From Train 1705730505Document6 pagesPower Transfer From OHE To Traction Motor From Train 1705730505KONDAPARTHI NEHALPas encore d'évaluation

- High Speed RailwayDocument27 pagesHigh Speed RailwayRoffianto Adi NugrohoPas encore d'évaluation

- MRL WP1 D ANS 013 06 D1 1 Railway Network Key Elements and Main Sub Systems SpecificationDocument145 pagesMRL WP1 D ANS 013 06 D1 1 Railway Network Key Elements and Main Sub Systems SpecificationMarc MPPas encore d'évaluation

- Traction TransformationDocument7 pagesTraction TransformationdabrevipulPas encore d'évaluation

- Earthing Bonding Code - 16.01.2020Document17 pagesEarthing Bonding Code - 16.01.2020amitPas encore d'évaluation

- Global Logistics For EUDocument304 pagesGlobal Logistics For EUEngineerOmarPas encore d'évaluation