Académique Documents

Professionnel Documents

Culture Documents

4 Fastenings For High Speed Track - Vipul Kumar (RDSO)

Transféré par

devidattairsme0 évaluation0% ont trouvé ce document utile (0 vote)

145 vues10 pageshigh speed rail

Titre original

4 Fastenings for High Speed Track_Vipul Kumar(RDSO)

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documenthigh speed rail

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

145 vues10 pages4 Fastenings For High Speed Track - Vipul Kumar (RDSO)

Transféré par

devidattairsmehigh speed rail

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 10

Fastenings for High Speed Track

- Vipul Kumar, Executive Director/Track,

Research Design & Standards Organisation,

Ministry of Railways, India

1.0 Background

The primary purpose of a fastener is to connect or fix the rail with the sleeper

(tie). The fixing of rail to a sleeper may be done directly or indirectly with the

help of fastenings. In the process the fastening is subjected to severe vertical,

lateral and longitudinal forces. The forces, which are predominantly dynamic,

increase rapidly with the increasing loads and speeds. In addition, vibrations are

generated by moving loads mainly on account of geometrical irregularities of

track and wheel and due to forces set up by the imbalance in the rolling stock.

Traditional rigid fastening system of wooden and metal sleeper era were not

found capable to meet the challenge of heavy dynamic forces effectively as they

worked out loose under the high frequency vibrations of the order of 300 to

1000 Hertz even at a moderate speed of 100 kmph

1

. This type of fastening in fact

is unable to hold the rail to the sleeper firmly and with a constant pressure for a

good length of time. This led to development of elastic fastening system, even

known initially as double elastic fastening system having resilience both below

the rail in the form of a resilient rail pad, and above it in the form of a resilient

clip or tension clamp, primarily acting like a spring. There had been large

number of elastic fastening system developed since 1940 when the French

Railway system felt the need for going for concrete ties. The elastic fastening

systems had been developed initially by operating railway systems continuously

improving upon them over the years based on the experience gained. Some

prominent systems developed include Mills Clips and Hey Back of British

Railways; R. N. Griffon and Nabla of French Railways system; K-type and Delta

Clip fastener of German Railways; D.E. Clip of Netherland Railways; JRN clip of

Japanese Railway; and IRN-202 of Indian Railways.

JNR Fastening system

IRN-202 Fastener

(Indian Railways)

Typical K Fastener

DE Clip Fastener

(Netherlands)

Nabla Fastening System of SNCF

At some stage, the process of fastening development had been primarily taken

over by private players realizing the commercial potential of the product. The

elastic fastening systems developed so far have more or less served well and

proven their efficacy for conventional tracks of speeds upto 160 kph with axle

loads upto 250 KN. On Japanese and French Railways system and also on some

parts of German Railways systems, some of the fastening system developed

earlier e.g. Nabla, JNR and H.M. Fastening systems have even served well for

speeds upto 330 kmph for conventional ballasted tracks. This could be achieved

with modifications of certain components in the fastening system e.g. rail pad for

modifications in the overall resilience, (technically speaking equivalent

stiffness), holding mechanism to the sleeper, reconfiguring the tension clamp of

the fastening system, etc.

High speed tracks normally get subjected to even greater forces and vibrations

caused by higher momentum. This increases challenge for the fastening system

to perform its designated functions and is the prime reason fastening system

design for high speed track assuming an important role.

2.0 Pre-requisite of an Elastic Fastening System

(i) To provide an elastic link between the rail and sleeper for absorption /

transfer of the rail forces to the sleeper.

(ii) Keeping the rail in rail seat position on the sleeper and provide required

vertical, lateral and longitudinal stability during the disturbing dynamic

forces caused on account of traffic, thermal stresses etc. In other words, it

must retain the track geometry within certain tolerances against the

disturbing forces.

(iii) It should have sufficient fatigue resistance for long life. Ideally, the life of

each component of elastic fastening system should be equal to at least life

of rail, if not the sleeper.

(iv) The fastening system should be able to maintain its properties of

functional characteristics irrespective of the number of removal and re-

application required for maintenance of track.

(v) The fastening system should be simple to be used by the field staff i.e.

application, removal and maintenance of the fastening should be easy.

(vi) The fastening system should ideally be fit and forget type requiring no

maintenance or very little maintenance.

(vii) The fastening system should be able to provide sustainable track

circuiting for the need of automatic signaling system irrespective of

climatic condition.

(viii) The fastening system should have reasonable resistance against

unauthorised removal (anti-vandal feature).

(ix) The fastening system should have minimal number of components from

long term economic consideration to keep the inventory low for

maintenance establishment.

(x) To the extent possible the fastening system should be such that it is easy

to inspect and install the fastening.

(xi) The fastening system should be economical for the given traffic, climatic

conditions and other socio-technological considerations pertaining to a

given railway system/area. In other words, the fastening system should

be such that in the long run it is economically produced indigenously with

dependence on the export being minimal possible.

For high speed track the attenuation of noise and vibration to acceptable levels

becomes additional requirement for environmental considerations as the

frequency of secondary vibrations produced may go upto 5000 Hz

2

. The dynamic

behavior of the track plays an important role in generating wheel-rail rolling

noise. Vibrations generated are transmitted through the track and wheel

structures, and these vibrations are then responsible for radiating air-borne

noise. Like conventional tracks, in high speed tracks also the track geometry

plays the prime role in generation of noise and vibrations with elastic fastening

system having the responsibility for maintaining the track geometry. Therefore,

it plays a very vital role in the whole track structure in a high speed corridor.

3.0 Design Considerations

Normal design considerations are drawn from the functions a fastenings system

is supposed to perform as brought out in the preceding paragraph. Most

fastening systems have evolved through empirical approach in the early stages of

development with stipulations of laboratory testing of each component and

fatigue test of the whole assembly for the expected loads. There have been

continual efforts to draw standard criteria for design of fastening system.

Symposium done on Elastic Track Fastening in the year 1992 as a special session

of A.R.E.A Committee 5 (Track), Subcommittee 4 (Track Design)

3

summarizes

following aspects to be considered while designing an elastic fastener:

For Clip (Tension Clamp):

- Design working point of the clip (load deflection state after installation)

- The elastic limit of the clip

- The spring rate (Slope of the deflection line)

The presentation underlines the following aspect while designing the clip:

The basic concept of a system design that maintains a consistent elastic (spring)

resistance without permanent deformation, preferably over as large a service load

range as practicable. Designers strive for an accommodating elastic range below

the yield point or by deflection limiting design (building a mechanical stop).

For fastening system as a whole:

- Vertical loads which affect tie stress and rail uplift in the precession wave,

therefore, laying one of the criteria for shoulder and clip and design Vertical

loads also affect the pressure on the tie and in turn on the ballast thus

determining the pad design in a big way. Pad design is also determined by needs

of noise and vibration mitigation.

- Longitudinal loads (from traction forces and rail temperature variations)

determining design of rail pad (providing required friction for mobilizing creep

resistance), clip (with adequate toe load to generate required longitudinal/creep

resistance) and shoulder design

- Lateral Loads which is incurred by fastening system when the L/V ratio exceeds

the coefficient of friction between rail and the rail seat thus determining pad,

shoulder and clip design

Design considerations for high speed fastenings system is mostly retained as

protected knowledge with most of high speed railway system or their

manufacturers. European National specification, however, in the final draft of EN

13481-1:2012 categories type C as a fastening system designed for conventional

mail line railways with a typical axle load of 225 KN, a typical curve radius of 400

m, a typical maximum speed of 250 km/h, a typical rail section of 60E1 and a

typical sleeper or support spacing of 600 mm. For higher speed (not specified by

EN code, but inferred to be in excess of 250 km/h) the specification categorizes D

as fastening system designed for lines with large radius curves, often used for

high speed trains and having a typical axle load of 180 kN, a typical curve radius

of 800m, a typical rail section of 60E1, a typical sleeper or support spacing of 600

mm and any typical maximum speed. The other corresponding EN specifications

provide acceptance criteria and method of laboratory testing of various

components of fastening system.

4.0 High speed fastening system for Ballastless Track (BLT)

Use of ballast less track (also known as slab track) may be inevitable in locations

like tunnels, viaducts and station areas. Missing resilience of ballast in a

ballastless track adds another challenge to fastening system which gets further

magnified in high speed regime for reasons discussed in preceding paragraphs.

As ballasted tracks require frequent intermediate interventions for regular

upkeep, many inter-city high speed routes contemplating heavy traffic are

planned as ballast less track, which also provide designed control on noise

vibration mitigation.

Due to ever increasing use of BLT, a large amount of research and trial work has

been done and still in progress on advanced railway systems for developing

ballast less track with compatible fastening system. Generally ballast track

should refer to the base below the fastening system but due to the complexity

involved in track response to moving loads and need for controlling combined

response at design stage, fastening system design need to be considered as an

integral part of whole track system. However, it is important to note that the

fastening system manufactures generally are not the same ones (in the current

scenario) as the firms/organizations offering ballast track design/form. Though

the compatibility of each others system is claimed by both BLT and fastening

system manufactures, track designers have to discharge huge amount of

responsibility in choosing the right system for a given set of not only operating

conditions in terms of speed and axle loads, but also for given alignment; civil

structure chosen (tunnel, viaduct, etc.); formation and foundation conditions of

nearby buildings; environmental norms to be complied; etc.

Owing to large number of variations of BLT and fastenings systems tried and

used world over, a number of classifications

4

are in vogue. Some of the popular

classifications are brought out as under:

a. Based on Type of Civil Structure :

(i) BLT on earthwork

(ii) BLT on bridges/Viaducts

(iii) BLT in Tunnels

On high speed routes, design of BLT with fastening system in each of above case

needs to be examined separately due to varying responses offered by these civil

structures to moving loads.

Ballastless track on embankment Ballastless track in tunnel

b. Classification based on Type of intermediate base of BLT :

(i) Compact systems; BLT with concrete sleepers placed in in-situ concrete,

like Rheda, Zublin, etc.

(ii) Base plated systems; BLT with elastically supported base plates on the top

of the slab.

(iii) Coated concrete sleeper or concrete-block systems. These sleepers or

blocks are fixed in a concrete support construction by a resilient

intermediary material. This material with resilient properties can be a

rubber boot or an embedding material. Sonneville or Stedef are examples

of this type.

(iv) Embedded rail systems slab track with continuously-supported

embedded rails in a concrete slab (with recesses) or in steel channels on

bridges.

(v) Prefabricated slab systems; concrete prefabricated slabs, either

reinforced and/or prestressed with any rail fastening design.

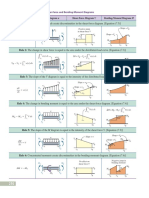

RHEDA 2000 system

Stedef Twin Block System

Embedded Rail system

Shinkansen Slab Track system

There are other classifications as well e.g. low attenuation and high attenuation

BLT based on the extent of vibrations and noise attenuations; light intermediate,

heavy intermediate based on the medium between two resilience; etc.

5.0 Selection of Fastening System for high speed Tracks

This is one of the most important aspects for new corridors even for

conventional speeds particularly on BLT and may be very crucial for high speed

tracks. There are no set rules for selection of fastening system other than

checking its compliance to the requirements brought out in para-2 above. More

organized operators do carry out ABC analysis evaluating compliance of each

shortlisted fastening system through an inter-weight assigned to each parameter

working out over all score and then taking final decision on cost benefit analysis.

Uzbek Railways in early 2000 selected fastening system for its upgraded track

between Tashkent and Samarkand on the basis of this method.

Some operators base their decision on past proven record of fastening system

which can be a very effective way of selection if the operating conditions in terms

of speed, axle load, civil structure, vehicle characteristics, etc (just to name a few)

are similar. However, the reliability of this method can be extremely suspicious

even with minor changes in operating conditions in case of high speed corridors.

Some consultants do claim that they can model track component response with

varying operating conditions so as to make an informed decision about the

suitability of given track components. Clear acceptance of their claim, however is

not available in public domain. Nevertheless, it is better to have some model

based analysis along with proven-ness in near similar conditions for taking final

decision about the selection of fastening system for such an important track

component that can make or mar the throughput capacity envisaged from the

planned corridor. This is on account of the fact that the combined vehicle-track

system is complex and has many natural frequencies

5

. When one of the excitation

frequencies corresponds to a natural frequency of the system there is

particularly strong vibration. As the primary vibrations are caused as a result of

forces between wheels and rails, there is lot of energy associated with these

primary frequencies which are normally in the range of 0-20 Hz and most civil

structure may have their natural frequencies in the same range. The damage to

these may be substantial if primary excitation frequencies match with some of

the track components and civil structures natural frequencies in such a way that

formation of nodes and antinodes reinforces each other rather than cancelling.

This is too complex a phenomenon to be studied mathematically or even through

modeling in its totality and adhoc decisions taken in some cases have lead to

failure in operating corridors to designed capacities.

Many advanced Railway systems planning high speed corridors therefore

carryout detailed testing of proposed vehicle-track system through test tracks so

that compatibility of vehicle, track and civil structure is substantiated before

large scale commitment and investments. The Railway systems not privileged

enough to have such testing tracks have to innovate and take an informed

decision technically to get the right technology so that track structure can serve

for next 75-100 years.

High speed corridors are normally planned between two important business

cities where distance generally would exceed 400 kms needing huge amount of

capital investment. In the opinion of the author, it may not be a bad idea to first

construct (say) a 40-50 kms stretch of the corridor and use it as a test track to

judge the efficacy of shortlisted systems, be it pertaining to track or traction or

rolling stock, through extensive run over a short span of time varying from six

months to a year. With so much of public money at stake it is better late by a year

or so rather than run the corridor at half the designed capacity for next decade or

two unless major intervention and premature expenditure solves the problem.

References:

1. ERSF-Consultancy, phase-I report to UTY by RITES Ltd., Author: Vipul Kumar

2. The Dynamic Behavior of rail fasteners by D. J. Thompson and J.W. Verheij

3. Committee 5 presentation of Elastic Fasteners, 1995 A.R.E.A Annual Technical

Conference.

4. Ballastless TrackAn Overview and Developments in India by Vipul Kumar, Ashwani

Kumar and Rituraj, IPWE Seminar, Chennai, January-2013

5. Modern Railway Track by Coenraad Esveld

Vous aimerez peut-être aussi

- Railroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975D'EverandRailroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Arnold D. KerrÉvaluation : 5 sur 5 étoiles5/5 (1)

- P WayDocument6 pagesP WayDHARMENDRAPas encore d'évaluation

- Systra TaiwanDocument2 pagesSystra TaiwanSudathipTangwongchaiPas encore d'évaluation

- Rail System Engineering Fundamentals 65Document65 pagesRail System Engineering Fundamentals 65Mustafa Bilge AydoğduPas encore d'évaluation

- Thesis On Rail EngineeringDocument215 pagesThesis On Rail EngineeringOm SinghPas encore d'évaluation

- The Maintenance of Permanent Way PartDocument77 pagesThe Maintenance of Permanent Way PartRanjanjharkhandPas encore d'évaluation

- Maintenance of Track GaugeDocument22 pagesMaintenance of Track GaugeMaicon H. RossiniPas encore d'évaluation

- Technical Specification Turnouts and Expansion SwitchesDocument141 pagesTechnical Specification Turnouts and Expansion Switchescezar100% (1)

- Rail Track Drainage Technical Guide V3.0Document24 pagesRail Track Drainage Technical Guide V3.0scorpio1878Pas encore d'évaluation

- Flash Butt WeldingDocument20 pagesFlash Butt WeldingRakesh SrivastavaPas encore d'évaluation

- Types of Railway Turnouts and Their ComponentsDocument10 pagesTypes of Railway Turnouts and Their ComponentsrobbsPas encore d'évaluation

- TCRP RPT 71v4 PDFDocument110 pagesTCRP RPT 71v4 PDFKeith RegachoPas encore d'évaluation

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part7Document6 pagesTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part7linghuchongPas encore d'évaluation

- Construction of MRT Chaloem Ratchamongkhon Line Underground Structures North and Japanese Shield Tunnel TechnologyDocument10 pagesConstruction of MRT Chaloem Ratchamongkhon Line Underground Structures North and Japanese Shield Tunnel TechnologyTeera AthirahPas encore d'évaluation

- Arema Mre 2015 Toc-Vol1 Ch4Document2 pagesArema Mre 2015 Toc-Vol1 Ch4Adnan Hariadi Bustami0% (2)

- Railway Engineering PDFDocument22 pagesRailway Engineering PDFDivyesh Prajapati75% (4)

- Pwi Journal 1017 Vol135 Pt4 - Rail Thermal Force Calculations For Jointed Track - Article 3Document7 pagesPwi Journal 1017 Vol135 Pt4 - Rail Thermal Force Calculations For Jointed Track - Article 3gururaja nPas encore d'évaluation

- Railway Engineering Unit 1Document198 pagesRailway Engineering Unit 1neeraja medapatiPas encore d'évaluation

- Pandrol DFC - Operation & Maintenance ManualDocument20 pagesPandrol DFC - Operation & Maintenance ManualOon Chee Koon100% (1)

- HS Rail Turnout Lit Review - Final - v2Document32 pagesHS Rail Turnout Lit Review - Final - v2Oscar Orlando CuervoPas encore d'évaluation

- Reliability Analysis of Switches and Crossings 2013 v1.4Document30 pagesReliability Analysis of Switches and Crossings 2013 v1.4varuna189Pas encore d'évaluation

- Transportation Engineering: Types of Rails Spacing and Stifness of RailsDocument30 pagesTransportation Engineering: Types of Rails Spacing and Stifness of Railsyousaf khanPas encore d'évaluation

- Components of Railway Track 1Document21 pagesComponents of Railway Track 1Mudasar HussainPas encore d'évaluation

- Prospekt OEBB-Porr FF-System enDocument12 pagesProspekt OEBB-Porr FF-System enH Mahmut DüzenPas encore d'évaluation

- Glossary of Railway Terminology Selection en FR de PDFDocument451 pagesGlossary of Railway Terminology Selection en FR de PDFMenchu MartínPas encore d'évaluation

- Track Modulus 9Document12 pagesTrack Modulus 9Marius DiaconuPas encore d'évaluation

- GCRT5019 Iss 2 Track StandardsDocument40 pagesGCRT5019 Iss 2 Track StandardsSofia D'AlessandroPas encore d'évaluation

- Slab Track Laboratory Test ProgramDocument92 pagesSlab Track Laboratory Test ProgramYuvita ValentinaPas encore d'évaluation

- Railway Braking PDFDocument6 pagesRailway Braking PDFTANYA AGARWALPas encore d'évaluation

- TCRP Wheel Rail Noise ReportDocument220 pagesTCRP Wheel Rail Noise ReportAnonymous OmwbxkB100% (1)

- Abstract - Automated Railway Track Inspection SystemDocument1 pageAbstract - Automated Railway Track Inspection SystemRaghav AggarwalPas encore d'évaluation

- Standard Turnouts PDFDocument8 pagesStandard Turnouts PDFfbturaPas encore d'évaluation

- Ballastless Track Systems-Experiences Gained in Austria and GermanyDocument20 pagesBallastless Track Systems-Experiences Gained in Austria and GermanyBesim GülcüPas encore d'évaluation

- Best Practice Guide - Construction Railways Operations PDFDocument21 pagesBest Practice Guide - Construction Railways Operations PDFsuman100% (1)

- TMC 202 PDFDocument184 pagesTMC 202 PDFVerce VasilevskaPas encore d'évaluation

- TMC 224 PDFDocument88 pagesTMC 224 PDFsajuxPas encore d'évaluation

- Lec#8, Points and CrossingsDocument46 pagesLec#8, Points and CrossingsNawaz AliPas encore d'évaluation

- A Good Practice Guide For Managing The Wheel-Rail Interface of Light Rail and Tramway SystemsDocument21 pagesA Good Practice Guide For Managing The Wheel-Rail Interface of Light Rail and Tramway SystemsIbraheem Adel SheerahPas encore d'évaluation

- History of Mass TransitDocument4 pagesHistory of Mass TransitDebjani PandaPas encore d'évaluation

- Design of Light Rail Transit at Complex Intersections PDFDocument18 pagesDesign of Light Rail Transit at Complex Intersections PDFMonico DeytiquezPas encore d'évaluation

- Points and Crossings Are Provided To Help Transfer Railway Vehicles From One Track To AnotherDocument17 pagesPoints and Crossings Are Provided To Help Transfer Railway Vehicles From One Track To AnotherMuhammad ÍmranPas encore d'évaluation

- Wa0014Document334 pagesWa0014Paramvir chahliaPas encore d'évaluation

- Engineering Standard - Track Slab - NSWDocument14 pagesEngineering Standard - Track Slab - NSWenggmohan100% (1)

- AS1085.1 2017 Railway Track Material-Steel Rails-HistoryDocument85 pagesAS1085.1 2017 Railway Track Material-Steel Rails-HistoryAndré CaridePas encore d'évaluation

- Section5 Level CrossingsDocument54 pagesSection5 Level CrossingsCecilio Rosa MontePas encore d'évaluation

- Lesson Plan For Training of P. Way Supervisor (Promotional Course) PDFDocument368 pagesLesson Plan For Training of P. Way Supervisor (Promotional Course) PDFP C GargavaPas encore d'évaluation

- 02 Oliver NenadovicDocument39 pages02 Oliver NenadovicRinu RavikumarPas encore d'évaluation

- The Importance of Sleepers Spacing in RailwaysDocument15 pagesThe Importance of Sleepers Spacing in RailwaysPatrick Macedo100% (1)

- HSR Rs Final enDocument150 pagesHSR Rs Final enSümeyye Kaya100% (1)

- Towers: Lattice TowerDocument3 pagesTowers: Lattice Towernipuna22Pas encore d'évaluation

- Rail-Weld Failures Prevention, Monitoring & DetectionDocument8 pagesRail-Weld Failures Prevention, Monitoring & DetectionShipra MishraPas encore d'évaluation

- Railway Track Manual Part 1Document167 pagesRailway Track Manual Part 1Sima Viorel100% (3)

- Multi-Conductor Train Simulations For Electrification SystemDocument27 pagesMulti-Conductor Train Simulations For Electrification SystemRinu RavikumarPas encore d'évaluation

- Rail Adjustment - Engineering ManualDocument65 pagesRail Adjustment - Engineering ManualMuhammad Fahim NaseemPas encore d'évaluation

- Rails and Joints: Transportation Engineering - IDocument10 pagesRails and Joints: Transportation Engineering - IAnas ShaikhPas encore d'évaluation

- British Rail AlignmentDocument39 pagesBritish Rail AlignmentOm SinghPas encore d'évaluation

- Handbook of Railroad Construction; For the use of American engineersD'EverandHandbook of Railroad Construction; For the use of American engineersPas encore d'évaluation

- Rolling Stock For Metro Railway-2nd Draft 25-1-20 by DevidattaDocument46 pagesRolling Stock For Metro Railway-2nd Draft 25-1-20 by DevidattadevidattairsmePas encore d'évaluation

- UIC Leaflet 406Document56 pagesUIC Leaflet 406devidattairsme100% (1)

- Maintenance ThesisDocument76 pagesMaintenance ThesisdevidattairsmePas encore d'évaluation

- Fuel Cell Technology For Indian Railways: HKKJR LJDKJ Jsy Ea KyDocument11 pagesFuel Cell Technology For Indian Railways: HKKJR LJDKJ Jsy Ea KydevidattairsmePas encore d'évaluation

- Parallel Session 1Document1 pageParallel Session 1devidattairsmePas encore d'évaluation

- 7 High Speed - Turnout Actuation, Locking and Detection Devices-Cost Efficient Service Proven SolDocument28 pages7 High Speed - Turnout Actuation, Locking and Detection Devices-Cost Efficient Service Proven SoldevidattairsmePas encore d'évaluation

- 5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilityDocument12 pages5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilitydevidattairsmePas encore d'évaluation

- 1 Alignment Design Criteria For Dedicated High Speed Railway Lines - Arbind Kumar, Amrendra Jha (RITEDocument12 pages1 Alignment Design Criteria For Dedicated High Speed Railway Lines - Arbind Kumar, Amrendra Jha (RITEdevidattairsmePas encore d'évaluation

- 3 High Speed OHE of Indian Railways Issues, Challenges and Options - N.N.lal (RDSO)Document11 pages3 High Speed OHE of Indian Railways Issues, Challenges and Options - N.N.lal (RDSO)devidattairsmePas encore d'évaluation

- 2 A Study For Development of Low Cost Train Digital Communication Network For High Speed Rail TraDocument12 pages2 A Study For Development of Low Cost Train Digital Communication Network For High Speed Rail TradevidattairsmePas encore d'évaluation

- Ben Hielscher Portfolio TemplateDocument2 pagesBen Hielscher Portfolio TemplateChiefPas encore d'évaluation

- Uog-Iot Construction Technology and Management Bsc. Program - Year IiiDocument120 pagesUog-Iot Construction Technology and Management Bsc. Program - Year Iiigugsa araya100% (1)

- Slab Bridge 6m Span Superstructure DesignDocument12 pagesSlab Bridge 6m Span Superstructure DesignEngineeri TadiyosPas encore d'évaluation

- MCQDocument5 pagesMCQAhmed HamzaPas encore d'évaluation

- Md. Tofazzal HosenDocument22 pagesMd. Tofazzal HosenMorshedul HoquePas encore d'évaluation

- Section 03 37 13 - ShotcreteDocument7 pagesSection 03 37 13 - ShotcreteWilber Will Huillca Santa CruzPas encore d'évaluation

- Basic Construction DesignDocument8 pagesBasic Construction DesignAbigail LoricoPas encore d'évaluation

- Daily Progress ReportDocument2 pagesDaily Progress ReportStephen Harold RayosoPas encore d'évaluation

- IES: Books For Civil EngineeringDocument5 pagesIES: Books For Civil EngineeringDeep DebnathPas encore d'évaluation

- ID 67 Gan DesDocument18 pagesID 67 Gan DesCrystal JanePas encore d'évaluation

- OCF by Jaspal SirDocument2 pagesOCF by Jaspal SirAnkur SinhaPas encore d'évaluation

- 03 Priced South Meadows Mall Structural Steel Roof S Station Canopy & Line Shops & Architectural Features BOQ Rev F 04302023Document9 pages03 Priced South Meadows Mall Structural Steel Roof S Station Canopy & Line Shops & Architectural Features BOQ Rev F 04302023Marlon KachuwaPas encore d'évaluation

- Earthquake Engineering Assignment Ii: Case Study: Picture #6Document4 pagesEarthquake Engineering Assignment Ii: Case Study: Picture #6Ricky PriyatmokoPas encore d'évaluation

- Design Criteria For Sewage SystemsDocument400 pagesDesign Criteria For Sewage SystemselcusiPas encore d'évaluation

- New NRLDDocument203 pagesNew NRLDnlnmurthy28Pas encore d'évaluation

- 3-Liquid Retaining StructuresDocument3 pages3-Liquid Retaining StructuresTabish IslamPas encore d'évaluation

- Precast Concrete ConstructionDocument37 pagesPrecast Concrete ConstructionRuta Parekh100% (1)

- OTTVDocument8 pagesOTTVsuaidah shima100% (1)

- Beam Column - IS 800Document2 pagesBeam Column - IS 800parishith0% (1)

- Coastal Planning Management-Lesson4-Hydraulic StudyDocument47 pagesCoastal Planning Management-Lesson4-Hydraulic StudyshirleyPas encore d'évaluation

- (Fixed Head Pile) : Pile Cap Bott GLDocument2 pages(Fixed Head Pile) : Pile Cap Bott GLShivendra KumarPas encore d'évaluation

- Plumbing System - Building Service - NewDocument135 pagesPlumbing System - Building Service - NewAung San HtwePas encore d'évaluation

- JKR Rates 2011Document45 pagesJKR Rates 2011Derek Martin100% (2)

- ST Nerf 30 Septic Tank Details ST Nerf 30Document1 pageST Nerf 30 Septic Tank Details ST Nerf 30mhazarath murariPas encore d'évaluation

- Mini Project Civil AbstractDocument1 pageMini Project Civil AbstractVidhun Ravindran100% (2)

- Equation Load Diagram W Shear-Force Diagram V Bending-Moment Diagram MDocument1 pageEquation Load Diagram W Shear-Force Diagram V Bending-Moment Diagram MAndres Felipe Prieto AlarconPas encore d'évaluation

- Circular TanksDocument8 pagesCircular TanksMohamed Ehab100% (1)

- Stack Ep PT AntamDocument2 pagesStack Ep PT AntammoddysPas encore d'évaluation

- Analysis of Deformation of Vertically Loaded Piles - Mark F. RandolphDocument13 pagesAnalysis of Deformation of Vertically Loaded Piles - Mark F. RandolphJHIH KAI CHANGPas encore d'évaluation

- Super Final MH ESTIMATEDocument214 pagesSuper Final MH ESTIMATEIshor ThapaPas encore d'évaluation