Académique Documents

Professionnel Documents

Culture Documents

Triaxial Test

Transféré par

Vilma Puma InostrozaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Triaxial Test

Transféré par

Vilma Puma InostrozaDroits d'auteur :

Formats disponibles

The Hashemite University

Faculty of Engineering

Civil engineering

Department

Name :

Ahmad Jameel

Awwad

! D : "#$%&'

Exp. No!

(%)*

Exp. Name:

( T+A,A- TE.T *

Deu Date:

%$/"/$))0

Dr! : 123456 789:

Eng!:1;<=56 >9?@

TRIAXIAL TEST

Objective : 0

To introduce the reader to the basic procedure for

determine the undrained" soil shear strength parameter & c

& the "elastic " parameter of stress-strain modulus Es &

Poisson ratio of soil. The method for both cohesion less &

cohesive soil are given

Equipment : 0

Compression machine.

Triaxial cell.

pecimen mold! rubber membrane! membrane

stretcher! rubber binding strips & prose stone.

"acuum pump & air pressure source #ith necessar$

pressure indicate.

Calipers.

pecimen trimmer for cohesive tube samples.

Genera !i"cu""ion : 0

%ne of the primar$ purposes of this test is to determine

the shear strength parameter of the soil. These parameter are

defined b$ Coulombs shear strength e&uation .

' c ( n tan

)here :

' shear strength * +pa,

C ' soil cohesion or antiparticles adhesion *+pa, .

n ' intergranular pressure * +pa,.

' angle of internal friction.

The cohesion term is self explanator$ as being similar to

glue stic+ing particles together. The n tan term is usual

description of friction bet#een t#o particles! used in ph$sics

as -! #here 'tan & - ' n ! the normal stress bet#een

the t#o particles.

.f #e appl$ a normal pressure n on a volume of sat. oil the

pressure is carried.

To remove the increase in pore pressure #e obtain :

' C / ( *n ( 0 u, tan

#roce$ure : 0

1. 2asten the base plant to the base of the cell. 3ttach a rubber

membrane of the proper diameter to the base plant! using

rubber strips or bands.

4. )eigh a container of dr$ sand so that the sample densit$ can

be obtained and approximatel$ duplicated for succeeding tests.

5. Place a specimen mold around the rubber membrane and fold

the top portion of the membrane do#n over the mold. 6o not

fold ! ho#ever! if the mold is so large that the membrane #ill

be torn in the process.

7. Carefull$ place the sand in the membrane ! using a tamper to

maintain the sample shape and densit$ . )hen producing a

sample of re&uired densit$ it ma$ be desirable to divide the

height into e&ual increments ! compute the &uantit$ of *#et,

soil for each height! and place that portion in each sample

segment.

8. Place a porous stone *damp for #et soil , and then the top platen

on the sample. .t ma$ also be necessar$ to coat the outer rim of

the plant #ith silicone grease to obtain a more lea+ proof seal.

9. .f it is desired to saturate the sample! open the appropriate

valves of lines 3 and : and observe the sample until it is

saturated. 3 slight vacuum on the sample can be used to speed

up the saturation process.

;. Chec+ that the compression machine is set to the desired

strain rate *generall$ bet#een <.8 and 1.48 mm=mm, as

specified b$ $our instructor.

>. Turn on the compression machine! and ta+e simultaneous load

and deformation readings using 6ata heet 18b from $our data

sheet section. ?eadings ma$ be ta+en at until either

a. @oad pea+s and then falls off! or

b. 6eformation is some#hat greater than 18 percent

strain! or

c. @oad holds constant for three or four successive

readings.

Sampe %acuation:

6eformation' <.<A7mm

@oad P' 1<.44A -

train B ' C@=@' .<A7=;9'.<<147

3/' 3= *1 - B, ' 1158.7 mmD

6eviator tress! CEf' P=3/' .<<A<<7 FPa.

?esults:

E12 ' 1<<.559;FPa

E52 ' 1<< FPa

CE12 ' <.559; FPa

Et ' FPa

u ' FPa

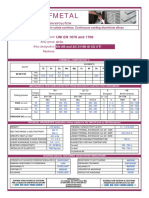

Dis.

(Kpa)

Force % Acr (mm^2)

0

0

0 0 0 0 1334

0.094

100.452

10.229 0.0012368 0.123684 0.00900913 1135.404316

0.241

100.452

181.135 0.003111 0.31105 0.15922453 113.60413

0.393

100.452

245.04 0.005111 0.51105 0.2155498 1139.894454

0.54

100.452

281.931 0.001053 0.10526 0.24684992 1142.115028

0.69

100.452

303.241 0.009089 0.90895 0.2649805 1144.389855

1.065

100.452

339.468 0.0140132 1.401316 0.2951596 1150.11668

1.445

100.452

360.8 0.0190132 1.901316 0.3120942 1155.98808

1.82

100.452

33.564 0.023944 2.3943 0.3215324 1161.822594

2.198

100.452

384.219 0.0289211 2.892105 0.3290185 116.3231

2.53

100.452

390.612 0.0338553 3.385526 0.3329341 113.3181

2.948

100.452

396.366 0.038895 3.8894 0.3359105 119.62361

3.32

100.345

399.136 0.04363 4.3632 0.3365635 1185.914989

3.05

100.452

399.136 0.0485 4.85 0.33481316 1192.11563

4.084

100.345

398.01 0.053368 5.33684 0.33216924 1198.398131

4.46

100.185

394.84 0.0586842 5.868421 0.3288 1204.69663

4.83

100.452

388.481 0.063644 6.36444 0.320269 1211.0891

5.21

100.452

369.302 0.068644 6.86444 0.30330808 121.580492

5.595

100.452

313.896 0.036184 .361842 0.25642634 1224.11605

5.94

100.452

256.359 0.086053 .860526 0.20829615 1230.4286

6.352

100.452

21.362 0.083589 8.35895 0.15650 123.42246

!ata an$ cacuation:

&i'ure":

( !i"cu""ion ) %oncu"ion :

G 6iscussion %f ?esult : <

%ne of the primar$ purposes of this test is to

determine the shear strength parameter of the soil.

The Fohr circle dro#n increase because the spacemen #as

saturated

G%ne of the most important stiffness properties of soil is

hear strength of soil! that can be determine b$ Triaxial Test

b$ appl$ing compression force CE1 on the sample that confined

b$ #ater to develop lateral stresses E5. The test done #ith

undrained condition that mean E5 ' pressure of #ater that

surrounded the specimen.

-ormal stresses #hen the specimen #as failure E12 ' FPa

)hen adopt CE1 that cause failure of the specimen! Fohr/s

circle dra#n to determine hear strength of the tested soil!

#here u ' HPa

Fodulus of elasticit$ of soil is the slope of *E1- E5, "s. strain

graph! that #as Et ' FPa

The length of sample should t#ice the diameter *@'I 46,! to

avoid potential failure Jones overlap.

The device done the test can do different tests as KK!C6!CK!

and permeabilit$.

Re*erence : 0

3TF 6 4>8<

3TF 6 7;9;

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Hyperelastic Quad4Document1 pageHyperelastic Quad4Vilma Puma InostrozaPas encore d'évaluation

- 1 Vibrating SystemsDocument7 pages1 Vibrating SystemsVilma Puma InostrozaPas encore d'évaluation

- C5Document4 pagesC5Vilma Puma InostrozaPas encore d'évaluation

- Blind TextDocument39 pagesBlind TextVilma Puma InostrozaPas encore d'évaluation

- Geo 11 Paper 120Document9 pagesGeo 11 Paper 120Vilma Puma InostrozaPas encore d'évaluation

- ThAnalysis Catalogue enDocument44 pagesThAnalysis Catalogue enHanLe DuyPas encore d'évaluation

- Introduction To Material Science Rev1Document36 pagesIntroduction To Material Science Rev1Blessings James BwalyaPas encore d'évaluation

- ESIA 5 Structural Integrity in The 21st Century - The Lifetime of Plant, Structures and Components - Evaluation, Design, ExtensiDocument3 pagesESIA 5 Structural Integrity in The 21st Century - The Lifetime of Plant, Structures and Components - Evaluation, Design, ExtensiRoelf MostertPas encore d'évaluation

- Chirai Anjar Rigid Pavement Design As Per IRC 58 2011Document60 pagesChirai Anjar Rigid Pavement Design As Per IRC 58 2011chetan c patilPas encore d'évaluation

- Multiscale Modeling of Compressive Behavior of Carbon Nanotube/polymer CompositesDocument6 pagesMultiscale Modeling of Compressive Behavior of Carbon Nanotube/polymer CompositesShahid MehmoodPas encore d'évaluation

- 07a30602 Metallurgical Thermodynamics and KineticsDocument6 pages07a30602 Metallurgical Thermodynamics and KineticsSharad Kumar AgarwalPas encore d'évaluation

- Typical Properties - GRAFOIL® Grade GTBDocument2 pagesTypical Properties - GRAFOIL® Grade GTBMamacintPas encore d'évaluation

- Heat Capacity of Sodium Silicate Liquids: Pascal RichetDocument3 pagesHeat Capacity of Sodium Silicate Liquids: Pascal RichetDaniel SetyadiPas encore d'évaluation

- XRF/XRD and SEM-EDS QuestionsDocument2 pagesXRF/XRD and SEM-EDS QuestionsWidiya Noor DianaPas encore d'évaluation

- Termal AnalysiiiisDocument5 pagesTermal AnalysiiiisSalman AshfaqPas encore d'évaluation

- 5 60 Lecture23Document4 pages5 60 Lecture23sgybleePas encore d'évaluation

- Theory and Applications of Colloidal Suspension Rheology-Cambridge University Press (2021)Document437 pagesTheory and Applications of Colloidal Suspension Rheology-Cambridge University Press (2021)Conta EstudoPas encore d'évaluation

- Practical Yield Line DesignDocument175 pagesPractical Yield Line DesignGan Chin Phang100% (1)

- Reservoir Seismic 6Document57 pagesReservoir Seismic 6Manish ChaturvediPas encore d'évaluation

- STK400Document2 pagesSTK400irne83Pas encore d'évaluation

- Discussion and Conclusion Lab 3Document3 pagesDiscussion and Conclusion Lab 3api-406010100% (1)

- ASTM A710 Engineering Report Grade 50 Sheet Steel Formability Material For ClampsDocument54 pagesASTM A710 Engineering Report Grade 50 Sheet Steel Formability Material For ClampsTony KrolikowskiPas encore d'évaluation

- Seismic Design of Shallow Foundations PDFDocument40 pagesSeismic Design of Shallow Foundations PDFNicon Paul100% (1)

- 4 - Settlement of Shallow FoundationsDocument28 pages4 - Settlement of Shallow FoundationsKhalid AljanabiPas encore d'évaluation

- Lecture 2 - Particle Characterization & Size Reduction v2Document32 pagesLecture 2 - Particle Characterization & Size Reduction v2roxette100% (1)

- Emc 1Document21 pagesEmc 1Ömer YılmazPas encore d'évaluation

- Contents of CAMPUSDocument78 pagesContents of CAMPUSVicky GautamPas encore d'évaluation

- Crystallographic Defect: Point DefectsDocument4 pagesCrystallographic Defect: Point DefectsMathan KumarPas encore d'évaluation

- Title: Latent Heat of FusionDocument4 pagesTitle: Latent Heat of FusionJanine Anne De VeraPas encore d'évaluation

- Brittleness IndexDocument3 pagesBrittleness IndexViviRachmawatiPas encore d'évaluation

- #135 Thermal Diffusion Coefficient of Major Plastics - Technical Tutorial - MISUMIDocument2 pages#135 Thermal Diffusion Coefficient of Major Plastics - Technical Tutorial - MISUMImuthuPas encore d'évaluation

- Zinc DIE CASTINGDocument10 pagesZinc DIE CASTINGFrancisco BocanegraPas encore d'évaluation

- EDC U-4 FET NotesDocument110 pagesEDC U-4 FET NotesVaishnavi NandikantiPas encore d'évaluation

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghPas encore d'évaluation

- TI - CP - 2342 - e - 2-EHMA F - 2016 - 09Document2 pagesTI - CP - 2342 - e - 2-EHMA F - 2016 - 09Siddhant HabbuPas encore d'évaluation