Académique Documents

Professionnel Documents

Culture Documents

Material Science Assignment

Transféré par

Wilson TengCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Material Science Assignment

Transféré par

Wilson TengDroits d'auteur :

Formats disponibles

1

Group Assignment

Prepared by: 1. Wilson Teng Yisheng (1104947 )

2. Bong Wilson (1104987 )

3. Teoh Kheng Hwa (1103790)

4. Lee Le Yu (1104890)

5. Ng Wei Zhang (1105014)

6. Cheok Kah Guan (1105017)

Programme Bachelor of Engineering (Hons) Mechanical Engineering

Course UEME 1122 Material Science

Year One

Semester One

Prepared for: Dr. Yap Yeow Hong

Date August 18, 2012

UNIVERSITI TUNKU ABDUL RAHMAN (UTAR)

FACULTY OF ENGINEERING AND SCIENCE (FES)

2

Introduction

A light-emitting diode (LED) is a semiconductor light source made from a combination

of chemically polarized semiconductors. The chemical composition is chosen to define

the energy of the electrons that pass across the boundary between the two types of

semiconductor. This electron energy is converted to light as electrons flow though the

device. The electron energy defines the wavelength of the resultant coloured light.

Early development:

1907:

first experimenter H. J. Round (British)

1927:

first researcher to publish journal Oleg Vladimirovich Losev (Russian)

1955:

Rubin Braunstein reported on infrared emission from gallium arsenide (GaAs) in

simple diode structures.

1961:

3

Robert Biard and Gary Pittman (American experimenter) found that GaAs emitted

infrared radiation when electric current was applied and received the patent for

the infrared LED.

First visible spectrum LED:

1962:

develop by Nick Holonyak (father of the light-emitting diode)

1960s:

red LEDs became commercially available.

1970s 2000s:

1972:

Nick Holonyak invented yellow LED and improved the brightness of red and red-

orange LEDs by a factor of ten.

1976:

T. P. Pearsall created high-brightness, high-efficiency LEDs for optical fiber

telecommunications.

1993:

Shuji Nakamura (Japanese) demonstrated first high-brightness blue LED.

1995:

Alberto Barbieri investigated the efficiency and reliability of high-brightness LED.

These developments produce white LED.

4

Chemical Structure of LED

There are several types of semiconductor of LED. The chemical structure includes

molecular geometry, electronic structure and crystal structure of molecules.

1. Gallium Arsenide (GaAs) - has molecular shape of linear shape.

-has crystal structure of zincblende.

-has formula weight of 144.64.

-has lattice constant of 0.56533nm.

-produce red and infrared light.

2. silicon carbide (SiC) has electron mobility of 900cm

2

/V.s(all polytypes)

-can doped n-type by nitrogen or phosphorus

-can doped p-type y aluminium, boron or beryllium.

-produce blue light.

5

Structure of major SiC polytypes.

()3C-SiC

crystal structure :Zinc

blende(cubic)

4H-SiC

crystal structure:hexagonal

()6H-SiC

crystal structure:hexagonal

3. Gallium Nitride-has coordination geometry of tetrahedral.

-has band gap of 3.4 eV.

-has electron mobility of 440 cm2/ (V s) at temperature 300 K.

-has crystal structure of Wurtzite.

-emitting green, pure green or emerald green and blue light.

Gallium Nitride

6

Properties that make LED unique or desirable for the applications

1. Ability to generate photons, which can be seen as light due to the interaction

between electrons and holes. This is caused by the property of N-type material

bonded to a section of P-type material.

2. The size of gap between the conduction band and lower orbitals also contribute to

the uniqueness of LED. This is because the size of the gap between the conduction

band and lower orbitals can determine frequency of the photon. In simple words, it

determines the color of the light. It can also produce infrared when the frequency of

photon is so low that it is not visible to the human eye. This is to produce infrared

LED used in remote controls.

3. LEDs are also specially constructed to release a large number of photons outward.

The light are concentrated by the plastic house in a particular direction. As you can

see in the diagram, most of the light from the diode bounces off the sides of the

bulb, traveling on through the rounded end. Hence, allowing LED to be brighter

than incandescent bulbs and fluorescent lamps.

Diagram of LED

7

4. LEDs output more lumens of light. For example, LED bulb produces 76.9 lumens

per watt compared to an incandescent bulb's 17 lumen per watt.

5. LED are also very durable as they can last up to 50 000 hours or more.

8

Current and Potential Applications of LED

1. LED can be used to replace incandescent lamps as indicator as eco friendly

lighting.

2. LEDs are being commonly used for traffic signals, vehicle brake lighting and exit

signs.

3. Most of the LED lights in outdoor places are used as decoration lights, because

LED lights have different colors and shapes,

4. Another task for control circuitry is failure recognition. Modules consist of

individual LEDs which can be tested for total failure of a circuit or application.

5. LED displays are packages of many LEDs arranged in a pattern, the most familiar

pattern being the 7-segment displays for showing numbers (digits 0-9).

6. LEDs are used as movement sensors, as in optic computer mouse.

7. Remote controls, such as for TVs, VCRs, and LED Computers, infrared LEDs

are used.

8. LEDs are small, durable and need little power, so they are used in hand held

devices such as flashlights.

9. Infrared LEDs are also apply in night vision uses including security cameras.

10. LEDs can also use for Touch sensing.

11. LED can function as photodiodes, as they can be used for both photo emission

and detection.

9

Processing of Light-emitting diode

Diodes are made of very thin layers of semiconductor material which allow

electrons to move from one layer to another, thereby generating light. The particular

semiconductors used for LED manufacture are gallium arsenide (GaAs), gallium

phosphide (GaP), or gallium arsenide phosphide (GaAsP). The processing of light-

emitting diode are summarized as follow.

(A) Making semiconductor wafers

1. Gallium, arsenic, and/or phosphor are purified, mixed, heated and pressure liquefy

and press together in the chamber to force into a solution. A rod is dipped into the

solution and pulled out slowly. The solution cools and crystallizes on the end of

the rod, forming ingot of GaAs, GaP, or GaAsP.

2. The ingot is then sliced into very thin wafers of semiconductor and polished.

3. The wafers are cleaned through a rigorous chemical and ultrasonic process using

various solvents.

(B) Adding epitaxial layers

10

4. Impurities, or dopants, are added to the crystal by a process called Liquid Phase

Epitaxy (LPE). In this technique, epitaxial layerssemiconductor layers that have

the same crystalline orientation as the substrate beloware deposited on a wafer

while it is drawn under reservoirs of molten GaAsP.

5. The wafer is then immersed in a gaseous atmosphere containing the dopants

nitrogen or zinc ammonium in high temperature furnace tube.

(C) Adding metal contacts

6. Contact patterns are reproduced in photoresist, a light-sensitive compound. The

liquid resist is deposited in drops while the wafer spins, distributing it over the

surface.

11

7. A chunk of metal is heated to temperatures that cause it to vaporize. It condenses

and sticks to the exposed semiconductor wafer.

8. A single 2 inch-diameter wafer produced which gives an indication of the size of

the finished diodes. The diodes are cut apart into "die" either by cleaving or by

sawing with a diamond saw.

(D) Mounting and packaging

9. Individual dies are mounted on the appropriate package. The back of the wafer is

coated with metal and forms an electrical contact with the lead it rests on. A tiny

gold wire is soldered to the other lead and wire-bonded to the patterned contacts

on the surface of the die.

10. The entire assembly is sealed in plastic. The wires and die are suspended inside a

mold (liquid plastic or epoxy).

12

Disadvantages of LED

1. The cost of LED is more expensive compared to others conventional lighting.

Besides, some semi-conductor materials used cost more than others.

2. LED is a temperature dependence diode. It depends on the ambient temperature of

the operating environment. The ambient temperature affects the emission

spectrum of LED. The LED will overheat if over-driving in high temperature and

will lead to failure.

3. LED have small area light source. LED not approximates a "point source" of light.

It does not radiate light from all angles.

4. The light produce by the LED is intense low light which is very dangerous for our

eyes. The blue LED harms our eyes because it exceeds the safe limit which is

called the blue hazard. Besides, LED also lead to headaches, disturbed sleep and

eye strain.

5. LED will cause blue pollution. It is because the cool-white LED emits more blue

light and more light pollution than others light sources.

13

Disposal Method of LED

LED are recyclable. LED does not contain mercury, it will not affect the disposal process

and it can be safely recycled.

14

Reference

Advantages and disadvantages of LEDs. (n.d). Retrieve on 2012, August 11

th

. Retrieve

from http://www.lumec.com/learning-center/led/advantages_and_disadvantages.html

Blue LEDs: A health hazard?(2007). Retrieve on 2012, August 11

th

. Retrieve from

http://texyt.com/bright+blue+leds+annoyance+health+risks

Bush, S. (2010). 50 year history of the LED. Retrieve on 2012, August 15

th

. Retrieve

from http://www.electronicsweekly.com/Articles/28/05/2012/49501/50-year-history-of-

the-LED.htm

Gallium arsenide.(2007). Retrieved 2012, August 18

th

. Retrieve from

http://www.chemistrydaily.com/chemistry/Gallium_arsenide

Harris, T, Fenlon, W.(2002). How light emitting diodes work. Retrieve on 2012, August

16

th

. Retrieve from http://electronics.howstuffworks.com/led.htm

Howell, W.(n.d). A brief history of LED lighting. Retrieve on 2012, August 15

th

.

Retrieve from

http://www.artisticlicence.com/WebSiteMaster/App%20Notes/appnote022.pdf

15

Leslie G. Melcer (n.d.). Light-emitting diode. Retrieved 2012, August 4

th

. Retrieve from

http://www.madehow.com/Volume-1/Light-Emitting-Diode-LED.html#b

Light emitting diode.(2007). Retrieved 2012, August 18

th

. Retrieve from

http://www.chemistrydaily.com/chemistry/Light-emitting_diode#LED_materials

Light-emitting Diode (LED) Technology and Applications.(2009). Retrieve on 2012,

August 7

th

. Retrieve from http://oee.nrcan.gc.ca/equipment/lighting/248

Marais,B.J, Brittle, J, Painczyk, K, Hasseling, A.C, Beyers, N, Wasserman, E, Soolingan,

D.V, Warren, R.M.(2008). Clinical Infectious Disease. Use of light-emitting diode

fluorescence microscopy to detect acid-fast bacilli in sputum 47 (2): Pp. 203-207.

Retrieve on 2012, August 12

th

. Retrieve from

http://cid.oxfordjournals.org/content/47/2/203.full

Song, J(2010). Advantages and disadvantages of LED. Retrieve on 2012, August 11

th

.

Retrieve from http://www.ledke.com/news/Advantages-Disadvantages-LED.html

The elusive blue laser.(1997). Retrieved 2012, August 18

th

. Retrieve from

http://hyperphysics.phy-astr.gsu.edu/hbase/electronic/led.html

16

Vochin, A. (2009). History of LEDs (Light Emitting Diodes). Retrieve on 2012, August 15

th

.

Retrieve from http://gadgets.softpedia.com/news/History-of-LEDs-Light-Emitting-Diodes-1487-01.html

Vous aimerez peut-être aussi

- RACI R Web3 1Document14 pagesRACI R Web3 1EmmsStitch100% (1)

- Cost of Quality (COQ) : Sign inDocument2 pagesCost of Quality (COQ) : Sign inWilson TengPas encore d'évaluation

- PMP Exam Reference Materials: Register Log inDocument1 pagePMP Exam Reference Materials: Register Log inWilson TengPas encore d'évaluation

- Kotter - S 8-Step Change Model - Change Management Tools From Mind ToolsDocument7 pagesKotter - S 8-Step Change Model - Change Management Tools From Mind ToolsWilson TengPas encore d'évaluation

- Building Control Regulations 2003Document102 pagesBuilding Control Regulations 2003kongPas encore d'évaluation

- Seven Management - Planning - New Management Tools - ASQDocument2 pagesSeven Management - Planning - New Management Tools - ASQWilson TengPas encore d'évaluation

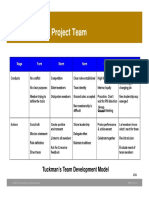

- 9.3 Develop Project Team: Tuckman's Team Development ModelDocument1 page9.3 Develop Project Team: Tuckman's Team Development ModelWilson TengPas encore d'évaluation

- PMI Talent TriangleDocument1 pagePMI Talent TriangleWilson TengPas encore d'évaluation

- 15 SmacnaDocument9 pages15 Smacnaarln_605551822Pas encore d'évaluation

- Dimensional MetrologyDocument6 pagesDimensional MetrologyWilson Teng100% (1)

- TorsionDocument5 pagesTorsionWilson TengPas encore d'évaluation

- Cover of Practical Report Mechanics-May 2011Document1 pageCover of Practical Report Mechanics-May 2011Wilson TengPas encore d'évaluation

- Metallic Crystal StructureDocument6 pagesMetallic Crystal StructureWilson TengPas encore d'évaluation

- Circuit TheoryDocument14 pagesCircuit TheoryWilson TengPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- MANUAL Health O Meter Scale 800KLDocument2 pagesMANUAL Health O Meter Scale 800KLElkin MaldonadoPas encore d'évaluation

- Face SerumDocument10 pagesFace SerumLiliana CojocaruPas encore d'évaluation

- Using Dyne Pens and Solutions To Measure Surface EnergyDocument3 pagesUsing Dyne Pens and Solutions To Measure Surface EnergyShouvik MukhopadhyayPas encore d'évaluation

- Solutions To Exercises, Chapter 19: Okuyama & Maskill: Organic ChemistryDocument6 pagesSolutions To Exercises, Chapter 19: Okuyama & Maskill: Organic ChemistryM Irfan KhanPas encore d'évaluation

- King Khalid University College of Engineering Department of Chemical EngineeringDocument9 pagesKing Khalid University College of Engineering Department of Chemical EngineeringbaderPas encore d'évaluation

- Step by Step To The Perfect PedicureDocument6 pagesStep by Step To The Perfect PedicurepinkyPas encore d'évaluation

- The Design of The 2016-17 Young Lives School Survey in EthiopiaDocument10 pagesThe Design of The 2016-17 Young Lives School Survey in EthiopiaFuadPas encore d'évaluation

- Gretton, Hare, Catchpole - Psychopathy and Offending From Adolescence To Adulthood - A 10-Year Follow-UpDocument10 pagesGretton, Hare, Catchpole - Psychopathy and Offending From Adolescence To Adulthood - A 10-Year Follow-UpMaria Isabel Trujillo MayaPas encore d'évaluation

- Microsoft Word - SOP ON DispensingDocument4 pagesMicrosoft Word - SOP ON DispensingPalawan Baptist HospitalPas encore d'évaluation

- Report Information From Proquest: February 24 2014 06:18Document19 pagesReport Information From Proquest: February 24 2014 06:18Emma Elena StroePas encore d'évaluation

- Metals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument43 pagesMetals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDheeraj KumarPas encore d'évaluation

- ImpetigoDocument31 pagesImpetigoUmmu Insyirah100% (1)

- English Dept Guidebook: Grammar & Exercises for Level 4Document57 pagesEnglish Dept Guidebook: Grammar & Exercises for Level 4KIngLyonLuis100% (1)

- CIVIL BILL OF QUANTITIESDocument16 pagesCIVIL BILL OF QUANTITIESTomPas encore d'évaluation

- Is411 8Document1 pageIs411 8amoghimiPas encore d'évaluation

- The Payment of Bonus Act 1965 PDFDocument30 pagesThe Payment of Bonus Act 1965 PDFappu kunda100% (1)

- Mind Map Burn & BleedingDocument2 pagesMind Map Burn & BleedingUlfia KhoirinnissaPas encore d'évaluation

- AMB4519R9v06-3238 12ports (LB 4T, PCS-2.6G 4T Dual Beam) 2.6m Twin BeamDocument3 pagesAMB4519R9v06-3238 12ports (LB 4T, PCS-2.6G 4T Dual Beam) 2.6m Twin BeamMIGUEL PEREDA QUIJANOPas encore d'évaluation

- Plateau Pressure Ventilation MeasurementDocument1 pagePlateau Pressure Ventilation MeasurementImtiaz AliPas encore d'évaluation

- Mini-Pitch Session Exceptionalities and InclusionDocument18 pagesMini-Pitch Session Exceptionalities and Inclusionapi-486583325Pas encore d'évaluation

- PDI Quality Manual Rev 4 - 1.0 Table of ContentsDocument1 pagePDI Quality Manual Rev 4 - 1.0 Table of ContentslouiePas encore d'évaluation

- M Shivkumar PDFDocument141 pagesM Shivkumar PDFPraveen KumarPas encore d'évaluation

- Idioma Extranjero I R5Document4 pagesIdioma Extranjero I R5EDWARD ASAEL SANTIAGO BENITEZPas encore d'évaluation

- Cakes Amp Sugarcraft - April-May 2019 EditDocument45 pagesCakes Amp Sugarcraft - April-May 2019 Editapi-197110397100% (1)

- Spiegel Et Al 1999 Psycho OncologyDocument12 pagesSpiegel Et Al 1999 Psycho Oncologyfatimaramos31Pas encore d'évaluation

- Navi Cure prospectus summaryDocument50 pagesNavi Cure prospectus summaryGaurav SrivastavaPas encore d'évaluation

- Plant Nematology: A Briefly IntroductionDocument463 pagesPlant Nematology: A Briefly IntroductionRodrigo CarralPas encore d'évaluation

- Integration of The Saprobic System Into The European Union Water Framework DirectiveDocument14 pagesIntegration of The Saprobic System Into The European Union Water Framework DirectiveMihaela MirabelaPas encore d'évaluation

- HVDC Vs HVAC TransmissionDocument2 pagesHVDC Vs HVAC TransmissionBilal SahiPas encore d'évaluation

- Observations of Children's Interactions With Teachers, PeersDocument25 pagesObservations of Children's Interactions With Teachers, PeersMazlinaPas encore d'évaluation