Académique Documents

Professionnel Documents

Culture Documents

TEPZZ - 6Z768B - T: European Patent Specification

Transféré par

zweisteine777Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TEPZZ - 6Z768B - T: European Patent Specification

Transféré par

zweisteine777Droits d'auteur :

Formats disponibles

Note: Within nine months of the publication of the mention of the grant of the European patent in the European

Patent

Bulletin, any person may give notice to the European Patent Office of opposition to that patent, in accordance with the

Implementing Regulations. Notice of opposition shall not be deemed to have been filed until the opposition fee has been

paid. (Art. 99(1) European Patent Convention).

Printed by Jouve, 75001 PARIS (FR)

(19)

E

P

1

2

6

0

7

6

8

B

1

*EP001260768B1*

(11) EP 1 260 768 B1

(12) EUROPEAN PATENT SPECIFICATION

(45) Date of publication and mention

of the grant of the patent:

23.07.2014 Bulletin 2014/30

(21) Application number: 02253028.1

(22) Date of filing: 29.04.2002

(51) Int Cl.:

F23R 3/04

(2006.01)

F23R 3/34

(2006.01)

F23R 3/28

(2006.01)

F23C 6/04

(2006.01)

(54) A tubular combustion chamber

Rohrbrennkammer

Chambre de combustion tubulaire

(84) Designated Contracting States:

CH DE FR GB LI SE

(30) Priority: 15.05.2001 GB 0111788

(43) Date of publication of application:

27.11.2002 Bulletin 2002/48

(73) Proprietors:

ROLLS-ROYCE PLC

London, SW1E 6AT (GB)

Rolls-Royce Canada Limited

Lachine,

Quebec H9P 1A3 (CA)

(72) Inventors:

Freeman, Christopher

Farnsfield,

Nottingham NG22 8JN (GB)

Day, Ivor John

Comberton,

Cambridge CB3 7EE (GB)

Scarinci, Thomas

Mont Royal,

Quebec H3P 2J8 (CA)

(74) Representative: Barcock, Ruth Anita et al

Rolls-Royce plc

Intellectual Property Department

P.O. Box 31

Derby DE24 8BJ (GB)

(56) References cited:

EP-A- 0 863 369 EP-A- 1 108 957

US-A- 2 560 074 US-A- 4 412 414

US-A- 5 235 814 US-A- 5 475 979

US-A- 6 016 658 US-A- 6 164 055

EP 1 260 768 B1

2

5

10

15

20

25

30

35

40

45

50

55

Description

[0001] The present invention relates generally to a

combustion chamber, particularly to a gas turbine engine

combustion chamber.

[0002] In order to meet the emission level require-

ments, for industrial low emission gas turbine engines,

staged combustion is required in order to minimise the

quantity of the oxide of nitrogen (NOx) produced. Cur-

rently the emission level requirement is for less than 25

volumetric parts per million of NOx for an industrial gas

turbine exhaust. The fundamental way to reduce emis-

sions of nitrogen oxides is to reduce the combustion re-

action temperature, and this requires premixing of the

fuel and a large proportion, preferably all, of the combus-

tion air before combustion occurs. The oxides of nitrogen

(NOx) are commonly reduced by a method, which uses

two stages of fuel injection. Our UK patent no.

GB1489339 discloses two stages of fuel injection. Our

International patent application no. WO92/07221 disclos-

es two and three stages of fuel injection. In staged com-

bustion, all the stages of combustion seek to provide lean

combustion and hence the low combustion temperatures

required to minimise NOx. The term lean combustion

means combustion of fuel in air where the fuel to air ratio

is low, i.e. less than the stoichiometric ratio. In order to

achieve the required low emissions of NOx and CO it is

essential to mix the fuel and air uniformly.

[0003] The industrial gas turbine engine disclosed in

our International patent application no. WO92/0722 uses

a plurality of tubular combustion chambers, whose axes

are arranged in generally radial directions. The inlets of

the tubular combustion chambers are at their radially out-

er ends, and transition ducts connect the outlets of the

tubular combustion chambers with a row of nozzle guide

vanes to discharge the hot gases axially into the turbine

sections of the gas turbine engine. Each of the tubular

combustion chambers has two coaxial radial flow swirl-

ers, which supply a mixture of fuel and air into a primary

combustion zone. An annular secondary fuel and air mix-

ing duct surrounds the primary combustion zone and sup-

plies a mixture of fuel and air into a secondary combustion

zone.

[0004] One problem associated with gas turbine en-

gines is caused by pressure fluctuations in the air, or gas,

flow through the gas turbine engine. Pressure fluctua-

tions in the air, or gas, flow through the gas turbine engine

may lead to severe damage, or failure, of components if

the frequency of the pressure fluctuations coincides with

the natural frequency of a vibration mode of one or more

of the components. These pressure fluctuations may be

amplified by the combustion process and under adverse

conditions a resonant frequency may achieve sufficient

amplitude to cause severe damage to the combustion

chamber and the gas turbine engine. Alternatively the

amplitude of the pressure fluctuations may be sufficiently

large such as to induce damage to the combustion cham-

ber and the gas turbine engine in their own right.

[0005] It has been found that gas turbine engines,

which have lean combustion, are particularly susceptible

to this problem. Furthermore it has been found that as

gas turbine engines which have lean combustion reduce

emissions to lower levels by achieving more uniform mix-

ing of the fuel and the air, the amplitude of the resonant

frequency becomes greater. It is believed that the ampli-

fication of the pressure fluctuations in the combustion

chamber occurs because the heat released by the burn-

ing of the fuel occurs at a position in the combustion

chamber, which corresponds, to an antinode, or pressure

peak, in the pressure fluctuations.

[0006] Our European patent application No.

00311040.0 filed 11 December 2000, which claims pri-

ority from UK patent application 9929601.4 filed 16 De-

cember 1999 discloses a combustion chamber arranged

to reduce this problem. The combustion chamber has at

least one fuel and air mixing duct for supplying a fuel and

air mixture to a combustion zone in the combustion cham-

ber. Fuel injection means is arranged to supply fuel into

the at least one fuel and air mixing duct. Air injection

means is arranged to supply air into the at least one fuel

and air mixing duct. The air injection means comprises

a plurality of air injectors spaced apart in the direction of

flow through the at least one fuel and air mixing duct to

reduce the magnitude of the fluctuations in the fuel to air

ratio of the fuel and air mixture supplied into the at least

one combustion zone.

[0007] US6016658 discloses a combustion system for

a gas turbine engine.

[0008] However, although the fuel to air ratio fluctua-

tions have been reduced there is a risk of auto ignition

of the fuel in the fuel and air mixing duct in the wakes

from the air injectors due to the possibility of excessively

long residence times in the fuel and air mixing duct. The

risk of excessively long residence time is a function of

the gas turbine engine pressure ratio. The higher the

pressure ratio, the higher the risk of autoignition.

[0009] Accordingly the present invention seeks to pro-

vide a combustion chamber which reduces or minimises

the above-mentioned problem.

[0010] Accordingly the present invention provides a

combustion chamber according to claim 1.

[0011] The present invention also provides a combus-

tion chamber according to claim 2.

[0012] Preferably the combustion chamber according

to claim 2 comprises a primary combustion zone and a

secondary combustion zone downstream of the primary

combustion zone.

[0013] Preferably the combustion chamber comprises

a primary combustion zone, a secondary combustion

zone downstream of the primary combustion zone and

a tertiary combustion zone downstream of the secondary

combustion zone.

[0014] The at least one fuel and air mixing duct may

supply fuel and air into the primary combustion zone. The

at least one fuel and air mixing duct may supply fuel and

air into the secondary combustion zone. The at least one

1 2

EP 1 260 768 B1

3

5

10

15

20

25

30

35

40

45

50

55

fuel and air mixing duct may supply fuel and air into the

tertiary combustion zone.

[0015] Preferably the fuel injector means is arranged

between the upstream end and the downstream end of

the at least one fuel and air mixing duct, a portion of the

air injector means are arranged upstream of the fuel in-

jector means and a portion of the air injector means are

arranged downstream of the fuel injector means.

[0016] Preferably each air injector means at the down-

stream end of the fuel and air mixing duct is arranged to

supply more air into the fuel and air mixing duct than said

air injector means at the upstream end of the fuel and air

mixing duct.

[0017] Preferably each air injector means at a first po-

sition in the direction of flow through the fuel and air mix-

ing duct is arranged to supply more air into the fuel and

air mixing duct than said air injector means upstream of

the first position in the fuel and air mixing duct.

[0018] Preferably each air injector means at the first

position in the fuel and air mixing duct is arranged to

supply less air into the fuel and air mixing duct than said

air injector means downstream of the first position in the

fuel and air mixing duct.

[0019] Preferably the volume of the fuel and air mixing

duct being arranged such that the average travel time

from the fuel injection means to the downstream end of

the fuel and air mixing duct is greater than the time period

of the fluctuation.

[0020] Preferably the volume of the fuel and air mixing

duct being arranged such that the length of the fuel and

air mixing duct multiplied by the frequency of the fluctu-

ations divided by the velocity of the fuel and air leaving

the downstream end of the fuel and air mixing duct is at

least one.

[0021] Preferably the volume of the fuel and air mixing

duct being arranged such that the length of the fuel and

air mixing duct multiplied by the frequency of the fluctu-

ations divided by the velocity of the fuel and air leaving

the downstream end of the fuel and air mixing duct is at

least two.

[0022] Preferably the plurality of air injectors extend in

the direction of flow through the at least one fuel and air

mixing duct over a length equal to half the wavelength of

the fluctuations of the air supplied to the at least one fuel

and air mixing duct.

[0023] Preferably the length of an air injector in the

direction of flow through the at least one fuel and air mix-

ing duct multiplied by the frequency of the fluctuations

divided by the velocity of the fuel and air inside the at

least one mixing duct is at least one.

[0024] Preferably the length of an air injector in the

direction of flow through the at least one fuel and air mix-

ing duct multiplied by the frequency of the fluctuations

divided by the average velocity of the fuel and air inside

the at least one mixing duct is at least two.

[0025] Preferably the at least one fuel and air mixing

duct comprises a swirler. Preferably the swirler is a radial

flow swirler.

[0026] The present invention will be more fully de-

scribed by way of example with reference to the accom-

panying drawings, in which:-

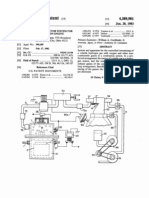

Figure 1 is a view of a gas turbine engine having a

combustion chamber according to the present inven-

tion.

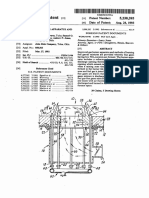

Figure 2 is an enlarged longitudinal cross-sectional

view through the combustion chamber shown in fig-

ure 1.

Figure 3 is an enlarged cross-sectional view of part

of the primary fuel and air mixing duct shown in figure

2.

Figure 4 is an enlarged cross-sectional view of part

of the secondary fuel and air mixing duct shown in

figure 2.

Figure 5 is a cross-sectional view of an alternative

fuel and air mixing duct not forming part of the inven-

tion.

Figure 6 is a cross-sectional view in the direction of

arrows W-W in figure 5.

Figure 7 is a cross-sectional view in the direction of

arrows X-X in figure 5.

Figure 8 is a cross-sectional view of another alter-

native fuel and air mixing duct not forming part of the

invention.

Figure 9 is a cross-sectional view in the direction of

arrows Y-Y in figure 8.

Figure 10 is a cross-sectional view in the direction

of arrows Z-Z in figure 8.

Figure 11 is a graph comparing the fuel to air ratio

fluctuation with radial distance in a radial flow fuel

and air mixing duct according to the present inven-

tion and a radial flow fuel and air mixing duct accord-

ing to the prior art.

Figure 12 is a graph of the fuel to air ratio of a fuel

and air mixing duct according to the present inven-

tion divided by the fuel to air ratio of a fuel and air

mixing duct according to the prior art against the fre-

quency of fluctuation multiplied by the length of the

fuel and air mixing duct divided by the velocity of the

fuel and air mixture leaving the fuel and air mixing

duct.

Figure 13 is a cross-sectional view of an alternative

fuel and air mixing duct.

Figure 14 is cross-sectional view in the direction of

arrows T-T in figure 13.

Figure 15 is a cross-sectional view of a further fuel

and air mixing duct.

Figure 16 is a graph of the fuel to air ratio of fuel and

air mixing ducts according to the present invention

against the frequency of the fluctuation multiplied by

the length of the fuel and air mixing duct divided by

the velocity of the fuel and air mixture leaving the

fuel and air mixing duct.

[0027] An industrial gas turbine engine 10, shown in

figure 1, comprises in axial flow series an inlet 12, a com-

3 4

EP 1 260 768 B1

4

5

10

15

20

25

30

35

40

45

50

55

pressor section 14, a combustion chamber assembly 16,

a turbine section 18, a power turbine section 20 and an

exhaust 22. The turbine section 18 is arranged to drive

the compressor section 14 via one or more shafts (not

shown). The power turbine section 20 is arranged to drive

an electrical generator 26 via a shaft 24. The operation

of the gas turbine engine 10 is quite conventional, and

will not be discussed further. Alternatively, the turbine

section 18 may drive part of the compressor section 14

via a shaft (not shown) and the power turbine section 20

may be arranged to drive part of the compressor section

14 via a shaft (not shown) and is arranged to drive an

electrical generator 26 via a shaft 24. However, the power

turbine section 20 may be arranged to provide drive for

other purposes.

[0028] The combustion chamber assembly 16 is

shown more clearly in figures 2, 3 and 4. The combustion

chamber assembly 16 comprises a plurality of, for exam-

ple eight or nine, equally circumferentially spaced tubular

combustion chambers 28. The axes of the tubular com-

bustion chambers 28 are arranged to extend in generally

radial directions. The inlets of the tubular combustion

chambers 28 are at their radially outermost ends and

their outlets are at their radially innermost ends.

[0029] Each of the tubular combustion chambers 28

comprises an upstream wall 30 secured to the upstream

end of an annular wall 32. A first, upstream, portion 34

of the annular wall 32 defines a primary combustion zone

36, a second, intermediate, portion 38 of the annular wall

32 defines a secondary combustion zone 40 and a third,

downstream, portion 42 of the annular wall 32 defines a

tertiary combustion zone 44. The second portion 38 of

the annular wall 32 has a greater diameter than the first

portion 34 of the annular wall 32 and similarly the third

portion 42 of the annular wall 32 has a greater diameter

than the second portion 38 of the annular wall 32.

[0030] A plurality of equally circumferentially spaced

transition ducts 46 are provided, and each of the transi-

tion ducts 46 has a circular cross-section at its upstream

end 48. The upstream end 48 of each of the transition

ducts 46 is located coaxially with the downstream end of

a corresponding one of the tubular combustion chambers

28, and each of the transition ducts 46 connects and seals

with an angular section of the nozzle guide vanes.

[0031] The upstream wall 30 of each of the tubular

combustion chambers 28 has an aperture 50 to allow the

supply of air and fuel into the primary combustion zone

36. A radial flow swirler 52 is arranged coaxially with the

aperture 50 in the upstream wall 30.

[0032] A plurality of fuel injectors 56 are positioned in

a primary fuel and air mixing duct 54 formed upstream

of the radial flow swirler 52. The walls 58 and 60 of the

primary fuel and air mixing duct 54 are provided with a

plurality of circumferentially spaced slots 62 and 64 re-

spectively which form a primary air intake to supply air

into the primary fuel and air mixing duct 54. Each circum-

ferentially spaced slot 62 and 64 extends radially, longi-

tudinally, in the direction of flow, of the primary fuel and

air mixing duct 54 over a distance D. The slots 62 and

64 extend purely radially.

[0033] A central pilot igniter 66 is positioned coaxially

with the aperture 50. The pilot igniter 66 defines a down-

stream portion of the primary fuel and air mixing duct 54

for the flow of the fuel and air mixture from the radial flow

swirler 52 into the primary combustion zone 36. The pilot

igniter 66 turns the fuel and air mixture flowing from the

radial flow swirler 52 from a radial direction to an axial

direction. The primary fuel and air is mixed together in

the primary fuel and air mixing duct 54.

[0034] The primary fuel and air mixing duct 54 reduces

in cross-sectional area from the intake 62, 64 at its up-

stream end to the aperture 50 at its downstream end.

The shape of the primary fuel and air mixing duct 54

produces a constantly accelerating flow through the duct

54.

[0035] The fuel injectors 56 are supplied with fuel from

a primary fuel manifold 68.

[0036] An annular secondary fuel and air mixing duct

70 is provided for each of the tubular combustion cham-

bers 28. Each secondary fuel and air mixing duct 70 is

arranged circumferentially around the primary combus-

tion zone 36 of the corresponding tubular combustion

chamber 28. Each of the secondary fuel and air mixing

ducts 70 is defined between a second annular wall 72

and a third annular wall 74. The second annular wall 72

defines the inner extremity of the secondary fuel and air

mixing duct 70 and the third annular wall 74 defines the

outer extremity of the secondary fuel and air mixing duct

70. The second annular wall 72 of the secondary fuel and

air mixing duct 70 has a plurality of circumferentially

spaced slots 76 which form a secondary air intake to the

secondary fuel and air mixing duct 70. Each circumfer-

entially spaced slot 76 extends axially, longitudinally, in

the direction of flow, of the secondary fuel and air mixing

duct 70. The slots 76 extend purely axially.

[0037] At the downstream end of the secondary fuel

and air mixing duct 70, the second and third annular walls

72 and 74 respectively are secured to a frustoconical wall

portion 78 interconnecting the wall portions 34 and 38.

The frustoconical wall portion 78 is provided with a plu-

rality of apertures 80. The apertures 80 are arranged to

direct the fuel and air mixture into the secondary com-

bustion zone 40 in a downstream direction towards the

axis of the tubular combustion chamber 28. The aper-

tures 80 may be circular or slots and are of equal flow

area.

[0038] The secondary fuel and air mixing duct 70 re-

duces in cross-sectional area from the intake 76 at its

upstream end to the apertures 80 at its downstream end.

The shape of the secondary fuel and air mixing duct 70

produces a constantly accelerating flow through the duct

70.

[0039] A plurality of secondary fuel systems 82 are pro-

vided, to supply fuel to the secondary fuel and air mixing

ducts 70 of each of the tubular combustion chambers 28.

The secondary fuel system 82 for each tubular combus-

5 6

EP 1 260 768 B1

5

5

10

15

20

25

30

35

40

45

50

55

tion chamber 28 comprises an annular secondary fuel

manifold 84 arranged coaxially with the tubular combus-

tion chamber 28 at the upstream end of the secondary

fuel and air mixing duct 70 of the tubular combustion

chamber 28. Each secondary fuel manifold 84 has a plu-

rality, for example thirty two, of equi-circumferentially-

spaced secondary fuel apertures 86. Each of the sec-

ondary fuel apertures 86 directs the fuel axially of the

tubular combustion chamber 28 onto an annular splash

plate 88. The fuel flows from the splash plate 88 through

an annular passage 90 in a downstream direction into

the secondary fuel and air mixing duct 70 as an annular

sheet of fuel.

[0040] An annular tertiary fuel and air mixing duct 92

is provided for each of the tubular combustion chambers

28. Each tertiary fuel and air mixing duct 92 is arranged

circumferentially around the secondary combustion zone

40 of the corresponding tubular combustion chamber 28.

Each of the tertiary fuel and air mixing ducts 92 is defined

between a fourth annular wall 94 and a fifth annular wall

96. The fourth annular wall 94 defines the inner extremity

of the tertiary fuel and air mixing duct 92 and the fifth

annular wall 96 defines the outer extremity of the tertiary

fuel and air mixing duct 92. The tertiary fuel and air mixing

duct 92 has a plurality of circumferentially spaced slots

98 which form a tertiary air intake to the tertiary fuel and

air mixing duct 92. Each circumferentially spaced slot 98

extends axially, longitudinally, in the direction of flow, of

the tertiary fuel and air mixing duct 92. The slots 98 extend

purely axially.

[0041] At the downstream end of the tertiary fuel and

air mixing duct 92, the fourth and fifth annular walls 94

and 96 respectively are secured to a frustoconical wall

portion 100 interconnecting the wall portions 38 and 42.

The frustoconical wall portion 100 is provided with a plu-

rality of apertures 102. The apertures 102 are arranged

to direct the fuel and air mixture into the tertiary combus-

tion zone 44 in a downstream direction towards the axis

of the tubular combustion chamber 28. The apertures

102 may be circular or slots and are of equal flow area.

[0042] The tertiary fuel and air mixing duct 92 reduces

in cross-sectional area from the intake 98 at its upstream

end to the apertures 102 at its downstream end. The

shape of the tertiary fuel and air mixing duct 92 produces

a constantly accelerating flow through the duct 92.

[0043] A plurality of tertiary fuel systems 104 are pro-

vided, to supply fuel to the tertiary fuel and air mixing

ducts 92 of each of the tubular combustion chambers 28.

The tertiary fuel system 104 for each tubular combustion

chamber 28 comprises an annular tertiary fuel manifold

106 positioned at the upstream end of the tertiary fuel

and air mixing duct 92. Each tertiary fuel manifold 106

has a plurality, for example thirty two, of equi-circumfer-

entially spaced tertiary fuel apertures 108. Each of the

tertiary fuel apertures 108 directs the fuel axially of the

tubular combustion chamber 28 onto an annular splash

plate 110. The fuel flows from the splash plate 110

through the annular passage 112 in a downstream direc-

tion into the tertiary fuel and air mixing duct 92 as an

annular sheet of fuel.

[0044] As discussed previously the fuel and air sup-

plied to the combustion zones is premixed and each of

the combustion zones 36, 40 and 44 is arranged to pro-

vide lean combustion to minimise NOx. The products of

combustion from the primary combustion zone 36 flow

into the secondary combustion zone 40 and the products

of combustion from the secondary combustion zone 40

flow into the tertiary combustion zone 44.

[0045] Some of the air, indicated by arrow A, for pri-

mary combustion flows to a chamber 114 and this flow

through the slots 62 in wall 58 into the primary fuel and

air mixing duct 54. The remainder of the air, indicated by

arrow B, for primary combustion flows to a chamber 116

and this flow through the slots 60 in wall 56 into the pri-

mary fuel and air mixing duct 54. The air, indicated by

arrow C, for secondary combustion flows to the chamber

116 and this flow through the slots 76 in wall 72 into the

secondary fuel and air mixing duct 70. The air, indicated

by arrow E, for tertiary combustion flows to the chamber

118 and this flow through the slots 98 in wall 94 into the

tertiary fuel and air mixing duct 92.

[0046] The combustion process amplifies the pressure

fluctuations for the reasons discussed previously and

may cause components of the gas turbine engine to be-

come damaged if they have a natural frequency of a vi-

bration mode coinciding with the frequency of the pres-

sure fluctuations. Alternatively the amplitude of the pres-

sure fluctuations may be sufficiently great to cause dam-

age to the components of the gas turbine engine.

[0047] The pressure fluctuations, or pressure waves,

in the combustion chamber produce fluctuations in the

fuel to air ratio at the exit of the fuel and air mixing ducts.

The pressure fluctuations in the airflow and the constant

supply of fuel into the fuel and air mixing ducts of the

tubular combustion chambers results in the fluctuating

fuel to air ratio at the exit of the fuel and air mixing ducts.

[0048] Consider the equation:-

Where U is the velocity of the air, M is the mass, P is the

pressure, u is the change in velocity, p is the change

in pressure, FAR is the fuel to air ratio and (FAR) is the

change in the fuel to air ratio.

[0049] Thus in a typical fuel and air mixing duct, if p/P

is about 1%, then u/U is about 30% and hence the

(FAR)/FAR is about 30% into the combustion chamber.

[0050] The present invention seeks to provide a fuel

and air mixing duct which supplies a mixture of fuel and

air into the combustion chamber at a more constant fuel

to air ratio. The present invention provides at least one

point of fuel injection into the fuel and air mixing duct and

a plurality of points of air injection into the fuel and air

7 8

EP 1 260 768 B1

6

5

10

15

20

25

30

35

40

45

50

55

mixing duct. The air injection points are spaced apart

longitudinally, along the slots, in the direction of flow of

the fuel and air mixing duct. The pressure of the air at

the longitudinally spaced air injection points at any instant

in time is different. Thus as the fuel and air mixture flows

along the fuel and air mixing duct the fuel and air mixture

becomes weaker due to the additional air. More impor-

tantly the maximum difference between the actual fuel

to air ratio and the average fuel to air ratio becomes rel-

atively low, see line F in figure 11. However for a single

fuel injection point and a single air injection point the max-

imum difference between the actual fuel to air ratio and

the average fuel to air ratio remains relatively high, see

line G in figure 11.

[0051] A single point of fuel injection means that there

is one or more fuel injectors arranged at the same dis-

tance from the combustion zone, or alternatively one or

more fuel injectors are arranged at a fixed time delay

from the combustion zone. Thus the fuel injectors are

arranged at a position such that the time of travel from

the point of fuel injection to the combustion zone is the

same for all of the fuel injectors.

[0052] Calculations show, see figure 12, that the vari-

ation in the fuel to air ratio for a fuel and air mixing duct

with a single fuel injection point and multiple air injection

points are a few percent of the variation in the fuel to air

ratio for a fuel and air mixing duct with a single fuel in-

jection point and a single air injection point if the volume

of the fuel and air mixing duct is such that the following

equation is satisfied

Where L is the length of the fuel and air mixing duct, F

is the frequency, U is the exit velocity of the fuel and air

mixture and X is a number greater than 2. The greater

the number X, the lower the variation in the fuel to air

ratio. For example with X = 2, the variation is about 7%,

for X = 3, the variation is about 4%, for X = 4, the variation

is about 3%. Preferably X is a number greater than 3,

more preferably X is a number greater than 4 and more

preferably X is a number greater than 5.

[0053] For a tubular combustion chamber, the frequen-

cy of the lowest acoustic mode of the combustion cham-

ber is

Where F is the frequency of the pressure fluctuations, c

is the average speed of sound inside the combustion

chamber and L is the overall length of the tubular com-

bustion chamber.

[0054] For an annular combustion chamber, the fre-

quency of the lowest acoustic mode of the combustion

chamber is

Where F is the frequency of the pressure fluctuations, c

is the average speed of sound inside the combustion

chamber and D is the diameter of the annular combustion

chamber.

[0055] For the present invention to work effectively the

air injectors, slots, need to extend over a length X such

that

Where X is the length of the slots and U is the average

velocity of the air inside the mixing duct. Preferably FX/U

> 2.

[0056] This results in the following design rules, for a

tubular combustion chamber X > 4LU/c or more prefer-

ably X > 8LU/c and for an annular combustion chamber

X > nDU/c or more preferably X > 2DU/c.

[0057] The above equations indicate that as the oper-

ating temperature of the combustion chamber increases,

the speed of sound increases and therefore the amount

of damping by the invention increases. This is an advan-

tage of the present invention.

[0058] The progressive introduction of air along the

length of the fuel and air mixing duct through the slots

results in a number of physical mechanisms which con-

tribute to the reduction, preferably elimination, of the

pressure fluctuations, pressure waves or instabilities, in

the combustion chamber. The physical mechanisms are

the creation of a low velocity region, integration of the

fuel to air ratio fluctuations, damping of pressure waves

and destruction of phase relationships. The advantage

of the slots over apertures is that there is a narrow resi-

dence time distribution, hence a reduced risk of autoig-

nition of the fuel, while maintaining excellent fuel to air

ratio characteristics.

[0059] The airflow in the vicinity of the fuel injector ex-

periences fluctuations in its bulk velocity due to the pres-

sure fluctuations in the fuel and air mixing duct. This cre-

ates a local fluctuation in fuel concentration, a local fuel

to air ratio, which then flows downstream at the bulk ve-

locity of the air in the fuel and air mixing duct. Due to the

mixing of the fuel and air in the fuel and air mixing duct

these fuel to air ratio fluctuations normally diffuse out,

although the process is quite slow. However, if the local

convective velocity is low and the local turbulent intensity

is high, as in the present invention, any fuel to air ratio

9 10

EP 1 260 768 B1

7

5

10

15

20

25

30

35

40

45

50

55

fluctuations are substantially dissipated by the time the

fuel to air ratio fluctuations reach the combustion cham-

ber.

[0060] Any fluctuation in the local fuel to air ratio in the

vicinity of the fuel injector flows downstream and the pro-

gressive introduction of air along the length of the fuel

and air mixing duct integrates out any fluctuations in the

local fuel to air ratio due to the fuel injector. This is be-

cause the pressure of the air supplied along the length

of the slots of air injectors fluctuates with time. If the av-

erage time of travel of a fluid particle from the vicinity of

the fuel injector to the downstream end of the fuel and

air mixing duct is longer than the time period of the pres-

sure fluctuations, then the fluid particle originating from

the vicinity of the fuel injector is subjected to a number

of cycles of becoming leaner and richer that average out

the initial fuel concentration fluctuation. This determines

the spatial extent of the air injectors, i.e. the length D of

the fuel and air mixing duct containing air injectors. This

also determines the width, or cross-sectional area, of the

fuel and air mixing duct as this affects the total residence

time in the fuel and air mixing duct.

[0061] The average air velocity through the slots is cho-

sen so that the air injectors or slots are sensitive to pres-

sure fluctuations originating in the combustion chamber.

As a pressure wave propagates from the downstream

end of the fuel and air mixing duct towards the fuel injector

it progressively loses amplitude because energy is used

fluctuating the air pressure in the air injectors. This re-

duces the possibility of the pressure fluctuations produc-

ing a local fuel to air ratio fluctuation in the vicinity of the

fuel injector. This also completely changes the coupling

between the interior and exterior of the combustion

chamber.

[0062] A consistent relationship is required between

the pressure fluctuations inside the combustion chamber

and the fluctuations in the chemical energy supplied to

the combustion chamber in order for the occurrence of

combustion instability. The chemical energy input to the

combustion chamber is proportional to the strength of

the fuel and air mixture supplied to the combustion cham-

ber and the air velocity at the exit of the fuel and air mixing

duct. The plurality of air injectors integrate out the pres-

sure fluctuations and the fluctuations in the strength of

the fuel and air mixture. Also any fuel to air ratio fluctu-

ations present at the downstream end of the fuel and air

mixing duct are uncorrelated with the pressure fluctua-

tions that produced them. The possibility of positive re-

inforcement of pressure fluctuations or fuel to air ratio

fluctuations is reduced.

[0063] Mixing of the fuel and air in the fuel and air mix-

ing duct is achieved by the vortex flow set in motion by

the slots.

[0064] A further advantage of the use of slots as air

injectors is that the risk of auto ignition of the fuel is re-

duced because the fuel residence time in the fuel and air

mixing duct is less uncertain than with a plurality of

spaced apertures. The slots eliminate the wakes and

boundary layer transverse vortices formed by the dis-

crete apertures in cross flow relationship. The slots are

staggered on opposite walls to avoid a stagnation zone

on the wall opposite a slot. The slots are made as narrow

as possible in order to reduce the wake at the trailing

edge of the slot, typically the slots have a width of 1mm.

The distance between slots is about the same as the

distance between the walls of the fuel and air mixing duct.

The slots are aligned with the direction of flow of the fuel

and air mixture to avoid the formation of stagnant zones

in the wakes of the slots.

[0065] Another advantage is that the slots create large

scale vortex motion which promotes effective mixing of

the fuel and air in the fuel and air mixing duct.

[0066] Another advantage is that it is easier to make a

small number of slots than a larger number of apertures.

[0067] An alternative fuel and air mixing duct 120 not

forming part of the invention is shown in figures 5, 6 and

7. A rectangular cross-section fuel and air mixing duct

120 comprises four sidewalls 122, 124, 126 and 128. The

walls 124 and 126 have a plurality of transversely spaced

slots 130 and 132 respectively which form an air intake

to the fuel and air mixing duct 120. The slots 130 and

132 extend longitudinally of the fuel and air mixing duct

120. The slots 130 in the wall 124 are staggered from

the slots 132 in the wall 128 so that each slot 130 in the

wall 124 is equi-distant from two adjacent slots 132 in

the wall 128 and visa-versa. A single fuel injector 140 is

provided to supply fuel into the upstream end 134 of the

fuel and air mixing duct 120. The fuel injector 140 is sup-

plied with fuel from a fuel manifold 138.

[0068] Another alternative fuel and air mixing duct 150

not forming part of the invention is shown in figures 8, 9

and 10. A circular cross-section fuel and air mixing duct

150 comprises a tubular wall 152 which has a plurality

of circumferentially spaced slots 154 which form an air

intake to the fuel and air mixing duct 150. The slots 154

extend longitudinally, axially, of the fuel and air mixing

duct 150. A single fuel injector 160 is provided to supply

fuel into the upstream end 156 of the fuel and air mixing

duct 150. The fuel injector 160 is supplied with fuel from

a fuel manifold.

[0069] Another primary fuel and air mixing duct 170

according to one embodiment of the present invention is

shown in figures 13 and 14. The primary fuel and air

mixing duct 170 comprises walls 174 and 176 which are

provided with a plurality of circumferentially spaced ra-

dially extending slots 178 and 180 respectively which

form a primary air intake to supply air into the primary

fuel and air mixing duct 170. The slots 178 in the wall

174 are staggered from the slots 180 in the wall 176 so

that each slot 178 in the wall 174 is equi-distant from two

adjacent slots 180 in the wall 176 and visa-versa. The

primary fuel and air mixing duct 170 also has a plurality

of fuel injectors 172 positioned in the primary fuel and air

mixing duct 170 upstream of the slots 178 and 180. Ad-

ditionally a plurality of circumferentially spaced apertures

182 are provided to form part of the primary air intake

11 12

EP 1 260 768 B1

8

5

10

15

20

25

30

35

40

45

50

55

upstream of the fuel injectors 172. The apertures 182

supply up to 40% of the primary air upstream of the fuel

injectors 172. The apertures 182 are provided to prevent

the formation of a stagnant zone, a zone with no net ve-

locity, at the upstream end of the primary fuel and air

mixing duct 170. The stagnant zone mainly consists of

fuel and a small fraction of air, in operation, which results

in long residence times for the fuel with an increased risk

of auto ignition of the fuel in the primary fuel and air mixing

duct 170. The apertures 182 minimise the risk of auto

ignition. The primary fuel and air mixing duct 170 also

increases in cross-sectional area, as shown, in a down-

stream direction. The introduction of air upstream of the

fuel injectors 172 only has a minor effect on the fuel to

air ratio as shown in figure 16, where line H indicates the

fluctuation in the amplitude of the fuel to air ratio in figure

3 and line I indicates the fluctuation in the amplitude of

the fuel to air ratio in figures 13 and 14.

[0070] A further secondary fuel and air mixing duct 190

according to another embodiment of the present inven-

tion is shown in figure 15 and is similar to that shown in

figure 4. The secondary fuel and air mixing duct 190 com-

prises inner annular wall 194 and outer annular wall 196.

The inner and outer annular walls 194 and 196 are pro-

vided with a plurality of circumferentially spaced and ax-

ially extending slots 198 and 200 respectively which form

a secondary air intake to supply air into the secondary

fuel and air mixing duct 190. The secondary fuel and air

mixing duct 190 also has an annular fuel injector slot 192

positioned in the secondary fuel and air mixing duct 190

upstream of the slots 198 and 200. Additionally a plurality

of circumferentially spaced apertures 202 are provided

to form part of the secondary air intake upstream of the

fuel injector slot 192. The apertures 202 may supply up

to 20% of the secondary air, preferably up to 10% of the

secondary air. The apertures 202 also prevent the for-

mation of a stagnant zone and auto ignition, at the up-

stream end of the secondary fuel and air mixing duct 190.

The secondary fuel and air mixing duct 190 also increas-

es in cross-sectional area, as shown, in a downstream

direction. A similar arrangement of additional apertures

may be applied to the tertiary fuel and air mixing duct to

prevent the formation of a stagnant zone and auto igni-

tion.

[0071] The upstream ends of the slots may be posi-

tioned upstream of the fuel injectors to avoid fuel being

trapped upstream of a vortex associated with the up-

stream edge of a blunt body or air jet.

[0072] The slots in the walls of the fuel and air mixing

duct may be arranged perpendicularly to the walls of the

fuel and air mixing duct or at any other suitable angle.

[0073] The fuel supplied by the fuel injector may be a

liquid fuel or a gaseous fuel.

[0074] The invention is also applicable to other fuel and

air mixing ducts. For example the fuel and air mixing ducts

may comprise any suitable shape, or cross-section, as

long as there are a plurality of points of injection of air

arranged longitudinally in a slot, in the direction of flow

through the fuel and air mixing duct, into the fuel and air

mixing duct. The slots may be provided in any one or

more of the walls defining the fuel and air mixing duct.

[0075] The invention is also applicable to other air in-

jectors, for example hollow slotted members may be pro-

vided which extend into the fuel and air mixing duct to

supply air into the fuel and air mixing duct.

[0076] The fuel and air mixing duct may have a swirler,

alternatively it may not have a swirler. The fuel and air

mixing duct may have two coaxial counter swirling swirl-

ers. The swirler may be an axial flow swirler.

[0077] Although the invention has referred to an indus-

trial gas turbine engine it is equally applicable to an aero

gas turbine engine or a marine gas turbine engine.

Claims

1. A tubular combustion chamber (28) comprising at

least one combustion zone (36,40,44) defined by at

least one peripheral annular wall (32), at least one

fuel and air mixing duct (70,92,190) for supplying a

fuel and air mixture to the at least one combustion

zone (36,40,44), the at least one fuel and air mixing

duct (70, 92, 190) having an upstream end and a

downstream end, fuel injection means (90, 112, 192)

for supplying fuel into the at least one fuel and air

mixing duct (70,92,190), air injection means

(76,98,198,200,202) for supplying air into the at least

one fuel and air mixing duct (70,92,190), the pres-

sure of the air supplied to the at least one fuel and

air mixing duct (70,92,190) fluctuating, wherein the

air injection means (76,98,198,200,202) comprise a

plurality of air injectors (76,98,198,200) spaced apart

transversely to the direction of flow through the at

least one fuel and air mixing duct (70,92,190), each

air injector (76,98, 198, 200) comprising a slot ex-

tending in the direction of flow through the at least

one fuel and air mixing duct (70,92, 190) to reduce

the magnitude of the fluctuations in the fuel to air

ratio of the fuel and air mixture supplied into the at

least one combustion zone (36,40,44),

wherein the combustion chamber (28) comprises a

primary combustion zone (36) and a secondary com-

bustion zone (40) downstream of the primary com-

bustion zone (36),

wherein the at least one fuel and air mixing duct (70,

92,190) comprises a single annular fuel and air mix-

ing duct (70, 92, 190), the plurality of air injectors

(76, 98, 198, 200) being circumferentially spaced

apart and the plurality of air injectors (76, 98, 198,

200) extending axially, in the direction of the longi-

tudinal axis of the tubular combustion chamber, the

single annular fuel and air mixing duct (70, 92, 190)

comprising an inner annular wall (72, 94, 194) and

an outer annular wall (74, 96, 196), the plurality of

air injectors (76, 98, 198, 200) being arranged in the

inner and outer annular walls (72, 94, 74, 96, 194,

13 14

EP 1 260 768 B1

9

5

10

15

20

25

30

35

40

45

50

55

196), characterised in that the plurality of air injec-

tors (76, 98, 198)in the inner annular wall (72,94,194)

are staggered circumferentially with respect to the

plurality of air injectors (76,98,200)in the outer an-

nular wall (74, 96, 196).

2. A tubular combustion chamber (28) comprising at

least one combustion zone (36,40,44) defined by at

least one peripheral annular wall (32), at least one

fuel and air mixing duct (54,170) for supplying a fuel

and air mixture to the at least one combustion zone

(36,40,44), the at least one fuel and air mixing duct

(54,170) having an upstream end and a downstream

end, fuel injection means (56,172) for supplying fuel

into the at least one fuel and air mixing duct (54,170),

air injection means (62,64,178,180,182) for supply-

ing air into the at least one fuel and air mixing duct

(54,170), the pressure of the air supplied to the at

least one fuel and air mixing duct (54,170) fluctuat-

ing,

wherein the air injection means (62,64,178,180, 182)

comprise a plurality of air injectors (62,64,178,180)

spaced apart transversely to the direction of flow

through the at least one fuel and air mixing duct

(54,170), each air injector (62,64,178,180) compris-

ing a slot extending in the direction of flow through

the at least one fuel and air mixing duct (54,170) to

reduce the magnitude of the fluctuations in the fuel

to air ratio of the fuel and air mixture supplied into

the at least one combustion zone (36,40,44),

wherein the at least one fuel and air mixing duct (54,

170) comprises a radial fuel and air mixing duct, the

plurality of air injectors (62,64,178,180) being cir-

cumferentially spaced apart and the plurality of air

injectors (62, 64, 178, 180) extending radially with

respect to the longitudinal axis of the tubular com-

bustion chamber, the radial fuel and air mixing duct

(54,170) comprising a first radial wall (58,174) and

a second radial wall (60,176) spaced apart axially in

the direction of the longitudinal axis of the tubular

combustion chamber, the plurality of air injectors (62,

64, 178, 180) being provided in the first and second

radial walls (58, 60, 174, 176),

characterised in that the plurality of air injectors

(62, 178) in the first radial wall (58,174) are staggered

circumferentially with respect to the plurality of air

injectors (64, 180) in the second radial wall (60, 176).

3. A combustion chamber as claimed in claim 2 wherein

the combustion chamber comprises a primary com-

bustion zone (36) and a secondary combustion zone

(40) downstream of the primary combustion zone

(36).

4. A combustion chamber as claimed in claim 1 or claim

3 wherein the combustion chamber (28) comprises

a primary combustion zone (36), a secondary com-

bustion zone (40) downstream of the primary com-

bustion zone (36) and a tertiary combustion zone

(44) downstream of the secondary combustion zone

(40).

5. A combustion chamber as claimed in claim 3 or claim

4 as dependent on claim 3 wherein the radial fuel

and air mixing duct (54, 170) supplies fuel and air

into the primary combustion zone (36).

6. A combustion chamber as claimed in claim 1 or claim

4 as dependent on claim 1 wherein the single annular

fuel and air mixing duct (70, 190) supplies fuel and

air into the secondary combustion zone (40).

7. A combustion chamber as claimed in claim 4 as de-

pendent on claim 1 wherein the single annular fuel

and air mixing duct (92, 190) supplies fuel and air

into the tertiary combustion zone (44).

8. A combustion chamber as claimed in any of claims

1 to 7 wherein the fuel injection means (172, 192) is

arranged between the upstream end and the down-

stream end of the or each fuel and air mixing duct

(170, 190), at least a portion (182, 202) of the plurality

of air injectors (178, 180, 182, 198, 200, 202) are

arranged upstream of the fuel injection means (172,

192) and at least a portion (178, 180, 198, 200) of

the plurality of air injectors (178,180,182, 198, 200,

202) are arranged downstream of the fuel injection

means (172,192).

9. A combustion chamber as claimed in any of claims

1 to 8 wherein each one of the plurality of air injectors

(62,64, 76, 98, 178,180, 198, 200) at the downstream

end of the or each fuel and air mixing duct (54, 70,

92, 170, 190) is arranged to supply more air into the

fuel and air mixing duct than each one of the plurality

of air injectors (62, 64, 76, 98, 178, 180, 182, 198,

200, 202) at the upstream end of the or each fuel

and air mixing duct.

10. A combustion chamber as claimed in any of claims

1 to 9 wherein each one of the plurality of air injectors

(62, 64, 76, 98, 178,180, 198, 200) at a first position

in the direction of flow through the or each fuel and

air mixing duct (54, 70, 92, 170, 190) is arranged to

supply more air into the fuel and air mixing duct than

said plurality of air injectors (62, 64, 76, 98, 178, 180,

182, 198, 200, 202) upstream of the first position in

the fuel and air mixing duct.

11. A combustion chamber as claimed in claim 10

wherein said each one of the plurality of air injectors

at the first position in the or each fuel and air mixing

duct is arranged to supply less air into the fuel and

air mixing duct than said plurality of air injectors

(62,64, 76, 98, 178,180, 198, 200)downstream of the

first position in the or each fuel and air mixing duct.

15 16

EP 1 260 768 B1

10

5

10

15

20

25

30

35

40

45

50

55

12. A combustion chamber as claimed in any of claims

1 to 11 wherein the volume of the or each fuel and

air mixing duct (54,70,92, 170, 190) being arranged

such that the average travel time from the fuel injec-

tion means (56,90,112, 172, 192) to the downstream

end of the fuel and air mixing duct is greater than the

time period of the fluctuation.

13. A combustion chamber as claimed in any of claims

1 to 11 wherein the volume of the fuel and air mixing

duct (54,70,92, 170, 190) being arranged such that

the length of the fuel and air mixing duct multiplied

by the frequency of the fluctuations divided by the

velocity of the fuel and air leaving the downstream

end of the fuel and air mixing duct is at least one.

14. A combustion chamber as claimed in claim 13

wherein said volume of the or each fuel and air mixing

duct being arranged such that the length of the fuel

and air mixing duct multiplied by the frequency of the

fluctuations divided by the velocity of the fuel and air

leaving the downstream end of the fuel and air mixing

duct is at least two.

15. A combustion chamber as claimed in any of claims

1 to 11 wherein the plurality of air injectors

(62,64,76,98, 178, 180, 198, 200) extend in the di-

rection of flow through each fuel and air mixing duct

(54,70,92, 170, 190) over a length (D) equal to half

the wavelength of the fluctuations of the air supplied

to the or each fuel and air mixing duct.

16. A combustion chamber as claimed in any of claims

1 to 14 wherein the length (D) of an air injector

(62,64,76,98, 178, 180, 198, 200) in the direction of

flow through the or each fuel and air mixing duct

(54,70,92, 170, 190) multiplied by the frequency of

the fluctuations divided by the velocity of the fuel and

air inside the fuel and air mixing duct is at least one.

17. A combustion chamber as claimed in claim 16

wherein said length (D) of the air injector multiplied

by said frequency of the fluctuations divided by said

average velocity of the fuel and air is at least two.

Patentansprche

1. Eine rohrfrmige Brennkammer (28), die zumindest

eine Verbrennungszone (36, 40, 44), die durch zu-

mindest eine ringfrmige Auenwand (32) definiert

wird, zumindest eine Brennstoff- und Luftmischlei-

tung (70, 92, 190) zur Zufuhr eines Brennstoff- und

Luftgemischs zur zumindest einen Verbrennungszo-

ne (36, 40, 44), wobei die zumindest eine Brennstoff-

und Luftmischleitung (70, 92, 190) ein vorgeschal-

tetes Ende und ein nachgeschaltetes Ende hat, eine

Brennstoffeinspritzvorrichtung (90, 112, 192) zur Zu-

fuhr von Brennstoff in die zumindest eine Brennstoff-

und Luftmischleitung (70, 92, 190), eine Lufteinblas-

vorrichtung (76, 98, 198, 200, 202) zur Zufuhr von

Luft in die zumindest eine Brennstoff- und Luft-

mischleitung (70, 92, 190) aufweist, wobei der Druck

der der zumindest einen Brennstoff- und Luft-

mischleitung (70, 92, 190) zugefhrten Luft fluktuiert,

wobei die Lufteinblasvorrichtung (76, 98, 198, 200,

202) eine Vielzahl an Luftinjektoren (76,98,198,200)

umfasst, die in Abstnden quer zu Richtung des

Stroms durch die zumindest eine Brennstoff- und

Luftmischleitung (70,92,190) angeordnet sind, wo-

bei jeder Luftinjektor (76, 98, 198, 200) einen Schlitz

aufweist, der in der Richtung des Stroms durch die

zumindest eine Brennstoff- und Luftmischleitung

(70, 92, 190) verluft, um die Zahl der Schwankun-

gen im Brennstoff-Luftverhltnis des Brennstoff-

Luftgemisches, das der zumindest einen Verbren-

nungszone (36, 40, 44) zugefhrt wird, zu reduzie-

ren,

wobei die Brennkammer (28) eine primre Verbren-

nungszone (36) und eine sekundre Verbrennungs-

zone (40), die der primren Verbrennungszone (36)

nachgeschaltet ist, umfasst,

wobei die zumindest eine Brennstoff- und Luft-

mischleitung (70, 92, 190) eine einzelne ringfrmige

Brennstoff- und Luftmischleitung (70, 92, 190) um-

fasst, wobei die Vielzahl an Luftinjektoren (76, 98,

198, 200) in Abstnden rundum angeordnet ist und

die Vielzahl der Luftinjektoren (76, 98, 198, 200) axial

in Richtung der Lngsachse der rohrfrmigen Brenn-

kammer verluft, wobei die eine ringfrmige Brenn-

stoff- und Luftmischleitung (70, 92, 190) eine ring-

frmige Innenwand (72, 94, 194) und eine ringfrmi-

ge Auenwand (74, 96, 196) umfasst, wobei die Viel-

zahl der Luftinjektoren (76, 98, 198, 200) in der ring-

frmigen Innen- und Auenwand (72, 94, 74, 96,

194, 196) angeordnet ist, dadurch gekennzeich-

net, dass die Vielzahl der Luftinjektoren (76, 98,

198) in der ringfrmigen Innenwand (72, 94,194)

rundum hinsichtlich der Vielzahl der Luftinjektoren

(76, 98, 200) in der ringfrmigen Auenwand (74,

96, 196) versetzt ist.

2. Eine rohrfrmige Brennkammer (28), die zumindest

eine Verbrennungszone (36, 40, 44), die durch zu-

mindest eine ringfrmige Auenwand (32) definiert

wird, zumindest eine Brennstoff- und Luftmischlei-

tung (54, 170) zur Zufuhr eines Brennstoff- und Luft-

gemischs zur zumindest einen Verbrennungszone

(36, 40, 44), wobei die zumindest eine Brennstoff-

und Luftmischleitung (54, 170) ein vorgeschaltetes

Ende und ein nachgeschaltetes Ende hat, eine

Brennstoffeinspritzvorrichtung (56, 172) zur Zufuhr

von Brennstoff in die zumindest eine Brennstoff- und

Luftmischleitung (54, 170), eine Lufteinblasvorrich-

tung (62, 64, 178, 180, 182) zur Zufuhr von Luft in

die zumindest eine Brennstoff- und Luftmischleitung

17 18

EP 1 260 768 B1

11

5

10

15

20

25

30

35

40

45

50

55

(54, 170) aufweist, wobei der Druck der zumindest

einen Brennstoff- und Luftmischleitung (54, 170) zu-

gefhrten Luft fluktuiert,

wobei die Lufteinblasvorrichtung (62, 64, 178, 180,

182) eine Vielzahl an Luftinjektoren (62, 64, 178,

180) umfasst, die in Abstnden quer zu Richtung

des Stroms durch die zumindest eine Brennstoff-

und Luftmischleitung (54, 170) angeordnet sind, wo-

bei jeder Luftinjektor (62, 64, 178, 180) einen Schlitz

aufweist, der in der Richtung des Stroms durch die

zumindest eine Brennstoff- und Luftmischleitung

(54, 170) verluft, um die Zahl der Schwankungen

im Brennstoff-Luftverhltnis des Brennstoff-Luftge-

misches, das der zumindest einen Verbrennungszo-

ne (36, 40, 44) zugefhrt wird, zu reduzieren,

wobei die zumindest eine Brennstoff- und Luft-

mischleitung (54,170) eine radiale Brennstoff- und

Luftmischleitung umfasst, wobei die Vielzahl an Luf-

tinjektoren (62, 64, 178, 180) in Abstnden rundum

angeordnet ist und die Vielzahl der Luftinjektoren

(62, 64, 178, 180) radial zur Lngsachse der rohr-

frmigen Brennkammer verluft, wobei die radiale

Brennstoff- und Luftmischleitung (54, 170) eine erste

radiale Wand (58, 174) und eine zweite radiale Wand

(60, 176) umfasst, die axial in Richtung der Lngs-

achse der rohrfrmigen Brennkammer angeordnet

sind, wobei die Vielzahl der Luftinjektoren (62, 64,

178, 180) in der ersten und zweiten radialen Wand

(58, 60, 174, 176) angeordnet ist,

dadurch gekennzeichnet, dass die Vielzahl der

Luftinjektoren (62, 178) in der ersten radialen Wand

(58, 174) rundum hinsichtlich der Vielzahl der Luf-

tinjektoren (64, 180) in der zweiten radialen Wand

(60, 176) versetzt ist.

3. Eine Brennkammer entsprechend Anspruch 2, wo-

bei die Brennkammer eine primre Verbrennungs-

zone (36) und eine sekundre Verbrennungszone

(40), die der primren Verbrennungszone (36) nach-

geschaltet ist, umfasst.

4. Eine Brennkammer entsprechend Anspruch 1 oder

Anspruch 3, wobei die Brennkammer (28) eine pri-

mre Verbrennungszone (36), eine sekundre Ver-

brennungszone (40), die der primren Verbren-

nungszone (36) nachgeschaltet ist, und eine tertire

Verbrennungskammer (44), die der sekundren Ver-

brennungskammer (40) nachgeschaltet ist, umfasst.

5. Eine Brennkammer entsprechend Anspruch 3 oder

Anspruch 4 in Abhngigkeit von Anspruch 3, wobei

die radiale Brennstoff- und Luftmischleitung (54,

170) der primren Verbrennungszone (36) Brenn-

stoff und Luft zufhrt.

6. Eine Brennkammer entsprechend Anspruch 1 oder

Anspruch 4 in Abhngigkeit von Anspruch 1, wobei

die einzelne ringfrmige Brennstoff- und Luft-

mischleitung (70, 190) der sekundren Verbren-

nungszone (40) Brennstoff und Luft zufhrt.

7. Eine Brennkammer entsprechend Anspruch 4 in Ab-

hngigkeit von Anspruch 1, wobei die einzelne ring-

frmige Brennstoff- und Luftmischleitung (92, 190)

der tertiren Verbrennungszone (44) Brennstoff und

Luft zufhrt.

8. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 7, wobei die Brennstoffeinspritzvor-

richtung (172, 192) zwischen dem vorgeschalteten

Ende und dem nachgeschalteten Ende der oder je-

der Brennstoff- und Luftmischleitung (170, 190) an-

geordnet ist, zumindest ein Teil (182, 202) der Viel-

zahl an Luftinjektoren (178, 180, 182, 198, 200, 202)

der Brennstoffeinspritzvorrichtung (172, 192) vorge-

schaltet ist und zumindest ein Teil (178, 180, 198,

200) der Vielzahl an Luftinjektoren (178, 180, 182,

198, 200, 202) der Brennstoffeinspritzvorrichtung

(172, 192) nachgeschaltet ist.

9. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 8, wobei jeder der Vielzahl an Luftin-

jektoren (62, 64, 76, 98, 178, 180, 198, 200) am

nachgeschalteten Ende der oder jeder Brennstoff-

und Luftmischleitung (54, 70, 92, 170, 190) so an-

geordnet ist, dass er der Brennstoff- und Luft-

mischleitung mehr Luft zufhrt als jeder der Vielzahl

von Luftinjektoren (62, 64, 76, 98, 178,180, 182, 198,

200, 202) am vorgeschalteten Ende der oder jeder

der Brennstoff- und Luftmischleitung.

10. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 9, wobei jeder der Vielzahl von Luftin-

jektoren (62, 64, 76, 98, 178, 180, 198, 200) an einer

ersten Position in der Strmungsrichtung durch die

oder jede Brennstoff- und Luftmischleitung (54, 70,

92, 170, 190) so angeordnet ist, dass sie der Brenn-

stoff- und Luftmischleitung mehr Luft zufhrt als die

genannte Vielzahl an Luftinjektoren (62, 64, 76, 98,

178, 180, 182, 198, 200, 202), die der ersten Position

der Brennstoff- und Luftmischleitung vorgeschaltet

ist.

11. Eine Brennkammer entsprechend Anspruch 10, wo-

bei jeder der genannten Vielzahl an Luftinjektoren

an der ersten Position in der oder jeder Brennstoff-

und Luftmischleitung so angeordnet ist, dass er der

Brennstoff- und Luftmischleitung weniger Luft zu-

fhrt als die genannte Vielzahl an Luftinjektoren (62,

64, 76, 98, 178, 180, 198, 200) die der ersten Position

in der oder jeder Brennstoff- und Luftmischleitung

nachgeschaltet ist.

12. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 11, wobei das Volumen der oder jeder

Brennstoff- und Luftmischleitung (54, 70, 92, 170,

19 20

EP 1 260 768 B1

12

5

10

15

20

25

30

35

40

45

50

55

190) so angeordnet ist, dass die durchschnittliche

Wegzeit von der Brennstoffeinspritzvorrichtung (56,

90, 112, 172, 192) zum nachgeschalteten Ende der

Brennstoff- und Luftmischleitung grer als der Zeit-

raum der Schwankungen ist.

13. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 11, wobei das Volumen der Brennstoff-

und Luftmischleitung (54, 70, 92, 170, 190) so an-

geordnet ist, dass die Lnge der Brennstoff- und

Luftmischleitung multipliziert mit der Hufigkeit der

Schwankungen geteilt durch die Geschwindigkeit,

mit der Brennstoff und Luft aus dem nachgeschalte-

ten Ende der Brennstoff- und Luftmischleitung aus-

treten, mindestens eins ist.

14. Eine Brennkammer entsprechend Anspruch 13, wo-

bei das genannte Volumen der oder jeder Brenn-

stoff- und Luftmischleitung so angeordnet ist, dass

die Lnge der Brennstoff- und Luftmischleitung mul-

tipliziert mit der Hufigkeit der Schwankungen geteilt

durch die Geschwindigkeit, mit der Brennstoff und

Luft aus dem nachgeschalteten Ende der Brenn-

stoff- und Luftmischleitung austreten, mindestens

zwei ist.

15. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 11, wobei die Vielzahl der Luftinjekto-

ren (62, 64, 76, 98, 178, 180, 198, 200) in der Str-

mungsrichtung durch jede Brennstoff- und Luft-

mischleitung (54, 70, 92, 170, 190) ber eine Lnge

(D) verluft, die der Hlfte der Wellenlnge der

Schwankungen der Luft, die der oder jeder Brenn-

stoff- und Luftmischleitung zugefhrt wird, ent-

spricht.

16. Eine Brennkammer entsprechend einem der An-

sprche 1 bis 14, wobei die Lnge (D) eines Luftin-

jektors (62, 64, 76, 98, 178, 180, 198, 200) in der

Strmungsrichtung durch die oder jede Brennstoff-

und Luftmischleitung (54, 70, 92, 170, 190) multipli-

ziert mit der Hufigkeit der Schwankungen geteilt

durch die Geschwindigkeit des Brennstoffs und der

Luft in der Brennstoff- und Luftmischleitung mindes-

tens eins ist.

17. Eine Brennkammer entsprechend Anspruch 16, wo-

bei die genannte Lnge (D) des Luftinjektors multi-

pliziert mit der genannten Hufigkeit der Schwan-

kungen geteilt durch die genannte durchschnittliche

Geschwindigkeit von Brennstoff und Luft mindes-

tens zwei ist.

Revendications

1. Une chambre de combustion tubulaire (28) compre-

nant au moins une zone de combustion (36, 40, 44)

dfinie par au moins une paroi annulaire priphri-

que (32), au moins un conduit de mlange dair et

de combustible (70, 92, 190) destin fournir un

mlange dair et de combustible la au moins une

zone de combustion (36, 40, 44), le au moins un

conduit de mlange dair et de combustible (70, 92,

190) possdant une extrmit amont et une extr-

mit aval, un moyen dinjection de combustible (90,

112, 192) destin fournir du combustible dans le

au moins un conduit de mlange dair et de combus-

tible (70, 92, 190), un moyen dinjection dair (76, 98,

198, 200, 202) destin fournir de lair dans le au

moins un conduit de mlange dair et de combustible

(70, 92, 190), la pression de lair fournie au moins

un conduit de mlange dair et de combustible (70,

92, 190) fluctuant, o le moyen dinjection dair (76,

98, 198, 200, 202) comprend une pluralit dinjec-

teurs dair (76, 98, 198, 200) espacs transversale-

ment la direction dcoulement au travers du au

moins un conduit de mlange dair et de combustible

(70, 92, 190), chaque injecteur dair (76, 98, 198,

200) comprenant une fente stendant dans la direc-

tion dcoulement au travers du au moins un conduit

de mlange dair et de combustible (70, 92, 190) de

faon rduire la magnitude des fluctuations dans

le rapport combustible sur air du mlange dair et de

combustible fourni la au moins une zone de com-

bustion (36, 40, 44),

o la chambre de combustion (28) comprend une

zone de combustion primaire (36) et une zone de

combustion secondaire (40) en aval de la zone de

combustion primaire (36),

o le au moins un conduit de mlange dair et de

combustible (70, 92, 190) comprend un conduit de

mlange dair et de combustible annulaire unique

(70, 92, 190), la pluralit dinjecteurs dair (76, 98,

198, 200) tant espacs circonfrentiellement et la

pluralit dinjecteurs dair (76, 98, 198, 200) sten-

dant axialement dans la direction de laxe longitudi-

nal de la chambre de combustion tubulaire, le con-

duit de mlange dair et de combustible annulaire

unique (70, 92, 190) comprenant une paroi annulaire

interne (72, 94, 194) et une paroi annulaire externe

(74, 96, 196), la pluralit dinjecteurs dair (76, 98,

198, 200) tant agencs dans les parois annulaires

interne et externe (72, 94, 74, 96, 194, 196), carac-

tris en ce que la pluralit dinjecteurs dair (76,

98, 198) dans la paroi annulaire interne (72, 94, 194)

sont circonfrentiellement en quinconce par rapport

la pluralit dinjecteurs dair (76, 98, 200) dans la

paroi annulaire externe (74, 96, 196).

2. Une chambre de combustion tubulaire (28) compre-

nant au moins une zone de combustion (36, 40, 44)

dfinie par au moins une paroi annulaire priphri-

que (32), au moins un conduit de mlange dair et

de combustible (54, 170) destin fournir un mlan-

ge dair et de combustible la au moins une zone

21 22

EP 1 260 768 B1

13

5

10

15

20

25

30

35

40

45

50

55

de combustion (36, 40, 44), le au moins un conduit

de mlange dair et de combustible (54, 170) poss-

dant une extrmit amont et une extrmit aval, un

moyen dinjection de combustible (56, 172) destin

fournir du combustible dans le au moins un conduit

de mlange dair et de combustible (54, 170), un

moyen dinjection dair (62, 64, 178, 180, 182) des-

tin fournir de lair dans le au moins un conduit de

mlange dair et de combustible (54, 170), la pres-

sion de lair fournie au moins un conduit de mlange

dair et de combustible (54, 170) fluctuant,

o le moyen dinjection dair (62, 64, 178, 180, 182)

comprend une pluralit dinjecteurs dair (62, 64,

178, 180) espacs transversalement la direction

dcoulement au travers du au moins un conduit de

mlange dair et de combustible (54, 170), chaque

injecteur dair (62, 64, 178, 180) comprenant une

fente stendant dans la direction dcoulement au

travers du au moins un conduit de mlange dair et

de combustible (54, 170) de faon rduire la ma-

gnitude des fluctuations dans le rapport combustible

sur air du mlange dair et de combustible fourni

la au moins une zone de combustion (36, 40, 44),

o le au moins un conduit de mlange dair et de

combustible (54, 170) comprend un conduit de m-

lange dair et de combustible radial, la pluralit din-

jecteurs dair (62, 64, 178, 180) tant espacs cir-

confrentiellement et la pluralit dinjecteurs dair

(62, 64, 178, 180) stendant radialement par rapport

laxe longitudinal de la chambre de combustion

tubulaire, le conduit de mlange dair et de combus-

tible radial (54, 170) comprenant une premire paroi

radiale (58, 174) et une deuxime paroi radiale (60,

176) espaces axialement dans la direction de laxe

longitudinal de la chambre de combustion tubulaire,

la pluralit dinjecteurs dair (62, 64, 178, 180) tant

placs dans les premire et deuxime parois radia-

les (58, 60, 174, 176),

caractris en ce que la pluralit dinjecteurs dair

(62, 178) dans la premire paroi radiale (58, 174)

sont circonfrentiellement en quinconce par rapport

la pluralit dinjecteurs dair (64, 180) dans la

deuxime paroi radiale (60, 176).

3. Une chambre de combustion selon la Revendication

2 o la chambre de combustion comprend une zone

de combustion primaire (36) et une zone de com-

bustion secondaire (4 0) en aval de la zone de com-

bustion primaire (36).

4. Une chambre de combustion selon la Revendication

1 ou 3, o la chambre de combustion (28) comprend

une zone de combustion primaire (36), une zone de

combustion secondaire (40) en aval de la zone de

combustion primaire (36) et une zone de combustion

tertiaire (44) en aval de la zone de combustion se-

condaire (40).

5. Une chambre de combustion selon la Revendication

3 ou 4 lorsquelle dpend de la Revendication 3, o

le conduit de mlange dair et de combustible radial

(54, 170) fournit du combustible et de lair dans la

zone de combustion primaire (36).

6. Une chambre de combustion selon la Revendication

1 ou 4 lorsquelle dpend de la Revendication 1, o

le conduit de mlange dair et de combustible annu-

laire unique (70, 190) fournit du combustible et de

lair dans la zone de combustion secondaire (40).

7. Une chambre de combustion selon la Revendication

4 lorsquelle dpend de la Revendication 1, o le

conduit de mlange dair et de combustible annulaire

unique (92, 190) fournit du combustible et de lair

dans la zone de combustion tertiaire (44).

8. Une chambre de combustion selon lune quelconque

des Revendications 1 7, o le moyen dinjection

de combustible (172, 192) est agenc entre lextr-

mit amont et lextrmit aval du ou de chaque con-

duit de mlange dair et de combustible (170, 190),

au moins une partie (182, 202) de la pluralit din-

jecteurs dair (178, 180, 182, 198, 200, 202) est

agence en amont du moyen dinjection de combus-

tible (172, 192) et au moins une partie (178, 180,

198, 200) de la pluralit dinjecteurs dair (178, 180,

182, 198, 200, 202) est agence en aval du moyen

dinjection de combustible (172, 192).

9. Une chambre de combustion selon lune quelconque

des Revendications 1 8 o chaque injecteur de la

pluralit dinjecteurs dair (62, 64, 76, 98, 178, 180,

198, 200) au niveau de lextrmit aval du ou de

chaque conduit de mlange dair et de combustible

(54, 70, 92, 170, 190) est agenc de faon fournir

plus lair dans le conduit de mlange dair et de com-

bustible que chaque injecteur de la pluralit dinjec-

teurs dair (62, 64, 76, 98, 178, 180, 182, 198, 200,

202) au niveau de lextrmit amont du ou de chaque

conduit de mlange dair et de combustible.

10. Une chambre de combustion selon lune quelconque

des Revendications 1 9 o chaque injecteur de la

pluralit dinjecteurs dair (62, 64, 76, 98, 178, 180,

198, 200) au niveau dune premire position dans la

direction dcoulement au travers du ou de chaque

conduit de mlange dair et de combustible (54, 70,

92, 170, 190) est agenc de faon fournir plus lair

dans le conduit de mlange dair et de combustible

que ladite pluralit dinjecteurs dair (62, 64, 76, 98,

178, 180, 182, 198, 200, 202) en amont de la pre-

mire position dans le conduit de mlange dair et

de combustible.

11. Une chambre de combustion selon la Revendication

10 o ledit chaque injecteur de la pluralit dinjec-

23 24

EP 1 260 768 B1

14

5

10

15

20

25

30

35

40

45

50

55

teurs dair au niveau de la premire position dans le

ou dans chaque conduit de mlange dair et de com-

bustible est agenc de faon fournir moins lair

dans le conduit de mlange dair et de combustible

que ladite pluralit dinjecteurs dair (62, 64, 76, 98,

178, 180, 198, 200) en aval de la premire position

dans le ou dans chaque conduit de mlange dair et

de combustible.

12. Une chambre de combustion selon lune quelconque

des Revendications 1 11 o le volume du ou de