Académique Documents

Professionnel Documents

Culture Documents

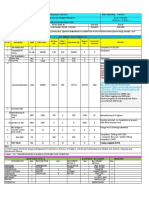

Stat Prod Range en

Transféré par

hjyujyagghjafhgjhgafTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stat Prod Range en

Transféré par

hjyujyagghjafhgjhgafDroits d'auteur :

Formats disponibles

WE CARE

RECYCLING TECHNOLOGY

STATIC EQUIPMENT

2 3

CONTENTS

Recycling Technology

Overview Machines . . . . . . . . . . . . . . 4

DW SERIES

Shredders . . . . . . . . . . . . . . . . . . . . . . . . 6

AK/NZ SERIES

Grinders . . . . . . . . . . . . . . . . . . . . . . . . 12

DF 307 Rotaro

Fine Shredder . . . . . . . . . . . . . . . . . . . 18

SM/SST SERIES

Screeners . . . . . . . . . . . . . . . . . . . . . . .20

DST 512 / 513

Star Screen . . . . . . . . . . . . . . . . . . . . . . 26

WS 2002

Windsifter . . . . . . . . . . . . . . . . . . . . . . . 27

DM 215 E

Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DSP 20-5

Screw Press . . . . . . . . . . . . . . . . . . . . .30

AT SERIES

Feed Hoppers . . . . . . . . . . . . . . . . . . . 32

Typical Applications . . . . . . . . . . . . . 34

Doppstadt System Engineering

Technical Support . . . . . . . . . . . . . . . . 36

Mobile Recycling

Overview . . . . . . . . . . . . . . . . . . . . . . . . 42

CALBE PRODUCTION & DISTRIBUTION OF MOBILE DOPPSTADT MACHINES

VELBERT PRODUCTION & DISTRIBUTION OF DOPPSTADT STATIC EQUIPMENT

WE CARE

4 5

SM 518 A

SST 518 SST 720

SST 1525 E DST 512 / 513 SST 1025

SM 620 A SM 518 F

SST 725 DW 206 CERON

DW 2060 E

DW 3080 E2

DF 307 ROTARO

DW 2560 E1

AK 435 E

DW 3060 E1

NZ 180 AK 235 E

DW 306 CERON

WS 2002

AT 300

DSP 20-5

AT 600

DM 215 E

RECYCLING EQUIPMENT OVERVIEW

W

I

N

D

S

I

F

T

E

R

F

E

E

D

H

O

P

P

E

R

S

S

C

R

E

E

N

E

R

S

S

H

R

E

D

D

E

R

S

G

R

I

N

D

E

R

S

M

I

X

E

R

F

I

N

E

S

H

R

E

D

D

E

R

S

C

R

E

W

P

R

E

S

S

6 7

1

5

2

2

3

7

6

5

5

6 7

3 4

1

DW SERIES

Shredders

POWERFUL AND FLEXIBLE

The shredding by roller and comb is suit-

able for the most difcult tasks. Roller teeth

made of wear-resistant steel tear the mate-

rial through the shredding comb. The comb

opens automatically if necessary in order to

avoid damages by large unshreddable con-

taminants. All the wear parts are quickly and

easily replaceable.

The stationary shredders of the DW series

stand out for the high throughput and the

lumpy structure of the shredded materials.

An adjustment to different specic condi-

tions of the plant design is possible thanks to

the connections in the feeding and discharge

areas.

The machine is driven directly by DC current

or AC motors. By means of individual speed

regulation (only DC motors) an optimum

process adjustment can be realized. The large

protection doors and aps enable an efcient

maintenance from outside of the machine.

Since all the shredding tools of the mobile

Doppstadt series can be used, there is a

wide range of possible applications.

COMPOSTING, WASTE WOOD, GARBAGE AND REFUSE-DERIVED

FUEL PROCESSING, VOLUME REDUCTION

Optional:

Fe-separation,

windsifting and

further processing

1

ROLLER & SHREDDING COMB

2

FEED HOPPER

3

ROLLER EXCHANGE ACCESS

4

CONTROL PANEL

5

DRIVE COMPARTMENT

6

MAINTENANCE ACCESS PANEL

7

LOWER DISCHARGE CONVEYOR

*option Explanations and illustrations by the example of the DW 306.

typical stages

for waste wood

processing

Final product:

for thermal utilization and recycling

A

K

/

N

Z

S

e

r

ie

s

G

r

in

d

in

g

S

M

/

S

S

T

S

e

ries

S

c

r

e

e

n

in

g

3

2

Shredding

DW Series 1

typical stages

for compost

production

S

M

/

S

S

T

S

e

rie

s

S

c

r

e

e

n

in

g

Final product:

compost

DU 320

Turning

G

r

in

d

in

g

A

K

/

N

Z

S

e

r

i e

s

3

4

2

S

hredding

D

W

Series

1

typical stages for

refuse derived fuel

processing

Final product:

for thermal utilization

D

W

S

e

rie

s (finger basket*)

G

r

in

d

in

g

3

2

DW Series 1

Shredding

S

M

/

S

S

T

S

e

r

i e

s

S

c

r

e

e

n

i

n

gtypical stages for

volume reduction

and domestic waste

processing

Final product:

shredded and separated fractions

S

M

/SST Series

S

creening

Shredd

in

g

DW Serie

s

1

2

KEY BENEFITS

Wide range of applications shredding

of various materials

Greater efficieny due to the direct

drive rotor

Resistant to damage by foreign objects

Hydraulically controlled shredding comb

for machine protection guarantees high

up-time of running machine

Low power consumption by way of

direct motor drive

Can be combined with other Doppstadt

products

One-man operation

(remote control of main functions)

8 9

DW 2060 E DW 2560 E1

DW 306 CERON

DW 3080 E2 DW 3060 E

DW 206 CERON

DW SERIES

DW 3060 E1

The Doppstadt DW 3060 E1 is used for the processing of

household waste and waste wood. The 3 m (9' 10") roller turns

at an adjustable 7 28 rpm. 21 roller and 22 comb teeth are

used to cause the shredding of in-fed materials.

Total weight basic machine 23,750 kg (52,359 lb)

Drive type DC motor

power 315 kW

Shredding rotor length 3,000 mm (9'10")

diameter 600 mm (2')

no. of teeth 21

Dimensions basic machine L/W/H 7,180/2,600/3,150 mm

Excluding: Hopper, Mounting (23'6"/8'6"/10'4")

Frame, Discharge Conveyor

DW 2560 E1

DW 2560 E1 is the standard machine for domestic waste and

the processing of old wood. Its 2.5m (8' 2") long shredding

roller rotates at a variable 7 28 rpm. Materials are shredded by

17 roller and 18 comb teeth.

Total weight basic machine 19,600 kg (43,211 lb)

Drive type DC motor

power 210/315 kW

Roller length 2,500 mm (8'2")

diameter 600 mm (2')

no. of teeth 17

Dimensions basic machine L/W/H 6,550/2,600/3,150 mm

Excluding: Hopper, Mounting (21'6"/8'6"/10'4")

Frame, Discharge Conveyor

DW 3080 E2

The Doppstadt DW 3080 E2 Mammut is a special machine

for heavy duty applications. Its 3 m shredding roller revolves

at 7 28 rpm (adjustable). 13 or (21) roller and 14 or (22) comb

teeth shred the materials.

Total weight basic machine 32,500 kg (71,650 lb)

Drive type DC motor

power 315/318 kW(BioPower)

Roller length 3,000 mm (9'10")

diameter 800 mm (2'7")

no. of teeth 21 (13)

Dimensions basic machine L/W/H 6,800/2,800/2,760 mm

Excluding: Hopper, Mounting (22'3"/9'2"/9'1")

Frame, Discharge Conveyor

Total weight basic machine 11,900 kg (26,235 lb)

Drive type AC motor

power 132/160 kW

Roller length 2,000 mm (6'6")

diameter 600 mm (2')

no. of teeth 14

Dimensions basic machine L/W/H 6,150/2,000/2,520 mm

Excluding: Hopper, Mounting (20'2"/6'6"/8'3")

Frame, Discharge Conveyor

DW 2060 E

The smallest Doppstadt DW machine DW 2060 E is ideal

for the shredding of domestic waste and old timber. The 2m

(6' 6") toothed roller turns at 23 rpm. 14 roller and 15 comb

teeth shred the materials.

DW 206 CERON

The DW 206 CERON has an extremely robust steel construc-

tion and is therefore ideal for use for shredding of industrial

waste and mixed construction waste. A comb sieve can be

supplied in one step of the process for a ner shredding result.

14 or (28 by BioPower) roller and 15 comb teeth shred the

materials.

Total weight basic machine 24,600 kg (54,233 lb)

Drive type DC motor

power 210/315/380 kW

Roller length 2,000 mm (6'7")

diameter 600 mm (2')

no. of teeth 14 (28 by BioPower)

Dimensions basic machine L/W/H 6,445/2,400/3,300 mm

Excluding: Hopper, Mounting (21'2"/7'10"/10'10")

Frame, Discharge Conveyor

DW 306 CERON

The DW 306 CERON is built using exceptionally strong, heavy

duty components and is therefore ideal for the shredding of in-

dustrial and construction waste. For the production of various

grain sizes during operation, a suitable ribbed sieve can be

added as an optional extra. 21 or (42 by BioPower) roller and

22 comb teeth shred the materials.

Total weight basic machine 31,500 kg (69,446 lb)

Drive type DC motor

power 315/380 kW

Roller length 3,000 mm (9'10")

diameter 600 mm (2')

no. of teeth 21 (42 by BioPower)

Dimensions basic machine L/W/H 7,450/2,760/3,600 mm

Excluding: Hopper, Mounting (24'5"/9'1"/11'10")

Frame, Discharge Conveyor

10 11

DW SERIES TECHNICAL DATA

DW 306 CERON

DW 3080 E2 DW 206 CERON

DW 3060 E1

Drive

Power/Type 132 kWAC motor

160 kWAC motor

210 kWDC motor

315 kWDC motor

315 kWDC motor 315 kWDC motor

380 kWDC motor

(BioPower)

210 kWDC motor

315 kWDC motor

380 kWDC motor

315 kWDC motor

380 kWDC motor

Shredding roller

Length 2,000 (6'6") 2,500 mm (8'2") 3,000 mm (9'10") 3,000 mm (9'10") 2,000 mm (6'7") 3,000 mm (9'10")

Diameter 600 mm (2') 600 mm (2') 600 mm (2') 800 mm (2'7") 600 mm (2') 600 mm (2')

Nominal speed 23 rpm 831 rpm (210 kW) variable 728 rpm 728 rpm variable 728 rpm variable 831 rpm (210 kW) variable 728 rpm 728 rpm variable

No. of teeth 14 17 21 21 (13) 14 (28 by BioPower) 21 (42 by BioPower)

Comb

Length 2,000 mm (6'6") 2,500 mm (8'2") 3,000 mm (9'10") 3,000 mm (9'10") 2,000 mm (6'7") 3,000 mm (9'10")

No. of teeth 15 18 22 14 (22) 15 22

Dimensions & Weight

Basic machine

(Length/Width/Height)Ex-

cluding: Hopper, Mounting

Frame, Discharge Conveyor

6,150/2,000/2,520 mm

(20'2"/6'6"/8'3")

6,550/2,600/3,150 mm

(21'6"/8'6"/10'4")

7,180/2,600/3,150 mm

(23'6"/8'6"/10'4")

6,800/2,800/2,760 mm

(22'3"/9'2"/9'1")

6,445/2,400/3,300 mm

(21'2"/7'10"/10'10")

7,450/2,760/3,600 mm

(24'5"/9'1"/11'10")

Total Weight 11,900 kg (26,235 lb) 19,600 kg (43,211 lb) 23,750 kg (52,359 lb) 32,500 kg (71,650 lb) 24,600 kg (54,233 lb) 31,00 kg (69,446 lb)

Lower Discharge Conveyor

Standard AA=3,200 mm x BB=800 mm

[v=1.8 m/s]

(AA=10'5"x BB=2'7" [v=5'11"/s])

AA=4,200 mm x BB=1,000 mm

[v=2.0 m/s]

(AA=13'9"x BB=3'3" [v=6'7"/s])

AA=4,200 mm x BB=1,000 mm

[v=1.9 m/s]

(AA=13'9"x BB=3'3" [v=6'3"/s])

AA=4,000 mm x BB=1,000 mm

[v=2.0 m/s]

(AA=13'1"x BB=3'3" [v=6'7"/s])

AA=3,500 mm x BB=1,200 mm

[v=2 m/s]

(AA=11'6"x BB=3'11" [v=6'3"/s])

AA=4,450 mmx BB=1,200 mm

[v=2 m/s]

(AA=14'7"x BB=3'11" [v=6'3"/s])

Option AA=6,300 mm x BB=800 mm

[v=1.8 m/s]

(AA=20'8"x BB=2'7" [v=5'11"/s])

reversible

AA=7,800 mm x BB=1,000 mm

[v=1.8 m/s]

(AA=25'7"x BB=3'3" [v=5'11"/s])

reversible

AA=7,800 mm x BB=1,000 mm

[v=1.9 m/s]

(AA=25'7"x BB=3'3" [v=6'3"/s])

reversible

AA=7,000 mm x BB=1,000 mm

[v=1.9 m/s]

(AA=23'x BB=3'3" [v=6'3"/s])

reversible

AA=7,350 mm x BB=1,200 mm

[v=2 m/s]

(AA=24' 1"x BB=3'11" [v=6'7"/s])

reversible

AA=8,300 mm x BB=1,200 mm

[v=2 m/s]

(AA=27' 3"x BB=3'11" [v=6'7"/s])

reversible

Optional equipment hopper plates on 3 or 4 sides, mount-

ing frame, operating platform, comb

extension, damping down facility (dust

suppression), remote controls, special

coating, profbus interface

hopper plates on 3 or 4 sides, mount-

ing frame, operating platform, comb

extension, damping down facility (dust

suppression), remote controls, special

coating, profbus interface

hopper plates on 3 or 4 sides,

mounting frame, operating platform,

comb extension, damping down facility

(dust suppression), remote controls,

special coating, profbus interface

hopper plates on 3 or 4 sides,

mounting frame, operating platform,

comb extension, damping down facility

(dust suppression), remote controls,

special coating, profbus interface

hopper plates on 3 or 4 sides,

mounting frame, operating platform,

comb extension, damping down facility

(dust suppression), remote controls,

special coating, profbus interface

hopper plates on 3 or 4 sides, mounting frame,

operating platform, comb extension, damping

down facility (dust suppression), remote controls,

special coating, profbus interface

Model DW 2060 E DW 2560 E1 DW 3060 E1 DW 3080 E2 DW 206 CERON DW 306 CERON

As of April 2014 subject to technical alterations. The specications are approximate.

Illustrations and descriptions might include options that are not part of the standard equipment.

AA = Conveyor length, BB = Conveyor width

Illustration showing machine hopper plate, mounting frames

and discharge conveyors (part only)

The height of the basic (DW 206 and DW 306 CERON machines change when

380kW version is chosen due to the higher motor housing

DW2060E

2,910

9' 7"

3

,7

8

0

1

2

' 5

"

2

,5

2

0

8

' 3

"

6,150

20' 2"

3

,0

0

0

9

' 1

0

"

2,000

6' 7"

DW 2560E

3,060

10'

3

,1

5

0

1

0

' 4

"

4

,8

5

0

1

5

' 1

1

"

6,550

21' 6"

2,600

8' 6"

2

,5

5

0

8

' 4

"

3

,5

5

0

1

1

' 8

"

CERON DW-306

3,640

11' 11"

5

,0

3

0

1

6

' 6

"

7,450

24' 5"

2,760

9' 1"

3

,6

0

0

1

1

' 1

0

"

3

,7

3

0

1

2

' 3

"

DW 3060E 1

7,180

23' 7"

2,600

8' 6"

3

,1

5

0

1

0

' 4

"

3,620

11' 11"

4

,8

3

0

1

5

' 1

0

"

2

,5

5

0

8

' 4

"

3

,5

3

0

1

1

' 7

"

DW 206

2,660

8' 9"

5

,0

3

0

1

6

' 6

"

6,445

21' 2"

2,760

9' 1"

3

,3

0

0

1

0

' 1

0

"

3

,7

3

0

1

2

' 3

"

DW 3080E

3,200

10' 6"

5

,5

2

0

1

8

' 1

"

7,500

24' 7"

2,800

9' 2"

2

,4

8

0

8

' 2

"

4

,2

2

0

1

3

' 1

0

"

12 13

1

6 7 8

2 3 4

5

1

6

7

8

2

3 5

4

AK/NZ SERIES

Grinders

POWERFUL AND VERSATILE

The grinders of the AK and NZ series reduce

the material by means of the large ail drum.

The free-swinging ails inside, provided with

replaceable wearing tips, grind the material

tearing it along the bafe plate. According to

the demands on the throughput capacity and

the material size, various mesh sizes of the

grinding basket are available.

The Doppstadt grinders stand out for their free-

swinging ail holders with separately replaceable

wearing tools and the heavy gyrating mass of

the ail drum working at approx. 1,000 rpm.

Easy maintenance thanks to large protection

doors on all sides and the central lubrication

Separate drives for scraper foor and feed-in

roller optimizing the material feed and the

throughput (AK 435)

Wide range of possible applications as all the

shredding tools of the mobile Doppstadt series

can be used.

Optional:

Fe-separation,

wind-sifting,

further processing

COMPOSTING, WASTE WOOD PROCESSING

1

DRIVE COMPARTMENT

2

CHAIN DRIVEN

SCRAPER CONVEYOR

3

FEED ROLLER

4

FLAIL DRUM

5

COUNTER BAFFLE PLATE

6

MAINTENANCE ACCESS

7

LOWER DISCHARGE CONVEYOR

8

SIEVE (OPEN)

*option Explanations and illustrations by the example of the AK 435 E

pre-shredded pre-shredded

typical stages

for waste wood

processing

Final product:

for thermal utilization and recycling

A

K

/

N

Z

S

e

r

ie

s

3

2

Shredding

DW Series

1

S

c

r

e

e

n

in

g

S

M

/

S

S

T

S

e

ries

G

r

in

d

i

n

g

typical stages

for compost

production

Final product:

Compost

G

r

in

d

in

g

DU 320

Turnin

g

A

K

/

N

Z

S

e

r

i e

s

4

3

2

S

hredding

D

W

Series

S

c

r

e

e

n

in

g

1

S

M

/

S

S

T

S

e

r

ie

s

Use only pre-shredded

material in the NZ

KEY BENEFITS

Continuous grinding by means of load

sensing material in-feed

Resistance against foreign objects due

to free swinging flails and compensating

counter baffle and sieve

Individually replaceable grinding tips

(flail/teeth)

Rapid exchange system for the meshed

grinder sieve

Minimisation of dust and vibration in the

drive compartment due to separation of

the drive and grinding units

Combination options with other

Doppstadt plant

One-man operation

(remote control of main functions)

14 15

AK 235 E

The ail drum itself weighs approximately 1.3 tonnes and is

equipped with 16 freely swinging ails and 28 ripping teeth.

The drum spins at approx. 1,300 rpm. The exchangeable

meshed sieves are available between 30 and 320 mm.

Total weight basic machine 9,500 kg (20,944 lb)

Drive type AC motor

power 160 kW

Flail drum width 1,430 mm (4'8")

diameter 900 mm (2'11")

fails/teeth 16/28

Dimensions basic machine L/W/H 6,400/2,050/1,700 mm

Excluding: Hopper, Mounting (21'/6'8"/5'7")

Frame, Discharge Conveyor

AK 435 E

On this machine the ail drum weighs approximately 2.5

tonnes and is equipped with 36 freely swinging ails. The drum

spins at approx. 1,000 rpm. The exchangeable meshed sieves

are available between 30 and 400 mm.

Total weight basic machine 14,000 kg (30,865 lb)

Drive type AC motor

power 250/315 kW

Flail drum width 1,750 mm (5'9")

diameter 1,100 mm (3'7")

fails 36

Dimensions basic machine L/W/H 6,900/2,500/1,800 mm

Excluding: Hopper, Mounting (22'7"/8'2"/5'11")

Frame, Discharge Conveyor

NZ 180

The Doppstadt NZ 180 has been designed specically for

integration as part of a processing plant. Its ail drum is

identical to that of the AK 435 E. Load sensing in the in-feed

provides for high throughput performance.

Total weight basic machine 13,500 kg (29,762 lb)

Drive type AC motor

power 250/315/450 kW

Flail drum width 1,750 mm (5'9")

diameter 1,100 mm (3'7")

fails 36

Dimensions basic machine L/W/H 4,750/2,700/1,950 mm

Excluding: Hopper, Mounting (15'7"/8'10"/6'4")

Frame, Discharge Conveyor

AK/NZ SERIES

16 17

AK/NZ SERIES TECHNICAL DATA

Drive

Power/Type 160 kWAC motor 250 kWAC motor

315 kWAC motor

250 kWAC motor

315 kWAC motor

450 kWAC motor

Flail drum

Width 1,430 mm

(4'8")

1,750 mm

(5'9")

1,750 mm

(5'9")

Diameter with fails 900 mm

(2'11")

1,100 mm

(3'7")

1,100 mm

(3'7")

Weight (equipped) 1,050 kg

(2,315 lb)

2,500 kg

(5,511 lb)

2,500 kg

(5,511 lb)

Rotation 1,150 rpm 1,040 rpm 1,040 rpm

No. of fails 16 36 36

No. of teeth 28

Dimensions

Basic machine (Length/Width/Height) 6,400/2,050/1,700 mm

(21'/6'8"/5'7")

6,900/2,500/1,800 mm

(22'7"/8'2"/5'11")

4,750/2,700/1,950 mm

(15'7"/8'10"/6'4")

Feeeding cross section (Length/Width) 2,940/1,800 mm

(9'8"/5'11")

2,940/2,000 mm

(9'8"/6'7")

600/1,780 mm

(2'/5'10")

Weight 9,500 kg

(20,944 lb)

14,000 kg

(30,865 lb)

13,500 kg

(29,762 lb)

Lower discharge conveyor AA=5,000 mm x BB=1,200 mm

(AA=16'5"x BB=3'11")

AA=6,000 mm x BB=1,600 mm

(AA=19'8"x BB=5'3")

AA=3,600 mm x BB=1,600 mm

(AA=11'10"x BB=5'3")

Optional equipment soft starter, special coatings, noise and dust protection covers,

mounting frame, damping down facility, remote controls

soft starter, special coatings, noise and dust protection covers,

mounting frame, damping down facility, remote controls

soft starter, special coatings, noise and dust protection covers,

mounting frame, damping down facility, remote controls

Model AK 235 E AK 435 E NZ 180

As of April 2014 subject to technical alterations. The specications are approximate.

Illustrations and descriptions might include options that are not part of the standard equipment.

AA = Conveyor length, BB = Conveyor width

AK 435 E NZ 180 AK 235 E

Illustration show machine mounting frames and discharge conveyors.

NZ 180

600

2'

3

,

3

8

0

1

1

'

1

"

4,750

15' 7"

2,700

8' 10"

1

,

8

0

0

5

'

1

1

"

AK 235E

2,940

9' 8"

3

,

5

7

2

1

1

'

9

"

6,400

21'

2,050

6' 9"

2

,

8

5

0

9

'

4

"

1

,

3

3

0

4

'

4

"

AK 435E

2,662

8' 9"

3

,

5

1

0

1

1

'

6

"

6,900

22' 8"

2,500

8' 2"

2

,

8

6

6

9

'

5

"

18 19

5

4 6 1 7

3

5

3

2

4

1

1

2

DF 307 Rotaro

Fine Shredder

POWERFUL & VERSATILE

Doppstadts DF 307 ROTARO is an especially

efcient, single shaft secondary shredder for

processing derived fuel products as well as

other ne materials. Its robust steel body,

yet simple assembly, guarantees long life-

span and high running smoothness. High

rotor mass also increases energy efciency in

operation, since torque peaks do not have to

be compensated for by electric drives alone.

The shaft is driven by two three-phase AC

motors, power coupled to the rotor by drive

belts.

Cutting blades are easily exchanged and can

be repeatedly reused, which guarantees the

shortest downtime during the knife exchange

and therefore, high usability of the machine.

Coarseness of the end product can be

selected using interchangeable sieves with

different mesh size.

Drive type AC Motor

power 2 x 160 kW

Rotor length 3,000 mm (9'10")

diameter: excl. knives 600 mm (1'11")

incl. knives 750 mm (2'5")

RPM 300 rpm

weight 4,400 kg (9,700 lb)

Dimensions basic machine L/W/H 3,920/2,510/3,895 mm

(12'10"/8'2"/12'9")

In-Feed dimensions L/W 3,000/1,300 mm

(9'10"/4'3")

Total Weight 24,000 kg (52,910 lb)

Discharge Conveyor AA = 4,200 x BB = 800 mm

(AA = 13'9" x BB = 2'7")

DF 307 ROTARO

1

DRIVE COMPARTMENT

2

SIEVE

3

EXCHANGEABLE BLADES

4

SHEAR PIN COUPLING

5

MAINTENANCE ACCESS

6

HYDRAULIC PUSHER SYSTEM

7

CONTROL UNIT

KEY BENEFITS

Robust steel construction ensures

durability and smooth operation

Hydraulic pusher system with load

sensing control for maximum throughput

Large maintenance access panels

guarantee good accessibility to

shredding chamber

Rapid change of exchangeable knives

on rotor and counter-blade by way of

simple fixing arrangements to reduce

downtime

Easy sieve exchange - mesh size to

customer requirements

High energy efficiency due to large

rotor mass

Shear pin coupling on rotor drive

protects the machine against damage

from imported foreign objects

Rapid restart mode after incidents

maximises up-time

DF 307 ROTARO

DF 307

3,920

12' 10"

2,510

8' 2"

3,000

9' 10"

3

,

8

9

5

1

2

'

9

"

1,956

6' 5"

ROTARO

20 21

2 2 3

4 5 6 7

6

5

4 3

2

7

1

5

1

SM/SST

SERIES

Trommel

Screens

OPTIMUM SCREENING

Stationary trommel screens of the DOPP-

STADT SM/SST series can be used for ne

screening on landll sites, for screening of

the organic fraction in Mechanical-Biological-

Treatment (MBT) plants, in recycling plants, in

waste wood processing and for other separa-

tion and sorting applications.

The rotating drum can even screen the most

difcult materials making the best possible

use of the load-sensing material feed and the

large screening surface. The screens with mo-

dular design can be adjusted to special tasks.

Optional cleaning systems (brush or drum

scraper) are also available.

The machines are mounted on substructures

which are adapted to the project.

The Doppstadt screens can be used either

with belt discharge or as a hopper machine.

Optional:

Fe-separation,

windsifting and

further processing

pre-shredded

pre-shredded

COMPOSTING, COMPOSTING-WOOD, DOMESTIC

AND INDUSTRIAL WASTE AND RDF PROCESSING

pre-shredded

pre-shredded

pre-shredded

1

DRIVE UNIT

2

DRUM TRANSMISSION

3

CLEANING BRUSH

4

SCREENING DRUM

5

SCRAPER

6

MAINTENANCE ACCESS

7

CONTROL PANEL

Explanations and illustrations by the example of the SST 725

FINE & COARSE GRAIN SEPARATION

typical stages

for waste wood

processing

Final product:

for thermal utilization and recycling

A

K

/

N

Z

S

e

r

ie

s

G

r

in

d

in

g 3

2

Shredding

DW Series

1

S

M

/

S

S

T

S

e

ries

S

c

r

e

e

n

in

g

typical stages

for compost

production

S

M

/

S

S

T

S

e

rie

s

S

c

r

e

e

n

in

g

Final product:

Compost

G

r

in

d

in

g

A

K

/

N

Z

S

e

r

i e

s

3

4

2

S

h

redding

D

W

Series

1

Turning

DU 320

typical stages for

refuse derived fuel

processing

Final product:

for thermal utilization

G

r

in

d

in

g

3

2

Shredding

DW Series

1

D

W

S

e

r

ie

s

(fin

g

er basket*)

S

c

r

e

e

n

i

n

g

S

M

/

S

S

T

S

e

r

i e

stypical stages for

volume reduction

and domestic waste

processing

Final product:

shredded and separated fractions

S

M

/SST Series

S

creening

2

Shredd

in

g

DW Serie

s

1

KEY BENEFITS

Optional load sensing control to

material feed for optimum throughput

Exchangeable trommel-sreens

facilitate flexibility in applications

Customised options for various

processes available

Combinability with other Doppstadt

plant

22 23

Drum-screens used by the SST 518 are identical to those used by

Doppstadts mobile machine versions and therefore interchange-

able. A wide range of different types of drum-screens are available.

SST 518

SST 518 machines utilise a solid steel frame. Large protective

side doors provide excellent access for cleaning and main-

tenance work. The drum-screen is ca. 5 m long ( 1.8 m). A

range of screens with different sized apertures enables diverse

screening functions.

Weight basic machine 7,800 kg (17,196 lb)

Drive type geared AC motor

power 11 kW

Screening drum length 4,700 mm (15'5")

diameter 1,800 mm (5'11")

Dimensions basic machine L/W/H 6,900/2,400/3,100 mm

(22'8"/7'11"/10'2")

SST 1525

The largest SST model of these screening machines with a ro-

bust frame chassis is the SST 1525. Large doors on the side of

the machine enable easy access for cleaning and maintenance.

The drum is driven by a friction wheels and is 2 x 7 m long, and

has a diameter of 2.5 m. The SST 1525 is a module of 2 SST 725

screening machines. For different screening requirements dif-

ferent drum perforation sizes are available.

Weight basic machine 29,500 kg (65,036 lb)

Drive type geared AC motor

power 4x15 kW

Screening drum length 2x7,000 mm (2x23')

diameter 2,500 mm (8'2")

Dimensions basic machine L/W/H 17,600/3,000/3,260 mm

(57'9"/9'10"/10'8")

SST 1025

SST 1025 machines utilise a solid steel frame. Large protective

side doors provide excellent access for cleaning and mainte-

nance work. The drum-screen is approximately 10 m in length

and has a diameter of 2.5 metres. Various sized screen per-

foration (punched to customers requirements) is available to

perform a diverse range of screening functions.

Weight basic machine 21,000 kg (46,297 lb)

Drive type geared AC motor

power 4x11 kW

Screening drum length 10,000 mm (32'10")

diameter 2,500 mm (8'2")

Dimensions basic machine L/W/H 12,300/3,000/3,260 mm

(41'4"/9'10"/10'8")

Weight basic machine 5,900 kg (13,007 lb)

Drive type geared AC motor

power 15 kW

Screening drum length 5,430 mm (17'10")

diameter 2,000 mm (6'7")

Dimensions basic machine L/W/H 6,780/2,350/2,950 mm

(22'3"/7'9"/9'8")

SM 518 A

The trommel of the SM 518 A is approximately 5 m in length

with a diameter of 1.8 m. A diverse range of screening func-

tions can be carried out using an assortment of drum-screens

with varying perforations.

SST 720

The SST 720 is made from buckle resistant heavy duty square

tubing. Large entry doors on the side of the machine enable

easy access for cleaning and maintenance. The SST 720 is an

enclosed machine with a helical guide n in the drum, which is

itself driven by friction wheels. The screening drum is 7 m long

and has a diameter of 2.0 m.

Weight basic machine 13,000 kg (28,660 lb)

Drive type geared AC motor

power 22 kW

Screening drum length 7,000 mm (23')

diameter 2,000 mm (6'7")

Dimensions basic machine L/W/H 9,480/2,500/3,300 mm

(31'1"/8'2"/10'10")

SM 518 F

The SM 518 F is a screening machine integrated with a

compactly built-on separate feed hopper at one end.

The screening specication of this machine is that of the

SM 518 A.

SST 725

SST 725 machines utilise a solid steel frame. Large protective

side doors provide excellent access for cleaning and mainte-

nance work. The drum-screen is approximately 7 m in length

and has a diameter of 2.5 metres. Various sized screen per-

foration (punched to customers requirements) is available to

perform a diverse range of screening functions.

Weight basic machine 15,200 kg (33,510 lb)

Drive type geared AC motor

power 2x15 kW

Screening drum length 7,000 mm (23')

diameter 2,500 mm (8'2")

Dimensions basic machine L/W/H 9,350/3,000/3,260 mm

(22'3"/9'10"/10'8")

Drum-screens used by the SM 518 A and SM 518 F are identical to those used by Doppstadts mobile machine

versions and therefore interchangeable. A wide range of different types of drum-screens are available.

Weight basic machine 7,900 kg (17,416 lb)

Drive type geared AC motor

power 11 kW/3 KW

Screening drum length 4,700 mm (15'5")

diameter 1,800 mm (5'11")

Bunker volume 4.5 m

3

(159 ft

3

)

Dimensions basic machine L/W/H 9,200/2,400/2,700 mm

(30'2"/7'10"/8'10")

Weight basic machine 4,700 kg (10,362 lb)

Drive type geared AC motor

power 11 kW

Screening drum length 4,700 mm (15'5")

diameter 1,800 mm (5'11")

Dimensions basic machine L/W/H 6,200/2,300/2,480 mm

(20'4"/7'7"/8'2")

SM/SST SERIES

SM 620 A

The SM 620 A is approximately 5.5 m in length with a dia-

meter of 2 m. A diverse range of screening functions can

be carried out using an assortment of drum-screens with vary-

ing perforations.

Drum-screens used by the SM 620 A are identical to those used by

Doppstadts mobile machine versions and therefore interchange-

able. A wide range of different types of drum-screens are available.

24 25

SM/SST SERIES TECHNICAL DATA

SST 725

SST 1525 SST 1025

SST 720 SM 518 A

SM 620 A

SM 518 F

SST 518

As of April 2014 subject to technical alterations. The specications are approximate.

Illustrations and descriptions might include options that are not part of the standard equipment.

AA = Conveyor lenght, BB = Conveyor width

Illustration show machine mounting frames and discharge conveyors.

Drive

Power/Type 11 kWgeared AC motor 15 kWgeared AC motor

3 kWdischarge hopper

15 kWgeared AC motor 11 kWgeared AC motor 22 kWgeared AC motor 2 x 15 kWgeared AC motor 4 x 11 kWgeared AC motor 4 x 15 kWgeared AC motor

Power transmission sprocket/chain sprocket/chain sprocket/chain sprockets/chain friction wheels friction wheels friction wheels friction wheels

Trommel

Diameter 1,800 mm

(5' 11")

1,800 mm

(5' 11")

2,000 mm

(6'7")

1,800 mm

(5' 11")

2,000 mm

(6'7")

2,500 mm

(8'2")

2,500 mm

(8'2")

2,500 mm

(8'2")

Length 4,700 mm

(15' 5")

4,700 mm

(15' 5")

5,430 mm

(17'10")

4,700 mm

(15' 5")

7,000 mm

(23')

7,000 mm

(23')

10,000 mm

(32'10")

2 x 7,000 mm

(2 x 23')

Screening surface approx. 23.1 m

(249 sq ft)

approx. 23.1 m

(249 sq ft)

approx. 30.2 m

(325 sq ft)

approx. 23.1 m

(249 sq ft)

approx. 38.8 m

(418 sq ft)

approx. 43.5 m

(468 sq ft)

approx. 63.8 m

(686 sq ft)

approx. 95.8 m

(1,031 sq ft)

Perforation custom custom custom custom custom custom custom custom

Standard RPM 12 rpm 12 rpm 12 rpm 12 rpm 10 rpm 10 rpm 10 rpm 10 rpm

Variable RPM (Set

at CPanel-optional)

721 rpm 721 rpm 718 rpm 7 21 rpm 7 18 rpm 415 rpm 415 rpm 4 15 rpm

Dimensions

Basic machine

(L/W/H)

6,200/2,300/2,480 mm

(20' 4"/7' 7"/8' 2")

9,200/2,400/2,700 mm

(30' 2"/7'10"/8' 10")

6,830/2,400/2,750 mm

(22'5"/7'10"/9')

6,900/2,400/3,100 mm

(22' 8"/7' 11"/10' 2")

9,480/2,500/3,300 mm

(31'1"/8'2"/10'10")

9,350/3,000/3,260 mm

(22'3"/9'10"/10'8")

12,300/3,000/3,260 mm

(40'4"/9'10"/10'8")

17,600/3,000/3,260 mm

(57'9"/9'10"/10'8")

Weight

(incl. drumbut excl.

discharge conveyor)

approx. 4,700 kg

(10,362 lb)

approx. 7,900 kg

(17,416 lb)

approx. 5,900 kg

(13,007 lb)

approx. 7,800 kg

(17,196 lb)

approx. 13,000 kg

(28,660 lb)

approx. 15,200 kg

(33,510 lb)

approx. 21,000 kg

(46,297 lb)

approx. 29,500 kg

(65,036 lb)

Fine grain collection

conveyor (optional)

AA = 3,500 mmx

BB = 1,000 mm

(AA=11' 5"x BB=3' 3")

AA = 3,500 mmx

BB = 1,000 mm

(AA=11' 5"x BB=3' 3")

AA = 4,250 mmx

BB = 1,350 mm

(AA=13' 11"x BB=4' 5")

AA = 3,500 mmx

BB = 1,000 mm

(AA=11' 5"x BB=3' 3")

AA=6,000mm x BB=1,000 mm

(AA=19' 8"x BB=3' 3")

AA=6,000mm x BB=1,500 mm

(AA=19' 8"x BB=4' 11")

AA=8,750mm x BB=1,500 mm

(AA=28' 8"x BB=4' 11")

AA=6,000mm x BB=1,500 mm

(AA=19' 8"x BB=4' 11")

Optional equipment Machine mounting legs, single

sided maintenance walkway,

cleaning brush, drumscraper,

screening drum, sack ripper, drive

fns, switchboard cabinet with

frequency converter, distribution

box with controls, Profbus-PLC,

customised RAL colour

Machine mounting legs, single

sided maintenance walkway,

cleaning brush, drumscraper,

screening drum, sack ripper, drive

fns, switchboard cabinet with

frequency converter, distribution

box with controls, Profbus-PLC,

customised RAL colour

Machine mounting legs, single

sided maintenance walkway,

cleaning brush, drumscraper,

screening drum, sack ripper, drive

fns, switchboard cabinet with

frequency converter, distribution

box with controls, Profbus-PLC,

customised RAL colour

Machine mounting legs, single

sided maintenance walkway,

cleaning brush, drumscraper,

screening drum, sack ripper, drive

fns, switchboard cabinet with

frequency converter, distribution

box with controls, Profbus-PLC,

customised RAL colour

Machine mounting legs, single sided

maintenance walkway, cleaning brush,

drumscraper, screening drum, sack rip-

per, drive fns, switchboard cabinet with

frequency converter, distribution box with

controls, Profbus-PLC, customised

RAL colour

Machine mounting legs, single sided

maintenance walkway, cleaning brush,

drumscraper, screening drum, sack rip-

per, drive fns, switchboard cabinet with

frequency converter, distribution box with

controls, Profbus-PLC, customised

RAL colour

Machine mounting legs, single sided

maintenance walkway, cleaning brush,

drumscraper, screening drum, sack rip-

per, drive fns, switchboard cabinet with

frequency converter, distribution box with

controls, Profbus-PLC, customised

RAL colour

Machine mounting legs, single sided

maintenance walkway, cleaning brush,

drumscraper, screening drum, sack rip-

per, drive fns, switchboard cabinet with

frequency converter, distribution box with

controls, Profbus-PLC, customised

RAL colour

Model SM 518 A SM 518 F SM 620 A SST 518 SST 720 SST 725 SST 1025 SST 1525

SM 518A

5

,0

6

0

16

' 7

"

6,580

21' 7"

2,300

7' 7"

2

,9

5

0

9

' 8

"

3

,3

2

0

10

' 11"

SM 518 F

9,200

30' 2"

2,300

7' 7"

3

,0

0

0

9

' 10

"

2,400

7' 10"

3,480

11' 5"

1,9

7

5

6

' 6

"

SM 620A

4

,9

5

0

16

' 3

"

6,830

22' 5"

2,400

7' 10"

2

,7

5

0

9

'

3

,3

2

0

10

' 11"

SST 518

5

,2

0

0

17

' 1"

6,900

22' 8"

2,400

7' 10"

3

,10

0

10

' 2

"

3

,4

8

0

11' 5

"

SST 725

5

,6

6

0

18

' 7

"

9,350

30' 8"

3,000

9' 10"

3

,2

6

0

10

' 8

"

4

,17

0

13

' 8

"

SST 720

5

,3

0

8

17

' 5

"

9,214

30' 3"

2,500

8' 2"

3

,3

0

8

10

' 10

"

3

,6

2

1

11' 1"

SST 1025

5

,6

6

0

18

' 7

"

12,300

40' 4"

3,000

9' 10"

3

,2

6

0

10

' 8

"

4

,17

0

13

' 8

"

SST 1025

5

,2

5

8

17

' 3

"

17,600

57' 9"

3,000

9' 10"

3

,2

6

0

10

' 8

"

4

,17

0

13

' 8

"

26 27

DST 512 / 513 Star Screen TECHNICAL DATA WS Windsifter TECHNICAL DATA

As of April 2014 subject to technical alterations. The specications are approximate.

Illustrations and descriptions might include options that are not part of the standard equipment.

DST 512 / 513 Star Screen

The DST star screens are adapted to suit the task of

screening green waste and compost. The following

features are equipped in order to minimize cleaning

time and to improve the screening result.

Elliptical stars and different shaft speeds

Variable star module speed

Differing speeds within the Star-screen module

Metal tipped star fngers cleans shaft and star disc

sides, disperses lumps of materials

A mixture of grading size(s) can be achieved by using

different size stars, star shapes and spacers in the

different modules along the screening bed.

WS Windsifter

The WS is the amongst the stationary wind sifter models

from Doppstadt, packed into a new, appealing product

design, qualies this "compact system" as the top of the

range on the market.

All the relevant sections are easily and individually ad-

justable with ideal accessibility of the maintenance ele-

ments at the same time. The Doppstadt WS is the only

wind sifter on the market with a working width of up to

3000 mm. Nonetheless, our engineers and technicians

succeeded in realising an extremely compact construc-

tion. The new WS is also set up for the worldwide export

in standard sea containers. The patented system with

the highest aerodynamic efciency creates an unbeliev-

able throughput of up to 400 m

3

/h.

Weight basic machine 3,400 kg (7,496 lb)

Drive type Detachable geared motor SEW

power 2 x 7.5 kWAC/IE2

Screening bed DST 512 DST 513

length 5,000 mm(16'5") 5,000 mm(16'5")

width 1,200 mm(3'11") 1,350 mm(4'5")

diameter

6 m

2

(65 sq ft) 6.5 m

2

(70 sq

ft)

Dimensions L/B/H 5,100/2,230/1,100 mm

basic machine (16'9"/7'4"/3'7")

Dimensions length 6,877 9,847 mm (22'7" 32'4")

(depending on working length)

width 2,005 4,005 mm (6'7" 13'2")

(depending on working width)

height 1,600 mm (5'3")

Conveyor belt Axles distance 2,900 mm (9'6")

Width of belt 1,000 3,000 mm (3'3" 9'10")

(depending on working width)

height of frame 190 mm (7")

drive 3.0 kW

Conveying speed 1.5 m/s

Air classifer drum diameter 600 mm (2')

rated power 1.5 kW

Fan rated power 22 30 kW

(depending on working width)

DST 512 / 513 Star Screen

DST STERNSIEB

5,084 (5,592)

16' 8" (18' 4")

1,960 (2,139)

6' 5" (7')

2,230 (2,407)

7' 4" (7' 11")

1

,1

0

0

3

' 7

"

As of April 2014 subject to technical alterations. The specications are approximate.

Illustrations and descriptions might include options that are not part of the standard equipment.

Drive

Power Detachable geared motor with separate fan and temperature sensor

Type SEW

Power rating (per drive) 2 x 7.5 kWAC/IE2

Voltage 230/400 V

Frequency 50 Hz

IP rating IP 54

Speed control (optional) Frequency converter

Dimension

Frame width 2,230 mm(7'4")

Frame length 5,100 mm(16'9")

Weight 3,400 kg (7,496 lb)

Screening bed (module)

Working length 5,000 mm(16'5")

DST 512 DST 513

Working width 1,200 mm (3'11") 1,350 mm(4'5")

Screening surface area 6.0 m (65 ft

2

) 6.5 m

(70 ft

2

)

Star segment diameter 235 mm (9") 300 mm(1')

Diameter relevant to required screening size

Number of shafts per module 26 star screen shafts 235/255 mm(9"/10")

24 star screen shafts 330/340 mm(1'1"/1'1")

Shaft speed approx. 90 200 rpm, incl. switch cabinet and frequency converter (optional position)

Model DST 512 / 513 Star Screen

WS Windsifter

WS 2002

5

,0

6

0

1

6

' 7

"

7,453

24' 5" 2,000

6' 7"

2

,8

2

3

9

' 3

"

3,221

10' 7"

Parameter

Length 6,877 mm

(22'7")

8,362 mm

(27'5")

9,847 mm

(32'4")

6,877 mm

(22'7")

8,362 mm

(27'5")

9,847 mm

(32'4")

Infeed belt

width (overall)

1,000 mm

(3'3")

1,000 mm

(3'3")

1,000 mm

(3'3")

1,500 mm

(4'11")

1,500 mm

(4'11")

1,500 mm

(4'11")

Infeed belt

width (usable)

822 mm

(2'8")

822 mm

(2'8")

822 mm

(2'8")

1,322 mm

(4'4")

1,322 mm

(4'4")

1,322 mm

(4'4")

Width

(assembled)

2,005 mm

(6'7")

2,005 mm

(6'7")

2,005 mm

(6'7")

2,505 mm

(8'3")

2,505 mm

(8'3")

2,505 mm

(8'3")

Transportation

width (max.)

1,950 mm

(6'5")

1,950 mm

(6'5")

1,950 mm

(6'5")

2,450 mm

(8')

2,450 mm

(8')

2,450 mm

(8')

Model WS 1001 WS 1002 WS 1003 WS 1501 WS 1502 WS 1503

Parameter

Length 6,877 mm

(22'7")

8,362 mm

(27'5")

9,847 mm

(32'4")

6,877 mm

(22'7")

8,362 mm

(27'5")

9,847 mm

(32'4")

6,877 mm

(22'7")

8,362 mm

(27'5")

9,847 mm

(32'4")

Infeed belt

width (overall)

2,000 mm

(6'7")

2,000 mm

(6'7")

2,000 mm

(6'7")

2,500 mm

(8'2")

2,500 mm

(8'2")

2,500 mm

(8'2")

3,000 mm

(9'10")

3,000 mm

(9'10")

3,000 mm

(9'10")

Infeed belt

width (usable)

1,822 mm

(6')

1,822 mm

(6')

1,822 mm

(6')

2,322 mm

(7'7")

2,322 mm

(7'7")

2,322 mm

(7'7")

2,822 mm

(9'3")

2,822 mm

(9'3")

2,822 mm

(9'3")

Width

(assembled)

3,005 mm

(9'10")

3,005 mm

(9'10")

3,005 mm

(9'10")

3,505 mm

(11'6")

3,505 mm

(11'6")

3,505 mm

(11'6")

4,005 mm

(13'2")

4,005 mm

(13'2")

4,005 mm

(13'2")

Transportation

width (max.)

2,950 mm

(9'8")

2,950 mm

(9'8")

2,950 mm

(9'8")

3,450 mm

(11'4")

3,450 mm

(11'4")

3,450 mm

(11'4")

3,950 mm

(13')

3,950 mm

(13')

3,950 mm

(13')

Model WS 2001 WS 2002 WS 2003 WS 2501 WS 2502 WS 2503 WS 3001 WS 3002 WS 3003

28 29

3

2

1

1 2 3

2

DM 215 E

Mixer

VERSATILE & FLEXIBLE

The DM 215 E is equipped with three helical

rotors within a 15 m

3

chamber for the homo-

geneous mixing together of different organic

biomaterials, substrates and sludge. This

machine can be set to function on a single

load or constant feed and discharge basis e.g.

for batch processes. A mixing chamber lid*

can be closed during operation. Additives e.g.

lime, can also be loaded into the mixer using

a helical screw controlled dosing hopper*.

MIXING, COMPOSTING & PREPROCESSING

OF BIOWASTE FOR ANAEROBIC DIGESTION

Optional: (Fe) separation, windsifting and secondary processing.

DM 215 E

This machine is driven using a 3 phase motor and is tted with

an engine guard, which automatically disengages and stops the

motor, to prevent damage, in the event of operational disturbance.

Total weight basic machine 14,200 kg (31,305 lb)

Drive type 3 Phase

power 160 kW

Chain driven

Mixer chamber volume 15 m

3

(530 ft

3

)

length/width 4,000/2,300 mm (13'1"/7'6")

helical rotors 3

2 x top: diameter 830 mm (2'8")

1 x bottom: diameter 1,080 mm (3'6")

length 3,900 mm (12'9")

Dimensions L/W/H 7,735/2,500/2,800 mm

basic machine (25'4"/8'2"/9'2")

KEY BENEFITS

Large, accessible mixer chamber

Three helical mixing rotors with

exchangeable blades

Various blade forms for assorted

applications

Easy and ample maintenance access

One-man operation

(remote control of main functions)

1

MIXING CHAMBER

2

MAINTENANCE ACCESS

3

DRIVE

*optional

typical

stages for

mixing

Final Product:

for recycling

DM 215

M

ixing

2

1

L

oading main product / L

o

a

d

in

g

2

n

d

p

r

o

d

u

c

t

typical stages

for compost

production

S

M

S

e

rie

s

S

c

r

e

e

n

in

g

Final product:

Compost

DU 320

Turning

Loading

p

ro

duct 1 and 2

M

ix

in

g

D

M

2

1

5

3

4

2

1

typical stages

for processing

organic waste for

fermentation

Final Product 1

(solid fraction): for thermal utilization, composting

Final Product 2

(fluid fraction): for biogas production

D

M

2

1

5

M

ix

in

g

D

S

P

2

0

-5

P

re

s

s

in

g

3

2

Shredding

DW Series

1

30 31

1 2 6 4

3

3

1

6

5

2

DSP 20-5

Screw Press

FLEXIBLE APPLICATION

The DSP 20-5 screw press separates biode-

gradable waste by extracting uid content and

turning it into liquid and solid bi-materials, using

a hydro-motor with planetary gearing. A pressing

cone forces the wet material, at a predetermined

pressure, through sieves which are available in

different mesh sizes. Extracted liquids are suitable

as process in-feed for anaerobic digesters and the

separated dry material can be composted or used

as thermal fuel.

A 500 mm diameter screw press, rotating at

between 5 and 20 rpm (variable), ensures high

throughput.

The DSP 20-5 makes it possible e.g. mixed bio-

waste to be separated from its liquid content

using differently perforated mesh screens.

Typical applications: food and supermarket waste,

biomass, paper mill scrap and residues etc.

COMPOSTING AND ANAEROBIC

DIGESTION MATERIALS

1

SIEVE

2

PRESS CONE -

HYDROMOTOR

3

MATERIAL FEED

4

SCREW PRESS

5

SOLIDS DISCHARGE

6

WEAR PLATE

DSP 20-5

Total weight 3,700 kg (8.157 lb)

Drive type hydromotor with planetary gearing

power 30 kW

Helical Press diameter 500 mm (1'7")

length 2,500 mm (8'2")

RPM 5 20 rpm

Hydraulic equipment drive electrohydraulic

power 55 kW

L/W/H 2,400/900/1,850 mm

(7'10"/2'11"/6')

Discharge hopper drive hydromotor with spur gear

volume approx. 5 m

3

(177 ft

3

)

L/W/H 3,250/1,650/2,250 mm

(10'8"/5'5"/7'5")

Optional extra feed hopper, mounting frame

typical stages

for processing

bio wastes for

fermentation

Final Product 1 (solid): for thermal utilization, composting

Final Product 2 (fluid): for biogas

If required (e.g.

when input material

contains a

considerable

amount of plastics)

S

c

re

e

n

in

g

DM 215

Mixing

S

M

S

e

rie

s 4

3

2

Shredding

DW Series

D

S

P

2

0

-

5

P

r

e

s

s

in

g

1

KEY BENEFITS

Max. throughput and optimum fluid extraction

during pressing due to variable mesh size of

sieves

Simple sieve exchange and variety of mesh

sizes with customised perforation upon request

Easy replacement of wearing parts on screw

press

Trouble free ejection of solid material content

due to rotation of the press cone

Load sensing hydraulic control of the press

cone

High durability

Up to 70 % fluid extraction from organic waste

Driven by means of hydromotor with minimal

maintenance requirements

Pressure dependant speed regulation for

hydraulic drive (optimal torque)

32 33

3 2

1

2

3

AT SERIES

Feed Hoppers

FLEXIBLE DEPLOYMENT

The Doppstadt AT Series Feed Hoppers are

suitable for processing e.g. Biomass and RDF

(Refuse Derived Fuel) materials, as well as for the

handling of mixed, domestic and industrial waste,

particularly in-line and in conjunction with other

Doppstadt plant.

These machines serve mainly as an in-feeder,

buffer and controlled forwarder of materials in

process.

Their robust steelwork ensures stability and long

life. The anged hopper sides are reinforced and

protected from impact damage by wheel loaders

e.g. motorised shovels and diggers etc.

AT 600

Drive type Electric speed control by VFI

Drive power 2 kW

Total weight 5,550 kg (8,157 lb)

Overall dimensions length 7,830 mm (25'8")

width 2,250 mm (7'4")

height 2,700 mm (8'10")

Hopper height 2,000 mm (6'6")

width 6,300 mm (20'8")

capacity 10,0 m

3

(353 ft

3

)

Conveyor belt length 6,500 mm (21'3")

belt width 1,000 mm (3'3")

belt speed 0.02 0.075 ms

-1

AT 300

Drive type Electric speed control by VFI

Drive power 2 kW

Total weight 3,200 kg (8,157 lb)

Overall dimensions length 4,750 mm (15'7")

width 2,250 mm (7'4")

height 1,800 mm (5'10")

Hopper height 1,800 mm (5'10")

length 3,500 mm (11'5")

capacity 5 m

3

(177 ft

3

)

Conveyor belt length 3,380 mm (11'1")

belt width 1,000 mm (3'3")

belt speed 0.02 0.075 ms

-1

KEY BENEFITS

Feed and discharge rollers operate at the

same speed ensuring smooth and safe

carriage of even heavy materials

Hopper flanges are reinforced and protected

from impact damage by loaders and

mechanical shovels

Steel-armoured conveyor belt

Robust structural steelwork ensures stability

and long lifetime of equipment

Conveyor speed step-less variable

adjustment of electrohydraulic drive

Good accessibility large maintenance

access panels

1

HOPPER CONVEYOR

2

CONTROL UNIT

3

MAINTENANCE ACCESS

34 35

TYPICAL APPLICATIONS

Input Output

Input Output

Input Output

Fine grain Coarse grain

Illustrations, Specications, Dimensions and Weights are for guidance only. Subject to change.

Biomass Processing Plant

Input Waste-wood Class A1

Density approx. 0.2 to 0.3 mg/m

3

Moisture content (40%)

Output Biomass: 12 to 80 mm

(0.5" to 3.15")

for thermal utilisation

Throughput 30 to 35 tonnes/h

Machine- DW 3060 E 315 kW

confguration SST 1025 44 kW

Conveyors & Magnets 40 kW

Waste-wood Processing Plant

Input Waste-wood

Output Material: 0 to 50 mm

(0" to 1.97")

for chipboard industry

Throughput 20 to 25 tonnes/h

Machine- DW 2560 E1 210 kW

confguration NZ 180 315 kW

Conveyors & Magnets 30 kW

Industrial Waste Processing Plant

Input Industrial waste

Output Recyclable material

Fine grain: 0 to 45 mm

(0 to 1.77")

Coarse grain: 45 to 300 mm

(1.77" to 11.81")

Throughput 35 to 40 tonnes/h

Machine- DW 3080 E 315 kW

confguration SST 725 22 kW

Sorting house DSH 9060 25 kW

Conveyors & Magnets 40 kW

36 37

Doppstadt

System

technology

Support

SYSTEM ENGINEERING WITH KNOW HOW

Multi-functional machines form the foundation

of our modern approach towards the handling

of recyclable materials. An extensive range of

equipment provides ecological and cost effec-

tive solutions for the processing and recycling

of many different valuable resources. Doppstadt

Systems provides support and direction for the

essential procedural steps required in the mod-

ern treatment of waste products.

Slow-speed shredders

High-speed grinders

Fine shredder

Screening machines (drum and star screens)

Sifters

Mixer

Screw press (for separating solids and fuids)

Conveyor systems

Feed hoppers

Our equipment is exible and suitable for many

different, individual or complex series of inte-

grated applications. Customised products and

accessories complete the full range of what

Doppstadt Systems has to offer.

Clients benet from our extensive years of expe-

rience in environmental engineering.

Doppstadt provides in-line and stand-alone

solutions for:

Composting

Biomass production

Mechanical biological waste treatment

Timber & waste wood processing

Waste sorting

Refuse derived fuel (RDF) preparation

Handling of biomass for fermentation

WE WILL SHOW YOU EVERYTHING THERE IS TO SEE

PLUS THINGS THAT DO NOT YET EXIST AND IN 3D!!

Computer animated visualisation helps design

engineers to communicate with clients when

planning new systems. Our 3D DoppPlan tool

leaves no room for misinterpretation. We make

plans clearly visible and, with added realistic

photo illustration, we bring your planning aspira-

tions to life. The 3D collision check tool shows

where/if equipment or structures foul each other

e.g. in a production hall with built in objects like

air conditioners, support columns, or beams with

restrictive clearance heights. Any permutation of

machines can be referenced from the programs

equipment library and then be combined and

viewed in a true scale 3D picture.

A 3D viewer is also available and the visualisa-

tions can be forwarded to and checked by our

clients on their own PC. Changes and revisions

are displayed quickly and without problems.

In addition to standard system layouts, we also

design special custom made applications (includ-

ing 3D) using modern professional CAD software.

WHAT WE OFFER CLIENTS:

Expert support for system layout,

planning and optimised operation

A world-wide network of

suppliers ensuring fast service

Fast visual planning results using

the DoppPlan design software

40 years of achievement in

mechanical engineering solutions

Unrivalled competence in process

control backed by our experience

and comprehensive references in

environmental engineering

38 39

ECOLOGICAL & COST EFFECTIVE REFEEDING OF

MATERIALS BACK INTO THE RECYCLE CHAIN

Biomass production

We support our clients in their need to manu-

facture CO2 neutral fuels. Whether these are

made from waste wood or directly from timber

biomass, Doppstadt provides established and

proven machines for shredding, grinding and the

screening out of contaminable properties.

Composting

Green waste, organic household and kitchen

wastes are generally composted. Doppstadt

system technology enables the grinding down

of raw material in an economical and therefore,

cost effective manner by screening removal of

contaminants.

Mechanical biological waste treatment

Doppstadt recycling technology offers viable

solutions for any required steps in the mechani-

cal pre-processing and classication of various

input materials including; slow-speed shredding,

drum and star screening machines, wind sifters

and sorting cabinets. We offer a range of suitable

plant for all sorts of waste e.g. household rubbish,

bulky refuse or industrial/construction waste.

Pre-processing of waste for anaerobic digestion

Appropriate waste preparation for fermenta-

tion is essential for a high yield rate of gas and

therefore the economical operation of any

fermentation plant. We offer a range of suitable

shedders for the preparation of dry fermentation

materials. Doppstadt also offers system technol-

ogy to gain suitable suspension from your waste

material as input for wet fermentation.

Bespoke applications

Do you have a need for special processes or

applications where components like shredders,

screening machines or other Doppstadt equip-

ment might be integrated? We have successfully

implemented many such special installations and

can both advise and demonstrate them to you.

Please ask one of our specialists who will be

happy to advise you.

AND IF YOU ALREADY HAVE

EQUIPMENT?

Prot from our expertise and extensive services:

General overhaul of Doppstadt plant

Reftting of Doppstadt components into existing equipment

Expansion of systems and reconfguration of machines

Doppstadt

System

technology

Support

DOPPSTADT SERVICES

AT A GLANCE

Know How in processing materials

System layout planning

3D visualisation during the planning

process

Optimisation of equipment

World-wide distribution network

Service on site

40 41

42 43

AK 535 AK 635 AK 510 K BioPower

AK 235

AK 510 BioPower

DW 2060 DW 2060 K BioPower DW 2560 DW 3060

DW 3060 K DW 3060 SA DW 3080 K3

optional:

DW 3060 BioPower

optional:

DW 3060 K BioPower

optional:

DW 3060 SA BioPower

AK 635 SA AK 635 K DZ 750 DZ 750 K

SM 414 SM 414 K SM 518 SM 620

SM 620 E Hybrid SM 620 K SM 720 SM 1200 Triex

DU 265

SM 1200 SA Triex

DU 320

BioPress DBP 205

DH 910 DH 910 K

DH 910 SA DH 910 SA-B

DH 811

DH 811 L DH 812 Q

MOBILE RECYCLING EQUIPMENT OVERVIEW

THE DOPPSTADT RANGE

OF MOBILE MACHINES

FURTHER INFORMATION

ABOUT MOBILE RECYCLING

EQUIPMENT IS AVAILABLE AT:

WWW.DOPPSTADT.COM

Doppstadt Calbe GmbH

Barbyer Chaussee 3

D-39240 Calbe/Saale

Germany

Tel.: +49 (0)39291 55-0

Fax: +49 (0)39291 55-350

E-Mail: info@doppstadt.com

WE CARE

Doppstadt Systemtechnik GmbH

Steinbrink 4

D-42555 Velbert

Germany

Phone: +49 (0) 2052 889-0

Fax: +49 (0) 2052 889-144

E-Mail: systemtechnik@doppstadt.de

Internet: www.doppstadt.com

Werner Doppstadt

Umwelttechnik GmbH & Co. KG

Steinbrink 13

42555 Velbert

Germany

Phone: +49 (0)2052 889-0

Fax: +49 (0)2052 889-144

E-Mail: info@doppstadt.de

Internet: www.doppstadt.com

Vous aimerez peut-être aussi

- 2-A-GNLW363CD Standard Decanter CentrifugeDocument6 pages2-A-GNLW363CD Standard Decanter CentrifugeGeorgePas encore d'évaluation

- Rotary Lobe PDFDocument2 pagesRotary Lobe PDFpablo ortizPas encore d'évaluation

- CCB Cleancut PsDocument2 pagesCCB Cleancut PsJose RamirezPas encore d'évaluation

- Hayabusa Turbo Stage Kit CarDocument1 pageHayabusa Turbo Stage Kit Carha5611Pas encore d'évaluation

- Penta HW ManDocument139 pagesPenta HW ManPablo Herson Black Rodriguez EliasPas encore d'évaluation

- List of Oil ZF PDFDocument16 pagesList of Oil ZF PDFJhon SyalfiandyPas encore d'évaluation

- D45 CatDocument5 pagesD45 CatJiménez ManuelPas encore d'évaluation

- JCB Tracked Robot Loaders 190T1110TDocument6 pagesJCB Tracked Robot Loaders 190T1110TFajrin M. NatsirPas encore d'évaluation

- Common Challenges Relative To The Use of Decanter Centrifuges For Barite Recovery in The Oil & Gas Industry - BrochureDocument13 pagesCommon Challenges Relative To The Use of Decanter Centrifuges For Barite Recovery in The Oil & Gas Industry - BrochureCentrifugal SeparatorPas encore d'évaluation

- Airflex® Air Cooled Disc Clutches and Brakes: Section EDocument22 pagesAirflex® Air Cooled Disc Clutches and Brakes: Section Erony adonay sandovalPas encore d'évaluation

- Bilgemaster 200 PDFDocument7 pagesBilgemaster 200 PDFbanerjeeamlanPas encore d'évaluation

- G-Tech Rotary Lobe Pump OIM Manual PDFDocument23 pagesG-Tech Rotary Lobe Pump OIM Manual PDFGiorgiana Rosu100% (1)

- Pompa SelwoodDocument4 pagesPompa SelwoodakkilluaPas encore d'évaluation

- HD 2 109c Caterpillar 3406eDocument2 pagesHD 2 109c Caterpillar 3406eالمهندسوليدالطويلPas encore d'évaluation

- El640 480-Af1Document17 pagesEl640 480-Af1pericopepePas encore d'évaluation

- Garrett Cat 9 04 TurbosDocument49 pagesGarrett Cat 9 04 TurbosJorge Fernando H GPas encore d'évaluation

- Cop 34-84 - Eng, FR, SP, PoDocument70 pagesCop 34-84 - Eng, FR, SP, PoJALFAROROPas encore d'évaluation

- Mangeras Racores EatonDocument502 pagesMangeras Racores Eatonjonatan arangoPas encore d'évaluation

- Diesel Generating Set BF-DW750: Standby Power 50Hz Prime Power 50HzDocument5 pagesDiesel Generating Set BF-DW750: Standby Power 50Hz Prime Power 50HzheriPas encore d'évaluation

- Powerroc D45: Surface Drill Rig For Quarrying and MiningDocument5 pagesPowerroc D45: Surface Drill Rig For Quarrying and MiningYaroslav KazachenkoPas encore d'évaluation

- The Perfect Brew With Eaton's Beer Filtration GuideDocument8 pagesThe Perfect Brew With Eaton's Beer Filtration GuideEaton FiltrationPas encore d'évaluation

- TAD941GE: Volvo Penta Industrial DieselDocument2 pagesTAD941GE: Volvo Penta Industrial DieselGiangDoPas encore d'évaluation

- Fisher Diaphragm Rotary ActuatorDocument12 pagesFisher Diaphragm Rotary Actuatordennis_ugartePas encore d'évaluation

- 0001 0567 90 PDFDocument30 pages0001 0567 90 PDFGUSTAVO HEINERICI SCHMIDTPas encore d'évaluation

- Oki Microline Ml320, Ml321 Turbo Service ManualDocument145 pagesOki Microline Ml320, Ml321 Turbo Service Manualdwina rochePas encore d'évaluation

- CP CatalogDocument20 pagesCP CatalogCentral Hydraulics100% (1)

- ELGI Compressor Diesel Engine Powered PDFDocument8 pagesELGI Compressor Diesel Engine Powered PDFAmit KumarPas encore d'évaluation

- Eaton - Internormen Wind Power SolutionsDocument12 pagesEaton - Internormen Wind Power SolutionsEaton FiltrationPas encore d'évaluation

- Manual T10A65 B PDFDocument36 pagesManual T10A65 B PDFHéctor José Muñoz RocaPas encore d'évaluation

- Enerpac L2596 GDocument108 pagesEnerpac L2596 GGabriel OniszczukPas encore d'évaluation

- Wr430gb00b BMP Cat Discl EngDocument12 pagesWr430gb00b BMP Cat Discl EngJoseph BernardPas encore d'évaluation

- D391000587 MKT 001 PDFDocument32 pagesD391000587 MKT 001 PDFDwiki RamadhaniPas encore d'évaluation

- TAD532GE: Volvo Penta Genset EngineDocument2 pagesTAD532GE: Volvo Penta Genset EngineAndres Sorin100% (1)

- Duralite 1000N Spec Sheet PDFDocument1 pageDuralite 1000N Spec Sheet PDFJhonattan GonzalezPas encore d'évaluation

- Data Sheet: LenntechDocument12 pagesData Sheet: LenntechilieoniciucPas encore d'évaluation

- TurboDocument43 pagesTurboKkbhuvan KkPas encore d'évaluation

- FP Martin ElevadoresDocument19 pagesFP Martin ElevadoresGuilherme AlmeidaPas encore d'évaluation

- Eaton - Internormen Fluid Purifier SystemsDocument4 pagesEaton - Internormen Fluid Purifier SystemsEaton FiltrationPas encore d'évaluation

- Baldwin Fuel Dahl PDFDocument27 pagesBaldwin Fuel Dahl PDFjack sliverPas encore d'évaluation

- Circuit Diagram: F FIG.9.2 F F (HZ)Document8 pagesCircuit Diagram: F FIG.9.2 F F (HZ)rediffoooPas encore d'évaluation

- araña3CR285DME Eng MANUAL-DE-OPERACIONDocument20 pagesaraña3CR285DME Eng MANUAL-DE-OPERACIONtincho_0026Pas encore d'évaluation

- New Cat Prod LineDocument72 pagesNew Cat Prod LineSang Sang Barongan0% (1)

- Portable Air Compressors Hire & SaleDocument26 pagesPortable Air Compressors Hire & SaleJohn NottyPas encore d'évaluation

- Volvo Penta D12-Short SpecDocument4 pagesVolvo Penta D12-Short Speczulu800% (1)

- General Pump VHDocument18 pagesGeneral Pump VHnabit pedrozoPas encore d'évaluation

- HCR 1200 EdiiDocument7 pagesHCR 1200 EdiiKurniawanPas encore d'évaluation

- Tad1641ge PDFDocument2 pagesTad1641ge PDFjuanPas encore d'évaluation

- Weatherford PartsDocument19 pagesWeatherford PartsAlfred Hernandez MendozaPas encore d'évaluation

- Busch Instruction Manual Tyr WT 0100-0730 BP BV en 0870A00002 171107CZ V2Document36 pagesBusch Instruction Manual Tyr WT 0100-0730 BP BV en 0870A00002 171107CZ V2anon_839350798Pas encore d'évaluation

- FPT Energy GBDocument16 pagesFPT Energy GBAsif Shah100% (1)

- Chapter AppendixDocument36 pagesChapter AppendixBishoo ShenoudaPas encore d'évaluation

- APC200 ECM-ECI Generic Error Codes Ver3.6 PDFDocument17 pagesAPC200 ECM-ECI Generic Error Codes Ver3.6 PDFSÿlvain Jfs ÑdourPas encore d'évaluation

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- WoodWard Egcp 2Document4 pagesWoodWard Egcp 2Julian Pompy Buitrago Carrascal100% (1)

- HPS3000 Pump & GearboxDocument2 pagesHPS3000 Pump & GearboxFrederik CañabiPas encore d'évaluation

- KOSUN Centrifuge PDFDocument6 pagesKOSUN Centrifuge PDFMEHDIPas encore d'évaluation

- Makita Baterijski AlatDocument2 pagesMakita Baterijski Alatsealion72Pas encore d'évaluation

- Twin Shaft ShredderDocument88 pagesTwin Shaft ShredderZach Loves Sana0% (1)

- DW Series 2015Document20 pagesDW Series 2015kris CadwellPas encore d'évaluation

- Honda Accord 2008-2010 v6 OemDocument1 794 pagesHonda Accord 2008-2010 v6 OemAlbertoCòrdovaPas encore d'évaluation

- Self Priming Water Lifting Booster PumpDocument2 pagesSelf Priming Water Lifting Booster PumpzhelipumpPas encore d'évaluation

- Micro Precision Calibration, Inc. Local Calibration ProcedureDocument3 pagesMicro Precision Calibration, Inc. Local Calibration ProcedureWuzekPas encore d'évaluation

- How Bangalore Gets ElectricityDocument1 pageHow Bangalore Gets ElectricityNabeel AhmedPas encore d'évaluation

- SUPER Final ImportDocument41 pagesSUPER Final ImportronaldPas encore d'évaluation

- Celsius Scale Thermometer Displays The Ambient Temperature Through A LCD DisplayDocument6 pagesCelsius Scale Thermometer Displays The Ambient Temperature Through A LCD DisplayJaspinder SinghPas encore d'évaluation

- New Horizons and Opportunities of Modular Constructions and Their TechnologyDocument9 pagesNew Horizons and Opportunities of Modular Constructions and Their TechnologyPhD. Arch. Klodjan XhexhiPas encore d'évaluation

- Hardware Compatibility List (HCL) For Veritas Storage Foundation (TM) and High Availability Solutions 4.1 MP2 For SolarisDocument5 pagesHardware Compatibility List (HCL) For Veritas Storage Foundation (TM) and High Availability Solutions 4.1 MP2 For SolarisbennialPas encore d'évaluation

- Thermal Modeling and Design Considerations of Lithium-Ion BatteriesDocument8 pagesThermal Modeling and Design Considerations of Lithium-Ion BatteriesVarun Gupta100% (1)

- 2014 BayHelix Annual Conference Program v2Document19 pages2014 BayHelix Annual Conference Program v2Ulfa Yasmin ShahabPas encore d'évaluation

- Saudi Electricity Company - Southern Region (Saudi Arabia)Document7 pagesSaudi Electricity Company - Southern Region (Saudi Arabia)azeemmet9924Pas encore d'évaluation

- GSECL - Daily Progress Report 11.9.21Document2 pagesGSECL - Daily Progress Report 11.9.21krishna mohanPas encore d'évaluation

- ENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enDocument5 pagesENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enStéphanie Océane NadjiPas encore d'évaluation

- Operating Manual: Wheel Loader L538 - 432 From 13100Document284 pagesOperating Manual: Wheel Loader L538 - 432 From 13100Jacques Van Niekerk80% (5)

- Vale International Pellet Plant PDFDocument2 pagesVale International Pellet Plant PDFSrinivasanPas encore d'évaluation

- ابراج STCDocument5 pagesابراج STCMohamed F. AbdullahPas encore d'évaluation

- Summative Exam For Ignition SystemDocument1 pageSummative Exam For Ignition SystemJestoniPas encore d'évaluation

- K Sera Sera CaseDocument12 pagesK Sera Sera CaseAditya SinghPas encore d'évaluation