Académique Documents

Professionnel Documents

Culture Documents

BR LaVision Automotive

Transféré par

Rahul BanerjeeCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BR LaVision Automotive

Transféré par

Rahul BanerjeeDroits d'auteur :

Formats disponibles

LaVision

We count on Photons

LaVision Automotive

Innovative Measurement Technologies

2

Focusing on Automotive

Research & Development

Optical diagnostic technologies such as laser imaging and ber sensors are powerful development

tools in many research laboratories of the automotive industry. They are successfully applied to

measure in-cylinder processes, air ows around and inside car bodies and to study deformation and

strain behavior of automotive parts under stress. In-situ optical measurements are non-intrusive to

the process and measure with intrinsic high spatial and temporal resolution.

LaVisions laser diagnostic instruments give invaluable insight for a better understanding of the

automotive process. They allow a much faster and more efcient development and, thus, save time

and money. LaVision has a long history successfully cooperating with the automotive industry

worldwide. We are a reliable and competent partner for our customers providing advanced

measurement solutions for their challenging diagnostics requirements, today and in the future.

Whether your measurement focus is on engine performance, aerodynamic testing or on

dynamic deformation and strain measurements - LaVision is your partner to nd the best

measurement solution.

Optical Diagnostics

for Automotive R&D

material deformation: page 13

aerodynamic testing: page 12

soot emission: page 11

mixture formation: page 4 - 8

combustion: page 10

in-cylinder charge motion: page 9

Energy efciency and environmental friendliness implies an enormous challenge to improve internal

combustion engines. The detailed information on the complex in-cylinder processes gained by

optical diagnostics is complementary to traditional indication systems. In many cases optical

measurements are the only way to validate Computational Fluid Dynamics (CFD) simulations.

The optical methods are aiming at improving fuel efciency and reducing pollutant emissions.

They help to optimize the development process of engines and engine concepts:

direct injection and multiple injections

downsizing concepts and turbo charging

HCCI, Exhaust Gas Recirculation (EGR) and variable valve train

alternative fuels like hydrogen, natural gas or fuels from biomass

transient engine conditions such as cold start and catalyst heating

LaVisions laser diagnostic systems are successfully applied to analyze in-cylinder processes such

as ow generation, fuel spray injection and mixture preparation, (auto-) ignition, combustion and

nally formation of pollutants including soot.

Depending on the requirement, the diagnostic solutions are designed for minimal modications

of the engine applying endoscopic imaging or for the use of ber sensors on production engines.

Engine Diagnostics using

Laser Imaging and

Optical Sensors

3

Optical Solutions for

Engine Diagnostics

Mixture Formation Imaging

in-cylinder fuel distribution: evaporated and liquid fuel

4

LaVisions laser systems enable versatile diagnostic applications for in-cylinder mixture

formation imaging. Fuel vapor, residual gas distribution and temperature elds are visualized

on a light sheet plane illuminated by a pulsed light source. Due to the short light pulses in

the nanosecond range even highly dynamic turbulent processes are captured without image blurring.

The measurement systems are based on Laser Induced Fluorescence (LIF) detecting inherent compo-

nents of the fuel or added molecular species. Illumination and detection both require optical access,

which can be provided either by a partly transparent cylinder and piston or applying keyhole imaging

using minimal invasive endoscopes.

in-situ visualization of the in-cylinder mixing process:

fuel and residual gas distribution and in-cylinder temperature elds

crank angle resolved measurement with high spatiotemporal resolution

complete integrated synchronization with engine test rig

time resolved imaging for transient cycle analysis of the compression stroke

air/fuel ratio maps near the spark plug

temperature homogeneity of the cylinder charge just before ignition

Optimizing Mixture

Formation

Optical Engine

Indication

Features

Special Topics

LaVisions Internal Combustion Optical Sensors (ICOS) measure crank angle resolved air/fuel ratio,

exhaust gas concentration and gas temperature locally at the spark (glow) plug or at any other

in-cylinder location using optical M5-probes. The ICOS systems provide highly time resolved data

of the relevant engine parameters at the tip of the probe. Single cycle parameter proles as well as

variations over many cycles are recorded.

Optical engine indication synchronized with standard pressure recording allows a much more

detailed characterization of the in-cylinder charge formation process. Information on the state

of the cylinder charge at a given crank angle is of upmost importance to improve engine

performance.

The ICOS measurement systems are based on infrared absorption spectroscopy of the relevant

molecules like water, CO

2

or hydrocarbons. The in-situ absorption technique is instantaneous and

needs no gas extraction. One probe can measure multiple parameters simultaneously.

crank angle resolved in-situ measurement of fuel concentration (air/fuel ratio), exhaust gas

concentration (EGR-rate) and gas temperature together with engine pressure indication

precise single cycle analysis at kilohertz sampling rates

applicable in unmodied production engines under real fuel conditions

ICOS probes: optical spark plugs (M12 and M14) or non-ring M5-thread probe

multiple parameter recording: air/fuel ratio + exhaust gas conc. + heat release with one probe

crank angle resolved fuel and exhaust concentration proles

together with cylinder pressure during cold start

Internal Combustion

Optical Sensors

5

Optimizing Mixture

Formation

Optical Engine

Indication

Measurement Principle of

Optical Engine Indication

Features of the

Internal Combustion

Optical Sensors (ICOS)

6

The ICOS system for fuel and exhaust gas measurements allows the simultaneous detection of both

gas components from the same probe. In combination with the cylinder pressure the local air/fuel

ratio is derived from the fuel concentration. The CO

2

detection reveals information about the Exhaust

Gas Recirculation (EGR) rate for each individual cycle and cylinder, thus, allowing a stability analysis

of EGR processes.

In contrast to conventional Flame Ionization Detectors (FIDs) or Non-Dispersive IR (NDIR) - Analyzers

ICOS does not need a gas sampling system and measures directly inside the cylinder without any

delay.

crank angle resolved fuel conc. (air/fuel ratio) and/or exhaust gas (CO

2

) conc. measurements

engine synchronized on-line measurements with 30 kHz sampling rate

simultaneous indication of multi gas components and heat release

variation of injection systems and strategies on the mixture formation process

investigation of special engine operation modes: cold start, EGR and stratied operation

crank angle resolved CO

2

concentration proles

internal and external EGR rates: EGR analysis over consecutive cycles and different cylinders

Ultra-Fast In-Cylinder

Gas Analysis

In-Cylinder

Gas Temperature

System Features

Applications

courtesy of IAV GmbH

Internal Combustion

Gas Concentration Sensor

crank angle resolved in-cylinder CO

2

concentration

measurements in a Diesel engine under varied EGR conditions

simultaneous single cycle fuel concentration measurements:

ICOS versus FID

Internal Combustion Optical Sensor:

- fast peak response

- instantaneous signal

FID:

- sample gas dilution

- delayed signal

LaVisions ICOS system for in-cylinder temperature indication measures locally the crank angle

resolved gas temperature before and after combustion. Especially the often unknown compression

stroke temperature rise is recorded in detail. These in-cylinder temperature proles give important

feedback for engine optimization, for the analysis of cycle by cycle variations and for the validation

of numerical models.

M12 or M14 fully functional spark plug probes

non-ring M5-thread probe or optical glow plug probe

line-of-sight (transmission) probes (requires optical access)

in-cylinder gas temperature measurements with a special focus on the compression stroke

engine synchronized on-line measurements with max 23 kHz sampling rate

effects of different EGR rates and valve timings on in-cylinder temperature

HCCI pre-combustion temperature analysis

detection of abnormal engine performance

7

Ultra-Fast In-Cylinder

Gas Analysis

In-Cylinder

Gas Temperature

Applications

System Features

courtesy of IAV GmbH

Internal Combustion

Gas Temperature Sensor

simultaneously recorded cycle averaged in-cylinder gas temperature and pressure

inside a DISI gasoline engine measured with the ICOS-Temperature system

ICOS-Temperature

Optical Probe Versions

8

Liquid fuel atomization and evaporation are directly affecting engine performance and exhaust

emissions. To nd the best spray injector conguration for a given engine concept is a challenging

task. Laser imaging of transient fuel sprays in heated high pressure test cells or directly inside the

cylinder offers an efcient analytical approach for spray characterization replacing old trial and error

experiments. LaVisions laser imaging systems provide information on various parameters such as

spray propagation and breakup, droplet size, velocity and temperature and on the evaporation

process.

For a comprehensive spray characterization sophisticated customer designed imaging systems are

offered as well as fully automated spray inspection systems for the inline quality control of spray

injectors.

phase locked as well as high speed imaging of various spray parameters in transient sprays:

spray geometry, patternation, penetration, propagation

spray velocity, evaporation, global droplet sizing

light sheet scans for 3D spray imaging

advanced imaging technology for dense sprays

For correlated size-velocity measurements on single droplets and time resolved mass ux

measurements LaVision offers advanced Phase Doppler Interferometers.

Comprehensive Spray

Characterization

In-Cylinder

Charge Motion

System Features

Fast Spray Analysis

Spray Imaging

2D Phase Doppler Interferometer (PDI)

For engines with lower emissions and better fuel economy such as DI engines a precise control

of the in-cylinder charge motion is essential. Flow elds in the intake manifold and the cylinder

are strongly affecting the in-cylinder mixture preparation. Both large scale-motion, such as swirl

and tumble ows, and small-scale turbulent motion inuence the combustion process and hence

emission levels. For homogeneous charge combustion turbulence is required at the time of ignition

for an efcient combustion. In the case of stratied charge combustion, an ignitable mixture has to

be guided to the spark plug by the internal cylinder ow in order to allow a reliable ignition and a

subsequent stable combustion.

LaVisions keyhole imaging approach using innovative laser and camera endoscopes with small

apertures is minimal invasive for the engine process not changing the ow eld under study.

The laser imaging technique Particle Image Velocimetry (PIV) provides crank angle resolved

2-dimensional velocity measurements of the charge motion with high spatial resolution.

High speed PIV measurements record ow eld movies of the transient mixture formation

of single engine cycles.

phase locked and crank angle resolved ow elds

endoscopic access for illumination and imaging

instantaneous in-cylinder tumble ow applying endoscopic imaging

9

Comprehensive Spray

Characterization

In-Cylinder

Charge Motion

courtesy of IAV GmbH

System Features

In-Cylinder Flow Fields

for Dynamic

Combustion Strategies

10

After ignition the ame front is propagating through the air-fuel mixture exchanging heat and mass.

Flame propagation and local temperature are signicantly affected by the local ow characteristics

and mixture composition which have a strong impact on pollutant formation such as nitric oxides

or soot particles. Thus, a thorough investigation is essential to improve the understanding of the

detailed processes in reaction chemistry to optimize engine efciency and reduce pollutant

emissions.

LaVision offers integrated diagnostic solutions for engine combustion applications. These imaging

systems visualize the location of ame kernels and the origin of unwanted pre-ignition spots leading

to engine knock via detection of chemiluminescence or Laser Induced Fluorescence (LIF) of ame

radicals. Laser imaging enables instantaneous detection of important species in reaction kinetics

like CH and OH, and is able to resolve the distribution of prominent pollutants like NO.

instantaneous detection of ame radicals like OH, CH and NO on laser light sheets

pyrometry in sooting ames to determine particle temperatures

high speed imaging of complete cycles:

spray injection - ignition - combustion - glowing soot particles

Combustion

Imaging

Insight into

Soot Formation

System Features

Improving

Combustion Efciency

Reducing Emissions

single shot laser imaging of OH-ame radicals

inside the cylinder of a gasoline engine

Combustion generated soot is known as one of the major pollutants emitted by Diesel engines.

The soot is composed of nanoparticles produced through the incomplete combustion of

hydrocarbon fuels. However, most of the soot particles are consumed by oxidation and do

not contribute to exhaust emissions. In-situ visualization of soot formation in combination with a

robust and most sensitive soot emission control are enabling diagnostic techniques to reach the

challenging emission levels set out for the future.

LaVision offers Laser Induced Incandescence (LII) as a technique for in-situ soot formation imaging

of soot volume fraction and primary particle size distributions.

instantaneous in-situ images of soot volume fraction and particle size distribution

excellent sensitivity with a detection limit in the range of parts per billion (ppb)

For on-line soot emission control LaVision offers a portable LII soot sensor with highest sensitivity.

correlated soot volume fraction and particle size measurements

outstanding sensitivity in the range of parts per trillion (ppt)

compact, rugged and portable instrument

11

Combustion

Imaging

Insight into

Soot Formation

System Features for

Soot Imaging

System Features for

Soot Emission Analysis

Soot Formation Imaging

courtesy of IAV GmbH

large eld PIV recording of a passenger car wake ow

12

Optimizing

Aerodynamic Efciency

Interior Climate Flows

Aero-acoustics

Aerodynamic testing is often the key to success in motor racing and also for transport vehicles to

achieve the best fuel economy. Multi-dimensional and often time-resolved Particle Image Velocimetry

(PIV) measurements are applied to balance aerodynamic shape with automotive styling, to reduce

wind noise (aero-acoustics) and to guide interior thermal ows in order to maximize passenger

comfort.

LaVisions Laser Imaging systems provide real-time and accurate airow measurements, support

remote measurement control including ow eld scanning in all directions and data synchronization

with other wind tunnel test parameters. This guarantees short development times avoiding costly

wind tunnel down-time.

remote control of multi-axis traversing systems and all imaging parameters

effective seeding methods for small and large ow elds

robust image calibration tolerates lower quality optical viewing windows

advanced data evaluation for online display of results

Aerodynamic Testing

and Passenger Comfort

System Features

The performance of the materials used in the automotive industry, and of the components

manufactured using those materials is critical to the safety of the construction, efcient use

of materials, and achievement of creating a light-weight fuel efcient design.

Digital Image Correlation (DIC) is a particularly popular full eld non-intrusive tool for surface

displacement and strain measurements and is able to collect data from sample sizes of microns

up to meters.

Displacements with high precision can be attained with state-of-art algorithms, allowing users

to measure tyre squash under static or dynamic loading, or performance of welded materials.

Bend testing of aerodynamic surfaces can be performed in the test laboratory under static load

conditions, or combined with PIV to calculate aeroelastic effects and Fluid-Structure Interaction

phenomena.

courtesy of IAV GmbH

tire squash deformation under static or dynamic loading

13

Non-Destructive

Materials Testing

Contact-free

Deformation and Strain

Measurements

14

Accessories

advanced

endoscopes

sealing inserts for

optical access

ber optics

spark plugs

exible

light guides

engine synchronizer/

simulator

exible

laser guiding

arm

Engine Synchronizer / Simulator

for Laser Imaging Systems

crank angle locked recording supporting engine acceleration modes

integrated rotary decoder enabling phase scans

automatic phase detection from pressure signal

simulation of engine encoder signals and pressure for fast system synchronization checks

control of injection(s), alternating engine operation incl. skip re modes

input signal level conditioning for improved encoder signal quality

exible light delivery guides for in-cylinder illumination

various laser and camera endoscopes for in-cylinder keyhole imaging

customized sealing inserts for optical access

M12 and M14 optical spark plugs

universal optical M5 probe, optical glow plug

Flexible Light Guides, Endoscopes

and Sealing Inserts

Optical Spark Plugs and

In-Cylinder Light Probes

Besides turn-key measurement systems LaVision is offering in the eld of automotive R&D:

contract measurements

equipment loan

on-site demonstrations and feasibility tests

inline/online quality control systems and

exible and customized optical measurement solutions

The LaVision team welcomes and encourages discussions and long term relationships with

prospective and existing customers regarding their measurement requirements.

Application specic measurement solutions in the eld of automotive R&D are our speciality.

15

Services and

Partnership

Services

Customer Partnership

courtesy of IAV GmbH

03/11

LaVision Inc.

211 W. Michigan Ave., Suite 100,

Ypsilanti, MI 48197 / USA

e-Mail: sales@lavisioninc.com

www.lavisioninc.com

Phone: (734) 485 - 0913

Fax: (240) 465 - 4306

LaVision GmbH

Anna-Vandenhoeck-Ring 19

D-37081 Goettingen / Germany

E-Mail: sales@LaVision.com

www.LaVision.com

Tel.: +49-(0)5 51-9004-0

Fax: +49-(0)551-9004-100

LaVisionUK Ltd

Downsview House / Grove Technology Park

Grove / Oxon / OX12 9FF / United Kingdom

e-Mail: sales@lavisionuk.com

www.lavisionUK.com

Phone: +44-(0)-870-997-6532

Fax: +44-(0)-870-762-6252

LaVisions Product Range

modular laser imaging systems based on

spectroscopic techniques for multi-parameter

and multi-dimensional ow eld measurements

for combustion, spray and ow visualization

imaging systems for remote and precise

surface deformation and strain inspection

software integrated advanced camera systems

ber optical sensor systems

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Wavelet ANN RBF ANN+++++++++++++++++++Document6 pagesWavelet ANN RBF ANN+++++++++++++++++++Rahul BanerjeePas encore d'évaluation

- Service Tax BookletDocument6 pagesService Tax BookletRahul BanerjeePas encore d'évaluation

- Diesel EthanolDocument10 pagesDiesel EthanolRahul BanerjeePas encore d'évaluation

- HP - Workstation DGS&D - JPDocument1 pageHP - Workstation DGS&D - JPRahul BanerjeePas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Specific Impulse: Overall PerformanceDocument4 pagesSpecific Impulse: Overall PerformanceRajeev GuptaPas encore d'évaluation

- d8r II Serp3245 AkaDocument0 paged8r II Serp3245 Akamacross13100% (4)

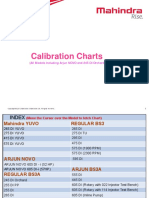

- Calibration Chart49Document104 pagesCalibration Chart49Sudeep Kumar80% (15)

- Combustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFDocument22 pagesCombustion Engineering-2000-Minimum Recirculation Flame Control (MRFC) Pulverized Solid Fuel Nozzle Tip PDFKrozePas encore d'évaluation

- I. C. EngineDocument26 pagesI. C. Enginenoelmecwan0% (1)

- Reciprocating EnginesDocument3 pagesReciprocating EnginesHarish Reddy Singamala100% (1)

- Evo 4-5-6 Conversion To Evo7-8 ECU Pinout DiagramsDocument10 pagesEvo 4-5-6 Conversion To Evo7-8 ECU Pinout Diagramsrjlaforteza100% (3)

- Engine F4HFA413A B C D F613 - E002 E003 AgricultureDocument6 pagesEngine F4HFA413A B C D F613 - E002 E003 AgricultureDani RisnandarPas encore d'évaluation

- 04rx8-Service Highlights PDFDocument540 pages04rx8-Service Highlights PDFAnonymous wpUyixsjPas encore d'évaluation

- Trk251 Service ManualDocument508 pagesTrk251 Service ManualDario F HillPas encore d'évaluation

- Pyréolophore - WikipediaDocument30 pagesPyréolophore - WikipediaArcely GundranPas encore d'évaluation

- Thermodynamics Lab ReportDocument41 pagesThermodynamics Lab ReportSaq LainPas encore d'évaluation

- Measurements of Swirling Flow in A Direct Injection Diesel Engine Under Motored and Fired ConditionsDocument8 pagesMeasurements of Swirling Flow in A Direct Injection Diesel Engine Under Motored and Fired Conditionsvijay1142Pas encore d'évaluation

- MAN B&W Diesel A/S: Service LetterDocument4 pagesMAN B&W Diesel A/S: Service LetterAleksandar Sasa SeferovicPas encore d'évaluation

- Volvo Plane Ice ReportDocument18 pagesVolvo Plane Ice ReportAreebPas encore d'évaluation

- 115 HP 4T PDFDocument527 pages115 HP 4T PDFlucas100% (7)

- Vdocuments - MX - Ford 8240 Tractor Service Repair Manual 1623289812Document9 pagesVdocuments - MX - Ford 8240 Tractor Service Repair Manual 1623289812Łukasz Tusiński0% (1)

- Effect of Intercooler On Turbocharged EngineDocument4 pagesEffect of Intercooler On Turbocharged EngineShivam SharmaPas encore d'évaluation

- CAT Power Plants Layout CATDocument280 pagesCAT Power Plants Layout CATburcin GozalPas encore d'évaluation

- Exhaust Gas Recirculation SystemDocument6 pagesExhaust Gas Recirculation SystemgustavoPas encore d'évaluation

- Bn-Full Instructor GuideDocument128 pagesBn-Full Instructor GuideBounna Phoumalavong100% (2)

- YEC Technical Letter PDFDocument163 pagesYEC Technical Letter PDFDang LinaPas encore d'évaluation

- Special Tools: With M6 X 20 MM BoltDocument2 pagesSpecial Tools: With M6 X 20 MM BoltJulio MezaPas encore d'évaluation

- D85ESS-2 PartbookDocument216 pagesD85ESS-2 Partbookyul haidirPas encore d'évaluation

- Gas Turbine and Rocket Propulsion (SPC492) : Aerospace DepartmentDocument20 pagesGas Turbine and Rocket Propulsion (SPC492) : Aerospace DepartmentganamPas encore d'évaluation

- GSX150 MB8NG4BF (L7)Document92 pagesGSX150 MB8NG4BF (L7)Javier LlumpoPas encore d'évaluation

- DEMOLEDOR Ref 25941 #1Document6 pagesDEMOLEDOR Ref 25941 #1German CeleitaPas encore d'évaluation

- Chapter-6 Carburation and InjectionDocument10 pagesChapter-6 Carburation and InjectionjeetPas encore d'évaluation

- Cummins Diesel Engine 6BTAA5.9G7 PDFDocument2 pagesCummins Diesel Engine 6BTAA5.9G7 PDFmkPas encore d'évaluation