Académique Documents

Professionnel Documents

Culture Documents

Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. Spencer

Transféré par

Kunal Pandey0 évaluation0% ont trouvé ce document utile (0 vote)

42 vues26 pagesabout wear of Tool steel and properties of material

Titre original

Wear Lecture

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentabout wear of Tool steel and properties of material

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

42 vues26 pagesIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. Spencer

Transféré par

Kunal Pandeyabout wear of Tool steel and properties of material

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 26

lnLroducuon Lo wear

Surfaces, lnLerfaces, and Lhelr

Appllcauons ll

nlcholas u. Spencer

8ecap: denluon of Lrlbology

!"#$%&%'( #* +,- *.#-/.- 0/1 +-.,/%&%'( %2 #/+-"0.3/' *4"20.-* #/ "-&035- 6%3%/ 0/1

"-&0+-1 *4$7-.+* 0/1 8"%.-**-*

8ubblng surfaces are never perfecLly aL

8oughness

1he normal load ls borne by Lhe asperlues on each

surface comlng lnLo conLacL wlLh each oLher

ConLacL areas are small (asperlues)

ressures are large

Asperlues become elasucally and plasucally

deformed upon conLacL wlLh each oLher

ConLacL areas lncrease

ConLacL pressure may evenLually exceed Lhe

elasuc llmlL of Lhe maLerlal

1rue area = apparenL area !"#$ lf surfaces are aLomlcally smooLh

%&'( *&(* ++ ,--*&(". *&(*

http://images.google.ch

8ecap: frlcuon and lubrlcauon

8eslsLance encounLered when one body ls moved over anoLher

9:;<=

0.001 (e.g. ln a lubrlcaLed bearlng under llghL loads)

10 (e.g. when clean meLals rub agalnsL each oLher ln vacuum)

0.1 - 1.0 (mosL -values for slldlng surfaces)

W = normal load

l = frlcuonal force

lrlcuon coemclenL ls dlsplayed as a funcuon of Lhe vlscoslLy muluplled by Lhe

Langenual veloclLy, and dlvlded by Lhe normal load (qu/W)

8ecap: Lhe SLrlbeck curve

ln lubrlcaLed sysLems, Lhe frlcuon coemclenL

changes as a funcuon of speed

A bearlng wanLs Lo be operaLed here!

Close Lo Lhe mlnlmum buL on Lhe rlghL

slde, so LhaL wlLh sllghL changes of Lhe

parameLers, Lhe sysLem ls drawn

Lowards Lhe mlnlmum

Film thickness decreases

Asperity-asperity

contact occurs

Cccurs aL hlgh loads or low speeds

Pydrodynamlc forces can no longer malnLaln a lubrlcanL lm beLween Lhe slldlng

surfaces

ulrecL conLacL beLween Lhe asperlues sLarLs Lo become domlnanL

8oundary lubrlcanL ls essenual under Lhese condluons, ln order Lo avold excesslve frlcuon

and wear

8oundary lubrlcanLs form adsorbed molecular lms on Lhe surfaces (overslmpllcauon)

8epulslve forces beLween Lhe

lms carry a slgnlcanL parL

of Lhe load

8ecap: boundary lubrlcauon

Lxample of boundary lubrlcanL: long-chaln carboxyllc aclds (polar end-groups make a

sLrong bond wlLh Lhe oxlde layer of meLal surfaces)

varlauon of frlcuon coemclenL as a funcuon

of Lhe lubrlcanL chaln lengLh for sLeel

surfaces

lrlcuon coemclenL as a funcuon of chaln

lengLh for hydrocarbons on LungsLen

surfaces

8ecap: boundary lubrlcauon

LxLreme-pressure addluves: molecules LhaL reacL ln exLreme condluons

(e.g. pressure, LemperaLure)

1hey reacL wlLh Lhe surface, produclng a proLecuve layer wlLh low shear sLrengLh

ln exacLly Lhe rlghL place

Some examples: zlnc

dlalkyldlLhlophosphaLe (Znu1), Lrlcresyl

phosphaLe (1C) and dlbenzyl dlsulde

SLrucLure of proLecuve lm

formed by Znu1 on sLeel

8ecap: boundary lubrlcauon

Wear

http://images.google.ch

Low frlcuon,

hlgh wear!

Plgh frlcuon,

low wear!

Whenever surfaces rub agalnsL each oLher, wear almosL always occurs

A slmple analysls ylelds a wear coemclenL k

Assumpuons

- Lhe conLacL beLween Lhe surfaces occurs aL asperlues

- Lhe Lrue conLacL area ls Lhe sum of Lhe lndlvldual asperlLy conLacLs

- Lhe Lrue conLacL area ls proporuonal Lo Lhe normal load

- Lhe local deformauon ls plasuc

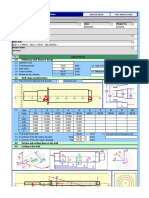

Wear: Lhe Archard equauon

Schemauc dlagram of Lhe formauon of a conLacL area durlng Lhe relauve mouon of

Lwo asperlues

Wear: Lhe Archard equauon

a) b) c) d) e)

c) - Lhe conLacL area becomes maxlmal

- Lhe normal load, supporLed by conLacL area, ls glven by:

d), e) - asperlLy conLacLs supporL Lhe normal load

- conunuous slldlng lnvolves conunuous creauon and desLrucuon of slngle-

asperlLy conLacL areas

p: ow pressure (lndenLauon hardness)

a: radlus of Lhe conLacL area

2

=:8>0

Maxlmal conLacL

area

Slngle asperlLy

real area = apparenL area

AsperlLy conLacLs supporL Lhe

normal load

/!. *## *0-(&1.$ 2!".*2.0 #(*3 .! 4(*& -*&52#(066666

Wear: Lhe Archard equauon

Cause of wear: removal of fragmenLs of maLerlal from Lhe asperlues

volume of removed maLerlal: proporuonal Lo Lhe cube of Lhe conLacL dlmenslon, a

a: radlus of hemlsphere

Assumpuon: noL aLs buL hemlspheres (a hemlsphere geLs rubbed o)

Assumpuon: a proporuon k forms parucles

v: mean wear volume produced by Lhe slldlng of an

asperlLy palr over each oLher

C: LoLal wear raLe, due Lo all asperlLy conLacLs (sum of

all conLrlbuuons over Lhe LoLal conLacL area)

Wear: Lhe Archard equauon

W: LoLal normal load

C: wear raLe (worn volume per unlL slldlng dlsLance)

k = k/3 (wear coemclenL)

P = p (lndenLauon hardness)

%7( ,&27*&3 (8'*5!"

- k ls dlmenslonless and < 1

- k/P ls used when hardness ls noL easlly denable

- k/P = quanuLy of worn maLerlal/unlL slldlng dlsLance/unlL normal load (e.g. mm

3

m

-1

n

-1

)

Wear raLe ls lndependenL of

Slldlng speed

ApparenL conLacL area

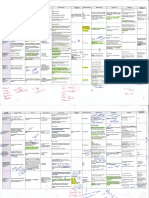

Wear: Lhe Archard equauon

ln wear volume over Lhe enure slldlng dlsLance ln an unlubrlcaLed pln-on-rlng

LesL, slldlng on Lool sLeel

CharacLerlsucs of Lhe maLerlals

under sLeady-sLaLe condluons

Surfaces musL oen be run-ln"

before Lhls behavlor can be

observed

Wear: Lhe Archard equauon

values of Lhe dlmenslonless wear coemclenL k for varlous maLerlals slldlng on Lool

sLeel, obLalned ln an unlubrlcaLed pln-on-rlng LesL ln alr

9*.(&1*# :#131"; -*&."(& <(*& 2!(=21(".0> ?

mlld sLeel Mlld sLeel 7!10

-3

a/b 8rass 1ool sLeel 6!10

-4

1lL 1ool sLeel 2.3!10

-3

a 8rass 1ool sLeel 1.7!10

-4

MMA 1ool sLeel 7!10

-6

copper-berylllum 1ool sLeel 3.7!10

-3

hardened Lool sLeel 1ool sLeel 1.3!10

-4

SLelllLe 1 1ool sLeel 3.3!10

-3

sLalnless sLeel (ferrluc) 1ool sLeel 1.7!10

-3

L 1ool sLeel 1.3!10

-7

1he values are hlghly dependenL on LesL condluons and Lhus provlde llule lnslghL

lnLo Lhe wear mechanlsms lnvolved

Mlld and severe wear

Wear and elecLrlcal

conLacL reslsLance for a

pln made from "/#

brass slldlng on

hardened sLelllLe (Co

alloy) as a funcuon of

Lhe normal load

oxlde-oxlde

Pexadecane used as a

lubrlcanL, buL noL under

hydrodynamlc condluons

meLal-meLal

blgger parucles

ne slze parucles

wearlng Lhrough Lhe oxlde layer

,&27*&3

(8'*5!"

7!#30

<(*& &*.(

1"2&(*0(0

,&27*&3

(8'*5!"

7!#30

Mlld and severe wear

oxlde-oxlde

meLal-meLal

blgger parucles

ne slze parucles

ConLacL reslsLance decreases unul

meLal-meLal conLacL ls reached

@&!- 1" (#(2.&12*#

&(010.*"2(

A7*";( 1" 2!#!& *"3

01B( !C 4(*& -*&52#(0

9DE@

<F,G

:FHFGF <F,G

%

G

,

/

:

D

%

D

I

/

ulerenL color because

now meLal parucles and no

longer oxlde

Mlld wear: 0.01-1 m

parucles, mosLly oxldes

Severe wear: 20-200 m

parucles, mosLly meLalllc

Mlld and severe wear

The mechanism of the transition is confirmed by the following results

Variation of wear coefficient with sliding speed for "/# brass sliding on steel at

various temperatures and environments

1ypes of wear

Adheslve

Abraslve

Surface laugue

Lroslve

Corroslve

1ypes of wear: adheslve

Adhesion result of the direct contact of bearing metals

Applied load is sufficient to rupture any protective surface film (oxides, etc.)

Contacting asperities deform elastically

Contacting asperities deform plastically

Shearing of adhesive junctions produces wear particles

Metal is transferred from one bearing surface to the other in sliding or rolling motion

Scuffing severe adhesive-wear damage

1ypes of wear: adheslve

www.machinerylubrication.com

Process of adhesive wear

The factors decreasing adhesive wear:

Lower load

Harder rubbing materials

Contaminated rubbing surfaces

Presence of solid lubricants

Presence of a lubricating oil

Anti-wear additives in oil

1ypes of wear: abraslve

A harder maLerlal ls rubblng agalnsL a soer maLerlal

1he wear of Lhe

soer maLerlal ls

caused by Lhe

asperlues on Lhe

harder surface

1wo rubblng parLs lnvolved ln Lhe

frlcuon process

1wo-body wear

A hard parucle ls Lrapped

beLween Lhe rubblng surfaces

1hree-body wear

1he parucle ls free

or parually

embedded lnLo

one of Lhe

maLerlals

1ypes of wear: abraslve

,J&*01K( 4(*& !" .7( L12&!M#(K(#

- lasuc deformauon

N#!';71";

- no maLerlal removal from Lhe wearlng

surface

- Wear mechanlsm ls parLly governed by plasuc deformauon

A'O";

- 1he abraslve parucle acLs as a cumng Lool

- Cccurs when hlghly concenLraLed sLresses are lmposed by

abraslve parucles

A&*2P1"; QJ&1R#( C&*2.'&(S

- Large wear fragmenLs are deLached from Lhe wearlng surface

- 1he volume of Lhe losL maLerlal ls hlgher Lhan Lhe volume of

Lhe wear Lrack

u

u

c

u

l

e

m

a

L

e

r

l

a

l

s

8

r

l

u

l

e

m

a

L

e

r

l

a

l

s

Surface faugue

Caused by cycllng loadlng durlng frlcuon

laugue occurs lf Lhe applled load ls

hlgher Lhan Lhe faugue sLrengLh of

Lhe maLerlal

laugue cracks sLarL aL Lhe maLerlal surface and

spread Lo Lhe subsurface reglons

1he cracks may connecL Lo each oLher

resulung ln separauon and

delamlnauon of Lhe maLerlal pleces

T&(O"; 4(*&

caused by cycllc slldlng of Lwo

surfaces across each oLher wlLh a

small ampllLude. 1he frlcuon force

produces alLernaung compresslon-

Lenslon sLresses, whlch resulL ln

surface faugue

F&!01K(: caused by lmplngemenL of parucles (solld, llquld or gaseous)

1hey remove fragmenLs of maLerlals from Lhe surface due Lo a momenLum eecL

1ypes of wear: eroslve and corroslve

A!&&!01K(: corroslon can acceleraLe wear

Cxldauon process promoLed by lncreased LemperaLure and removal of Lhe

proLecung oxlde lms from Lhe surface durlng Lhe frlcuon

Slldlng conunuous removal of Lhe oxlde lm followed by conunuous

formauon of new oxlde lm

Pard oxlde parucles removed from Lhe surface and Lrapped beLween Lhe slldlng/

rolllng surfaces Lhree-body abraslve wear mechanlsm

SLages of wear

U("(&*#1B(3 -*R(&" !C 4(*& -&!2(00

1he lnlual

wear raLe

(run-ln) ls

relauvely

hlgh

Wear occurs aL a

negllglble raLe

SumclenL debrls

has

acccumulaLed,

leadlng Lo fallure

Wear takes place even in properly

lubricated mechanisms

SLages of wear

/!&L*# 4(*&V beglns when Lhe Lrue area of bearlng conLacL (LoLal asperlLy-conLacL

area) has been subsLanually lncreased by plasuc deformauon and wear Lhe

lubrlcanL ls fully able Lo supporL Lhe load

- Cnly occaslonal meLal-Lo-meLal conLacLs

- Wear occurs aL a negllglble raLe (excepL for evenLs such as lubrlcanL

breakdown, sudden rlses ln LemperaLure shock loads, slgnlcanL reducuon ln

speed)

- normal wear may proceed lndenlLely, unul sumclenL debrls has accumulaLed Lo

cause one of Lhe followlng fallure modes

D"15*# 4(*& &*.(: mlcroscoplc surface asperlues peneLraLe Lhe lubrlcanL lm,

parucularly durlng Lhe low speeds of sLarL-up and shuL-down

T*1#'&(:

- SLress rlsers ln Lhe paLh of mouon, ulumaLely lnluaung faugue

- Abraslve wear changes surface roughness or dlmenslons appreclably

- hyslcal blockage

Vous aimerez peut-être aussi

- Discrete Element Method to Model 3D Continuous MaterialsD'EverandDiscrete Element Method to Model 3D Continuous MaterialsPas encore d'évaluation

- Young's ModulusDocument7 pagesYoung's ModulusNgatno100% (1)

- Self-Cleaning Filters Manual & Automatic GuideDocument4 pagesSelf-Cleaning Filters Manual & Automatic Guidedevang asher100% (1)

- Sensor Devices Mechanical SensorsDocument41 pagesSensor Devices Mechanical Sensorsdesaivilas60100% (1)

- VFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedDocument5 pagesVFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedelengineerPas encore d'évaluation

- Lecture 5 - Power SuppliesDocument48 pagesLecture 5 - Power SuppliesNimsiri AbhayasinghePas encore d'évaluation

- Preconstruction MeetingDocument32 pagesPreconstruction MeetingMar OlacsPas encore d'évaluation

- Document'S Code Attachment 10.3 Revision 0: ClientDocument4 pagesDocument'S Code Attachment 10.3 Revision 0: ClientrfriosEP100% (1)

- 722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)Document16 pages722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)rianafrian2611Pas encore d'évaluation

- Spray-Type Deaerating Heaters: TABLE 12.2Document2 pagesSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiPas encore d'évaluation

- Pivot PinDocument1 pagePivot Pinsourajpatel001100% (1)

- Design-Iv: Machinery and Electrical System Technical Spesification of Bilge SystemDocument44 pagesDesign-Iv: Machinery and Electrical System Technical Spesification of Bilge SystemMohammad Ibnu SabilillahPas encore d'évaluation

- SAE Steel Grades: Steels and Other Iron-Carbon Alloy PhasesDocument10 pagesSAE Steel Grades: Steels and Other Iron-Carbon Alloy PhasesCalcgen EngineeringPas encore d'évaluation

- WL705 Ultrasonic Water Level SensorDocument1 pageWL705 Ultrasonic Water Level SensorEdward YaoPas encore d'évaluation

- L9 Fastening SystemDocument6 pagesL9 Fastening Systemcontact@coreeslPas encore d'évaluation

- Schneider GV2 Motor Circuit BreakerDocument19 pagesSchneider GV2 Motor Circuit BreakercatalinccPas encore d'évaluation

- Design and Implementation of Liquid Level Detector Using Ultrasonic SensorDocument6 pagesDesign and Implementation of Liquid Level Detector Using Ultrasonic SensorInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Technological Institute of The PhilippinesDocument25 pagesTechnological Institute of The PhilippinesJohn Leonard FazPas encore d'évaluation

- Conical Base Cylindrical PE Tanks SpecsDocument4 pagesConical Base Cylindrical PE Tanks SpecsAmoolia Ngo0% (1)

- Catalogo Geral 2013 SchneiderDocument216 pagesCatalogo Geral 2013 SchneiderGersel RodriguesPas encore d'évaluation

- Sizing a Reciprocating Compressor for Natural Gas ServiceDocument6 pagesSizing a Reciprocating Compressor for Natural Gas ServiceNikhil Ashok Badgu100% (1)

- Welcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesDocument10 pagesWelcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesMarcelo MoraisPas encore d'évaluation

- Optional straight sidebar caterpillar drive chainDocument1 pageOptional straight sidebar caterpillar drive chainFernando Mendoza0% (1)

- Meta MEC Adjustable MCCBDocument16 pagesMeta MEC Adjustable MCCBECATOnlinePas encore d'évaluation

- Topic 1 - Mechanical Fastening 2Document11 pagesTopic 1 - Mechanical Fastening 2nazirulhakimPas encore d'évaluation

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- Piping Plans Poster - Flex - A - Seal PDFDocument1 pagePiping Plans Poster - Flex - A - Seal PDFAnatoli KarpobPas encore d'évaluation

- Materials Handling and HoistingDocument6 pagesMaterials Handling and HoistingNARGISPas encore d'évaluation

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraPas encore d'évaluation

- Teaching PLC Chap3Document39 pagesTeaching PLC Chap3bhagirath kansaraPas encore d'évaluation

- SCFM Vs ACFM Conversion Guide PDFDocument16 pagesSCFM Vs ACFM Conversion Guide PDFasteriskinPas encore d'évaluation

- Metal Joining Methods and Hand ToolsDocument28 pagesMetal Joining Methods and Hand ToolsLinda FondoPas encore d'évaluation

- UsingFusestoIncreaseSCCR PDFDocument16 pagesUsingFusestoIncreaseSCCR PDFKalpesh SinghPas encore d'évaluation

- Main Pivot Pin Diameter CalculationDocument2 pagesMain Pivot Pin Diameter Calculationjdutia83100% (1)

- Centrifugal Pump Temperature Rise CalculationDocument1 pageCentrifugal Pump Temperature Rise CalculationJohn PacelloPas encore d'évaluation

- Shaft Stress CalculationsDocument2 pagesShaft Stress CalculationsVivek PrajapatiPas encore d'évaluation

- Ccs CatalogDocument35 pagesCcs CatalogRicardo Betancourt MaldonadoPas encore d'évaluation

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaPas encore d'évaluation

- Coating - PaintsDocument76 pagesCoating - Paintsjeo TinioPas encore d'évaluation

- Section Modulus - of BeamDocument15 pagesSection Modulus - of BeamArif RusyanaPas encore d'évaluation

- Calculate Exhaust Capacity for PEB AreaDocument2 pagesCalculate Exhaust Capacity for PEB AreaAkhtar BahramPas encore d'évaluation

- DESIGN DATA FOR COOLING AND HEATING LOAD ESTIMATIONDocument5 pagesDESIGN DATA FOR COOLING AND HEATING LOAD ESTIMATIONFarzin ShahabPas encore d'évaluation

- Large Size Conveyor ChainDocument156 pagesLarge Size Conveyor ChainManatchaiSanPas encore d'évaluation

- Water Level SensorDocument4 pagesWater Level SensorJohn Gary Recto VillanuevaPas encore d'évaluation

- Dynamic Pressure For Circular Silos Under Seismic ForceDocument10 pagesDynamic Pressure For Circular Silos Under Seismic Forcesebastian9033Pas encore d'évaluation

- Case Study On Comparison of Wireless Technologies in Industrial ApplicationsDocument4 pagesCase Study On Comparison of Wireless Technologies in Industrial ApplicationsM PATHANPas encore d'évaluation

- Lecture 8 Shaft DesignDocument65 pagesLecture 8 Shaft DesignYasir A. Al-ShataifPas encore d'évaluation

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542Pas encore d'évaluation

- Buoyancy and Stability of Floating ObjectDocument12 pagesBuoyancy and Stability of Floating ObjectLorraine TalattadPas encore d'évaluation

- Overhead Conveyor Products PDFDocument16 pagesOverhead Conveyor Products PDFPierre Hopkins100% (1)

- Time To Empty Out Vessel No Dished EndsDocument2 pagesTime To Empty Out Vessel No Dished EndsHeiner PalaciosPas encore d'évaluation

- Ellipsoidal Flange to Circular Conversion DimensionsDocument3 pagesEllipsoidal Flange to Circular Conversion Dimensionsnaveenkumar_madasettPas encore d'évaluation

- Pipe Weight Formulas & TablesDocument12 pagesPipe Weight Formulas & TablesuzairmetallurgistPas encore d'évaluation

- Rotary Airlock Valve Design Data SheetDocument2 pagesRotary Airlock Valve Design Data SheetMohan BabuPas encore d'évaluation

- How Long Will A Bearing Last? Standardized Life Equations Help To AnswerDocument3 pagesHow Long Will A Bearing Last? Standardized Life Equations Help To AnswervijaykhandgePas encore d'évaluation

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengPas encore d'évaluation

- MItcal - Ejemplo de ClaseDocument102 pagesMItcal - Ejemplo de ClasedaagiraldogoPas encore d'évaluation

- Shear design of hollow core slabs using modified compression field theoryDocument17 pagesShear design of hollow core slabs using modified compression field theoryjrandeepPas encore d'évaluation

- Plate Loads CalculationDocument2 pagesPlate Loads CalculationarabindaPas encore d'évaluation

- Pneumatic control valve sizing guideDocument1 pagePneumatic control valve sizing guideJOSE MARTIN MORA RIVEROSPas encore d'évaluation

- API 571 Chart - Marked - ScanDocument10 pagesAPI 571 Chart - Marked - ScanKunal Pandey100% (1)

- IS.1154.2000 - Soft Film Solvent Deposited Water Displacing TypeDocument15 pagesIS.1154.2000 - Soft Film Solvent Deposited Water Displacing TypeKunal PandeyPas encore d'évaluation

- API 571 Important Questions and Notes - ScanDocument14 pagesAPI 571 Important Questions and Notes - ScanKunal Pandey100% (1)

- API-571 Mechanism ChartDocument1 pageAPI-571 Mechanism ChartKunal PandeyPas encore d'évaluation

- ASTM A29 Standard Specification Steel Bars Carbon and Alloy Hot Wrought General RequirementsDocument16 pagesASTM A29 Standard Specification Steel Bars Carbon and Alloy Hot Wrought General RequirementsAndrés Molina100% (2)

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocument28 pagesIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiPas encore d'évaluation

- API 580 Practice Questions 04 (190 Questions)Document1 pageAPI 580 Practice Questions 04 (190 Questions)Kunal PandeyPas encore d'évaluation

- Corcon 2022Document1 pageCorcon 2022Kunal PandeyPas encore d'évaluation

- Corrosion Preventives: Surface TreatmentDocument5 pagesCorrosion Preventives: Surface TreatmentvaishutholPas encore d'évaluation

- Stellite 1 DS01-22008 (S R0808)Document2 pagesStellite 1 DS01-22008 (S R0808)Kunal PandeyPas encore d'évaluation

- Free Machining Steel BrochureDocument4 pagesFree Machining Steel BrochureKunal PandeyPas encore d'évaluation

- H 13 Die FailureDocument25 pagesH 13 Die FailureKunal PandeyPas encore d'évaluation

- Comparitive Study of SGI & GCIDocument3 pagesComparitive Study of SGI & GCIKunal Pandey100% (1)

- Councillor Danny Thorpe: Leader, Royal Borough of GreenwichDocument2 pagesCouncillor Danny Thorpe: Leader, Royal Borough of GreenwichDr-Syed Ali TarekPas encore d'évaluation

- Study To Assess The Effectiveness of Planned Teaching Programme Regarding Knowledge of Traffic Rules Among Higher Secondary Students 15 18 Years in Selected Schools of DehradunDocument14 pagesStudy To Assess The Effectiveness of Planned Teaching Programme Regarding Knowledge of Traffic Rules Among Higher Secondary Students 15 18 Years in Selected Schools of DehradunEditor IJTSRDPas encore d'évaluation

- A Presentation On Kit KatDocument9 pagesA Presentation On Kit KatRaju DoleyPas encore d'évaluation

- Aloe Vera as an Alternative Treatment for Wound HealingDocument5 pagesAloe Vera as an Alternative Treatment for Wound HealingJeffllanoPas encore d'évaluation

- FAO Shrimp Culture - Pond Design, Operation and ManagementDocument53 pagesFAO Shrimp Culture - Pond Design, Operation and Managementfanuskhan80% (5)

- RC14001® & RCMS®: Your Guide To Implementing A Responsible Care® Management SystemDocument4 pagesRC14001® & RCMS®: Your Guide To Implementing A Responsible Care® Management SystemMohammed MehranPas encore d'évaluation

- Catalogue of DDSY23S Energy Meter: Smart Metering and System Solution ProviderDocument2 pagesCatalogue of DDSY23S Energy Meter: Smart Metering and System Solution ProviderNadine MichaelsPas encore d'évaluation

- Spxflow PDFDocument317 pagesSpxflow PDFAnonymous q2iHVf100% (3)

- Dasar Genetik GandumDocument282 pagesDasar Genetik GandumAlekkyPas encore d'évaluation

- SBR2018 - AbstractsDocument115 pagesSBR2018 - AbstractsGustavo ResendePas encore d'évaluation

- Psychological Aspects of Stress and Adaptation - AmolDocument12 pagesPsychological Aspects of Stress and Adaptation - Amoldanimon1984Pas encore d'évaluation

- Samsung Un40c5000 Un46c5000 QF Chassis N98aDocument114 pagesSamsung Un40c5000 Un46c5000 QF Chassis N98ajosue otonielPas encore d'évaluation

- Grade 8 Science Activity 1 Quarter 4Document8 pagesGrade 8 Science Activity 1 Quarter 4yoshirabul100% (2)

- Reglas para Añadir Al Verbo Principal: Am Is Are ReadDocument8 pagesReglas para Añadir Al Verbo Principal: Am Is Are ReadBrandon Sneider Garcia AriasPas encore d'évaluation

- Soil Loss EstimationDocument77 pagesSoil Loss Estimationmys85Pas encore d'évaluation

- CIVIL BILL OF QUANTITIESDocument16 pagesCIVIL BILL OF QUANTITIESTomPas encore d'évaluation

- Observations of Children's Interactions With Teachers, PeersDocument25 pagesObservations of Children's Interactions With Teachers, PeersMazlinaPas encore d'évaluation

- GSR (ROAD) 2015Document74 pagesGSR (ROAD) 2015Gautam RaiPas encore d'évaluation

- Cooling & Heating: ShellmaxDocument3 pagesCooling & Heating: Shellmaxvijaysirsat2007Pas encore d'évaluation

- SEAS Scoliosis Course NYC Feb 2018Document4 pagesSEAS Scoliosis Course NYC Feb 2018BorislavPas encore d'évaluation

- D 2144 - 01 - RdixndqDocument4 pagesD 2144 - 01 - RdixndqjayakumarPas encore d'évaluation

- Caffeine's Effect on Daphnia Heart RateDocument2 pagesCaffeine's Effect on Daphnia Heart RateMianto NamikazePas encore d'évaluation

- Science 9 Worksheet Week 5Document4 pagesScience 9 Worksheet Week 5Jaybie TejadaPas encore d'évaluation

- MEO Orals On Marine Electro Technology Function 5Document19 pagesMEO Orals On Marine Electro Technology Function 5Rajeev ValunjkarPas encore d'évaluation

- Deck Damage and Penetrations: Prepared by Richard B. Heagler, P.EDocument9 pagesDeck Damage and Penetrations: Prepared by Richard B. Heagler, P.ENelzon MamaniPas encore d'évaluation

- wk4 Stdconferencereflection ElmoreajaDocument4 pageswk4 Stdconferencereflection Elmoreajaapi-316378224Pas encore d'évaluation

- Bio Project-Polymerase Chain ReactionDocument21 pagesBio Project-Polymerase Chain ReactionS.AbiniveshPas encore d'évaluation

- Grade 6 School Lesson on Propagating Trees and Fruit TreesDocument10 pagesGrade 6 School Lesson on Propagating Trees and Fruit TreesGhrazy Ganabol LeonardoPas encore d'évaluation

- Final Final PosterDocument1 pageFinal Final Posterapi-486056653Pas encore d'évaluation

- Epreuve LV 2 Anglais Premiere L Composition 2e Semestre 2023Document2 pagesEpreuve LV 2 Anglais Premiere L Composition 2e Semestre 2023Thierno ousmane DialloPas encore d'évaluation