Académique Documents

Professionnel Documents

Culture Documents

FlangeCalculationASMEVIII Version5

Transféré par

alvinchuanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FlangeCalculationASMEVIII Version5

Transféré par

alvinchuanDroits d'auteur :

Formats disponibles

file spec.: c:\users\chuan kwee choong\documents\flange calaculation\[flangecalculationasmeviii-version5.xls]materialsheet -- printed 2014.8.

7/14:55

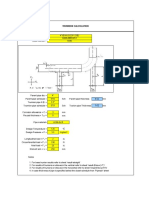

Flange Calculation sheet

Doc No Sheet

1/3

Bolted flange connections to ASME VIII, div. 2 Appendix 2 Rev. Date Made Check Appr.

Client Tag No

Project

Job No.

Location A 2014.08.07 MP

Design Basis

Design Code:

ASME Boiler & Pressure Vessel Code - section VIII, Division 1, Appendix 2

Units of calculation

Input Data

Variable Notes

Flange and Flange facing

Pipe Data Nominal Pipe Size

Pipe Schedule

Flange Pressure Rating

Pipe OD (actual)

Pipe wall thickness (Uncorroded)

Length of flange hub

Flange thickness

Bolt circle diameter

Hub Diameter (Largest)

Flange outside diameter

Bolts Bolt Standard

Bolt Size (Specify M-Type , ISO)=

Number of Bolts=

Bolt Root Area (per bolt)

Gasket Gasket Type

Gasket diameter , MEAN(RTJ)/OD(RF):

Gasket contact width w(RTJ) or N(RF)

Min. design seating stress

Gasket factor

Design Design Pressure

Conditions Design Temperature

Corrosion Allowance

External Axial Force (strain)

Loads Moment

Moment

Moment

Orientation of flange

Stresses Material

At design temperature

At ambient

Material

At design temperature

At ambient

E Modulus

Conclusion

######

#DIV/0!

Max. operating pressure before failure of flange or bolting is

#DIV/0!

#DIV/0!

#####

Mogens Pedersen - all rights reserved

#VALUE!

Imperial

Source of data Input

NPD

PCD

X

A

OD

pipe

tn

h

t

Bolting

M

x

M

y

M

z

x,y,z

d

bolt

n

bolt

A

bolt

t

max

ca

Faxial

w or N

y

m

Sa

Sb

Flange

Flange

Sf_oper

Sf_atm

P

c:\winapps\excel\xlstartFlangeCalculationASMEVIII-Version5.xls Page 1of 3 MogensPedersen/ 7/8/2014/ 2:56PM

file spec.: c:\users\chuan kwee choong\documents\flange calaculation\[flangecalculationasmeviii-version5.xls]materialsheet -- printed 2014.8.7/14:55 file spec.:

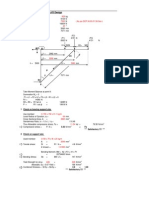

Flange Calculation sheet

Doc No Sheet

2/3

Bolted flange connections to ASME VIII, div. 2 Appendix 2 Bolted fla

Calculations

Gasket key dimensions

Gasket outside diameter 0.000 in SUMMAR

Basic gasket seating width b

0

= N/2 or w / 8 (RF or RTJ) Table 2-5-2 0.000 in

Effective gasket seating width b=b

0

for b

0

< 1/4" Operatin

or b = 0.5(or 2.52 for metric) * (b

0

)

0.5

for b

0

> 1/4" Table 2-5-2 0.000 in Longitudi

Gasket load reaction diameter G = mean gasket diameter for b

0

< 1/4" Radial Fla

or G = Gasket OD - 2*b for b

0

> 1/4" 0.000 in Tangentia

Flange values Combine

Thickness of hub at small end g

0

= t

n

- ca = 0.000 in Bolt Stres

Thickness of hub at back of flange g

1

= (X-B)/2 = 0.000 in Seating

Radial dist. from PCD to large hub diam. R = (PCD-X)/2 = 0.000 in Longitudi

Inside diameter of flange B (Corroded ID) = OD

pipe

- 2 * g

0

= 0.000 in Radial Fla

Tangentia

Equivalent Working Pressure using Kellogs Method Combine

Resulting Bending Moment Mres = No external Forces Specified 000 lb-in Bolt Stres

Equivalent Pressure Peq = 16 * M

res

/ ( * G

3

) + 4 * Faxial / ( * G

2

) #DIV/0!

Calculation Design Pressure P

d

= P + P

eq

#DIV/0!

REVERS

Load and Bolt Calculations m

0

values

Total joint-contact surface compression load Hp = 2 * b * * G * m * P

d

= #DIV/0! Longitudi

Total hydrostatic end force H = / 4 * G

2

* P

d

= #DIV/0! Radial Fla

Min. required bolting load for operating conditions Wm1 = Hp+H = #DIV/0! Tangentia

Min. required bolting load for gasket seating Wm2 = * b * G * y = 0 lb Combine

Total required cross-sectional area of bolts Am = greater of Wm1/Sb or Wm2/Sa = #DIV/0!

Total available cross-sectional area of bolts A

bolts

= 0.00 in Select mi

Flange design bolt load W = 0.5 * ( Am + A

bolts

) * Sa = #DIV/0! Max flang

Required bolt rootdiameter= = ( 4 * A

m

/ ( n

bolt

* ) )

0.5

#DIV/0! Max oper

Flange Moment Calculations Bolting

Flange Loads Lever arm Flange Moments

Operating Conditions

H

D

= / 4 * B

2

* P

d

= #DIV/0! hD = R + 0.5 * g1 = 0.00 in M

D

= H

D

* hD = #DIV/0! BLIND FL

H

G

= H

p

= #DIV/0! hG = 0.5 * ( PCD - G) = 0.00 in M

G

= H

G

* hG = #DIV/0! Minimum

H

T

= H - H

D

= #DIV/0! hT = 0.5 * ( R+g1+h

G

) = 0.00 in M

T

= H

T

* hT = #DIV/0! (Operatin

M

0 oper

= M

D

+ M

G

+ M

T

= #DIV/0!

Seating Conditions Minimum

H

G

= W = #DIV/0! h

G

= 0.00 in M

0 atm

= #DIV/0! (Seating -

Bolt Spacing= = PCD * SIN( / n

bolt

) #DIV/0! Max pres

Bolt pitch correction factor CF = [bolt_spacing / (2 * d

bolt

+ 6 * t / ( m + 0.5))]

0.5

(or minimum 1.0) #DIV/0! Operating

Flange Factors from fig. 2-7.1 Flange factors involving H/H_0 or g1/g0 Stress formula factors

K =A / B #DIV/0! h

0

= (B * go)

0,5

0.000 in = t * e +1 #VALUE!

T #DIV/0! h / h

0

#DIV/0! =

4

/

3

* e * t+1 #VALUE! Flange R

U #DIV/0! g

1

/ g

0

#DIV/0! = / T #VALUE!

Y #DIV/0! F #VALUE! = t

3

/ d #DIV/0! Rigidity in

Z #DIV/0! V #VALUE! = + #VALUE!

f #VALUE! m0 =CF * M

0 oper

/ B #DIV/0!

e = F / ho #VALUE! mG =CF*M

0 atm

/ B #DIV/0! Please c

Poisson's Ratio Assumed = 0.3 d = U / V * h

0

* g

0

2

#DIV/0!

Mogens Pedersen - all rights reserved

c:\winapps\excel\xlstartFlangeCalculationASMEVIII-Version5.xls Page 2of 3 MogensPedersen/ 7/8/2014/ 2:56PM

c:\users\chuan kwee choong\documents\flange calaculation\[flangecalculationasmeviii-version5.xls]materialsheet -- printed 2014.8.7/14:55

Flange Calculation sheet

Doc No Sheet

3/3

ange connections to ASME VIII, div. 2 Appendix 2

Calculations

RY OF STRESSES:

Calculated Allowable Accept

ng

nal Hub Stress: S

H

=f * m

0

/ ( * g

1

2

) = #VALUE! 1.5 * S

f oper

= 0 psi #VALUE!

ange Stress: S

R

= * m

0

/ ( * t

2

) = #VALUE! S

f oper

= 0 psi #VALUE!

al Flange Stress: S

T

= m

0

* Y / ( t

2

) - Z * S

R

= #DIV/0! S

f oper

= 0 psi #DIV/0!

d Stress: greater of (S

H

+S

R

) / 2 or (S

H

+S

T

) / 2 = #VALUE! S

f oper

= 0 psi #VALUE!

ss W

m1

/ A

bolts

#DIV/0! S

b

0 psi #DIV/0!

nal Hub Stress: S

H

= f * m

G

/ ( *g

1

2

) = #VALUE! 1.5 * S

f atm

= 0 psi #VALUE!

ange Stress: S

R

= * m

G

/ ( * t

2

) = #VALUE! S

f atm

= 0 psi #VALUE!

al Flange Stress: S

T

= m

G

* Y / ( t

2

) - Z * S

R

= #DIV/0! S

f atm

= 0 psi #DIV/0!

d Stress: greater of (S

H

+S

R

) / 2 or (S

H

+S

T

) / 2 = #VALUE! S

f atm

= 0 psi #VALUE!

ss W

m2

/ A

bolts

#DIV/0! S

a

0 psi #DIV/0!

SE CALCULATION - max operating pressure

s due to allowable stresses

nal Hub Stress: m

01

= * g

1

2

* 1.5 * S

f oper

/ f = #VALUE!

ange Stress: m

02

= * t

2

* S

f oper

/ = #VALUE!

al Flange Stress: m

03

= * t

2

* S

f oper

/ ( * Y- * Z ) = #VALUE!

d Stress: largest of m

04

= 2 * S

f oper

/ ( f / ( * g

1

2

) + Y / t

2

+ / ( * t

2

) ) = #VALUE!

m

04

= 2 * S

f oper

/ ( f / ( * g

1

2

) + / ( * t

2

) ) = #VALUE!

in. m

01

to m

04

m

0

= #VALUE!

ge moment M

0

= = m

0

* B / C

F

= #VALUE!

rating pressure P=

= 8 * M0 / [ * (B

2

* ( PCD - (X + B) / 2) + 8 * b * G * m * (PCD - G) + (G

2

- B2) * (PCD - (G + B)/ 2))] = #VALUE!

P= = A

bolts

* S

b

/ ( * ( 2 * b * m * G + 0.25 * G

2

) ) = #DIV/0!

LANGE THICKNESS CALCULATION: (3.5.5)

thickness of flange

ng - W=Wm1) e

oper

= ( 0.3 * G

2

* P / ( S

f oper

) + 1.909 * W

m1

* h

G

/ ( S

f oper

* G ) )

0.5

+ ca #DIV/0!

thickness of flange

- P=0) e

oper

= ( 0.3 * G

2

* P / ( S

f oper

) + 1.909 * W * h

G

/ ( S

f oper

* G ) )

0.5

+ ca #DIV/0!

ssure for actual thickness

g p

max

= (e - ca )

2

* S

f oper

/ ( 0.3 * G

2

+ 1.909 * * h

G

* (2 * b * m + 0.25 * G )) #DIV/0!

Rigidity Check (According to Appendix S)

ndex J = 52.14 * M

0 oper

* V / ( * Emod * G

0

2

* h

0

* 0.3) = #DIV/0! #DIV/0!

heck that correct input value is used for E-Modulus - (N/mm2)

Mogens Pedersen - all rights reserved

{

c:\winapps\excel\xlstartFlangeCalculationASMEVIII-Version5.xls Page 3of 3 MogensPedersen/ 7/8/2014/ 2:56PM

Vous aimerez peut-être aussi

- Wind Calculation SheetDocument32 pagesWind Calculation SheetaauppalPas encore d'évaluation

- FlangeCalculationASMEVIII Version5Document13 pagesFlangeCalculationASMEVIII Version5madodandembe100% (3)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyPas encore d'évaluation

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliPas encore d'évaluation

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Spherical Shells en 13445-3 - 7.4.3Document3 pagesSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SPas encore d'évaluation

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcPas encore d'évaluation

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriPas encore d'évaluation

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsPas encore d'évaluation

- Dennis R Moss 4th EditionDocument5 pagesDennis R Moss 4th Editionsenthil kumarPas encore d'évaluation

- Weld Neck Flange Design - As Per Denis MorisDocument2 pagesWeld Neck Flange Design - As Per Denis Morissouren1975Pas encore d'évaluation

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziPas encore d'évaluation

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaPas encore d'évaluation

- Mech. Design CalculationDocument182 pagesMech. Design CalculationSajad AbdulPas encore d'évaluation

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayPas encore d'évaluation

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyPas encore d'évaluation

- Rules For Classification: ShipsDocument23 pagesRules For Classification: ShipsMuhammad Nurazim100% (1)

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlPas encore d'évaluation

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenPas encore d'évaluation

- Horizontal Vessel Support: Vertical Saddle ReactionsDocument12 pagesHorizontal Vessel Support: Vertical Saddle ReactionsSanket BhaleraoPas encore d'évaluation

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Calculation of RC PAD2Document1 pageCalculation of RC PAD2m 418Pas encore d'évaluation

- Check 18Document6 pagesCheck 18Anonymous qBwHKusPas encore d'évaluation

- Flat Ends Welded Directly To The ShellDocument9 pagesFlat Ends Welded Directly To The ShellEng-CalculationsPas encore d'évaluation

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcPas encore d'évaluation

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomPas encore d'évaluation

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyPas encore d'évaluation

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyPas encore d'évaluation

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiPas encore d'évaluation

- Flat Ends With A Hub For Uniform Thickness ShellDocument5 pagesFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsPas encore d'évaluation

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyPas encore d'évaluation

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag0% (1)

- PVElite RefDocument6 pagesPVElite RefakhilPas encore d'évaluation

- Flange Check Bolt Tightening - WRC 538Document3 pagesFlange Check Bolt Tightening - WRC 538Sourendra DeyPas encore d'évaluation

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsPas encore d'évaluation

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalPas encore d'évaluation

- Stiffener Check For Pipe SupportDocument5 pagesStiffener Check For Pipe SupportSai Sushank100% (1)

- Flat Ends With A Relief GrooveDocument11 pagesFlat Ends With A Relief GrooveEng-CalculationsPas encore d'évaluation

- Cylindrical ShellsDocument3 pagesCylindrical ShellsEng-CalculationsPas encore d'évaluation

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TPas encore d'évaluation

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhoblePas encore d'évaluation

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)amaPas encore d'évaluation

- Platform - Bracing SupportDocument12 pagesPlatform - Bracing Supportpandiangv100% (1)

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaPas encore d'évaluation

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniPas encore d'évaluation

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Document4 pagesBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- CS-150-2c3 - Pulled Bend Min THKDocument1 pageCS-150-2c3 - Pulled Bend Min THKJoanna NewtonPas encore d'évaluation

- WRC Loadings and Sign ConventionDocument9 pagesWRC Loadings and Sign ConventionGovindan KrishnamoorthybashyamPas encore d'évaluation

- New PA Column - THK CalcDocument8 pagesNew PA Column - THK CalcSabariMechyPas encore d'évaluation

- FlangeDocument12 pagesFlangeGabriel RodríguezPas encore d'évaluation

- Flange KOD Vessel Calculation - Actual ConditionDocument21 pagesFlange KOD Vessel Calculation - Actual ConditionPeter PerezPas encore d'évaluation

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezPas encore d'évaluation

- Flange Asme ViiiDocument21 pagesFlange Asme Viiizahidwahla1Pas encore d'évaluation

- Mass BalanceDocument4 pagesMass BalancealvinchuanPas encore d'évaluation

- Extracts of SS636Document2 pagesExtracts of SS636alvinchuanPas encore d'évaluation

- Relative Discharging Power of Pipe LineDocument1 pageRelative Discharging Power of Pipe LinealvinchuanPas encore d'évaluation

- DD - 22 Floatation of Circular PipeDocument6 pagesDD - 22 Floatation of Circular PipealvinchuanPas encore d'évaluation

- Solve Differential EquationDocument4 pagesSolve Differential EquationalvinchuanPas encore d'évaluation

- Pipe Insulation CalculationDocument2 pagesPipe Insulation CalculationalvinchuanPas encore d'évaluation

- PUB Simplified Submission ProcessDocument1 pagePUB Simplified Submission ProcessalvinchuanPas encore d'évaluation

- SS 532-2016+corr 1 - PreviewDocument11 pagesSS 532-2016+corr 1 - PreviewalvinchuanPas encore d'évaluation

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanPas encore d'évaluation

- Pipe ThicknessDocument1 pagePipe ThicknessalvinchuanPas encore d'évaluation

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanPas encore d'évaluation

- Kimgds Flyer - 1Document2 pagesKimgds Flyer - 1alvinchuanPas encore d'évaluation

- API Sizing KIM - XLSMDocument1 pageAPI Sizing KIM - XLSMalvinchuanPas encore d'évaluation

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanPas encore d'évaluation

- Pipeline Analysis & Calculation Environment: Pipe SelectionDocument6 pagesPipeline Analysis & Calculation Environment: Pipe SelectionalvinchuanPas encore d'évaluation

- Restrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazineDocument1 pageRestrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazinealvinchuanPas encore d'évaluation

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanPas encore d'évaluation

- DD41 Manhole FlotationDocument4 pagesDD41 Manhole FlotationalvinchuanPas encore d'évaluation

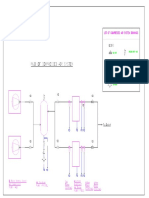

- Compressed Air P&ID DrawingDocument1 pageCompressed Air P&ID DrawingalvinchuanPas encore d'évaluation

- SL No Description Symbol Unit Value Remark: Calculation of Shell ThicknessDocument1 pageSL No Description Symbol Unit Value Remark: Calculation of Shell ThicknessalvinchuanPas encore d'évaluation

- FRP PipeDocument4 pagesFRP PipealvinchuanPas encore d'évaluation

- Water Heater Calculation Rev ADocument1 pageWater Heater Calculation Rev AalvinchuanPas encore d'évaluation

- Eng 5Document21 pagesEng 5MushtaqElahiShaikPas encore d'évaluation

- Stangard 1311 Insulkote (Class B) : High Build - High Breakdown Voltage Solventfree Epoxy Insulation CoatingDocument7 pagesStangard 1311 Insulkote (Class B) : High Build - High Breakdown Voltage Solventfree Epoxy Insulation CoatingManish CorporationPas encore d'évaluation

- BMTPC Green Technology For Mass Housing Compendium 06.05.2016 PDFDocument126 pagesBMTPC Green Technology For Mass Housing Compendium 06.05.2016 PDFsuhail haithaamPas encore d'évaluation

- Structural Maintenance DocksideDocument35 pagesStructural Maintenance DocksidefjalzinaPas encore d'évaluation

- Making Concrete Cylinders in The FieldDocument2 pagesMaking Concrete Cylinders in The FieldaaPas encore d'évaluation

- BS 5422 PDFDocument82 pagesBS 5422 PDFAnitha Mj75% (4)

- ASTM A269 Specification PDFDocument7 pagesASTM A269 Specification PDFrahulPas encore d'évaluation

- 1 s2.0 S2590007223000497 MainDocument7 pages1 s2.0 S2590007223000497 MainRavindu AriyarathnePas encore d'évaluation

- Cara Menghitung Ukuran Pipa Kapiler RefrigerasiDocument54 pagesCara Menghitung Ukuran Pipa Kapiler RefrigerasiZikko FirmansyahPas encore d'évaluation

- UBC Volume 2 Chapter16 PDFDocument38 pagesUBC Volume 2 Chapter16 PDFFarras Yudha Rahmat FarimansyahPas encore d'évaluation

- Chapter 2 Literature ReviewDocument26 pagesChapter 2 Literature ReviewSalvatory Lyakurwa67% (3)

- Chemical Resistance GuideDocument32 pagesChemical Resistance GuidevsvineeshPas encore d'évaluation

- Drytec DryerDocument9 pagesDrytec DryerBurhan Jamal KattanPas encore d'évaluation

- 007 UTube CleaningDocument2 pages007 UTube CleaninggshdavidPas encore d'évaluation

- Asphalt Mixes Properties and Pavement Structure Mechanics: Silvia Cápayová, Ivan Gschwendt, Andrea ZuzulováDocument11 pagesAsphalt Mixes Properties and Pavement Structure Mechanics: Silvia Cápayová, Ivan Gschwendt, Andrea ZuzulováRed RedPas encore d'évaluation

- PM1561 PDFDocument4 pagesPM1561 PDFBooth TelePas encore d'évaluation

- Carpet Specification SheetDocument4 pagesCarpet Specification SheetAliyah GrayPas encore d'évaluation

- Piling Practices Under Eurocode 7 (Contractor Point of View) PDFDocument42 pagesPiling Practices Under Eurocode 7 (Contractor Point of View) PDFBatu GajahPas encore d'évaluation

- Shrinkage After WeldingDocument6 pagesShrinkage After WeldingArvind KumarPas encore d'évaluation

- Concrete Ground Floors and Pavements Part 1Document99 pagesConcrete Ground Floors and Pavements Part 1Sandu NicolaePas encore d'évaluation

- White Rodgers 1F89-211 Non-Programmable Electronic Digital Heat Pump ThermostatDocument6 pagesWhite Rodgers 1F89-211 Non-Programmable Electronic Digital Heat Pump ThermostatJohnny_M412Pas encore d'évaluation

- Mathcad - AB DesignDocument10 pagesMathcad - AB DesignAjay BaniyaPas encore d'évaluation

- Bikesport Micro-Camper PDFDocument15 pagesBikesport Micro-Camper PDFviocons72Pas encore d'évaluation

- Comprehensive Group Pile Settlement Formula Based On 3D Finite Element AnalysesDocument15 pagesComprehensive Group Pile Settlement Formula Based On 3D Finite Element AnalysesPhetole Pat RaseteloPas encore d'évaluation

- Table Of: (Click Item To View)Document29 pagesTable Of: (Click Item To View)Mohamed AboelazmPas encore d'évaluation

- Superimposed, Reinforced, Built-Up Timber BeamsDocument16 pagesSuperimposed, Reinforced, Built-Up Timber Beamsmnmusor0% (1)

- FRP Net LiteraturDocument16 pagesFRP Net Literaturvijay10484Pas encore d'évaluation

- Civic CenterDocument7 pagesCivic CenterArt BerenguelPas encore d'évaluation

- Structural Steel Design 1 Mini ProjectDocument24 pagesStructural Steel Design 1 Mini ProjectMohd SaufiPas encore d'évaluation

- Sbsfid 12858 DifDocument20 pagesSbsfid 12858 DifYIBELTAL EBABU100% (2)