Académique Documents

Professionnel Documents

Culture Documents

Eaton Motor Control Basic Wiring PDF

Transféré par

ServasfloresDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Eaton Motor Control Basic Wiring PDF

Transféré par

ServasfloresDroits d'auteur :

Formats disponibles

TD03309004E For more information visit:

www.eaton.com

Basic Wiring for Motor Contol

Technical Data

New Information

April 2007

Introduction

A Refresher Course for the Product Modier

This text is designed as a refresher course for personnel

who will have the responsibility of modifying Cutler-

Hammer

products from Eatons electrical business to

meet their customers needs.

The scope of the material has been necessarily limited. It

covers the most commonly used products and wiring sche-

matics. Despite its brevity, you are cautioned not to skim

lightly over the content.

The Benet of Satisfaction and Condence

There is great satisfaction in being good at something.

Individuals who attain knowledge in a particular eld have

condence and the respect of their associates.

Studying this text will provide you with a fundamental and

solid knowledge of control wiring and the products you will

be working with.

When you are able to offer your customers tailor-made solu-

tions to their product needs, you are sure to feel great satis-

faction. And, when your endeavors help add to the

protability of your organization, you will very likely enjoy

greater benets.

We hope you agree after nishing this course of study.

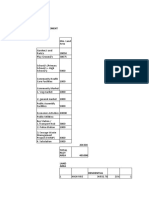

Table of Contents

Description Page

Language of Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Circuitry of a Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Two-Wire Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Three-Wire Control . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Control Power Transformers . . . . . . . . . . . . . . . . . . . . . . 8

Control Circuit Wiring of CPTs . . . . . . . . . . . . . . . . . .

9

Reversing Starters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cover Control Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Start/Stop with Pilot . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Hand/Off/Auto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Forward/Reverse with 2 Pilots . . . . . . . . . . . . . . . . . .

12

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

L3

T3

95

OL

OL

OL

OL

96

L2

T2

L1

1 3 2

T1

AC

Lines

M

M

M

M

M

Motor

Start

Stop

A1 A2

For more information visit:

www.eaton.com

TD03309004E

Technical Data

Page

2

Effective: April 2007

Basic Wiring for

Motor Contol

Language of Control

Circuit diagrams communicate information quickly and

efciently.

Every trade and profession has its method of communicat-

ing ideas and information quickly and efciently. In addition

to the terminology shown in the glossary of this text, dia-

grams play a vital role of communication in electrical cir-

cuits. A knowledge of symbols, diagrams and terminology

will aid in our understanding of electrical control.

The basic language of control is the circuit diagram. Consist-

ing of a series of symbols interconnected by lines to indicate

the ow of current to the various components, it tells in

remarkably short time a series of events that would take

many words to explain. Circuit diagrams are available in two

formats.

Wiring diagrams show the connections to the controller.

Wiring diagrams, sometimes called main or construc-

tion diagrams, show the actual connection points for the

wires to the components and terminals of the controller.

They show the relative location of the components. They can

be used as a guide when wiring the controller.

Figure 1

is a typical wiring diagram for a three-phase mag-

netic starter.

Figure 1. Typical Wiring Diagram

Line diagrams show circuits of the operation of the

controller.

Line diagrams, also called schematic or elementary dia-

grams, show the circuits which form the basic operation of

the controller. They do not indicate the physical relation-

ships of the various components in the controller. They are

an ideal means for troubleshooting a circuit.

Figure 2

shows a typical line or schematic diagram.

Figure 2. Typical Line or Schematic Diagram

L3

T3 95

Reset

96

L2

T2

L1

1

3

2

T1

97

98

3

2

1

M

OL

3-Phase

Motor

Start

Stop

A1 A2

L3

T3

95

OL

OL

OL

OL

96

L2

T2

L1

1 3 2

T1

AC

Lines

M

M

M

M

M

Motor

Start

Stop

A1 A2

TD03309004E For more information visit:

www.eaton.com

Technical Data

Effective: April 2007 Page

3

Basic Wiring for

Motor Contol

Symbols

Standardized symbols make diagrams easier to read.

Both line and wiring diagrams are a language of pictures. It

is not difcult to learn the basic symbols. Once you do, you

are able to read diagrams quickly, and can often understand

a circuit at a glance. The more you work with both line and

wiring diagrams, the better you will become in analyzing them.

The American Standards Association (ASA) and the National

Electrical Manufacturers Association (NEMA) are the agen-

cies which are responsible for setting up and maintaining the

symbol standards. Because of these standards, you will be

able to read all diagrams that come across your workbench.

Figure 3

shows many of the most commonly used symbols

on Control diagrams.

On Contacts and Switches or Pushbuttons, you will nd a

designation of NO or NC (Normally Open or Normally

Closed). This refers to the state of the contacts when power

is not applied to them. In tracing circuits on line diagrams,

you will need to visualize the opening or closing of the con-

tacts when the circuit is energized or de-energized.

The pushbutton symbols shown in

Figure 3

represent

Momentary pushbuttons. The contacts will change state

from their normal position only for as long as your nger is

on the button.

Later in this text, we will be working with actual applications

and line diagrams. So study these symbols carefully please.

Figure 3. Standard Diagram Symbols

Coils Single Voltage

Magnet Coils

Dual Voltage

Magnet Coils

Contacts Normally

Open

Normally

Closed

Timed

Open

Timed

Closed

Fuse Standard

Indicator

Lights

Standard

Motors AC Single-Phase

Three-Phase

Link

High

Voltage

1 2 3 4

Links

Low

Voltage

1 2 3 4

T.O.

T.C.

A-Amber

R-Red

R

G-Green

B-Blue

T1 T2

T1 T2 T3

Relays Thermal

Overload

Time

Delay

Switches Pushbutton

Pushbutton

Limit Switch

Normally

Open

Limit Switch

Held Open

Limit Switch

Normally

Closed

Limit Switch

Held Closed

Selector

Switch

Two-Position

Selector

Switch

Three-Position

Two-Wire

Pilot

Devices

Transformers Low Voltage

Control

Transformer

Reset

98

OL

97

96

95

T.C.

T.C.

T.O.

T.O.

TR

W/Inst.

Inter-

lock

Normally Closed

Normally Open

Jog Run

A

B

A

B

Off

Hand Auto

H1 H2

X1 X2

PT

For more information visit:

www.eaton.com

TD03309004E

Technical Data

Page

4

Effective: April 2007

Basic Wiring for

Motor Contol

Circuitry of a Starter

The two circuits of a motor starter are the power and con-

trol circuits.

There are two circuits to a starter the

Power Circuit

and

the

Control Circuit

.

The electricity that passes through the contacts of the

starter, through the overload relay, and out to the motor, is

called the power circuit. The thick lines of

Figure 4

represent

this power circuit. It is the power circuit that passes electric-

ity to the motor enabling it to run. For this reason, it is some-

times referred to as the motor circuit.

Common Control power and control circuits at same volt-

age. Separate Control is at different voltages.

The thin lines in

Figure 4

represent the control circuit. The

magnet coil of the starter is energized with this circuit, which

creates the electro-magnetic eld that pulls the power circuit

contacts closed.

The control circuit is separate from the motor circuit. The

control circuit may not be at the same voltage as the power

circuit. When the voltage of the control and power circuits is

the same, it is referred to as

Common Control

. If the volt-

ages are different, it is called

Separate Control

.

Figure 4. Typical Starter Wiring Diagram Three-Phase

Separate voltages supplied by different voltage sources.

How can you have two different voltages going into the

same starter? One method is to run different wires from dif-

ferent electrical voltage sources. You might have a 480V sup-

ply that is attached to the line side of the starter, and that

runs through to the motor. Another set of wires, from a dif-

ferent voltage source would bring 120V to the magnet coil.

The coil is energized by the 120V, and the pushbuttons or

other control devices operate at this same voltage. The

motor operates at the power circuit voltage, in this case,

480V. The coil rating must match the control source voltage,

and the starter is sized to match the horsepower and voltage

ratings of the power circuit.

Separate voltages supplied by Control Power Transformers.

Another method for supplying separate voltages for power

and control circuits, is to use a Control Power Transformer.

These are sometimes also referred to as Control Circuit

Transformers. One voltage source is used to supply the

motor. This same voltage is also supplied to the primary side

of the transformer. The transformers secondary supplies the

voltage to operate the magnet coil in the control circuit. A

more detailed explanation of transformers can be found on

Page 8

.

Common Control is when the power circuit and the control

circuit are fed from the same voltage source.

Common control is when the control circuit is tied back to

lines 1 and 2 of of the starter. It is supplied with the same

voltage as the power or motor circuit.

The understanding of Common Control and Separate Con-

trol becomes signicant when changing magnet coils from

one voltage to another.

Changing magnet coils from 120V or to 120V involves add-

ing or removing wire C.

If you stock starters or contactors with different rated mag-

net coils, and need to convert the device to a 120V magnet

coil for separate control, you must remove the connection to

the power circuit that is provided.

Figure 5

shows this con-

nection. Wire C is connected to L2 and terminal 96 on the

overload relay in all Cutler-Hammer starters supplied with

magnet coils greater than 120V. You must remove the wire,

and then connect the separate control voltage lines to the

number 1 terminal on the remote pilot device and terminal

96 on the overload relay.

On the other hand, if you are converting a starter that was

factory supplied for 120V Separate Control to a Common

Control device, you must put in this jumper.

If you are swapping out a 480V magnet coil to supply one

with 240V coil to meet a customers needs, you do not need

to worry about wire C. Only when changing to 120V or

less from any voltage greater than 120V or changing to any

voltage greater than 120V from 120V or less, is this

signicant.

L3

T3 95

Reset

96

L2

T2

L1

1

3

2

T1

97

98

3

2

1

M

OL

3-Phase

Motor

Start

Stop

A1 A2

TD03309004E For more information visit:

www.eaton.com

Technical Data

Effective: April 2007 Page

5

Basic Wiring for

Motor Contol

Circuitry of a Starter

Figure 5. Common vs. Separate Control

95

Reset

L3 L2 L1

5/ 3/ 1/

T3 T2 T1

T3 T2 T1

96

97

98

3

2

2/ 4/ 6/

M

OL

L2 L1 X2

CPT

Separate Control w/CPT

G

1

X1

3-Phase

Motor

A1 A2

95

Reset

L3 L2 L1

Common Control

Separate Control

5/ 3/ 1/

T3 T2 T1

T3 T2 T1

96

97

98

3

2

C

Remote Pilot

Devices

2-Wire Control

3-Wire Control

Start

Stop

3

2

1

1

3

Not for use with Auto

Reset OL Relays.

2/ 4/ 6/

M

1

OL

3-Phase

Motor

A1 A2

Remove Wire C when it is

supplied. Connect Separate

Control Lines to the No. 1

Terminal on the Remote

Pilot Device and the

Terminal 96 on the

Overload Relay.

For more information visit:

www.eaton.com

TD03309004E

Technical Data

Page

6

Effective: April 2007

Basic Wiring for

Motor Contol

Circuitry of a Starter

Two-Wire Control

Two-Wire Control circuits or Low Voltage Release

One of the common control wiring circuits used is known as

Two-Wire or Low Voltage Release (LVR). It utilizes a main-

tained contact type of pilot device such as a thermostat,

oat switch or presence sensor.

Figure 6

shows the line and

wiring schematics for this circuit.

When the maintained contacts on the pilot device are closed,

it energizes the coil of the starter, which connects the load

through the power circuit. When the contacts of the pilot

device open, the coil is de-energized, and the starter drops

the load off line.

Automatically restarts when power is restored if pilot

device is still closed.

The circuit provides for an automatic operation of the load.

If there is a power outage or loss, the starter will be

de-energized. This is why the circuit is often called Low

Voltage Release (LVR).

If the maintained contacts of the pilot device remain closed

during the power loss or outage the starter will be re-

energized when the power to the control circuit is restored.

Caution must be used in the application of this circuit

there is no personnel safety protection when the power is

restored.

Figure 6. Two-Wire Control

Three-Wire Control

Three-Wire Control circuits or Low Voltage Protection

The other very common control wiring circuit used is known

as Three-Wire or Low Voltage Protection (LVP). This circuitry

does provide personnel safety protection in the event of

power loss or outages. It utilizes momentary contact pilot

devices and a holding circuit contact.

This holding circuit, or seal-in circuit, is most commonly pro-

vided by an auxiliary contact on the contactor or starter.

Figure 7

shows the typical line and wiring diagrams for

Three-Wire control circuits.

Circuit does NOT automatically restart when power is

restored.

This circuitry provides LVR, because if there is a power out-

age or loss, the starter will be de-energized. But, it provides

Low Voltage Protection, because the circuit does not auto-

matically restart. The only way to restart this circuit is to

manually use the START button.

Because this circuit is very popular in motor control sys-

tems, lets go through the operation of it step-by-step.

The circuit consists of a Normally Closed (NC) STOP button

wired in series with a Normally Open (NO) START button. A

Normally Open (NO) Auxiliary contact on the starter will be

used as the holding circuit.

Figure 7. Three-Wire Control

95

L1 L2

PD OL

M

95 96

A1 A2

1 3

Reset

L3 L2 L1

5/ 3/ 1/

T3 T2 T1

T3 T2 T1

96

97

98

3

2

Two-Wire

Pilot Device

2

2/ 4/ 6/

M

1

1

OL

3-Phase

Motor

A1 A2

L3

T3 95

Reset

96

L2

T2

L1

1

3

2

T1

97

98

3

2

1

M

OL

3-Phase

Motor

Start

Stop

A1 A2

TD03309004E For more information visit:

www.eaton.com

Technical Data

Effective: April 2007 Page

7

Basic Wiring for

Motor Contol

Circuitry of a Starter

Three-Wire Control (Continued)

When the START button is depressed (

Figure 8

), it completes

the circuit to energize the coil of the starter. When that

occurs, the Normally Open (NO) Auxiliary contact closes.

This auxiliary is shown as | | M on the line diagram.

Figure 8. START Button Completes Circuit

When you remove your nger from the START button, its

contact returns to the Normally Open state. Even though this

opens a path to the coil, the circuit now travels through the

closed M contact to keep the starter energized.

The electricity ows from L1, through the Stop (NC), through

the path completed when contact M closed, to the coil,

through the overload relay control circuit, to L2 (

Figure 9

).

Figure 9. Electrical Path is through Contact M

Pressing the STOP (

Figure 10

) button will cause the Nor-

mally Closed (NC) contact to open the circuit, de-energize

the coil, and drop out contact M. Releasing the STOP button

will return the circuit to its original (off) state.

If there is a power outage or loss, the coil is de-energized,

contact M opens, and the starter drops the load off line.

When power is restored, the circuit CANNOT automatically

restart because the START button needs to be pushed to

complete the circuit. Because someone must manually

restart the circuit, this can provide a means of personnel

safety.

As we saw in the common vs. separate control wiring, the

control circuit is connected through a contact on the over-

load relay. When an overload is detected, this contact opens

the circuit and de-energizes the coil. If you are using a Three-

Wire control circuit, then the starter cannot automatically

restart the Start button with its NO contacts prevent the

circuit from being completed.

Figure 10. STOP Button Opens Circuit

With 3-Wire control, automatic reset on an overload relay

will NOT re-energize the circuit.

There is sometimes confusion with overload relays that

have an Automatic Reset capability.

In a Three-Wire circuit, with the overload relay set for Man-

ual Reset, both the RESET button on the overload, as well as

the START button, must be used to re-energize the circuit.

An overload relay in the Automatic mode would not auto-

matically re-energize the circuit, because the START button

is still open.

An overload relay with Automatic Reset, used with a two-

wire circuit would provide automatic restart. This type of cir-

cuitry must be used only on applications where personnel

safety is not an issue.

M

M

L1

Stop Start OL

L2

M

M

L1

Stop Start OL

L2

M

M

L1

Stop Start OL

L2

For more information visit:

www.eaton.com

TD03309004E

Technical Data

Page

8

Effective: April 2007

Basic Wiring for

Motor Contol

Control Power Transformers

Why use a Control Power Transformer?

The motor branch circuit is usually a segment of a larger

electrical distribution network in an industrial plant. The

motor circuit supplies the required power to the various con-

trol devices in order for them to operate. In some cases, the

various control devices are operated at the same voltage as

the motor. Sometimes, the voltage required to operate the

motor is too high to safely operate the control circuit, partic-

ularly in regards to personnel safety. As a means of reducing

the motor voltage to a safer control voltage level, we use a

device known as a Control Power Transformer.

Connected with the Primary winding to the Power circuit

Secondary winding to the Control Circuit.

A typical control transformer is shown in

Figure 11

below. It

consists of two separate coils of wire (windings) placed adja-

cent to each other on a common iron core. Note that the pri-

mary winding is connected to the power source. The

secondary winding is connected to the control circuit. The

purpose of the transformer is to transfer electric power from

the primary circuit to the secondary circuit. The transformer

either reduces (steps down) or increases (steps up) the volt-

age to match the requirements of the control circuit.

Figure 11. Typical Control Transformer

Magnetic eld from primary winding induces voltage in the

secondary winding.

Applying AC voltage to the primary winding of the trans-

former causes alternating current to ow in the winding.

This produces a magnetic eld that extends outside the

winding, in the shape of concentric loops as shown in

Figure 12

. The magnetic eld uctuates as the AC changes

direction. These magnetic lines cut across the conductors of

the secondary winding and induce a voltage.

Figure 12. AC Flow in Windings

Voltages based on number of turns on both windings.

The relationship of the voltage across the primary to the

voltage across the secondary is in direct proportion to the

number of turns on both windings. For example, 100 turns

on the primary, and 10 turns on the secondary, is a 10 to 1

ratio. If the primary is 500 volts, we will get 50 volts at the

secondary. This is referred to as a Step-Down transformer.

They are most commonly used in control circuits where the

motor voltage is 480V, 600V, or higher. The step-down con-

trol transformer would reduce the voltage to pushbuttons or

PLCs to 120V or even 24V.

A transformer with the reverse proportion of more turns on

the secondary winding than on the primary is called a Step-

Up transformer. It will increase the voltage according to the

ratio of turns.

Primary Winding

Connected to

AC Power Source

Iron Core

Secondary Winding

Connected to Load

Magnetic Field of Primary Winding Expands and

Contracts as AC Current Flow Increases and Decreases.

Voltage Induced in

Secondary Winding

AC Power

Source

Load

TD03309004E For more information visit:

www.eaton.com

Technical Data

Effective: April 2007 Page

9

Basic Wiring for

Motor Contol

Control Power Transformer

Primary connects to the power circuit Secondary

connects to the control circuit.

The schematic symbol for the transformer is represented by

two groups of scallops facing each other. These represent

the primary and the secondary windings. The winding with

the higher number of turns should be shown to have more

scallops than the other to identify it as either a step-down or

step-up transformer.

Figure 13

shows a basic control circuit with a step-down

transformer added. Note that the main motor circuit oper-

ates at 480V, while the control circuit is at 120V.

The primary winding of the transformer is connected to two

phases of the power circuit. The secondary winding is con-

nected to the control circuit.

Figure 13. Control Circuit with CPT

Control Circuit Wiring of CPTs

Magnet Coil and Pilot Lights rated for same voltage as Sec-

ondary of Transformer.

When you are installing a Control Power Transformer into a

starter, you must be sure that the magnet coil is rated for the

same voltage as the secondary of the transformer.

In addition, any pilot lights in this circuit must have the same

voltage as the secondary.

Dual Voltage units shipped with connections made for the

higher voltage.

When you are using a Control Power Transformer with a

dual voltage primary, check the transformer connections to

be sure that they match the voltage of your power source.

Cutler-Hammer transformers with dual voltage primaries

(i.e. 480V and 240V) are shipped with the transformer con-

nections made to supply the higher voltage. If the lower pri-

mary voltage is required for your application, change the

connections as shown on the nameplate of the transformer.

Remove wire C, if supplied, from starters control circuit.

As discussed earlier in this booklet, if wire C is supplied on

the starter (magnet coil voltages greater than 120V), you

must remove it. This will convert the starter from Common

Control to Separate Control.

The leads from the primary of the transformer are connected

to L1 and L2 on the starter. In this way, the primary of the

transformer is supplied with the same voltage as the power/

motor circuit of the starter.

The leads from the secondary of the transformer are con-

nected to Terminal 1 of the remote pilot device, and terminal

96 on the Freedom Series overload relay (see

Figure 14

).

Figure 14. CPT Wiring Diagram

L3

CPT

CPT

T3

95

Reset

96

96

G

95

L2

L2 L1

(Primary)

(Secondary)

H1

H1 H4 H3H2 H1 H4

240V

Connections for Dual

Voltage Transformer

480V

120V

H3H2

X2

X2 X1

G

X1

X1 X2

H1 H4 H3 H2

H1 H4 H3 H2

H4

T2

L1

5/ 3/ 1/

1

3

2

T1

2/ 4/ 6/

T3 T2 T1

97

98

3

3

2

2

1

1

M

M

M

OL

OL

3-Phase

Motor

Start

Start

Stop

Stop

A1 A2

A1 A2

CPT

BLK

L1

1

G

L2 X2 X1

To Terminal L1

on the Starter.

Ground Wire (Green)

remove if not required.

To Terminal 96 on

the Overload Relay.

To Terminal 1 on the

Remote Pilot Device.

To Terminal L2

on the Starter.

BLK

RED

Note: Connections for Dual

Voltage Rated Transformer-

see Transformer Nameplate.

For more information visit:

www.eaton.com

TD03309004E

Technical Data

Page

10

Effective: April 2007

Basic Wiring for

Motor Contol

Reversing Starters

To reverse a motor, you reverse the leads to the motor.

To reverse a motor, you need to reverse the leads to the

motor. When using a reversing magnetic starter, this task is

accomplished using two contactors, one overload relay, and

a mechanical interlock. The control circuit is designed to pro-

vide an electrical interlock as well.

Both the mechanical and electrical interlocking prevent the

simultaneous operation of the forward and reverse contactors.

Figure 15

shows the wiring diagram for a full-voltage mag-

netic reversing starter.

When the forward contacts (F) close, L1, L2, and L3 are con-

nected to T1, T2, and T3, just as they would be on a non-

reversing starter.

When the reverse contacts (R) close, the motor is connected

L1 to T3, L2 to T2, and L3 to T1. On a three-phase motor, it is

necessary to change only two leads in order to reverse the

rotation of the motor.

Figure 15. Reversing Starter Wiring Diagram

Mechanical Interlock prevents simultaneous operation.

To keep the forward and reverse contacts from operating

simultaneously, a mechanical device is used.

This device mounts in between the two contactors and phys-

ically prevents the power contacts from operating at that

same time.

Control circuitry provides an electrical interlock to prevent

operation at the same time.

Additionally, the control circuits are wired in such a way as

to prevent simultaneous operation. This is done with the use

of Normally Closed (NC) auxiliary contacts.

As the coil of one direction contactor is energized, its associ-

ated NC contact opens insuring an open electrical path to

the coil of the opposite contactors coil.

Figure 16

shows this

circuitry.

Figure 16. Reversing Starter Line Diagram

This circuit operates as follows: Depressing the FORWARD

pushbutton energizes coil F, completing the circuit from L1

to L2.

Coil F energizes NO auxiliary contact F, closing it for the

holding circuit.

Coil F also operates NC auxiliary contact F, opening it to

insure that coil R cannot be energized.

The mechanical interlock physically prevents the power con-

tacts of contactor R from operating.

When the STOP button is pushed, the entire circuit is de-

energized. All of the contacts return to their normal state.

The REVERSE pushbutton can then be depressed to operate

the reverse contactor.

Pressing the REVERSE button allows current to energize coil

R to complete the circuit to the motor. Power can ow

through NC contact F, since coil F is not energized. When coil

R is energized, NO contact R acts as the seal-in contact.

In this control circuit, the STOP button must be operated

before the direction of the motor can be changed.

The power circuit connections reverse the rotation of the

motor.

Refer back to the wiring diagram (

Figure 15

). Trace the

power circuit lines connected to Coil R.

A connection at L1 is traced through the power contacts, and

connected to T3, through the overload relay and to the motor.

The connection at L3 is traced through to be connected at T1.

L2 is connected to T2 as it would be in a non-reversing starter.

It is these connections that reverse the rotation of the motor.

95

FLS RLS

Reset

L3 L2 L1

5/ 3/ 1/

T3 T2 T1

T3 T2 T1

96

97

98

3

7

3

3

2

R

4

6 5

Rear

F

2

2

For

Pushbutton with

FOR and REV

Buttons Electrically

Interlocked.

Rev

Stop

2/ 4/ 6/

6 3 5 7

When Limit Switches are

used, omit Connectors A

and B and connect per

Dotted Lines.

Remove Wire C

when it is supplied.

Connect Separate

Control Lines to

the No. 1 Terminal

on the remote

pilot device

and Terminal

No. 96 on the

overload relay.

OL

L2 L3 L1

A1

A1

B

A

C

A2 A2

1

1

4

Rear

4

5

Separate Control

5

Motor

L1 L2

Lines

L3

Contactors F and R are

Mechanically Interlocked

F OL

OL

T1

T2

T3

Motor

OL

OL

C

R

F

R

F

F

F

F

A1 A2

R

R

R

(If Used)

R

Stop

REV

For

FLS

RLS

1 2

4 5 7

3 6 96 95

TD03309004E For more information visit:

www.eaton.com

Technical Data

Effective: April 2007 Page

11

Basic Wiring for

Motor Contol

Cover Control Circuits

There are many basic control circuits.

We will be reviewing many basic control circuits. We will

look at both the wiring diagram and the line diagram, and

discuss their operation. In some cases, alternative circuits

will also be demonstrated.

Understanding these circuits will be very helpful to you

when installing cover control kits to meet your customers

control needs.

Many of the circuits have their basis in the Three-Wire

circuit.

On

Pages 6

and

7

, we discussed the standard STOP/START

circuit. We saw that using a maintained contact pilot device

gave us automatic control. Then we looked at a three-wire

circuit using momentary contacts and an auxiliary contact to

hold the circuit closed.

Many of the control circuits we will discuss in this chapter,

will have their basis in this three-wire STOP/START circuit.

One very common variation to this circuit is the addition of a

pilot light. In

Figure 17

the pilot light will be on when the

motor is running. The circuit operates as follows: The START

button energizes Coil M, and power passes through the NC

contact of the overload relay to L2. Power is also supplied to

the Pilot light. When the coil is energized, holding contact M

closes, and allows power to continue to pass to the indicat-

ing light. As long as the motor is on, the pilot light will be

energized.

Figure 17. START/STOP with Pilot Light ON When Motor Running

A variation to this circuit is to have a pilot light indicate that

the motor is NOT running.

Figure 18

shows this circuit. It

operates as: There is a standard Three-Wire STOP/START

circuit. An additional auxiliary contact on the starter is what

operates the pilot light. Notice that it is an NC contact. When

the coil is energized, this contact will open. At that point, the

pilot light will turn off. When the starter is not energized, this

contact is closed, allowing power to pass from L1 to L2.

When the motor is off, the light is on when the motor is

on, the light is off. When wiring this circuit on enclosed con-

trollers, remember that a NC auxiliary contact is needed in

addition to the standard NO auxiliary contact.

Figure 18. START/STOP with Pilot Light OFF When Motor Running

Another very common control circuit is the HAND/OFF/

AUTO (HOA). It can be accomplished using either a three-

position selector switch, or three maintained pushbuttons.

Figure 19

shows this circuit.

Figure 19. HAND/OFF/AUTO Circuit

1/

L1

1

M

OL

A1 A2 2

3

3

2

1

98

97

96

95

95 96

T1

2/ 4/ 6/

T2 T3

T1 T2 T3

L1

1 2 3

L2

M

Pilot

Pilot

Light

Light

M

OL

A2 A1

Start

Start

Stop

Stop

R

R

3-Phase

Motor

Reset

L2 L3

3/ 5/

2

3

T1 T2 T3

X2

Start

Stop

L1

1

1

2 3

L2

M

M

Motor

4

4

Pilot Light

Pilot

Light

M

M

OL

OL

Start

Stop

G

Rear

L1 L2 L3

G

1/

L1

1

M

OL

A1 A2

2

3

3

4

4

4

A

A

Contact

Hand Off Auto

Position

B

X

X

X = Contact Closed

B

2

1 1

98

97

96

95

95 96

T1

2/ 4/ 6/

T2 T3

T1 T2 T3

L1

1

2

Hand

Off

Auto

3

3

4

4

L2

M

Pilot Device

Pilot Device

OL

A2 A1

Off

Hand Auto

3-Phase

Motor

Reset

L2 L3

3/ 5/

For more information visit:

www.eaton.com TD03309004E

Technical Data

Page 12 Effective: April 2007

Basic Wiring for

Motor Contol

Cover Control Circuits

How the HOA circuit works.

It operates: Power from L1 passes to the Hand position

(when set for that mode), energizes the coil, passes

through the overload relay contacts to L2. The Off position

de-energizes the circuit. If the switch is set for the Auto posi-

tion, power from L1 must rst pass through the automatic

device (such as a thermostat) before power reaches the coil.

If the contacts on the remote device are closed, the Auto

position allows the coil to energize. The circuit is on when-

ever the remote device is closed.

Reversing circuit with Two Pilot lights to indicate operation

direction.

On Page 10, we discussed the operation of a reversing cir-

cuit. In Figure 20 we show this same circuit, but with the

addition of two pilots to indicate the direction in which the

motor is operating.

The circuit works as follows: The NC-STOP button allows for

power to pass from L1. Pushing the FORWARD button closes

the NO contacts and energizing coil F, at the same time, NC

contacts F open and prevent Coil R from energizing. (The

electrical interlock of the circuit.) Additionally, the power is

also passed through the circuit to Pilot Light FOR indicating

that the motor is in the forward mode of operation.

The circuit operates the same when the REVERSE button is

operated, energizing the REV indicating light instead.

Mechanical as well as electrical interlocking prevent the

simultaneous operation of the motor direction.

Figure 20. 2 Pilot/FORWARD/REVERSE Circuit

Additional examples and explanations of control circuits can

be found in Eatons Standard Motor Control Line & Wiring

Diagrams, publication number TD03309001E.

This publication is available to you at no charge from your

local sales ofce.

L1

T1 T2 T3

Motor

FOR. Ind.

Light

REV. Ind.

Light

Stop

Stop

Rev

For

FOR

1

1

2

2

4

5 6

OL

98

97

96

95

8

4

Rear Rear

3

3

5

T1 T2 T3

8

2/ 4/ 6/

2

L1

L1

1/ 3/ 5/

L2

L2

L3

L3

3

4

7

F

5

8

1

2 3

8

95 96

6

7 5 4

F

R

R

Reset

RA1 A2

A2

A2

A2

A1

A1

A1

R

F

F

L2

OL

FOR.

Light

REV.

Light

REV.

TD03309004E For more information visit: www.eaton.com

Technical Data

Effective: April 2007 Page 13

Basic Wiring for

Motor Contol

Glossary

Some of the Terminology of Motor Control

Across-the-Line: A method of motor starting that connects

the motor directly to the supply line on starting or running.

Also known as Full-Voltage.

Auxiliary Contact: Contact of a switching device within the

control circuit, and operated when the magnet coil is

energized.

Bimetal: Two different metals bonded together to provide

fast heat transfer to trip contacts. Used in thermal overload

relays.

Common Control: Electricity to both Power circuit and Con-

trol circuit are supplied from the same voltage source. See

Page 4.

Contactor: A device to repeatedly establish or interrupt an

electric power circuit.

Control Circuit: A circuit that controls the magnet coil of a

contactor or starter, and operates pilot devices connected to

it. See Page 4.

Control Circuit Transformer: See Control Power Transformer

Control Power Transformer: A device that increases or

decreases voltage to a desired level to operate the control

circuit. See Page 8.

De-energize: To disconnect a component or circuit from the

power source.

Energize: To apply voltage to an electrical device.

Eutectic Alloy: A solder-like substance used in some thermal

overload relays to provide heat transfer to trip the contacts.

Converts from a solid to a liquid state at specic recurring

points.

Full Voltage Control: Connects the equipment directly to line

supply on starting. Also known as Across-the-Line.

Jogging (Inching): Momentary operation, small movement

of driven machine or motor.

Ladder Diagram: A schematic diagram where all the compo-

nents are in a ladder form, up and down picture, to show

function of circuit, regardless of physical location of devices.

Also known as a Line Diagram. See Page 2.

Line Voltage: The voltage being supplied to the equipment

from the power supply.

Load: Electrical devices that consume electricity to do useful

work, such as motors, solenoids, lights, etc. The output of a

motor circuit.

Low Voltage Protection (LVP): Also known as three-wire

control, providing non-automatic restart during power loss

or failure. Circuit must be manually restarted upon restora-

tion of power. See Page 6.

Low Voltage Release (LVR): Also known as two-wire control.

Provides a means to automatically restart a control circuit

upon restoration of power from loss or failure mode. See

Page 6.

Normally Closed: The position of a set of contacts that are

closed when the device has no electricity applied to it.

Normally Open: The position of a set of contacts that are

open (separated) when the device has no electricity applied

to it.

Open Circuit: A circuit without a complete path for the elec-

tricity to ow through.

Overload Relay: A device designed to protect a motor by

sensing the heat from excessive amperage draw of a

jammed or overworked motor, and dropping the devices off-

line (open circuit) before damage occurs. Often uses either a

bi-metal element or a eutectic alloy to sense the thermal

changes in the power circuit.

Parallel Circuit: An electrical circuit that has more than one

path for current ow. (Connected rungs on a ladder

diagram.)

Plugging: Braking of a motor by reverse line voltage or

phase sequence. Motor develops retarding force.

Power Circuit: Also known as the Motor Circuit. The electri-

cal path that passes electricity to the motor enabling it to

run. See Page 4.

Reduced Voltage Starter: Applies a reduced voltage or cur-

rent supply to the motor during starting to avoid excessive

inrush.

Rotor: The rotating part of an electric motor.

Schematic Diagram: A diagram that lays out the control sys-

tem circuit by circuit, and is composed of symbols and lines

representing the functions of devices regardless of their

physical locations. Also known as Ladder or Line diagram.

See Page 2.

Separate Control: There is a different voltage source supply-

ing the control circuit from that of the power/motor circuit.

See Page 4.

Series Circuit: an electrical circuit that has only one path for

the ow of the electricity. May have several pilot devices

through which the electricity must ow before the circuit is

completed.

Starter: A device to repeatedly establish or interrupt an elec-

tric power circuit to a motor, that also provides thermal pro-

tection to the motor. The two main components are a

Contactor and an Overload Relay.

Three-Wire Control: See Low Voltage Protection (LVP),

Page 6.

Two-Wire Control: See Low Voltage Release (LVR), Page 6.

Wiring Diagram: Shows all the devices in a circuit and their

physical relationship to each other. Terminal connections for

all components are identied to wire a complete circuit. See

Page 2.

Eaton Corporation

Electrical Group

1000 Cherrington Parkway

Moon Township, PA 15108

United States

877-ETN CARE (877-386-2273)

Eaton.com

2007 Eaton Corporation

All Rights Reserved

Printed in USA

Publication No. TD03309004E/CPG

April 2007

Vous aimerez peut-être aussi

- Electrical Symbols and SchematicsDocument42 pagesElectrical Symbols and Schematicsapi-384232693% (14)

- Schneider Wiring Diagram BookDocument109 pagesSchneider Wiring Diagram BooktanveerPas encore d'évaluation

- The Complete Guide To Wiring, 5th EditionDocument353 pagesThe Complete Guide To Wiring, 5th Editiontsofiarocha100% (3)

- 3-Mod 3-Electrical Diagrams and Schematics 3Document30 pages3-Mod 3-Electrical Diagrams and Schematics 3Jeppry saniPas encore d'évaluation

- AB Starter DiagramDocument39 pagesAB Starter Diagramrajinipre-1100% (1)

- Special Purpose MotorsDocument16 pagesSpecial Purpose MotorsHari ReddyPas encore d'évaluation

- Symbols For Electrical DwgsDocument11 pagesSymbols For Electrical DwgsSHAILEN BHATT50% (6)

- Circuit Digram SymbolsDocument19 pagesCircuit Digram Symbolsabdul-mateen100% (5)

- Electrical Choosing Relays Motor Starters ContactorsDocument2 pagesElectrical Choosing Relays Motor Starters ContactorsNishant KumarPas encore d'évaluation

- Troubleshooting and Repair of Small Household Appliances and Power ToolsDocument239 pagesTroubleshooting and Repair of Small Household Appliances and Power ToolsAnton Diedericks100% (1)

- Electric Motor Control DiagramsDocument68 pagesElectric Motor Control DiagramsManny100% (5)

- Motor Control CenterDocument81 pagesMotor Control CenterMohamed Mohamed100% (2)

- Mitsubishi Electric HD Technicians GuideDocument52 pagesMitsubishi Electric HD Technicians Guideadi22-22100% (1)

- Electrical Symbols Library NPPDocument26 pagesElectrical Symbols Library NPPNavon Florin100% (3)

- Basic Electric ControlDocument90 pagesBasic Electric Controljivajive100% (1)

- Basics of Control Components - Siemens WWDocument109 pagesBasics of Control Components - Siemens WWvozoscribd100% (1)

- From Schematic To Reality: Understanding SchematicsDocument13 pagesFrom Schematic To Reality: Understanding SchematicsjosemaneiraPas encore d'évaluation

- G Series 2-Cylinder Power PackageDocument8 pagesG Series 2-Cylinder Power PackageIAN.SEMUT100% (1)

- Electric Motors Control Diagram - BarbuDocument66 pagesElectric Motors Control Diagram - BarbuPeter NomikosPas encore d'évaluation

- Motor Wiring Digrams and ControlDocument36 pagesMotor Wiring Digrams and ControlEdeuamos true-ePas encore d'évaluation

- Electricity QuestionsDocument133 pagesElectricity QuestionskartavyajainPas encore d'évaluation

- Electrical SymbolsDocument26 pagesElectrical SymbolsXavier Izquierdo75% (8)

- AC Motor Control Circuits - WorksheetDocument22 pagesAC Motor Control Circuits - WorksheetAbhishek RoyPas encore d'évaluation

- 17th Edition WiringDocument12 pages17th Edition WiringCesar Bl100% (2)

- Eaton Motor Control Basic WiringDocument14 pagesEaton Motor Control Basic Wiringalmuamar5026100% (1)

- AC Motor TroubleshootingDocument15 pagesAC Motor TroubleshootingFAisal NAdeemPas encore d'évaluation

- The Art & Science of Protective Relaying - C. Russell Mason - GEDocument357 pagesThe Art & Science of Protective Relaying - C. Russell Mason - GEAasim MallickPas encore d'évaluation

- MCC 1Document13 pagesMCC 1www.otomasyonegitimi.comPas encore d'évaluation

- Electrical device protection circuit calculationsDocument18 pagesElectrical device protection circuit calculationsZaferullah KhanPas encore d'évaluation

- Understanding Electrical DiagramsDocument19 pagesUnderstanding Electrical Diagramsparamtap4257100% (2)

- Microcontroller Oscillator Circuit Design PDFDocument12 pagesMicrocontroller Oscillator Circuit Design PDFmike_helplinePas encore d'évaluation

- EE DiagramsDocument35 pagesEE DiagramsRai JeanPas encore d'évaluation

- Calculating Short Circuit Current Theory TechniquesDocument32 pagesCalculating Short Circuit Current Theory TechniquesServasflores50% (2)

- DST-PC, 02 PossibilitiesDocument35 pagesDST-PC, 02 PossibilitiestrutleptPas encore d'évaluation

- Module 13 Panelboards and SwitchboardsDocument32 pagesModule 13 Panelboards and SwitchboardsCamilla AlbaPas encore d'évaluation

- Motor Wiring Digrams and Control-2Document36 pagesMotor Wiring Digrams and Control-2Edeuamos true-e100% (1)

- Circuit BreakerDocument12 pagesCircuit BreakerHarshalPanchal100% (1)

- Specifications and RequirementsDocument22 pagesSpecifications and RequirementsMohammed AnasPas encore d'évaluation

- NEC Article 250Document42 pagesNEC Article 250unknown_3100% (1)

- Three Phase Electrical Circuit AnalysisDocument72 pagesThree Phase Electrical Circuit AnalysisBANDAPPA BHAIRAMADI100% (1)

- Motor Control Basic WiringDocument14 pagesMotor Control Basic WiringJohn Nen Bini100% (1)

- Schneider Wiring Diagram BookDocument120 pagesSchneider Wiring Diagram BookVinMarPas encore d'évaluation

- SUBSTATIONDocument12 pagesSUBSTATIONRaaj deepPas encore d'évaluation

- Motor ControlsDocument40 pagesMotor ControlsArlone ManaladPas encore d'évaluation

- Electrical Design Manual For Hospital PDFDocument126 pagesElectrical Design Manual For Hospital PDFJitendra Mahida100% (2)

- Module 10 LoadcentersDocument25 pagesModule 10 Loadcenterseyd bartulabaPas encore d'évaluation

- Standard Motor Control Line and Wiring DiagramsDocument36 pagesStandard Motor Control Line and Wiring Diagramsaugur886Pas encore d'évaluation

- Basics of Control ComponentsDocument21 pagesBasics of Control ComponentsikyabdullahPas encore d'évaluation

- Designing Low Voltage Feeder CircuitsDocument86 pagesDesigning Low Voltage Feeder Circuitscoopen100% (4)

- Electric Motor Controls TutorialDocument24 pagesElectric Motor Controls Tutorialvijai daniel100% (4)

- WP51-PowerEquipmentandDataCenterDesign v1 PDFDocument51 pagesWP51-PowerEquipmentandDataCenterDesign v1 PDFServasfloresPas encore d'évaluation

- Basic Principles of Motor Controls: Unit 1-IntroductionDocument8 pagesBasic Principles of Motor Controls: Unit 1-IntroductionMoustafa MahmoudPas encore d'évaluation

- Maintaining Electrical SystemsDocument8 pagesMaintaining Electrical SystemsHealthyCut FarmsPas encore d'évaluation

- Ship Safety Service & Training Manual - TanjaDocument22 pagesShip Safety Service & Training Manual - TanjaGeorge Gxg100% (1)

- AutoCAD Shortcuts Guide AutodeskDocument11 pagesAutoCAD Shortcuts Guide AutodeskkazdanoPas encore d'évaluation

- Solution Manual For Mechanical Vibration - William PalmDocument20 pagesSolution Manual For Mechanical Vibration - William PalmAfshar Arabi0% (1)

- Lightning Studies 20160908Document18 pagesLightning Studies 20160908Anonymous V6y1QL6hnPas encore d'évaluation

- Flow of A Film On The Outside of A Circular TubeDocument6 pagesFlow of A Film On The Outside of A Circular TubeShubh100% (6)

- SPDT and DPDT SwitchesDocument4 pagesSPDT and DPDT SwitchesShane CampbellPas encore d'évaluation

- Electrical GlossaryDocument11 pagesElectrical Glossarysrogan2323Pas encore d'évaluation

- Understanding Wye Transformer CalculationsDocument3 pagesUnderstanding Wye Transformer CalculationsBok ReyesPas encore d'évaluation

- 7.short Circuit CalculationsDocument14 pages7.short Circuit Calculationskvramanan_1Pas encore d'évaluation

- E 3019Document28 pagesE 3019sudhakaremcPas encore d'évaluation

- E I (EC 323) : Lectrical NstallationsDocument38 pagesE I (EC 323) : Lectrical NstallationsMalith DeemanthaPas encore d'évaluation

- MCC 1Document14 pagesMCC 1Arif SugestyanPas encore d'évaluation

- Troubleshooting Three-Phase AC Motors With U1210 Series Handheld Clamp Meters5990-5192ENDocument6 pagesTroubleshooting Three-Phase AC Motors With U1210 Series Handheld Clamp Meters5990-5192ENecomujPas encore d'évaluation

- An Energy Metering System using ATmega32 MicrocontrollerDocument8 pagesAn Energy Metering System using ATmega32 Microcontrollerthuthukani zamokuhle mthimkhuluPas encore d'évaluation

- Electrical Diagrams - DOL - Single Phasing - Denis T HallDocument7 pagesElectrical Diagrams - DOL - Single Phasing - Denis T HallSarath RaghavPas encore d'évaluation

- LAB 7 Elec Ins Wan HasbiDocument6 pagesLAB 7 Elec Ins Wan HasbiSyazwan HafidziPas encore d'évaluation

- Question No 1Document14 pagesQuestion No 1Hamza AliPas encore d'évaluation

- DTMF Based Prepaid Energy MeterDocument69 pagesDTMF Based Prepaid Energy MeterHemant Patel0% (1)

- DL 30130 - Extract From The ManualDocument6 pagesDL 30130 - Extract From The ManuallpestanaPas encore d'évaluation

- STD 019e2 PDFDocument102 pagesSTD 019e2 PDFServasfloresPas encore d'évaluation

- ANSI TIA StandardsDocument33 pagesANSI TIA StandardsJaime Palacios LocalesPas encore d'évaluation

- Short Circuit Calculation MethodsDocument6 pagesShort Circuit Calculation MethodsSyd MoralesPas encore d'évaluation

- (Architecture) Sustainable Landscape Design in Arid ClimatesDocument108 pages(Architecture) Sustainable Landscape Design in Arid ClimatesSham Salonga PascualPas encore d'évaluation

- Ontrol Equipment For MV Capacitor BanksDocument20 pagesOntrol Equipment For MV Capacitor BanksarieberdikariePas encore d'évaluation

- 2006 Denver Seminar PDFDocument24 pages2006 Denver Seminar PDFServasfloresPas encore d'évaluation

- Guide To Verifying Surge Protection Devices Dated 3-11-2010 PDFDocument9 pagesGuide To Verifying Surge Protection Devices Dated 3-11-2010 PDFServasfloresPas encore d'évaluation

- 69-2794 Manual HumidificadorDocument96 pages69-2794 Manual HumidificadorlaboratorioPas encore d'évaluation

- Job Safety Analysis: Perform The WeldDocument4 pagesJob Safety Analysis: Perform The WeldSachin Raj0% (1)

- GEAR PUMPS: COMPACT AND HIGH-PERFORMANCE LIQUID TRANSFERDocument5 pagesGEAR PUMPS: COMPACT AND HIGH-PERFORMANCE LIQUID TRANSFERGeorge Cobra100% (1)

- Machine Design ProblemsDocument39 pagesMachine Design ProblemsRon AquinoPas encore d'évaluation

- 1-2 Internal Combustion Power PlantDocument19 pages1-2 Internal Combustion Power PlantGeethika NayanaprabhaPas encore d'évaluation

- TeSys Deca Contactors - LC1D326SDDocument4 pagesTeSys Deca Contactors - LC1D326SDaligamers70Pas encore d'évaluation

- Prospectus English PDFDocument0 pageProspectus English PDFTushar SharmaPas encore d'évaluation

- INVERTER FREEZER CHEAT SHEET EpcDocument3 pagesINVERTER FREEZER CHEAT SHEET EpcHeco Hek Hek CanapiPas encore d'évaluation

- Template Tutor Sk016 (Terkini)Document6 pagesTemplate Tutor Sk016 (Terkini)cikgu_aminPas encore d'évaluation

- Trafo Neon SignDocument17 pagesTrafo Neon SignM. Azhary Srg. STPas encore d'évaluation

- Tüvis: TÜVIS-Prüfgrundlagen: AD 2000 Code, Volume 1, Register A Replaces Page - VersionDocument2 pagesTüvis: TÜVIS-Prüfgrundlagen: AD 2000 Code, Volume 1, Register A Replaces Page - VersionGentelmanOnlyPas encore d'évaluation

- PD Pilot DevicesDocument241 pagesPD Pilot DevicesaguilavmPas encore d'évaluation

- H1 Axial Piston Tandem Pumps: Size 045/053Document56 pagesH1 Axial Piston Tandem Pumps: Size 045/053Luis Arturo Arenales MaytaPas encore d'évaluation

- LowvoltageACdrivesforwaterandwastewater REVD enDocument28 pagesLowvoltageACdrivesforwaterandwastewater REVD enBalu MPas encore d'évaluation

- Energy StarDocument2 pagesEnergy StarsandyolkowskiPas encore d'évaluation

- MEP 283 Lecture NotesDocument57 pagesMEP 283 Lecture NotesPkay TandohPas encore d'évaluation

- Pimentel - 1994 - Constraints On The Expansion of The Global Food SupplyDocument9 pagesPimentel - 1994 - Constraints On The Expansion of The Global Food SupplygapofrohanPas encore d'évaluation

- R16B TechEEEIVYearRevisedSyllabusDocument52 pagesR16B TechEEEIVYearRevisedSyllabussundeep sPas encore d'évaluation

- @perkins: 400 Series 404C-22GDocument2 pages@perkins: 400 Series 404C-22GNibrasPas encore d'évaluation

- Astm 2161Document26 pagesAstm 2161tony juarezPas encore d'évaluation

- Area StatementDocument15 pagesArea StatementNeha GhatagePas encore d'évaluation

- ECE 306 Lab 4: Class AB Amplifier EfficiencyDocument8 pagesECE 306 Lab 4: Class AB Amplifier EfficiencyShehzadtajPas encore d'évaluation

- Sample Lab 2Document7 pagesSample Lab 2Febri SSPas encore d'évaluation