Académique Documents

Professionnel Documents

Culture Documents

ASPE - Exhaust Piping For Combustion Gases

Transféré par

miniongsky0%(1)0% ont trouvé ce document utile (1 vote)

42 vues4 pagesplumbing

Titre original

ASPE - Exhaust Piping for Combustion Gases

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentplumbing

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0%(1)0% ont trouvé ce document utile (1 vote)

42 vues4 pagesASPE - Exhaust Piping For Combustion Gases

Transféré par

miniongskyplumbing

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Montral ASPE technical and research committee Discussions

Translation from french by William (Bill)Hutchingame

Work done by J.P.Bourdage, G.Fafard

The plumbing engineer is responsible for the exhaust piping design for internal

combustion motors installed inside of buildings. Exhaust gases are created by emergency

power generators, gasoline pumps or dynamometers. In each case, the muffler must be

evacuated outside of the building as directly as possible with the least of restriction.

Excessive exhaust pressure loss harms evacuation of the combustion gas that create

back-pressure to the motors cylinders. This creates incomplete combustion of the fuel

inside the cylinders at the next cycle. A rule of thumb for an atmospheric suction motor

does not exceed a 20 inch water column of vacuum and a 27 inch water column for a

turbocompressure motor. The motor manufacturer must be consulted as soon as the

designer approaches these limits. The piping must be to the same diameter as the

manifold or larger diameter. All the elbows and directional changes must be with a long

radius configuration ( 5 diameters or higher).

Small mufflers are available for noise reduction to meet minimum requirements.

Residential zones, hospitals, and some applications require higher noise reduction with

over capacity of the mufflers, some times with two mufflers in series.

Static and dynamic pressure loss must be checked in each case. The muffler must be

installed as near as possible to the motor to prevent condensation and dirty oil in the

system; but never installed to the manifold itself. An explosion proof safety valve must

be installed upstream of each muffler.

A flexible joint should abate the motor vibrations to the muffler. A nipple must be fixed

to the manifold to facilitate maintenance of the flexible and allow a bit of cooling of the

exhaust.

Water, one of the by-products of combustion must never reach the cylinders of the motor.

Allow condensation legs to evacuate water from the pipe, slope the piping in the

direction toward the exterior. The muffler should have the same protection. (The high

quality mufflers have generally condensation legs).

The corrosive nature of exhaust gases require thicker pipes or corrosive resistant

materials. Schedule 40 may be acceptable for short runs. Stainless steel 304 is usual. All

the piping must be anchored and well supported.

High temperature approved insulation covered with aluminized steel jacket should cover

the piping where accessible to avoid maintenance persons to get burned. The piping

expansion must be free.

When a pipe passes trough a combustible wall or a roof, a vented jacket will be installed.

The moving air space will protect the environmental material to get to the auto ignition

point. This devise must exceed combustible surfaces on each side.

Guy Fafard page 1 de 4

The exhaust should never be located near: an oil or gas vent, a door or window, a

pedestrian passage, an air intake for ventilation or combustion, or a gas or fuel line.

The outlet must be protected from rain and snow flurries; bird screens will prevent

animals from entering the piping. Let us put great care from freezing. Exterior long runs

may generate condensation inside the pipes. This could create ice plugs that would cause

blockages and prevent exhaust of burned gas.

The exhaust is in fact a chimney stressed by high static pressures and vibrations

transmitted by dynamic pressure varying in function or frequencies of the explosions

inside the motor cylinders. The joints of the prefab chimneys are under stresses that

manufacturers are aware of to prevent leakage. Installation should be done by contractors

recognized for their competence. Only high quality controlled special cements should be

used.

Supports and anchors are very important and dont forget that the system must operate in

the worst situations as tremor, fire, terrorism and war.

The tests must be made at a 60 inch water column static pressure for prefab chimneys

according to UL 103. Provide expansion joints in sufficient quantity, the temperature

goes from900

o

F (482

o

C ) to 1100

o

F (593

o

C ) for diesel motors and up to 1400

o

F (760

o

C ) for gas motors.

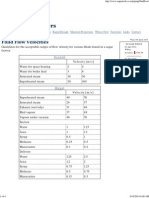

Check List

Muffler pressure lost

Total static and dynamic pressure lost

Local codes, NFPA et UL.

Piping at 9`` (229mm) min. from combustible surface

(6)

.

Vented J acket

(7)

for: roof, floor, walls.

Condensation legs.

Outlet protection against: animals, rain, snow, ice.

(8).

Type of pipes, anchors and supports.

Expansion joints, anti-vibration joints.

Safety valve against back-fire in each case.

(1) Back pressure : Caterpilar +/- 27``; John-Deer +/- 30``; Onan , Mitsubishi , Detroit Diesel +/- 41``.

(2) The action of time will corrode schedule 40 piping, the light inside will be reduced, metal

crystallization will be reduced by the heat, thermal shocks and gas speed.

(3) Each muffler and long run must be protected with safety valve against back fire to avoid explosion of

the gases accumulated in the piping after uncompleted combustion.

(4) Expansion can drag away the anchors, supports and twist all the piping.

(expansion of +/- 1 inches / 100

o

F x 100 `- 0``= +/- 14 inches for 100`-0`` at 1400

o

F ).

(5) Prefab Chimneys must be with internal structure ( norm UL 103 ).

(6) This includes electrical wires.

(7) Vented J acket with moving air space.

(8) NFPA 37-10 article 7-3.3 1998 et NFPA 211.

(9) Never use a flapper that can stick in ice.

NOTE: ASPE does not give any formal or tacit knowledge guaranty about this

information. Always check with the last edition of NFPA and UL.

Guy Fafard page 2 de 4

Guy Fafard page 3 de 4 Guy Fafard page 3 de 4

Guy Fafard page 4 de 4 Guy Fafard page 4 de 4

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Land Rover Popular PartsDocument25 pagesLand Rover Popular Partseleanor shelbyPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Vibration IsolationDocument1 pageVibration IsolationminiongskyPas encore d'évaluation

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFDocument240 pagesLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyPas encore d'évaluation

- AGE10503, Gas ProcessingDocument34 pagesAGE10503, Gas ProcessingiranmortezaPas encore d'évaluation

- CAT320B Service Repair Fault Code ZPWDocument32 pagesCAT320B Service Repair Fault Code ZPWZaw Phyo100% (1)

- Combining DOAS and VRF, Part 2 of 2Document9 pagesCombining DOAS and VRF, Part 2 of 2miniongskyPas encore d'évaluation

- Ornamental Garden PoolsDocument16 pagesOrnamental Garden PoolsminiongskyPas encore d'évaluation

- SRI FireFighting Equipments 2012 PDFDocument46 pagesSRI FireFighting Equipments 2012 PDFsullamsPas encore d'évaluation

- Wärtsilä 20 Product GuideDocument178 pagesWärtsilä 20 Product Guidedaniel adam0% (1)

- Math 1030 Working in The YardDocument4 pagesMath 1030 Working in The Yardapi-313345556Pas encore d'évaluation

- High-Rise Fire Protection System Design - Zoning & Series PumpingDocument4 pagesHigh-Rise Fire Protection System Design - Zoning & Series PumpingminiongskyPas encore d'évaluation

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyPas encore d'évaluation

- CIH Taco7aExpansionTankAirSepDocument16 pagesCIH Taco7aExpansionTankAirSepminiongskyPas encore d'évaluation

- Sugar - Fluid Flow VelocitiesDocument4 pagesSugar - Fluid Flow VelocitiesminiongskyPas encore d'évaluation

- Boilers - Types, Applications, and Efficiencies - Consulting-Specifying EngineerDocument4 pagesBoilers - Types, Applications, and Efficiencies - Consulting-Specifying EngineerminiongskyPas encore d'évaluation

- Air Changes Per Hour - University of LiverpoolDocument2 pagesAir Changes Per Hour - University of LiverpoolminiongskyPas encore d'évaluation

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDocument8 pagesApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyPas encore d'évaluation

- FMDS 1-35 Green Roof SystemsDocument27 pagesFMDS 1-35 Green Roof SystemsminiongskyPas encore d'évaluation

- Table 6 - Demographic2Document1 pageTable 6 - Demographic2miniongskyPas encore d'évaluation

- Hooking-Up Gensets To A UPSDocument8 pagesHooking-Up Gensets To A UPSminiongskyPas encore d'évaluation

- Pipe Support Spacing For Thermoplastic PipesDocument1 pagePipe Support Spacing For Thermoplastic PipesminiongskyPas encore d'évaluation

- Table - First Hour RatingDocument1 pageTable - First Hour RatingminiongskyPas encore d'évaluation

- Table - Hot Water Temperatures NHSDocument1 pageTable - Hot Water Temperatures NHSminiongskyPas encore d'évaluation

- Motor Start ConcernsDocument1 pageMotor Start ConcernsminiongskyPas encore d'évaluation

- Characteristic of Wastewater: Chapter OverviewDocument8 pagesCharacteristic of Wastewater: Chapter Overviewpenelopezeus39Pas encore d'évaluation

- Load Calculation JowharDocument6 pagesLoad Calculation JowharKhalid Abdirashid AbubakarPas encore d'évaluation

- Xerox Workcentre 6400: System Administrator Guide Guide de L'Administrateur SystèmeDocument184 pagesXerox Workcentre 6400: System Administrator Guide Guide de L'Administrateur SystèmeЃорѓи Поп-ЃорѓиевPas encore d'évaluation

- TIOut Brickwork 1Document4 pagesTIOut Brickwork 1kevin smithPas encore d'évaluation

- Dana dsh40 3 25 Parts ManualDocument36 pagesDana dsh40 3 25 Parts ManualOswaldo PalaciosPas encore d'évaluation

- The Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFDocument4 pagesThe Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFLog LouPas encore d'évaluation

- Index of Revisions Rev. Description And/Or Revised SheetsDocument17 pagesIndex of Revisions Rev. Description And/Or Revised Sheetsfabio.henriquePas encore d'évaluation

- Sigmazinc 109 HS: Description Principal CharacteristicsDocument4 pagesSigmazinc 109 HS: Description Principal CharacteristicsАлексейPas encore d'évaluation

- VCD-D ManualDocument13 pagesVCD-D ManualnimmuhkPas encore d'évaluation

- DWL-G120: Before You BeginDocument12 pagesDWL-G120: Before You BeginMark TeaterPas encore d'évaluation

- Arc Welding ReadingDocument16 pagesArc Welding ReadingJessica S. MellPas encore d'évaluation

- Voice Recognition Using MatlabDocument10 pagesVoice Recognition Using MatlabSneha Muralidharan100% (1)

- Custom PC Magazine UK January 2013Document132 pagesCustom PC Magazine UK January 2013Sei LaPas encore d'évaluation

- KinematicsDocument33 pagesKinematicsErik MagnoPas encore d'évaluation

- 14 Fine Tuned Assembly LineDocument4 pages14 Fine Tuned Assembly LineSadhish KannanPas encore d'évaluation

- Block PlanDocument1 pageBlock PlanJade Atkinson PhellainePas encore d'évaluation

- FB131Document7 pagesFB131Hoangvinh DuongPas encore d'évaluation

- TSC 247 PrinterDocument2 pagesTSC 247 Printerr4zorxPas encore d'évaluation

- BUTLER 1924 PAPER Studies in Heterogeneous EquilibriaDocument6 pagesBUTLER 1924 PAPER Studies in Heterogeneous Equilibriaglen19Pas encore d'évaluation

- Technical Service Bulletin (TSB) - VF7KFRHC8CS506525: 1. OriginDocument3 pagesTechnical Service Bulletin (TSB) - VF7KFRHC8CS506525: 1. Originalexp50Pas encore d'évaluation

- Common Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Document4 pagesCommon Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Yashi SrivastavaPas encore d'évaluation

- Plsed309005en (Web)Document174 pagesPlsed309005en (Web)Arifin SaniPas encore d'évaluation