Académique Documents

Professionnel Documents

Culture Documents

Selecting The Right Vibro

Transféré par

orkunituTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Selecting The Right Vibro

Transféré par

orkunituDroits d'auteur :

Formats disponibles

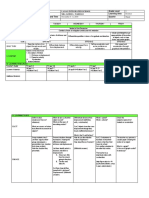

SELECTING THE RIGHT VIBRO-

ISOLATORS

Karman Rubber Vibro-Insulators come in a variety of styles and sizes

in order to handle most vibration isolation problems. The product

guide on page one shows the different styles of mounts that Karman

Rubber offers. Most of these mounts are designed to be used in either

the compression or shear direction as indicated in Figure 1.

Karman Rubber Vibro-Isolators are produced with either Natural

Rubber or Neoprene elastomers depending on the application.

Natural Rubber has a maximum operating temperature of 150F

and is good for most industrial applications. Natural Rubber is

affected by immmersion in oil.

Neoprene has a maxiumum operating temperature of 180F and is

resistant to oil.

To select the proper Vibro-Insulator for a specific application, it is

necessary to know the following information:

1. The maximum load that must be supported.

2. The number of mounts supporting the load.

3. The frequency of the disturbing vibration. (Note: If there is more than one frequency involved, the

lowest frequency is the determinilng one.)

4. Any restrictions on the size or style of the mount based on space limitations or assembly

considerations.

Karman Rubber will help you to select the proper Vibro-Isolators based on the information that you

provide. You may also select your own mount based on the following calculations.

Step 1: Calculate the load on each mounmt. If the load is evenly distributed, divide the total load by the

number of mounts.

Step 2: Calculate the lowest disturbing frequency (fd) based on the operating speed in cycles per second

(Hz). Convert fd from revolutions per minute (RPM) to cycles per second (Hz).

Step 3: Calculate the natural frequency (fn) that the system needs for 80% isolation.

Step 4: Calculate the requied static deflection (ds) to obtain the desired natural frequency (fn).

Step 5: Calculate the required spring rate (K) to obtain the desired natural frequency (fn).

Step 6: Select a mount that has a maximum load rating equal or greater than the calculated load per

mount and a spring rate (K) less than the calculated spring rate. Please note that overloading Vibro-

Insulators is not recommended, since it may lead to premature failure. However, excessive under

loading will not deflect the mount enough to provide satisfactory isolation.

Step 7: After you have selected the Vibro-Isolators you should calculate the transmissibility based on the

actual spring rate for the selected mount (see example below).

EXAMPLE CALCULATION

1.

2.

3.

4.

5.

6. Select a mount with a maximum load rating of at least 45 lbs per mount and a spring rate of 1,216

lbs/in or less. The 50 durometer K47 on page 22 has a maximum load of 50 lbs with a K Value of 675

lbs/in. in the compression direction.

7. Calculate the actual isolation based on using the K47 Vibro-Isolators at these operating conditions.

TERMINOLOGY

Compression - Deflecting a mount in the direction perpendicular to the mounting surface (see Figure 1).

Damping - The reduction of vibrational amplitude through the conversion of vibrational energy into heat.

Damping reduces the amount of amplification at resonance.

Disturbing frequency (fd) - The frequency of vibration caused by a source such as a motor expressed as

the number of oscillations that occur per unit time (RPM or Hz).

Durometer - The hardness of an elastometer based on a numbering scale that indicates the resistance to

indentation of an indicator point.

Isolation efficiency - The percentage of vibration that is absorbed by the rubber mount that protects the

equipment. It is equal to (1 - Transmissibility). An isolation efficiency of 80% is generally considered

satisfactory.

Load deflection curve - A plot of the applied load versus the distance that a mount is deflected.

Natural frequency (fn) - The frequency at which a system will vibrate freely if deflected from a static

equilibrium position.

Resonance - The condition existing when the disturbing frequency is the same as the natural frequency of

the system. At this condition the amount of vibration transmitted will be amplified instead of isolated.

Shear - Deflecting a mount in the direction parallel to the mounting surface (see Figure 1).

Static deflection (ds) - The deflection of a mount at a given static load.

Spring rate (k) - The ratio of the imposed static load to the resulting deflection of a particular rubber

amount expressed in lbs per inch.

Transmissibility (T) - A measure of the amount of vibration transmitted through a mount. A

transmissibility of 20% or less is normally desired.

Vous aimerez peut-être aussi

- Selecting The Right Vibro-Isolators - Karman Rubber CompanyDocument2 pagesSelecting The Right Vibro-Isolators - Karman Rubber Companyuamiranda3518Pas encore d'évaluation

- Selecting The Right Vibro-Isolators - Karman Rubber Company PDFDocument2 pagesSelecting The Right Vibro-Isolators - Karman Rubber Company PDFuamiranda3518Pas encore d'évaluation

- Selecting The Right Vibro-Isolators - Karman Rubber CompanyDocument3 pagesSelecting The Right Vibro-Isolators - Karman Rubber CompanyKapil NandwanaPas encore d'évaluation

- Calculation Guide of Vibration Isolators & Noise ControlDocument2 pagesCalculation Guide of Vibration Isolators & Noise ControlNarendraPas encore d'évaluation

- WDS Anti-Vibration Mount Performance and Selection GuideDocument2 pagesWDS Anti-Vibration Mount Performance and Selection GuiderrrrrPas encore d'évaluation

- MEBS6008 Environmental Services II Acoustic Treatment and Vibration ControlDocument26 pagesMEBS6008 Environmental Services II Acoustic Treatment and Vibration ControlSandeep BhatiaPas encore d'évaluation

- Frequently Asked Questions About Vibration: What Does It Mean To Isolate Vibration?Document8 pagesFrequently Asked Questions About Vibration: What Does It Mean To Isolate Vibration?joeeoj189189Pas encore d'évaluation

- Design For Quiet WHT PperDocument8 pagesDesign For Quiet WHT PperAdrian DavidescuPas encore d'évaluation

- Bilz - Vibration Isolation of Foundations & FrameworksDocument12 pagesBilz - Vibration Isolation of Foundations & FrameworksmikelotingaPas encore d'évaluation

- Basics of Vibration IsolationDocument8 pagesBasics of Vibration IsolationSAiTejaPas encore d'évaluation

- Vibrat RolDocument28 pagesVibrat RolHibelertCordóvaEspinosaPas encore d'évaluation

- Vibration Isolation TheoryDocument4 pagesVibration Isolation TheoryRa BalamuruganPas encore d'évaluation

- Firestone Marsh Mellow Springs W223580186Document26 pagesFirestone Marsh Mellow Springs W223580186MROstop.comPas encore d'évaluation

- Fan Vibration Isolation ED1900 PDFDocument4 pagesFan Vibration Isolation ED1900 PDFsivajirao70Pas encore d'évaluation

- Vibration Control Catalog - TechDocument72 pagesVibration Control Catalog - TechStuart TangPas encore d'évaluation

- Reduce Structure Vibrations to Protect EquipmentDocument7 pagesReduce Structure Vibrations to Protect EquipmentadbPas encore d'évaluation

- Basics of Vibration IsolationDocument8 pagesBasics of Vibration IsolationRajaSekarsajjaPas encore d'évaluation

- How To Select Vibration Isolators For OEM Machinery & EquipmentDocument11 pagesHow To Select Vibration Isolators For OEM Machinery & EquipmentfesalqpicPas encore d'évaluation

- Imperial Metric: Maximum Compression (5.8) Minimum Compression (6.8) Maximum Compression (147) Minimum CompressionDocument26 pagesImperial Metric: Maximum Compression (5.8) Minimum Compression (6.8) Maximum Compression (147) Minimum CompressionMROstop.comPas encore d'évaluation

- Fabreeka PadDocument16 pagesFabreeka Padlinhcdt3Pas encore d'évaluation

- Fabreeka PadDocument16 pagesFabreeka PadtelconrackPas encore d'évaluation

- Fi1,2 HP4 102 - ADocument5 pagesFi1,2 HP4 102 - AGliga Boris GligicPas encore d'évaluation

- Introduction to Anti-Vibration Mount SelectionDocument7 pagesIntroduction to Anti-Vibration Mount SelectionmodvillamancaPas encore d'évaluation

- Intro To Anti Vibration MountsDocument7 pagesIntro To Anti Vibration Mountsrmm99rmm99Pas encore d'évaluation

- Imperial Metric: Maximum Compression (4.35) Minimum Compression (5.1) Maximum Compression (110) Minimum CompressionDocument26 pagesImperial Metric: Maximum Compression (4.35) Minimum Compression (5.1) Maximum Compression (110) Minimum CompressionMROstop.comPas encore d'évaluation

- Fabr Pneumatic 033009Document28 pagesFabr Pneumatic 033009daniper89Pas encore d'évaluation

- Andrew MW 2.4mDocument5 pagesAndrew MW 2.4m'Theodora GeorgianaPas encore d'évaluation

- Aeroflex Wire Rope Isolators Protect Equipment in All EnvironmentsDocument28 pagesAeroflex Wire Rope Isolators Protect Equipment in All Environmentsraju3685Pas encore d'évaluation

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXPas encore d'évaluation

- 1.2 M Antenna SpecsDocument5 pages1.2 M Antenna SpecsRajendra AcharyaPas encore d'évaluation

- Learning On VibrationDocument42 pagesLearning On VibrationAnkit Shakyawar100% (1)

- General Information - Poles: (Poles Are Available Only in U.S.)Document2 pagesGeneral Information - Poles: (Poles Are Available Only in U.S.)KOUDJIL MohamedPas encore d'évaluation

- HP12 71WDocument5 pagesHP12 71WCulzPas encore d'évaluation

- Fi1,0 VHLP3 13 - ADocument5 pagesFi1,0 VHLP3 13 - AGliga Boris GligicPas encore d'évaluation

- Extracted Pages From 692D - Guidelines - Marine - Designers (L C Siet Bulon)Document3 pagesExtracted Pages From 692D - Guidelines - Marine - Designers (L C Siet Bulon)HUNG NIKKOPas encore d'évaluation

- VHLP4 7W 4WH - CDocument5 pagesVHLP4 7W 4WH - CDjarot BismantaraPas encore d'évaluation

- Broschure FlexiblemountsDocument155 pagesBroschure FlexiblemountsPrabakar MahesanPas encore d'évaluation

- Product Specifications: VHLPX2-7WDocument5 pagesProduct Specifications: VHLPX2-7WGuilhermePas encore d'évaluation

- Commscope Andew VHLP2-80-XXXDocument5 pagesCommscope Andew VHLP2-80-XXXАлександр КPas encore d'évaluation

- A Primer For Vibration IsolationDocument9 pagesA Primer For Vibration IsolationFadooollPas encore d'évaluation

- Isolator Design ConsiderationsDocument5 pagesIsolator Design ConsiderationsJinho JungPas encore d'évaluation

- Service Manual: FS-X3, FS-X1Document71 pagesService Manual: FS-X3, FS-X1videosonPas encore d'évaluation

- Best Practices For Installation of The Airfiber Af5/Af5U: Design GuideDocument4 pagesBest Practices For Installation of The Airfiber Af5/Af5U: Design GuideAntipas Komi Mawuli AziawaPas encore d'évaluation

- Lowfreq Preceng PDFDocument4 pagesLowfreq Preceng PDFho-faPas encore d'évaluation

- Vibration AnalyzersDocument16 pagesVibration Analyzersyogacruise100% (1)

- MH pgs0700Document15 pagesMH pgs0700Hamza Nouman100% (1)

- VHLPX4 7W 4GRDocument5 pagesVHLPX4 7W 4GRDavid Angulo EsguerraPas encore d'évaluation

- Design Examples For Shock Mount SelectionDocument4 pagesDesign Examples For Shock Mount Selectionmsasng9880Pas encore d'évaluation

- Korfund Spring MountsDocument50 pagesKorfund Spring Mountsuamiranda3518Pas encore d'évaluation

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesD'EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesPas encore d'évaluation

- Mechanical Vibration and Shock Analysis, Specification DevelopmentD'EverandMechanical Vibration and Shock Analysis, Specification DevelopmentPas encore d'évaluation

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Operational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseD'EverandOperational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseÉvaluation : 5 sur 5 étoiles5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- Magnelis Brochure enDocument8 pagesMagnelis Brochure enorkunituPas encore d'évaluation

- Web Datasheet c1.4Document12 pagesWeb Datasheet c1.4orkunituPas encore d'évaluation

- Selecting A Vibration Shock IsolatorDocument20 pagesSelecting A Vibration Shock IsolatorvilukPas encore d'évaluation

- Intro To Anti Vibration MountsDocument7 pagesIntro To Anti Vibration Mountsrmm99rmm99Pas encore d'évaluation

- SelecSelection Guide For Vibration Isolation For HVAC Equipmenttion Guide For Vibration Isolation For HVAC EquipmentDocument7 pagesSelecSelection Guide For Vibration Isolation For HVAC Equipmenttion Guide For Vibration Isolation For HVAC EquipmentorkunituPas encore d'évaluation

- Kahoot! With Groot!: 7.4k 829.3k 3m A Public KahootDocument4 pagesKahoot! With Groot!: 7.4k 829.3k 3m A Public KahootPranav S NairPas encore d'évaluation

- Vibration Measurement & AnalysisDocument48 pagesVibration Measurement & AnalysisSamPas encore d'évaluation

- U1251 90036Document190 pagesU1251 90036Hector TejedaPas encore d'évaluation

- BP 2069Document2 pagesBP 2069george tachePas encore d'évaluation

- Earth Frequency, Harmonics & Musical NotesDocument6 pagesEarth Frequency, Harmonics & Musical NotesJonel BoljanacPas encore d'évaluation

- Core Concepts 20-10-2017-SecuredDocument56 pagesCore Concepts 20-10-2017-Securedlucaspenalva123Pas encore d'évaluation

- Bio Zapper GuideDocument6 pagesBio Zapper Guidejumpin_aroundPas encore d'évaluation

- Korton's message of hope and changeDocument2 pagesKorton's message of hope and changeLucettaPas encore d'évaluation

- 01 OPTICS MCQ - CoNNect AcademyDocument45 pages01 OPTICS MCQ - CoNNect AcademyYousef ElnagarPas encore d'évaluation

- QY Electronic Co Ltd QRT-902 1000N.m Torque Signal CouplerDocument3 pagesQY Electronic Co Ltd QRT-902 1000N.m Torque Signal CouplerArpit VermaPas encore d'évaluation

- Physics All Chapters PDFDocument49 pagesPhysics All Chapters PDFCabdi Fitaax Kulmiye100% (1)

- Scotch YokeDocument2 pagesScotch YokeJay Mark Parayno100% (1)

- Phan Tich Cong C Dai HocenglishDocument143 pagesPhan Tich Cong C Dai HocenglishTrần Đức0% (1)

- Review of Principle and Analysis of Wave Guide: Sem. II, 2016/17 Microwave Devices and Systems by WaltengusDocument26 pagesReview of Principle and Analysis of Wave Guide: Sem. II, 2016/17 Microwave Devices and Systems by WaltengusYibe JosePas encore d'évaluation

- Whitepaper Ncode MethodsforAcceleratingDynamicDurabilityTests V2-Halfpenny PDFDocument19 pagesWhitepaper Ncode MethodsforAcceleratingDynamicDurabilityTests V2-Halfpenny PDFphysicsnewblolPas encore d'évaluation

- Ultrasonic Testing - Training NotesDocument80 pagesUltrasonic Testing - Training NotesRobert Maxwell88% (8)

- Bifiler and Trifiler SuspensionDocument4 pagesBifiler and Trifiler Suspensionchandan_j4uPas encore d'évaluation

- 25-12-19 - Sri Chaitanya SR - Icon All - GTM-2 - Question Paper - No PasswordDocument22 pages25-12-19 - Sri Chaitanya SR - Icon All - GTM-2 - Question Paper - No PasswordZomatoswiggyPas encore d'évaluation

- Vibration Analysis Category I (Level 1)Document9 pagesVibration Analysis Category I (Level 1)Choochart ThongnarkPas encore d'évaluation

- F5 ExperimentsDocument27 pagesF5 ExperimentsNarend Gunner80% (5)

- Multimedia Systems ExplainedDocument9 pagesMultimedia Systems ExplainedThomas KimPas encore d'évaluation

- FFT For ExperimentalistsDocument24 pagesFFT For ExperimentalistsMara FelipePas encore d'évaluation

- ApplicationGuide PDFDocument17 pagesApplicationGuide PDFsteam100deg1658Pas encore d'évaluation

- Grade 7, Quarter 3Document44 pagesGrade 7, Quarter 3James Lacuesta TabioloPas encore d'évaluation

- Vibration and Pulsation Analysis SolutionsDocument12 pagesVibration and Pulsation Analysis Solutions4jawwy markme026Pas encore d'évaluation

- Nature of Waves Lesson OutlineDocument31 pagesNature of Waves Lesson OutlineEllenor ErasanPas encore d'évaluation

- Electromagnetic WavesDocument1 pageElectromagnetic WavesJessicaMarizMagpocMendaroPas encore d'évaluation

- PD 06519-2-1988 (1999) Iec 479-2-1987Document26 pagesPD 06519-2-1988 (1999) Iec 479-2-1987Giorgos SiorentasPas encore d'évaluation

- Compendium Environment TestDocument221 pagesCompendium Environment TestnaniPas encore d'évaluation