Académique Documents

Professionnel Documents

Culture Documents

Metal Casting Process - 2

Transféré par

kiran_wakchaureTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metal Casting Process - 2

Transféré par

kiran_wakchaureDroits d'auteur :

Formats disponibles

The core is placed in the metal casting after the removal of the pattern.

Figure 5 shows the pattern

impression with the core in place.

Figure:5

Now the impression in the mold contains all the geometry of the part to be cast. This metal casting

setup, however, is not complete. In order for this mold to be functional to manufacture a casting,

in addition to the impression of the part, the mold cavity will also need to include a gating system.

Sometimes the gating system will be cut by hand or in more adept manufacturing procedures, the

gating system will be incorporated into the pattern along with the part. Basically, a gating system

functions during the metal casting operation to facilitate the flow of the molten material into the

mold cavity.

Elements Of A Gating System:

Pouring Basin:

This is where the molten metal employed to manufacture the part enters the mold. The pouring

basin should have a projection with a radius around it to reduce turbulence.

Down Sprue:

From the pouring basin, the molten metal for the casting travels through the down sprue. This

should be tapered so its cross-section is reduced as it goes downward.

Sprue Base:

The down sprue ends at the sprue base. It is here that the casting's inner cavity begins.

Ingate/Choke Area:

Once at the sprue base, the molten material must pass through the ingate in order to enter the inner

area of the mold. The ingate is very important for flow regulation during the metal casting

operation.

Runners:

Runners are passages that distribute the liquid metal to the different areas inside the mold.

Main Cavity:

The impression of the actual part to be cast is often referred to as the main cavity.

Vents:

Vents help to assist in the escape of gases that are expelled from the molten metal during the

solidification phase of the metal casting process.

Risers:

Risers are reservoirs of molten material. They feed this material to sections of the mold to

compensate for shrinkage as the casting solidifies. There are different classifications for risers.

Top Risers: Risers that feed the metal casting from the top.

Side Risers: Risers that feed the metal casting from the side.

Blind Risers: Risers that are completely contained within the mold.

Open Risers: Risers that are open at the top to the outside environment.

Figure 6 shows a mold with all its features, ready for metal casting.

Figure:6

The Metal Casting Operation

Pouring, Fluidity, Risers, Shrinkage And Other Defects

In the previous section the fundamentals of the metal casting process, as the basic starting point

for metal fabrication and part manufacture, were covered. Setup and design of a system to

perform a casting operation was explained. Main topics were molds, patterns, cores, and the

elements of a gating system. In this section we will explain the operation itself. We will begin

by assuming that there is a mold with a proper gating system in place and prepared for the

metal casting operation.

Pouring of the Metal:

When manufacturing by metal casting, pouring refers to the process by which the molten metal is

deliveredintothemold.Itinvolvesitsflowthroughthegatingsystemandintothemaincavity(casting

itself).

Goal: Metal must flow into all regions of the mold, particularly the casting's main cavity, before

solidifying.

Factors Of Pouring:

Pouring Temperature:

Pouring temperature refers to the initial temperature of the molten metal used for the casting as it is

poured into the mold. This temperature will obviously be higher than the solidification temperature of

the metal. The difference between the solidification temperature and the pouring temperature of the

metaliscalledthesuperheat.

Figure:8

Pouring Rate:

Volumetricrateinwhichtheliquidmetalisintroducedintothemold.Pouringrateneedstobecarefully

controlledduringthemetalcastingoperation,sinceithascertaineffectsonthemanufactureofthepart.

Ifthepouringrateistoofast,thenturbulencecanresult.Ifitistooslow,themetalmaybegintosolidify

beforefillingthemold.

Turbulence:

Turbulenceisinconsistentandirregularvariationsinthespeedanddirectionofflowthroughouttheliquid

metalasittravelsthoughthecasting.Therandomimpactscausedbyturbulence,amplifiedbythehigh

density of liquid metal, can cause mold erosion. An undesirable effect in the manufacturing process of

metal casting, mold erosion is the wearing away of the internal surface of the mold. It is particularly

detrimentalifitoccursinthemaincavity,sincethiswillchangetheshapeofthecastingitself.Turbulence

isalsobadbecauseitcanincreasetheformationofmetaloxideswhichmaybecomeentrapped,creating

porosity in the solid casting.

Fluidity:

Pouringisakeyelementinthemanufacturingprocessofmetalcastingandthemaingoalofpouringisto

getmetalto flowintoallregionsofthemoldbeforesolidifying.Thepropertiesofthemeltinacasting

processareveryimportant.Theabilityofaparticularcastingmelttoflowintoamoldbeforefreezingis

crucialintheconsiderationofmetalcastingtechniques.Thisabilityistermedtheliquidmetalsfluidity.

Test for Fluidity:

Inmanufacturingpractice,therelativefluidityofacertainmetalcastingmeltcanbequantifiedbytheuse

ofaspiralmold.Thegeometryofthespiralmoldactstolimittheflowofliquidmetalthroughthelength

ofitsspiralcavity.Themorefluiditypossessedbythemoltenmetal,thefartherintothespiralitwillbe

able to flow before hardening. The maximum point the metal reaches upon the casting's solidification

may be indexed as that melts relative fluidity.

Figure:9

SpiralMoldTest

How To Increase Fluidity In Metal Casting:

-Increase the superheat: If a melt is at a higher temperature relative to its freezing point, it will

remain in the liquid state longer throughout the metal casting operation, and hence its fluidity will

increase. However, there are disadvantages to manufacturing a metal casting with an increased

superheat. It will increase the melts likelihood to saturate gases, and the formation of oxides. It

will also increase the molten metals ability to penetrate into the surface of the mold material.

-Choose an eutectic alloy, or pure metal: When selecting a manufacturing material, consider

that metals that freeze at a constant temperature have a higher fluidity. Since most alloys freeze

over a temperature range, they will develop solid portions that will interfere with the flow of the

still liquid portions, as the freezing of the metal casting occurs.

-Choose a metal with a higher heat of fusion: Heat of fusion is the amount of energy involved

in the liquid-solid phase change. With a higher heat of fusion, the solidification of the metal casting

will take longer and fluidity will be increased.

Shrinkage:

Most materials are less dense in their liquid state than in their solid state, and more dense at lower

temperaturesingeneral.Duetothisnature,ametalcastingundergoingsolidificationwilltendtodecrease

in volume. During the manufacture of a part by casting this decrease in volume is termed shrinkage.

Shrinkage of the casting metal occurs in three stages:

1.Decreasedvolumeoftheliquidasitgoesfromthepouringtemperaturetothefreezingtemperature.

Figure:10

2.Decreasedvolumeofthematerialduetosolidification.

Figure:11

3.Decreasedvolumeofthematerialasitgoesfromfreezingtemperaturetoroomtemperature.

Figure:12

Risers:

Whendesigningasetupformanufacturingapartbymetalcasting,risersarealmostalwaysemployed.As

themetalcastingbeginstoexperienceshrinkage,themoldwillneedadditionalmaterialtocompensate

forthedecreaseinvolume.Thiscanbeaccomplishedbytheemploymentofrisers.Risersareanimportant

componentinthecasting'sgatingsystem.Risers,(sometimescalledfeeders),servetocontainadditional

molten metal. During the metal's solidification process, these reservoirs feed extra material into the

castingasshrinkageisoccurring.Thus,supplyingitwithanadequateamountofliquidmetal.Asuccessful

riserwillremainmoltenuntilafterthemetalcastingsolidifies.Inordertoreduceprematuresolidification

ofsectionswithintheriser,inmanymanufacturingoperations,thetopsofopenrisersmaybecovered

with an insulating compound, (such as a refractory ceramic), or an exothermic mixture.

Figure:13

Porosity:

One of the biggest problems caused by shrinkage, during the manufacture of a cast part, is porosity.

It happens at different sites within the material, when liquid metal can not reach sections of the

metal casting where solidification is occurring. As the isolated liquid metal shrinks, a porous or

vacant region develops.

Figure:14

Development of these regions

can be prevented during the

manufacturing operation, by

strategically planning the flow

of the liquid metal into the

casting through good mold

design, and by the

employment of directional

solidification. These

techniques will be covered in

detail in the gating system and

mold design section. Note that

gases trapped within the

molten metal can also be a

cause of porosity. The effects

of gases while manufacturing

parts by metal casting will be

discussed in the gases section.

Although proper metal casting

methods can help mitigate the

effects of shrinkage, some

shrinkage, (like that which

occurs in the cooling of the

work metal from the top of the

solid state to room

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- IRJET Manuscript TemplateDocument3 pagesIRJET Manuscript Templatekiran_wakchaurePas encore d'évaluation

- CFD Course: Sanjivani College of Engineering, KoparagaonDocument2 pagesCFD Course: Sanjivani College of Engineering, Koparagaonkiran_wakchaurePas encore d'évaluation

- Tom-I Question Bank UpdatedDocument174 pagesTom-I Question Bank Updatedkiran_wakchaurePas encore d'évaluation

- Simulation of Slider Crank Mechanism Using Adams ViesDocument5 pagesSimulation of Slider Crank Mechanism Using Adams Vieskiran_wakchaurePas encore d'évaluation

- Fuzzy Logic and It's ApplicationsDocument21 pagesFuzzy Logic and It's Applicationskiran_wakchaurePas encore d'évaluation

- Fea Tips Tricks Post ProcessinDocument12 pagesFea Tips Tricks Post Processinkiran_wakchaurePas encore d'évaluation

- Introduction To Kinematics of MachinesDocument16 pagesIntroduction To Kinematics of MachinesHarsha PrasadPas encore d'évaluation

- Frudensteins EquationDocument9 pagesFrudensteins Equationkiran_wakchaurePas encore d'évaluation

- Mechanical Stepless DrivesDocument7 pagesMechanical Stepless Driveskiran_wakchaure50% (2)

- U030 enDocument28 pagesU030 enkiran_wakchaurePas encore d'évaluation

- AMD Prepainted GalvalumeDocument4 pagesAMD Prepainted Galvalumekiran_wakchaurePas encore d'évaluation

- 03 Te Tom-IiDocument3 pages03 Te Tom-Iikiran_wakchaurePas encore d'évaluation

- 16 Jaggery From SugarcaneDocument8 pages16 Jaggery From Sugarcanekiran_wakchaurePas encore d'évaluation

- Ansys Commands and AcronymsDocument3 pagesAnsys Commands and Acronymskiran_wakchaurePas encore d'évaluation

- Prepared By: Prof K N Wakchaure: A Frame Which Supports The Cam and Guides The FollowerDocument11 pagesPrepared By: Prof K N Wakchaure: A Frame Which Supports The Cam and Guides The Followerkiran_wakchaurePas encore d'évaluation

- Metal Casting Process - 3Document11 pagesMetal Casting Process - 3kiran_wakchaurePas encore d'évaluation

- 2D & 3D TrussDocument43 pages2D & 3D Trusskiran_wakchaurePas encore d'évaluation

- Young's Modulus (Modulus of Elasticity) - E - Ultimate Tensile Strength - S Yield Strength - SDocument6 pagesYoung's Modulus (Modulus of Elasticity) - E - Ultimate Tensile Strength - S Yield Strength - Skiran_wakchaurePas encore d'évaluation

- Government Schemes: Jaggery Powder Plant ManufacturerDocument6 pagesGovernment Schemes: Jaggery Powder Plant Manufacturerkiran_wakchaurePas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Citrix Xenserver ® 6.0.2 Emergency Network Reset: Published Wednesday, 29 February 2012 1.0 EditionDocument6 pagesCitrix Xenserver ® 6.0.2 Emergency Network Reset: Published Wednesday, 29 February 2012 1.0 EditionJuan CarlosPas encore d'évaluation

- ECE320 Chapter 3 PDFDocument23 pagesECE320 Chapter 3 PDFAhsan NisarPas encore d'évaluation

- Oracle Exadata Technical Series: Smart ScanDocument59 pagesOracle Exadata Technical Series: Smart ScanVishnusivathej PotukanumaPas encore d'évaluation

- CSG CMT CalculationsDocument5 pagesCSG CMT Calculationsfrancisryan4519Pas encore d'évaluation

- Use of Multimeter TextDocument76 pagesUse of Multimeter Textprueba1100% (2)

- Piping Handbook Hydrocarbon Processing 1968 PDFDocument140 pagesPiping Handbook Hydrocarbon Processing 1968 PDFbogdan_chivulescuPas encore d'évaluation

- M S 1 1 - M S E 1 1: Hydraulic MotorsDocument36 pagesM S 1 1 - M S E 1 1: Hydraulic MotorsmehmetPas encore d'évaluation

- Textile AssignmentDocument8 pagesTextile AssignmentMahmudul Hasan Khan40% (5)

- Technical InformationDocument8 pagesTechnical Informationmyusuf_engineerPas encore d'évaluation

- Cable TrenchDocument57 pagesCable TrenchHari Krishna AaryanPas encore d'évaluation

- Production ManagementDocument81 pagesProduction ManagementrrathorePas encore d'évaluation

- Advance Concrete PDFDocument33 pagesAdvance Concrete PDFUdom RithPas encore d'évaluation

- DFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutDocument4 pagesDFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutRENSO BirouClujPas encore d'évaluation

- VORON2.2 ManualDocument120 pagesVORON2.2 ManualSsZzliMmPas encore d'évaluation

- Extended End-Plate Stiffener PDFDocument2 pagesExtended End-Plate Stiffener PDFaams_sPas encore d'évaluation

- Sop For LP Pump (R1)Document6 pagesSop For LP Pump (R1)SonratPas encore d'évaluation

- An-And-1-106 Basic CAN Bit TimingDocument9 pagesAn-And-1-106 Basic CAN Bit TimingNavneet Singh Pathania100% (1)

- How To Fix - External Disk Drive Suddenly Became RAWDocument96 pagesHow To Fix - External Disk Drive Suddenly Became RAWAntonio Marcano0% (1)

- CSC 263Document108 pagesCSC 263osecaloPas encore d'évaluation

- Chrony Beta and GammaDocument36 pagesChrony Beta and GammaÁdám MajorPas encore d'évaluation

- Brickwork ApparatusDocument4 pagesBrickwork ApparatusRoslie AbdullahPas encore d'évaluation

- Commisionign HVAC ChecklistDocument10 pagesCommisionign HVAC ChecklistCarolina HernándezPas encore d'évaluation

- Grabi Al Jubail ProfileDocument130 pagesGrabi Al Jubail ProfileSlid ISO100% (1)

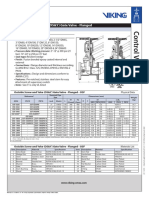

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoPas encore d'évaluation

- Master Thesis: Tasuku KanedaDocument77 pagesMaster Thesis: Tasuku Kanedamkali345Pas encore d'évaluation

- Deaton FE Slab DesignDocument57 pagesDeaton FE Slab DesignMohamed AliPas encore d'évaluation

- Ufgs 33 52 43.13Document40 pagesUfgs 33 52 43.13Tendai Felex MadukePas encore d'évaluation

- No35-Inclined Roof SystemDocument24 pagesNo35-Inclined Roof SystemKitanovic NenadPas encore d'évaluation

- Powerware 5110 UPS User's ManualDocument14 pagesPowerware 5110 UPS User's ManualjulbfuPas encore d'évaluation

- Operational Definition of TermsDocument2 pagesOperational Definition of TermsHazel Grace Tugado Torrecampo67% (3)