Académique Documents

Professionnel Documents

Culture Documents

AC To DC Power Conversion IEEE

Transféré par

vthiyagainTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AC To DC Power Conversion IEEE

Transféré par

vthiyagainDroits d'auteur :

Formats disponibles

AC to DC Power Conversion

Now and in the Future

PCIC-2001-14

Tony Siebert Anders Troedson Stephan Ebner

Member, IEEE Member, IEEE Member, IEEE

ABB Automation, Inc ABB Automation, Inc ABB Industrie AG

P.O. Box 372P.O. Box 372 CH- 5300 Turgi

Milwaukee, WI 53201 Milwaukee, WI 53201 Switzerland

USA USA

- 2 -

Agenda

Introduction

System Design Factors

Technology Assessment

Technology Comparison

Innovative Information Technology (IT) support

Conclusions

- 3 -

Rectifier History

1913 Fist Mercury-Arc rectifier

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

1925 Mercury-Arc rectifier for grid control

1939 First 50 kV HVDC transmission

1950 Development of Contact Rectifier

1947 Invention of Transistor

1902 Invention of Semiconductor Diode (Crystal type)

Mercury Arc Rectifier Contact Rectifier

- 4 -

Rectifier History

1958 First semicond. Diode rectifier

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

1960 First diode plant > 100 kA

1968 First thyristor rectifier

1970 First diode rectifier unit > 100 kA

Introduction of Thyristor Technology

Introduction of Diode Technology

Thyristor Rectifier Diode Rectifier

- 5 -

Rectifier History

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

1990 First thyristor rectifier for DC-Arc Furnace

1985 First thyristor rectifier for Aluminium Smelter

Ongoing Development of Diode Rectifier Technology

Ongoing Development of Thyristor Rectifier Technology

3 Thyristor Rectifier 4 Thyristor Rectifier 2 Thyristor Rectifier

- 6 -

Rectifier History

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

Mid-1990s first Chopper rectifier in Eletrolysis

Introduction of GTO Technology

Introduction of IGBT Technology

Introduction of IGCT Technology

IGBT Chopper Module PowerPac3

IGCT Chopper Module

- 7 -

System design and decision factors

AC-Network Design Parameter

Voltage level / voltage variation

Frequency / frequency variation

Available short circuit capability

Allowed power factor

Allowed harmonic distortion

DC-Process Design Parameter

Voltage / current operating range

Voltage / current ripple

Voltage / current regulation accuracy

Voltage / current regulation speed

Overload capabilities

Further Decision Factors

System reliability

System efficiency

Reparability and diagnostics

Footprint and mechanical dimension

Investment- / install- / life-cycle cost

Production load schedule criteria

Energy day-time tariffs criteria

Plant start-up / lay-off criteria

- 8 -

Process Ratings

Rectifier Application Current (Amps) Voltage (DC)

Chemical electrolysis 5,000 - 150,000 40 - 1,000 Volts

Aluminum potline 10,000 - 300,000 < 1,300 Volts

DC Arc Furnace 50,000 - 130,000 600 - 1,150 Volts

Graphitizing Furnaces 20,000 - 120,000 50 - 250 Volts

Zinc/Lead, etc electrolysis 5,000 - 100,000 100 - 1,000 Volts

Copper refining 10,000 - 50,000 40 - 350 Volts

Traction substations 1,000 - 5,000 500 - 1,500 Volts

LV AC Drive (DC bus) 0 - 10,000 250 - 1,000 Volts

MV Drive (DC bus) 0 - 5,000 3,400 - 6,000 Volts

Typical Rectifier Rating

- 9 -

Technology Assessment

Diode

Thyristor

Diode and DC/DC Converter

(Chopper)

Active Rectifier

- 10 -

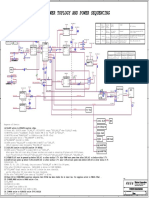

Diode Rectifier Topology

Double wye connection with interphase transformer

LOAD

6 puls circuit

3 - phase bridge connection

LOAD

6 puls circuit

- 11 -

Diode System Regulation Principle

Step of current setpoint

Step of OLTC

current without saturable reactor ramp control ( load impedance related )

current with saturable reactor ramp control

Range of saturable reactor control

T *) typ. 3 .. 5 s depending on OLTC drive

(saturable reactor control up to 5 ms depending on the load)

t [seconds]

I

dc

[kA]

T *)

- 12 -

Diode Rectifiers

Simplest Technology

Longest use

Used with On-Load-Tap-Changers

Used with saturable core reactors

(amplistats, voltage controlled reactors)

2 4 - Pul s e Di o de Re c t i f i e r

+7 . 5

- 7. 5

Lo a d

- 13 -

Thyristor Rectifier Topology

Double wye connection with interphase transformer

LOAD

6 puls circuit

3 - phase bridge connection

LOAD

6 puls circuit

- 14 -

Thyristor System Regulation Principle

Step of current setpoint

theor.current without phase angle ramp control () ( load impedance related )

current with phase angle ramp control in operation

Range of phase angle control

T *) typ. 100 ms .. 300 ms

possible up to 5 ms depending on the load

T *)

t [milliseconds]

I

dc

[kA]

Steps only with OLTC

- 15 -

Thyristor Rectifiers

Simple Technology

Widely Used

Can be used with On-Load-Tap-

Changers

Relatively fast control of current

2 4 - Pul s e Thy r i s t o r Re c t i f i e r

+7 . 5

- 7. 5

Lo a d

- 16 -

Diode Rectifier + DC-Chopper Topology

3 - phase bridge connection

LOAD

6 puls circuit

- 17 -

DC-Chopper Regulation Principle

Step of current setpoint

theor.current without PWM ramp control ( load impedance related )

current with PWM ramp control

Range of modulation control

T

1)

typ. 100 ms .. 300 ms with electrolyis process load

possible up to 1 .. 5 ms depending on the load

t [milliseconds]

I

dc

[kA]

T

1)

Tmod

2)

typ. 0.2 ms .. 1 ms

T

mod

2)

T

on

T

off

- 18 -

Diode Rectifier with Chopper Converter

Newer Technology

Relatively entering into Market

Merging of older (diode) and new

technology

Fast control of current

+7.5

-7.5

- 19 -

Active Rectifier Topology (AC-Chopper)

3 - phase bridge connection

LOAD

6 puls circuit

Active Current Source Inverter

- 20 -

AC-Chopper Regulation Principle

T

1)

typ. 100 ms .. 300 ms with electrolyis process load

possible up to 1 .. 5 ms depending on the load

Step of current setpoint

theor.current without ramp control ( load impedance related )

current with ramp control

Range of modulation control

t [milliseconds]

I

dc

[kA]

T

1)

Tmod

2)

typ. 0.2 ms .. 1 ms

T

mod

2)

T

on

T

off

- 21 -

Active Rectifier (AC-Chopper)

Newest Application of Technology

Limited Market entry

Based upon proven technology

Fast control of current

Active Current Source Inverter

Load

- 22 -

Technology use by Process

Application Diode Thyristor Chopper Active Rectifier

Chemical Electrolysis Seldom Standard Seldom Future

Aluminum Potline Standard Seldom Not Acceptable Distant Future

DC Arc Furnace Not Acceptable Standard Seldom Future

Graphitizing Furnace Standard Seldom Future Future

Zinc Electrolysis Standard Seldom Future Future

Copper Refining Seldom Standard Seldom Future

Traction Substation Standard Seldom Future Distant Future

LV AC Drive (DC Link) Standard Seldom Not Applicable Seldom

MV Drive (DC Link) Standard Seldom Not Applicable Seldom

- 23 -

Technology Share of Units > 10 kA

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

1

9

7

2

1

9

7

4

1

9

7

6

1

9

7

8

1

9

8

0

1

9

8

2

1

9

8

4

1

9

8

6

1

9

8

8

1

9

9

0

1

9

9

2

1

9

9

4

1

9

9

6

1

9

9

8

2

0

0

0

Chopper

Thyristor

Diode

Technology Share

- 24 -

Technology Comparison

Power Factor

Efficiency

Harmonic Distortion

Reliability / Availability / Service Support

Space Requirements

System Cost

- 25 -

The Process Load Characteristic

U

d o

I

d

Aluminium

Zinc

Chlorine

Copper

I

Range

U

Range

100 %

100 %

50 %

25 %

75 %

- 26 -

Power Factor Comparison

Power Factor vs Transformer Impedance

0.8800

0.8900

0.9000

0.9100

0.9200

0.9300

0.9400

0.9500

0.9600

6 7 8 9 10 11 12

Transformer Impedance

P

o

w

e

r

F

a

c

t

o

r

Diode / DB

Thyristor / DB

Note: Low Transformer Impedance = High Voltage

Harmonics

- 27 -

Power Factor Comparison

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

250.00 300.00 350.00 400.00 450.00

Ud [V]

P

F

[

-

]

Diode OLTC Thyristor OLTC Thyristor Uncompensated Thyristor Compensated

Diode vs Thyristor with Electrolysis Process Load

Ud

Id

- 28 -

Power Factor Comparison

Diode Good

Thyristor Low

Diode and Chopper Good

Active Rectifier Best

- 29 -

Efficiency vs. Voltage

0.9

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

1

0 200 400 600 800 1000 1200 1400 1600

Voltage

E

f

f

i

c

i

e

n

c

y

Typ Dio/Thy Bridge Typ Dio/Thy Single Way

Typ Chopper Dio/Thy Projects

- 30 -

Comparison at Nominal load Operation

Nominal Load Operation DC-Voltage: 500 V

DC-Current: 70 kA

DC-Power: 35 MW

Diode

System

Thyristor

System

Chopper

System

AC-Power (12p-Transformer) 39 MVA 41 MVA 38 MVA

Power Factor without correction 0.91 0.86 0.93

Compensation up to PF=0.93 3 MVAR 8 MVAR -

Compensation up to PF=0.98 10 MVAR 15 MVAR 7 MVAR

Losses

Transformer (including harmonics) 430 kW 450 kW 400 kW

Rectifier 183 kW 192 kW 170 kW

Chopper 250 kW

Line Filter (for PF=0.93) 56 kW 84 kW

Total 669 kW 726 kW 820 kW

Relative Difference -151 kW -94 kW 0 kW

Efficiency (for Components considered) 0.981 0.980 0.977

- 31 -

Comparison at Reduced load Operation

Reduced Load Operation DC-Voltage: 440 V

DC-Current: 50 kA

DC-Power: 22 MW

Diode

System

Thyristor

System

Chopper

System

AC-Power (12p-Transformer) 25 MVA 34 MVA 24 MVA

Power Factor without correction 0.90 0.65 0.93

Compensation up to PF=0.93 3 MVAR 8 MVAR -

Compensation up to PF=0.98 10 MVAR 15 MVAR 7 MVAR

Losses

Transformer (including harmonics) 240 kW 260 kW 170 kW

Rectifier 105 kW 120 kW 100 kW

Chopper 250 kW

Line Filter (for PF=0.93) 56 kW 84 kW

Total 401 kW 464 kW 520 kW

Relative Difference -119 kW -56 kW

Efficiency (for Components considered) 0.982 0.979 0.977

- 32 -

Efficiency Comparison

Diode High

Thyristor Medium - High

Diode and Chopper Low

Active Rectifier Medium - Low

- 33 -

Harmonic Comparison

1

5

7

11

13

17

19

23

25

29

31

35

37

41

43

47

0o

20o

40o

6 0 o

0

2

4

6

8

10

12

14

16

AC Current i n [ kA]

Har moni c Number

20 kA, 200 V DC, 6 Pul se Recti fi er

Di ode and Chopper ( 0 degrees) and Thyri stor

(variable

dependi ng on output DC vol tage)

0o

10o

20o

30o

40o

50o

60o

- 34 -

Harmonic Comparison

Diode Good

Thyristor Lower

Diode and Chopper Good

Active Rectifier Best

- 35 -

Reliability Comparison

Based Upon Component Count of

Rectifier Devices

Diode High

Thyristor High

Diode and Chopper Low

Active Rectifier Medium

- 36 -

Service Skill Comparison

Diode Low

Thyristor Medium

Diode and Chopper High

Active Rectifier High

- 37 -

System Cost Comparison

Diode Rectifier 105%

Thyristor Rectifier 100%

Diode & Chopper 124%

Active Rectifier 115%

Based upon past projects, component count and further

developments.

- 38 -

Space Comparison

Diode Average

Thyristor Larger

(with power factor included)

Diode and Chopper Larger

Active Rectifier Average

- 39 -

Conclusions

Considerations

Total System Requirements

Future Provision of System

Requirements

Customers Experience / Background

Technology comparison for exact

project

All Technologies Will continue for near

future

- Thank You -

Vous aimerez peut-être aussi

- Optimize Magnetic GapDocument45 pagesOptimize Magnetic GapteomondoPas encore d'évaluation

- Three-Phase TransformersDocument42 pagesThree-Phase TransformersabhinavPas encore d'évaluation

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsD'EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsPas encore d'évaluation

- Fundamentals of HVDC and FACTS Devices: Lecture NotesDocument22 pagesFundamentals of HVDC and FACTS Devices: Lecture NotesKiran KunchamPas encore d'évaluation

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarPas encore d'évaluation

- Magnetically Controlled Shunt Reactors - A New Type of FACTS DeviceDocument3 pagesMagnetically Controlled Shunt Reactors - A New Type of FACTS Devicemjbriceno@gmail.comPas encore d'évaluation

- Current Harmonic Analysis of Multi Pulse Diode Rectifiers With Phase Shifting TransformerDocument5 pagesCurrent Harmonic Analysis of Multi Pulse Diode Rectifiers With Phase Shifting TransformerJakka VenkatPas encore d'évaluation

- Transformer and Inductor Design Handbook Chapter 19Document10 pagesTransformer and Inductor Design Handbook Chapter 19Brijendra VermaPas encore d'évaluation

- Type VHXM: Under / Over Voltage RelayDocument6 pagesType VHXM: Under / Over Voltage RelayNikki AgarwalPas encore d'évaluation

- Arc Phenomena and Method of Arc Extinction in Air Circuit Breaker PDFDocument4 pagesArc Phenomena and Method of Arc Extinction in Air Circuit Breaker PDFHANRI ,Pas encore d'évaluation

- Auxiliary RelayDocument5 pagesAuxiliary RelayVijayaganthaan VisvanatthanPas encore d'évaluation

- VSC Course Lecture2Document27 pagesVSC Course Lecture2eng7senPas encore d'évaluation

- Shunt Reactor 0420101Document16 pagesShunt Reactor 0420101emy1188Pas encore d'évaluation

- Thyristor Controlled Reactor: Circuit DiagramDocument4 pagesThyristor Controlled Reactor: Circuit DiagramSpk SudhinPas encore d'évaluation

- Talking About HV Shunt Reactor Switching - EEPDocument5 pagesTalking About HV Shunt Reactor Switching - EEPa_mohid17Pas encore d'évaluation

- Inst TRX TRENCH PDFDocument20 pagesInst TRX TRENCH PDFBruce CoxPas encore d'évaluation

- Impulse GeneratorDocument3 pagesImpulse GeneratorTanmay RajePas encore d'évaluation

- LC5296 LC5296-H 5006RN LC5248E User Manual PDFDocument36 pagesLC5296 LC5296-H 5006RN LC5248E User Manual PDFPankaj MauryaPas encore d'évaluation

- Rapid Pressure Rise RelaysDocument4 pagesRapid Pressure Rise RelaysANGEL STRAGLIATIPas encore d'évaluation

- Harmonics Effect On Rectifier Current Imbalance Rev1Document6 pagesHarmonics Effect On Rectifier Current Imbalance Rev1Laurence MichaelPas encore d'évaluation

- A Seminar Report On "Transient Overvoltage in Distribution SystemDocument6 pagesA Seminar Report On "Transient Overvoltage in Distribution SystemAkhilesh PandeyPas encore d'évaluation

- IEEMA-Basics of Dual Ratio TransformersDocument3 pagesIEEMA-Basics of Dual Ratio TransformersHari Krishna.MPas encore d'évaluation

- Ztr290 Testing of MCSRDocument10 pagesZtr290 Testing of MCSRFernando Lud van MeizPas encore d'évaluation

- Sie91093-T1000 PlusDocument37 pagesSie91093-T1000 PlusRoyyan Hasmi FadhillahPas encore d'évaluation

- Zelio Timer Relays - RE7ML11BU PDFDocument19 pagesZelio Timer Relays - RE7ML11BU PDFAlex GonzalezPas encore d'évaluation

- 7.21 Outdoor Bus StructuresDocument191 pages7.21 Outdoor Bus StructuresEdyta MarzecPas encore d'évaluation

- Corona Characteristics ThilinaDocument6 pagesCorona Characteristics ThilinaThilina Jayaweera100% (2)

- Corona, Sag and Conductor Vibration: Batch IXDocument15 pagesCorona, Sag and Conductor Vibration: Batch IXShyamala Chettiraj100% (1)

- 13 SVC Systems Power Quality D 2008-03-12Document10 pages13 SVC Systems Power Quality D 2008-03-12satelite54100% (1)

- A2.24 Thermal PerformancesID55VER20Document15 pagesA2.24 Thermal PerformancesID55VER20Fajar Adi PrabowoPas encore d'évaluation

- Earth Fault RelayDocument1 pageEarth Fault RelayAliu AlaoPas encore d'évaluation

- Ezct-Ezct2k Truns Ratio Testing Notes Rev 2Document12 pagesEzct-Ezct2k Truns Ratio Testing Notes Rev 2hizbi7Pas encore d'évaluation

- Introduction To Instrument TransformersDocument20 pagesIntroduction To Instrument TransformersAbdul'Azeez Stanley IgwePas encore d'évaluation

- HVDC FinalDocument26 pagesHVDC FinalGoutham MadarapuPas encore d'évaluation

- Tap ChangerDocument10 pagesTap ChangerusefiPas encore d'évaluation

- Axial N Radial ForceDocument6 pagesAxial N Radial ForceEko SusantoPas encore d'évaluation

- S1 3 P 1Document5 pagesS1 3 P 1Mohd Ghazali JPMMPas encore d'évaluation

- Effect of Source InductanceDocument25 pagesEffect of Source InductanceSriram Anil Kumar Gandham100% (1)

- 5-Characteristic Cable Impedance-DigibridgeDocument3 pages5-Characteristic Cable Impedance-DigibridgealmonimePas encore d'évaluation

- Variable Shunt Reactors Cigre2014 A2 211 2014Document8 pagesVariable Shunt Reactors Cigre2014 A2 211 2014StrahinjaPas encore d'évaluation

- Design and Construction of 0 500V 3KVA Variac With Digital DisplayDocument9 pagesDesign and Construction of 0 500V 3KVA Variac With Digital DisplayEditor IJTSRDPas encore d'évaluation

- Why Transformer Does Not Work On DC Supply Instead of ACDocument4 pagesWhy Transformer Does Not Work On DC Supply Instead of ACAHMED YOUSEFPas encore d'évaluation

- Ds Ac DC HV Test Set PGK 110 HB Baur En-GbDocument3 pagesDs Ac DC HV Test Set PGK 110 HB Baur En-GbRomany AllamPas encore d'évaluation

- How The Efficiency of Radiator For Transformer Cooling Is MeasuredDocument4 pagesHow The Efficiency of Radiator For Transformer Cooling Is MeasuredAbdulyunus AmirPas encore d'évaluation

- LCM500 Leakage Current Monitor: User GuideDocument74 pagesLCM500 Leakage Current Monitor: User GuideThien Nguyen VanPas encore d'évaluation

- Aed Unit3Document68 pagesAed Unit3Anser Pasha100% (1)

- Transformer PPT For First YearDocument42 pagesTransformer PPT For First YearDhairya PathakPas encore d'évaluation

- Design and Analysis of Transformer Using MATLABDocument6 pagesDesign and Analysis of Transformer Using MATLABIJSTEPas encore d'évaluation

- Transformer Sweep Frequency Response Analyzer HYRZ-902 Technical ManualDocument18 pagesTransformer Sweep Frequency Response Analyzer HYRZ-902 Technical ManualPaulRuedaPas encore d'évaluation

- KYN61-40.5 Indoor Removable AC Metal-Clad SwitchgearDocument1 pageKYN61-40.5 Indoor Removable AC Metal-Clad SwitchgearCLAVOTPas encore d'évaluation

- Inductor Design With Magnetics Ferrite CoresDocument3 pagesInductor Design With Magnetics Ferrite CoresNikhil GuptaPas encore d'évaluation

- 7UT 61 Diff. Relay Secondary Injection Test Notes: For Even Vector Group (0,2,4,6,8,10)Document1 page7UT 61 Diff. Relay Secondary Injection Test Notes: For Even Vector Group (0,2,4,6,8,10)nadalllabeedPas encore d'évaluation

- Transmission Line CapacitanceDocument31 pagesTransmission Line CapacitancejcmeePas encore d'évaluation

- Transformers ConnectionsDocument6 pagesTransformers Connectionsgeorgel1980Pas encore d'évaluation

- Module 1 Lecture 1 - 4Document17 pagesModule 1 Lecture 1 - 4ukassyahPas encore d'évaluation

- Electric Drives System - PGDocument252 pagesElectric Drives System - PGKrishna SahooPas encore d'évaluation

- Auto Selection of Any Available PhaseDocument16 pagesAuto Selection of Any Available PhaseRyan HarrisPas encore d'évaluation

- IMS - LANTIME M1000: Time and Frequency Synchronization Platform in 1U Rackmount-EnclosureDocument14 pagesIMS - LANTIME M1000: Time and Frequency Synchronization Platform in 1U Rackmount-EnclosurevthiyagainPas encore d'évaluation

- Container Packing Broschuere Engl PDFDocument24 pagesContainer Packing Broschuere Engl PDFraer1971Pas encore d'évaluation

- Gateway Computer-ACP-4340Document12 pagesGateway Computer-ACP-4340vthiyagainPas encore d'évaluation

- Full Gigabit Ethernet Switch L2 Software 16 Ports - Ports On Rear - AFS677-ER16CPZZX08.0Document8 pagesFull Gigabit Ethernet Switch L2 Software 16 Ports - Ports On Rear - AFS677-ER16CPZZX08.0vthiyagainPas encore d'évaluation

- 450.27 - NFPA 70 (2017) National Electrical Code® HandbookDocument1 page450.27 - NFPA 70 (2017) National Electrical Code® HandbookvthiyagainPas encore d'évaluation

- Gigabit Ethernet 19' Switch, 2-20 Ports, Ports On Rear - AFS675-Ercpaaaaaaaauaeepzzx08.0Document7 pagesGigabit Ethernet 19' Switch, 2-20 Ports, Ports On Rear - AFS675-Ercpaaaaaaaauaeepzzx08.0vthiyagainPas encore d'évaluation

- Battery DatasheetDocument3 pagesBattery DatasheetvthiyagainPas encore d'évaluation

- Micro Station V8 I Ss 1 VBAfor Advanced Users TOCDocument4 pagesMicro Station V8 I Ss 1 VBAfor Advanced Users TOCvthiyagainPas encore d'évaluation

- IEEE Lightning Protection For Switch YardDocument50 pagesIEEE Lightning Protection For Switch Yardelayaraja100% (19)

- Manufacturer ReportDocument602 pagesManufacturer ReportvthiyagainPas encore d'évaluation

- Balanced Fault Calculation PDFDocument79 pagesBalanced Fault Calculation PDFvthiyagainPas encore d'évaluation

- IEEE PresentationPower RectifiersDocument40 pagesIEEE PresentationPower Rectifiersjllp64803Pas encore d'évaluation

- 400KV Protection PDFDocument140 pages400KV Protection PDFvthiyagain100% (1)

- Calculation of Non Linear Resistor (Al Hassa Housing 115Kv/13.8Kv S/S)Document7 pagesCalculation of Non Linear Resistor (Al Hassa Housing 115Kv/13.8Kv S/S)vthiyagainPas encore d'évaluation

- Nagoor Kani - Control System EngineeringDocument396 pagesNagoor Kani - Control System EngineeringArpit Sharma86% (44)

- Fault Analysis ECE4334Document64 pagesFault Analysis ECE4334vthiyagainPas encore d'évaluation

- Guide of Harmonics and Resonance With CapacitorsDocument12 pagesGuide of Harmonics and Resonance With CapacitorsrezakaihaniPas encore d'évaluation

- IEEE Tutorial Sag Tension CalculationDocument33 pagesIEEE Tutorial Sag Tension CalculationvthiyagainPas encore d'évaluation

- Flicker Analysis & Case StudiesDocument96 pagesFlicker Analysis & Case Studiesvthiyagain100% (1)

- Chapter 10: Symmetrical Components and Unbalanced Faults, Part IIDocument10 pagesChapter 10: Symmetrical Components and Unbalanced Faults, Part IIAmeer AmefPas encore d'évaluation

- Chapter 12Document42 pagesChapter 12biotech_vidhyaPas encore d'évaluation

- Direct Torque Control: Technical Guide No. 1Document32 pagesDirect Torque Control: Technical Guide No. 1vthiyagain100% (1)

- Differential ProtectionDocument19 pagesDifferential ProtectionvthiyagainPas encore d'évaluation

- IEC 60071 Insulation Coordination Abb LiteratureDocument8 pagesIEC 60071 Insulation Coordination Abb Literaturereza515hei100% (2)

- Design of Earthing MatDocument31 pagesDesign of Earthing MatvthiyagainPas encore d'évaluation

- AsymFault ExamplesDocument32 pagesAsymFault ExamplesvthiyagainPas encore d'évaluation

- Introduction To Symmetrical CompDocument14 pagesIntroduction To Symmetrical CompvthiyagainPas encore d'évaluation

- Design of Earthing MatDocument31 pagesDesign of Earthing MatvthiyagainPas encore d'évaluation

- 2 - Long Rod InsulatorsDocument1 page2 - Long Rod InsulatorsvthiyagainPas encore d'évaluation

- Delay Compensation in Model Predictive Current Control of A Three-Phase InverterDocument3 pagesDelay Compensation in Model Predictive Current Control of A Three-Phase InverterNam Doan0% (1)

- Aoc lm722 Users Manual 393032 PDFDocument20 pagesAoc lm722 Users Manual 393032 PDFAfonsoSouzaPas encore d'évaluation

- IMSO 2016 - Science Experiment - SolDocument5 pagesIMSO 2016 - Science Experiment - SolThanh Dinh100% (1)

- Microcontroller Based Pill Reminder: Ronak Rathod Divya Shah Aarsh PathakDocument21 pagesMicrocontroller Based Pill Reminder: Ronak Rathod Divya Shah Aarsh PathakabinayageethaPas encore d'évaluation

- Diodo BZXDocument3 pagesDiodo BZXAndrey SilvaPas encore d'évaluation

- 2f3e0 LA-8671P 1ADocument50 pages2f3e0 LA-8671P 1ASelmar CavalcantiPas encore d'évaluation

- Nokia Lumia 925 - Service ManualDocument68 pagesNokia Lumia 925 - Service Manualwds555Pas encore d'évaluation

- Find The Thevenin's Equivalent Circuit of The Circuit Shown in Fig., at Resistance RDocument59 pagesFind The Thevenin's Equivalent Circuit of The Circuit Shown in Fig., at Resistance RAkol MajookPas encore d'évaluation

- Chapter 1 Diode Circuit Final 24 PDFDocument45 pagesChapter 1 Diode Circuit Final 24 PDFMahankali SwathiPas encore d'évaluation

- LG 32lc3r-Zj Chassis Lp61a SMDocument38 pagesLG 32lc3r-Zj Chassis Lp61a SMsanPas encore d'évaluation

- A Prototype Design of Border Alert System For Fishermen Using Gps UpdateDocument32 pagesA Prototype Design of Border Alert System For Fishermen Using Gps UpdateKelly GalvEz50% (2)

- Physics XII CH 14 Physics Assertion Reasoning Semiconductor ElectronicsDocument7 pagesPhysics XII CH 14 Physics Assertion Reasoning Semiconductor ElectronicsAshwinPas encore d'évaluation

- 9.3 Astable Multivibrator: Return NextDocument8 pages9.3 Astable Multivibrator: Return Nextsankar2015Pas encore d'évaluation

- Making OSNR Measurements in A Modulated DWDM Signal EnvironmentDocument26 pagesMaking OSNR Measurements in A Modulated DWDM Signal EnvironmenthasPas encore d'évaluation

- EMC Fundamentals Sept 2006Document63 pagesEMC Fundamentals Sept 2006goodgoliers01Pas encore d'évaluation

- Embedded SystemsDocument21 pagesEmbedded Systemsmalhiavtarsingh100% (2)

- LAPORAN PRAKTIKUM ELEKTRONIKA DASAR Robot KepikDocument12 pagesLAPORAN PRAKTIKUM ELEKTRONIKA DASAR Robot Kepikagus saefullohPas encore d'évaluation

- "Final Year Ece Projects in Chennai, Bangalore, Vijayawada, Kakinada." GoodDocument18 pages"Final Year Ece Projects in Chennai, Bangalore, Vijayawada, Kakinada." Goodwondi BETPas encore d'évaluation

- SR 71 Blackbird Owners ManualDocument4 pagesSR 71 Blackbird Owners ManualmikletPas encore d'évaluation

- Capacitor Coupled Transistor Inverter Laboratory Excercise 4 - 2 AnswerDocument3 pagesCapacitor Coupled Transistor Inverter Laboratory Excercise 4 - 2 AnswerLear SoyonPas encore d'évaluation

- Plastic MemoryDocument14 pagesPlastic MemoryHarie Bandla100% (1)

- 8255 PPI-handouts To StudentsDocument4 pages8255 PPI-handouts To StudentsSurinder SuriPas encore d'évaluation

- Adjustment: 1. FirmwareDocument15 pagesAdjustment: 1. Firmwarerocklando777Pas encore d'évaluation

- Build Your Home-Made 500Khz Frequency Meter!Document12 pagesBuild Your Home-Made 500Khz Frequency Meter!nagdeep58Pas encore d'évaluation

- PDF of Digital Signal Processing Ramesh Babu 2 PDFDocument2 pagesPDF of Digital Signal Processing Ramesh Babu 2 PDFRoja Surkutlawar0% (1)

- Service Instructions 102171 2001-01-08 SB Parameter Changing Fra200Document2 pagesService Instructions 102171 2001-01-08 SB Parameter Changing Fra200ahmadba70Pas encore d'évaluation

- Acer Extensa 4220 4620 - WISTRON BIWA - POWER SEQUENCE PDFDocument1 pageAcer Extensa 4220 4620 - WISTRON BIWA - POWER SEQUENCE PDFLas DusPas encore d'évaluation

- Manual FW230 PDFDocument16 pagesManual FW230 PDFaze20100% (1)

- Analog & Digital SignalsDocument15 pagesAnalog & Digital SignalsNouman MemonPas encore d'évaluation

- 03 Timers Slides PDFDocument69 pages03 Timers Slides PDFRagini GuptaPas encore d'évaluation