Académique Documents

Professionnel Documents

Culture Documents

Eagar 006

Transféré par

Lauren GarciaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Eagar 006

Transféré par

Lauren GarciaDroits d'auteur :

Formats disponibles

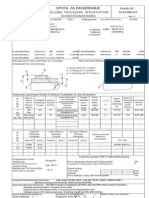

I N T E R - O F F I C E C O R R E S P O N D E N C E

* gETH\*Fx

B E T H L E E S T E E L

Apr i l 19, 1976

FILE REF. 2006-2

FROM

TO

SUBJECT

J, W. Frame

D. J . Blickwede

p?';Ki'rATIO OF PAPER ON WELDABILITY OF LNG HULL STEELS

pertached is a paper by T. W. Eagar and J. C. Baker on "LNG Hul l St e e l s

Vit}~ Improved High Heat I nput Wel dabi l i t y" t o be pr esent ed i n St. Louis

0-s J4ay 3, 1976. The conference "LOW-~emperature Pr oper t i es of Ship

plate'' i s a j o i n t l y sponsored ASM-ASTM-MPC symposium. The r equest f o r

a paper was made through J. B. Doran; bot h Met al l ur gi cal Engi neeri ng

a i d Plate Sal es have recommended that we p a r t i c i p a t e i n t h i s symposium

with a paper on our c ur r e nt LNG h u l l steel work. The 15 minute pr es ent at i on

will be made by J. C. Baker. The symposium proceedi ngs wi l l not be publ i shed.

We request appr oval t o pr es ent t h i s paper.

3. W. Frame

Manager

Product Research

Attachment

e ~ : TBW/EHK

EBMancke

DFBrion

RLWhi t e l e y

niTenxme1

J J O 'Keef e

EAZouck

JEWerner

LNG HULL STEELS WITH IMPROVED HIGH HEAT INPUT WELDABILITY

By T. W. Eagar and J. C. Baker

INTRODUCTION

Bethlehem St eel Corporation has been working i n conj unct i on wi t h

s ever al shi pyards i n a program coordi nat ed by t he Nat i onal Bureau of St andards

and sponsored by t he Maritime Admi ni st rat i on t o develop LNG s hi p h u l l s t e e l s

wi t h improved wel dabi l i cy at hi gh welding heat i nput s. The goal of our

Sl i de 1 research is t o develop ship steels capable of meeting 20 f t - l bs a t -60

i n the weld zone a f t e r high heat i nput welding, such a s 100 KJI i n 3/4 i nch

place. These steels w i l l be developed at t wo s t r engt h l evel s , 35 k s i yi e l d,

60 k s i t e n s i l e and 51 ks i yield, 7 1 ks i tensile.

The r at i onal e f o r t he program is t he reduced f abr i cat i on cos t of

r eadi l y weldable h u l l pl a t e a t hi gh heat i nput s . Such pl at es must r e t a i n good

low t emperat ure toughness i n t he weld and i n t he weld heat -affect ed zone.

Typi cal l y, shi pyards a r e cur r ent l y usi ng 4 t o 5 welding passes f o r 3/4 i nch

pl a t e at 60 KJI heat i nput . St eel s with improved wel dabi l i t y shoul d enabl e

higher pr oduct i vi t y t o be achieved wi t h t he high heat i nput s . Pot ent i al l y

they would al l ow welds t o be made i n two passes a t 100 KJI on 314 i nch

pl at e, wi t h less r epai r welding.

The pr i nci pal problem is t h a t under cur r ent welding condi t i ons t he

weld j oi nt toughness at low t emperat ures drops off r api dl y wi t h i ncr easi ng heat

Sl i de 2 i nput s f o r convent i onal normalized s hi p steels, pa r t i c ul a r l y a t the f usi on l i n e

of t he heat -affect ed zone. The i n i t i a l j oi nt preparat i on and t he posi t i on of

Sl i de 3

Sl i de 4

Sl i de 5

t he fusi on l i n e i n t he welded j oi nt are shown here. Other HAZ l ocat i ons a l s o

Charpy t est ed were a t t he 1, 3, and 5 mm posi t i ons. As can be seen from t he

next s l i de , t he Charpy Impact energy is a st r ong f unct i on of t he notch l ocat i on

wi t hi n t he HAZ, t he fusi on l i n e bei ng t he worst l ocat i on wi t h regard t o toughness.

For t hi s reason most of our work has been di r ect ed a t improving t he f usi on l i n e

I

toughness. The next s l i d e shows t he det er i or at i on i n f usi on l i n e toughness

with heat i nput f or a convent i onal C-Mn normalized s t e e l wi t h normal s ul f ur .

Even at r e l a t i ve l y low heat i nput s (below 60 KJI) t he 20 f t - l b requirement of

ABS is onl y margi nal l y me t . It should be poi nt ed out t ha t a l l t he s t e e l s t ha t

we have t est ed t o dat e have been l abor at or y produced.

The reason f o r this degradat i on i n toughness a t t he f usi on l i n e or

i n t he coarse-grain regi on of t he HAZ wi t h heat i nput is because of t he i ncr easi ng

wi dt h and gr ai n s i z e of t he coar se grai ned regi on as shown. Thi s compares wi t h

a base metal ASTM gr ai n s i z e of 11. To meet our toughness requirement a s t e e l

that is more r e s i s t a nt t o t he format i on of this coarse-grain regi on w i l l be

necessary. Good weld m e t a l toughness w i l l a l s o be requi red t o achi eve s a t i s -

f act or y pr oper t i es a t t he f usi on l i ne , si nce much of t he f r a c t ur e a t t h i s

posi t i on cracks through t he weld me t a l . The ABS s peci f i cat i on does r equi r e

a 20 f t - l b Charpy impact energy f o r t he weld m e t a l as wel l .

With regard t o weld metal toughness, C-Mn s t e e l s gener al l y have

marginal toughness at hi gh heat i nput s, whereas t he weld met al toughness

f o r t he microalloyed steels is somewhat lower and is usual l y below t he 20

f t - l b cr i t er i on. To dat e, a welding wi re cont ai ni ng 0.5% N i and 0.5% Mo

and a neut r al f l ux have given best r e s ul t s . We do pl an f ur t he r work i n

t h i s area.

RESEARCH RESULTS

Ef f ect of Sul fur Content

Low s ul f ur is known t o gi ve improved t r ansver se shel f energy i n

pl a t e steels. W e have found t ha t it a l s o lowers t he 20 f t - l b t r a ns i t i on tempera-

t ur e a t t he f usi on l i n e i n our steels, making t hese weldable a t hi gher heat

Sl i de 6 i nput s. The magnitude of t h i s s h i f t t o hi gher heat i nput s wi t h lower s ul f ur is

about 20 KJI. Furthermore, wi t h t he low s ul f ur s t e e l a l a r ge r cushion i n meeting

the 20 ft -l b requirement exists f o r heat i nput s below t he absol ut e maximum.

Thus* low S provides some improvement i n HAZ toughness and t hi s improvement

can be usef ul f o r many cur r ent l y used welding procedures. However, t he toughness

is still below 20 ft -l b a t 100 KJI and we bel i eve t ha t t o meet our research

obj ect i ve a low s ul f ur st eel wi t h t he addi t i on of some mi croal l oyi ng element

t o r e s t r i c t t he gr ai n s i z e i n t he coarse-grain regi on of t he HAZ w i l l be requi red.

Ef f ect of Microalloying

Regarding mi croal l oyi ng, we have br i e f l y eval uat ed t he e f f e c t s of

Cb, Ti , and V on HAZ toughness. Cb and Ti addi t i ons were found t o be bene-

Sl i de 7 f i c i a l a t high heat i nput s. However, a t low heat i nput s t her e is l i t t l e

improvement in f usi on l i n e toughness and sometimes t he toughness was found

t o be even degraded by t h e i r presence, a s is t he case shown f o r t he Cb s t e e l .

The reason f or t he f usi on l i n e toughness not being hi gher, par t i cul ar l y at

hi gher heat i nput s, is pa r t i a l l y because of poor weld met al toughness, i.e.,

. .

Sl i de 8

Sl i de 9

Sl i de 10

less t han 20 f t - l bs. Use of an a l t e r na t e welding wire and f l ux may hel p t o

a l l e vi a t e t he di f f i c ul t y. A t hi gh heat i nput s Cb and T i r e f i ne t he s t r uc t ur e

i n t he coarse gr ai n HA2 a s shown. This r ef i ned s t r uct ur e is bel i eved t o

decrease t he mean f r e e crack pat h and provide Improved impact r esi st ance.

A t low heat i nput s mi croal l oyi ng causes pr eci pi t at i on hardening although

T i does t h i s t o a much smal l er degree t han Cb i n t he steels of t h i s i nvest i -

gat i on. This hardening e f f e c t can, a t l e a s t pa r t i a l l y, negat e any benef i ci al

e f f e c t of s t r uct ur e refinement on HAZ toughness.

Vanadium was al s o found t o r e f i ne t he HAZ s t r uc t ur e somewhat at hi gh

heat i nput s but t her e was no improvement i n toughness. We cur r ent l y do not

have an expl anat i on f o r t h i s l a c k of improvement.

We have a l s o looked at the e f f e c t of ni t rogen addi t i ons. Nitrogen

was found not t o not i ceabl y a f f e c t base pl a t e toughness. However, i t di d

cause a 40-5o0F i ncr ease i n f usi on l i n e t r a ns i t i on temperature i n our

C-Mn, Cb, Ti , o r V s t e e l s . Possi bl e reasons f o r t he det r i ment al e f f e c t

of ni t rogen on f usi on l i n e toughness, hi nt ed by t he i ncr ease i n HAZ

hardness f or t he ni t rogen steels, a r e pr eci pi t at i on hardening and/or

decomposition of some ni t r i de s and i ncr ease i n f r e e ni t r ogen cont ent i n

the HAZ. We pl an t o conduct some s t r a i n aging experiments t o t r y t o

determine t he mechanism of how ni t rogen a f f e c t s mechanical pr oper t i es i n

t he HAZ versus t he base me t a l .

I n conclusion, we feel that Cb or T i microalloyed steels a r e the

most promising. However, we are cont i nui ng our st udi es t o develop compo-

s i t i o n a l limits and t o confirm t he benef i t s r eal i zed i n our l abor at or y t e s t s

on mill-produced pl at e. For the present, low S can provide s i gni f i cant

Improvements i n HAZ toughness and al l ow some i ncreases i n acceptable welding

heat input.

SLI DE 1

OBJECTIVES OF OUR RESEARCH PROGRAM

0 To develop improved LNG ship hull plates capable of meeting

20 ft-lbs at -60

welding (100 KJ 1

0 To develop these

(a) V-051

(b) EH36 (

in t he weld zone after high heat

in 314 inch plate).

improved steels at two strength leve

(35 ksi yield, 60 ksi tensile),

51 ksi yield, 71 ksi tensile).

nput

s:

SLIDE 2

Weld geometry and charpy notch location for 34"

double bevel groove plates.

a ) Joint Geometry

F L I 3 5

b ) Charpy Notch Location

F L - Fusion Li ne

I - Imm

3 - 3mm

5 - 5 mm

SLI DE 3

CHARPY IMPACT ENERGY AS A FUNCTION OF

NOTCH LOCATION WI THI N THE HEAT-AFFECTED ZONE

Charpy Energy at -60F

Heat Input Thickness Ft-Ibs

Steel

,

KJ 1 in. FL 1 mm 3 mm 5 mm

-

EH32, C-Mn,

Low sulfur

SLIDE 4

Charpy i mpact energy versus welding heat input for

conventional C- Mn steel

-

-

Values at Fusion Li ne

I I I I

50 70 90 100

WELD HEAT INPUT,KJI

SLIDE 5

W I DTH AND GRA I N S IZE OF COARSE-GRA IN HEAT-AFFECTED

REGION AS A FUNCTION WELDING HEAT INPUT

Approximate ASTM

Heat I nput Width of Bainitic Grain Size of

KJ I HAZ Region, in. Bainitic Region

Base Metal - Normalized C- Mn Steel with ASTM Grai n Size of 11

SLIDE 6

Chorpy impact energy versus welding heat input for

normalized C- Mn steels

WELD HEAT INPUT,KJI IN 3/4" PLATE

50

11.

6

(0

4 0 -

!<

u

m

83 30-

>

w

2

u

a

20

<n

01

-J

I

10-

-

\

\

\

Values at Fusion Line

\

\

Normal sulfur, ,025 %

\

\

- - Low sulfur ,.005 %

\

\

\

- --------

SLIDE 7

Chorpy impact energy versus welding heat input

Values at Fusion Line

C- Mn , Low S steel

- Ti,Low S st eel

* OO OOO* ~~OO Cb, Low S $tee 1

50 70 90 100

WELD HEAT INPUT, KdI IN 3/4" PLATE

SLIDE 9

EFFECT OF VANADIUM ON HAZ TOUGHNESS

Gleeble Simulated HAZ, 100 KJI i n 314 inch Plate

Fusion Line

Steel 20 ft-lbs Transition Temperature, OF

Vanadium +28

Vanadium-Nitrogen +70

SLI DE 10

EFFECT OF NITROGEN ON HAZ 20 FT-LBS TRANS ITION TEMPERATURE, OF

Gleeble Simulated HAZ, 100 KJI i n 314 I nch Plate

Base Metal Fusion Line

Steel 20 Ft-lb T. T. Hardness, VHN 20 ft-lb T. T. Hardness, VHN

All Steels are Normalized and Low Sul fur

Vous aimerez peut-être aussi

- Pages From HRN en 12952-5Document14 pagesPages From HRN en 12952-5Lauren GarciaPas encore d'évaluation

- 20100525083319116Document1 page20100525083319116Lauren GarciaPas encore d'évaluation

- 20100526100623668Document1 page20100526100623668Lauren GarciaPas encore d'évaluation

- Drawing1 Layout1Document1 pageDrawing1 Layout1Lauren GarciaPas encore d'évaluation

- 20100526125044214Document1 page20100526125044214Lauren GarciaPas encore d'évaluation

- 20100525083136149Document1 page20100525083136149Lauren GarciaPas encore d'évaluation

- 20100330123609293Document29 pages20100330123609293Lauren GarciaPas encore d'évaluation

- 20100326085743579Document2 pages20100326085743579Lauren GarciaPas encore d'évaluation

- 20100330101400145Document35 pages20100330101400145Lauren GarciaPas encore d'évaluation

- 20100329112643710Document2 pages20100329112643710Lauren GarciaPas encore d'évaluation

- Sandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in StainlessDocument26 pagesSandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in Stainlessalbejo_r9Pas encore d'évaluation

- 20100326074831446Document1 page20100326074831446Lauren GarciaPas encore d'évaluation

- 2 2009 03 1563509Document1 page2 2009 03 1563509Lauren GarciaPas encore d'évaluation

- 20100326085743579Document2 pages20100326085743579Lauren GarciaPas encore d'évaluation

- Effect of Heat Input To Weld Residual StressDocument4 pagesEffect of Heat Input To Weld Residual StressSurya DharmaPas encore d'évaluation

- 20100617082758841Document1 page20100617082758841Lauren GarciaPas encore d'évaluation

- BWE Brik Welding EvaluationDocument4 pagesBWE Brik Welding EvaluationLauren GarciaPas encore d'évaluation

- N 9003Document4 pagesN 9003Lauren GarciaPas encore d'évaluation

- CTODDocument4 pagesCTODthan79Pas encore d'évaluation

- Etd1649 PDFDocument61 pagesEtd1649 PDFLauren GarciaPas encore d'évaluation

- Dwg1 2825 RemarksDocument1 pageDwg1 2825 RemarksLauren GarciaPas encore d'évaluation

- 20100618071206827Document2 pages20100618071206827Lauren GarciaPas encore d'évaluation

- 20100716075629769Document3 pages20100716075629769Lauren GarciaPas encore d'évaluation

- Influence of Heat Input On Corrosion Resistance of SAW Welded Duplex JointsDocument4 pagesInfluence of Heat Input On Corrosion Resistance of SAW Welded Duplex JointsLauren GarciaPas encore d'évaluation

- 20100709123225199Document5 pages20100709123225199Lauren GarciaPas encore d'évaluation

- 20100713131211561Document2 pages20100713131211561Lauren GarciaPas encore d'évaluation

- 20100716121120727Document1 page20100716121120727Lauren GarciaPas encore d'évaluation

- 20100716101107497Document1 page20100716101107497Lauren GarciaPas encore d'évaluation

- 51 4 341 346Document6 pages51 4 341 346Lauren GarciaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- VAM Must Sumitomo 1209 PDFDocument4 pagesVAM Must Sumitomo 1209 PDFnwohapeterPas encore d'évaluation

- In Truth To Mollusca According To New Studies by J RutherfordDocument4 pagesIn Truth To Mollusca According To New Studies by J RutherfordbalaiPas encore d'évaluation

- Mechanical Advantage HomeworkDocument8 pagesMechanical Advantage Homeworkafeurbmvo100% (1)

- RE2S PE LPG CNG SPC Part 1Document32 pagesRE2S PE LPG CNG SPC Part 1Inversiones RinocellPas encore d'évaluation

- Phineas Gage: From The Passage of An Iron Rod Through The Head"Document1 pagePhineas Gage: From The Passage of An Iron Rod Through The Head"GlupiaSprawaPas encore d'évaluation

- Gold Advanced Progress Test 5Document6 pagesGold Advanced Progress Test 5BernardPas encore d'évaluation

- Epilepsy Lecture NoteDocument15 pagesEpilepsy Lecture Notetamuno7100% (2)

- HardikDocument21 pagesHardikGohil HardikPas encore d'évaluation

- 1 Introduction To Microsoft VirtualizationDocument36 pages1 Introduction To Microsoft VirtualizationRavinder KantPas encore d'évaluation

- The World S Finest Ideas in Cooling!: A Division ofDocument4 pagesThe World S Finest Ideas in Cooling!: A Division ofChiragPas encore d'évaluation

- Earth Bonding LeadsDocument2 pagesEarth Bonding LeadsrocketvtPas encore d'évaluation

- FPAL Product Code GuideDocument53 pagesFPAL Product Code GuideSRARPas encore d'évaluation

- Gcat Threathorizons Full Jan2023Document26 pagesGcat Threathorizons Full Jan2023josbjsPas encore d'évaluation

- Study of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderDocument3 pagesStudy of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderAnonymous AkoPas encore d'évaluation

- Ansible Automation SA Technical Deck Q2FY19Document43 pagesAnsible Automation SA Technical Deck Q2FY19daniel_vp21Pas encore d'évaluation

- Master of Business Administration in Aviation Management MbaamDocument10 pagesMaster of Business Administration in Aviation Management MbaamAdebayo KehindePas encore d'évaluation

- Business Model Navigator Whitepaper - 2019Document9 pagesBusiness Model Navigator Whitepaper - 2019Zaw Ye HtikePas encore d'évaluation

- Varaah KavachDocument7 pagesVaraah KavachBalagei Nagarajan100% (1)

- Chapter 5: Sampling Distributions: Solve The ProblemDocument4 pagesChapter 5: Sampling Distributions: Solve The ProblemEunice WongPas encore d'évaluation

- Jib Crane Assembly ManualDocument76 pagesJib Crane Assembly ManualRobert Cumpa100% (1)

- Article Unleashing The Power of Your StoryDocument17 pagesArticle Unleashing The Power of Your StoryAnkit ChhabraPas encore d'évaluation

- Sotero 05activity EnvironmetnDocument3 pagesSotero 05activity Environmetnbernadette soteroPas encore d'évaluation

- Toptica AP 1012 Laser Locking 2009 05Document8 pagesToptica AP 1012 Laser Locking 2009 05Tushar GuptaPas encore d'évaluation

- Sindarin-English Dictionary - 2nd EditionDocument192 pagesSindarin-English Dictionary - 2nd EditionNea Tan100% (1)

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDocument6 pagesModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕPas encore d'évaluation

- Into The Unknown 21 Doc PDFDocument9 pagesInto The Unknown 21 Doc PDFFernando AlbuquerquePas encore d'évaluation

- Scuba Diving - Technical Terms MK IDocument107 pagesScuba Diving - Technical Terms MK IJoachim MikkelsenPas encore d'évaluation

- 10 Q - Switching & Mode LockingDocument21 pages10 Q - Switching & Mode Lockingkaushik42080% (1)

- Deld12070 CC18 GT 371 C CDocument1 pageDeld12070 CC18 GT 371 C CDEBASIS BARMANPas encore d'évaluation

- Vertical Isolation VCBEnglishDocument1 pageVertical Isolation VCBEnglishdip461Pas encore d'évaluation