Académique Documents

Professionnel Documents

Culture Documents

Custo Soldagem

Transféré par

wpsssamsungDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Custo Soldagem

Transféré par

wpsssamsungDroits d'auteur :

Formats disponibles

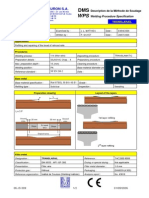

Potential savings in welding stainless steels

using flux cored welding wires

BHLER

Selection depends mainly on 3 factors that have essentially

equal significance in the decision-making process

Fig. 1: Deciding factors for the introduction of welding processes in

various welding shops

POTENTIAL SAVINGS IN WELDING STAINLESS STEELS

USING FLUX-CORED WIRES

H. Schabereiter, R. Drfler, J. Ziegerhofer

1. GENERAL

The use of high-alloyed flux-cored wires has undergone a remarkable upturn in recent years and more

particularly in the very recent past.

For cost reasons the constant aim in welding fabrication shops is to substitute established welding pro-

cedures with more up-to-date and above all more cost-effective processes. This is usually achieved by

means of a close working relationship between the technicians, salesmen and welders. The factors

shown in Fig. 1 represent the main considerations for this.

Flux-cored welding wires are primarily measu-

red on the properties of coated electrodes and

solid wires. For many years the consumption of

flux-cored wires in Europe was less than 5 % of

the overall potential for high-alloyed filler metals

and this has increased to almost 10 % in the last

few years. An additional increase in the con-

sumption of flux-cored wires is anticipated. This

will not be so much at the cost of coated elec-

trodes but rather as substitution of solid wires.

The following sections will deal in greater detail

with the most significant deciding factors for sel-

ecting welding processes and the possibilities of

reducing costs by using modern filler metals in

fabrication of corrosion resistant components.

2. SIGNIFICANT FACTORS FOR DECISION-MAKING

IN THE SELECTION OF WELDING PROCESSES

Generally speaking, the only welding processes

and filler metals considered in practice are those

where the weld metal deposits satisfy the require-

ments in the standards and the characteristics

specified for mechanical properties and corrosion

resistance.

Assuming these basic requirements, cost effi-

ciency is compared with additional factors influen-

cing overall cost outlay in the manufacture of

welded components.

Fig. 2: Typical factors in the cost calculation

Filler metal

Welding

current

Wire

extension

Welding

voltage

Duty cycle

Metal recovery

Weight of weld

Deposition rate

Joint area

Weight of

filler metal

Filler metal

costs

Electricity costs

Gas costs

Labour costs

Capital

expenditure

Total cost

of weld

Arc burning

time

Weld

dressing

Total

welding time

CRITERIA

FOR SELECTING

WELDING

PROCESSES

PRODUCTIVITY

PROFITABILITY

3

2.1 Productivity

Fig. 2 lists all the basic factors to be taken into account when determining the total costs of welded

joints.

In practice the main emphasis is placed on the welding time which actually only represents a fraction

of the total costs. The manufacturing costs depend on a series of additional variables which may have

a considerable effect in practice on a component's service life.

It is surely hardly necessary to illustrate or explain in detail the economic superiority of flux-cored wires

compared with coated electrodes. A detailed comparison of costs using flux-cored wires is, however,

useful in cases where semi or fully automatic welding processes using solid wires are employed. Some

of the factors significant for the total fabrication costs are frequently ignored when determining the

costs per metre or inch of weld which is usually the method used in practice. However, it is precisely

the factors which do not pertain purely to the welding time that may be crucial as reasons for process

changeover. Improved welding quality and quality assurance also represents an economic factor which

does not make itself felt until after the welding process has been changed over.

The following sections will illustrate as briefly as possible the productivity advantages when using flux-

cored wires for welding stainless steels.

2.1.1 Welds primarily in the flat and horizontal welding position

Best suitable flux cored wires for these welds have a rutile slag system with a slow freezing slag. These

wires operate in the spray transfer mode with minimum spatter formation. The self releasing slag

covers the weld completely. This type of flux-cored wire is suitable for single and multi-pass welds in

the flat and horizontal position, horizontal/vertical position as well as the slightly vertical-down position

(1 oclock).

Fig. 3 illustrates a comparison of deposition

rates for coated electrodes, solid and flux-cored

wires. The superiority of the flux-cored wires

compared with the other filler metals is clearly

visible. The reason for this is the high current

density (A/mm

2

) due to the current being con-

ducted through the metal strip mainly which

represents a smaller cross sectional area than

solid wires. Apart from submerged arc welding,

GMAW with flux cored wire belongs to the most

productive welding processes.

Fig. 3: Comparison of deposition rates of stick electrodes, solid wires

and flux-cored wires

Flux-cored wire

0.9 mm Argon + 18% CO2 distance of contact tip 15 mm

1.2 / 1.6 mm Argon + 18% CO2 distance of contact tip 20 mm

Solid wire Argon + 12% CO2 distance of contact tip 12 mm

Amperage (A)

Flux-cored wire 0.9 mm

Flux-cored wire 1.2 mm

Flux-cored wire 1.6 mm

Solid wire 1.0 mm

Solid wire 1.2 mm

Stick electrode

D

e

p

o

s

i

t

i

o

n

r

a

t

e

a

s

s

u

m

i

n

g

1

0

0

%

d

u

t

y

c

y

c

l

e

(

k

g

/

h

)

9

8

7

6

5

4

3

2

1

100 200 300 400

4 mm

5 mm

Welding position: horizontal (PA)

4

Fig. 4 shows the comparable lengths of fillet welds with a specified throat thickness of 3 mm and the

welding time of 1 minute. The considerably faster travel speed using the flux-cored wire (800 mm) com-

pared with the solid wire (670 mm) and the stick electrode (280 mm) speaks for itself.

a ... flux-cored wire 1.2 mm = 800 mm

b ... solid wire 1.0 mm = 670 mm

c ... stick electrode 3.2 mm = 280 mm

Fig. 5 illustrates additional comparisons of travel speed. In this case different fillet weld thicknesses

(3/5/7 mm) were produced using solid and flux-cored wire and the weld lengths achievable were mea-

sured. The welds obtainable using the flux-cored wires are between 19 and 50 % longer with the same

welding time.

Gas: Argon +18 % CO2 for flux-cored wire

Argon +12 % CO2 for solid wire

Plate 5 mm for 3 mm fillet welds

thickness: 10 mm for 5 & 7 mm fillet welds

Severe bead oxidation with MAG solid wire,

especially at 275 A. Wetting behaviour also not

good.

Only slight bead oxidation with MAG flux-cored

wire even at 275 A!!

throat thickness 3 mm 5 mm 7 mm

Bhler EAS 4 M-FD, 1.2 mm 80 cm/min 48 cm/min 21 cm/min

235 A, 33 V, 14 m/min (+ 19 %) (+ 33 %) (+ 23 %)

Bhler EAS 4 M-FD, 1.2 mm

54 cm/min 25 cm/min

275 A, 35 V, 18 m/min (+ 50 %) (+ 39 %)

Solid wire, 1.2 mm

60 cm/min 32 cm/min 15 cm/min

235 A, 28 V, 8 m/min

Solid wire, 1.2 mm

36 cm/min 18 cm/min

275 A, 31 V, 10.5 m/min

Solid wire, 1.0 mm

67 cm/min 36 cm/min 17 cm/min

235 A, 31 V, 14 m/min

Fig. 5: Comparison of travel speeds for MAG solid wire and MAG

flux-cored wire type 316L, welding position 2F

Fig. 4: Comparison of travel speed between stick electrode, solid

wire and flux-cored wire (type 316 L) in fillet welds, welding

position 2F

5

Post weld cleaning

The basic requirement for achieving optimum corrosion resistance with austenitic welds is the presence

of a completely clean bright metal surface. The passive layer responsible for corrosion resistance can

only form in the appropriate shape under these conditions. Thus the dressing of welds is equally a

variable which determines quality during the fabrication of welding components.

The cost saving benefits gained by welding with flux-cored wires as opposed to solid wires are listed

below.

Minimum post weld cleaning due to:

Flat and smooth weld finish (minimum grinding expenditure), see Fig. 6

Minimum spatter formation

Lower pickling expenditure (temper coloration is minimized), see Fig. 7

Less distortion due to increased travel speeds

Lower repair rates (pores, slag inclusions, fusion defects)

Actual information regarding the overall cost

savings achievable depend to some extent on

the cost structure and plant set-up of the indivi-

dual company as well as on the particular wel-

ding work undertaken.

However, with a saving in welding time of bet-

ween 19 and 50 % (see Fig. 5) and calculated

industry rates of an average DM 100.-/hr for

MIG/MAG welding in Western Europe, the flux-

cored electrode, which is more expensive than

solid wire, usually makes savings of between

10 and 30 % possible if the overall calculation

includes lower-cost weld dressing. Fig. 8 graphi-

cally illustrates this financial advantage when

using flux-cored wires in the flat or horizontal

welding position.

Fig. 7: Differences in weld oxidation between:

a) flux-cored wire

b) solid wire

a)

b)

Fig. 6: Component welding using flux-cored wire:

smooth, notch-free welds with good wetting

and uniform weld finish

Fig. 8: Cost savings when using flux-cored wire in the flat and

horizontal welding position

100

90

80

70

60

50

40

30

20

10

0

Solid wire Flux-cored wire

savings of

10 %

to

30 %

100 %

6

Statements from fabricators:

New filler metals are essentially developed by working closely with potential users. Following exten-

sive laboratory testing, samples are used in practice to determine the products' suitability for large-

scale production. Intensive discussions with consumers of stainless flux-cored wires then resulted in

the following practical knowledge.

Cost-effectiveness (quality and through put are decisive)

Productivity of the welding process

Duty cycle

Downtimes

Post weld cleaning

Power Sources

Conventional MAG welding machines with 4-roll drive and water-cooled torches

Average amperage when using flux-cored wires 1.2 mm can be 260 270 A. Higher than average

increase in productivity in this current range amperages compared with solid wire 1.2 mm (see Fig. 5)

Weld Dressing (pickling problems/costs)

Depends on design and plant set-up but still up to 30 % lower costs using flux-cored wire

Pickling baths approx. DM 150.-/hr, waste disposal extremely expensive

Spray pickling collection neutralisation disposal of liquid

Glass bead blasting hourly rates DM 250.- to 350.-

The following additional benefits for the user of flux cored wires are worth mentioning:

Easier to operate than MAG solid wire

No pulsed power source required (lower noise level)

Lower gas costs (Argon + 18 % CO2 instead of Argon + 2 % CO2)

Smooth bead appearance

Less risk of fusion defects and thus lower repair rates

Easier control of heat input due to higher welding speeds

Good root pass welding characteristics with extra high productivity gains when using ceramic backing

2.1.2 Positional welding

Positional type flux-cored wires produce a rutile slag that solidifies rapidly and are therefore suitable

for all welding positions. Both, mixed gases and 100 % CO2, are used as shielding gases. The typical

characteristics of such FCAW wires are:

Rutile slag with rapid solidification (high melting point)

Excellent backing effect for the weld pool

Use of high current intensities possible for out-of-position welding, e.g. 160 A instead of 100 120 A

using solid wire (3G, 3F)

Up to 100 % higher travel speeds

Excellent wetting behaviour, flat and smooth treat profile

Powerful penetrating arc, spray transfer, minimum spatter formation

Good mechanical properties

7

Fig. 9 reproduces a comparison of the travel

speeds achievable in single-V butt welds in the

vertical-up position (filler passes). The flux-

cored electrode permits a saving in welding time

of 45 % compared with solid wires. Comparison

welds produced on the same basis using filler

metals for ferritic-austenitic duplex steels have

resulted in time savings of up to 100 %.

The upper part of the Fig.10 clearly shows that

a flat bead configuration when using the flux-

cored wire is easy to assess in spite of the con-

siderably higher current intensity (155 A) com-

pared with the solid wire electrode (115 A).

It is only possible to produce a similar flat fillet

weld by using a solid wire by further reducing

the current intensity to 100 A. From the econo-

mic point of view, reducing the current intensity

naturally has an adverse effect on the welding

time and therefore on the costs.

In positional welding actual cost comparisons

result in overall cost savings of more than 50 %

when using positional flux-cored wires despite

considerably lower prices for solid wire.

Fig. 10 shows cross-sections of fillet welds which were produced using solid wires and flux-cored wires

in the vertical-up (3 F) position.

Fig. 9: Travel speed achievable in single-V butt welds in the verti-

cal up position

Fig. 10: Weld profiles of fillet welds performed using solid wire

and flux-cored wire respectively in the vertical-up position

Flux-cored wire 1.2 mm

8.2 m/min, 25 V

155 A

spray arc

Bead configuration

= flat

Solid wire 1.0 mm

6.4 m/min, 25 V

115 A

Pulsed arc

Bead configuration

= convex

Flux-cored wire 1.2 mm

8.2 m/min, 25 V

155 A

Spray arc

Bead configuration

= flat

Solid wire 1.0 mm

5 m/min, 25 V

100 A

Pulsed arc

Bead configuration

= flat

Welding position: vertical up

Fast freezing slag of the FCAW 55 Ampere higher current!

Current intensity: 160.0 A 110.0 A

Voltage: 25.0 V 19.5 V

Wire speed: 8.0 m/min 5.0 m/min

*

Solid wire electrodes 1.2 mm exhibit neither welding nor

economic advantages over 1.0 mm in out-of-position

welding.

SINGLE-V BUTT WELD, VERTICAL UP,

1

ST

FILLER PASS

19.5

13.4

25

20

15

10

05

00

Weld length with flux cored wire

+ 45 % compared to solid wire

8

In Fig. 11 it is easy to see the time saving and

the cost benefit gained by using a positional

type flux-cored wire. Approximately 70 to 80 %

higher travel speeds can be achieved in fillet

welds compared with the solid wire electrode.

This is many times higher than with manual arc

welding.

Fig. 13: Macro-section and side bend test specimen

from a thick-walled pipe joint.

Fig. 12: Example of practical application

Fig. 11: Comparison of weld lengths achievable in the same

amount of time

Flux-cored wire Solid wire Stick electrode

9

Fig. 12 illustrates a particular example of a prac-

tical application. Here dished boiler ends with

wall thicknesses of 38 mm are manufactured

from material AISI 316L. The double-V butt welds

are produced by automatic welding in the verti -

cal-up position. Bhler EAS 4 PW-FD 1.2 mm

was used as the flux-cored wire. The self-pee-

ling slag and smooth weld finish with only slight

oxidation (can be removed by brushing easily)

are clearly visible.

Joining pipes in the Offshore industry gives rise

to almost all the welding positions possible in

practical use. As an example, Fig. 13 shows a

macro-section and a side bend test specimen

originating from a thick-walled 1.4462 pipe joint.

The pipe dimensions are 508 x 49 mm.

Bhler CN 22/9 PW-FD 1.2 mm was used as

the flux-cored wire with optimum results regar-

ding welding characteristics, mechanical pro-

perties and corrosion resistance.

2.1.3 Sheet metal fabrication using 0.9 mm FCAW wires

1.2 mm is the most commonly used diameter

of flux-cored wire employed in practice for

wall thicknesses above 3 mm. Flux-cored

wires of 0.9 mm diameter are especially

suitable for joining thin metal sheets above

1.5 mm.

They are ideal for welding small, well-wetted

weld cross-sections at high travel speed and

with less heat input. This is one aspect that

has an effect on costs since there are fewer

distortion problems and less post-weld

straightening at the same time as visual

benefits, Fig. 14.

2.1.4 Lower-priced shielding gases

Stainless steel flux-cored wires are welded using the commercially available shielding gases

Argon + 1525 % CO2. At approx. 16 litres per minute the gas flow rate is the same as when welding

solid wires using argon + 2 % CO2. The use of shielding gas containing higher levels of CO2 for slag-

forming flux-cored wires is rendered possible since every single metal droplet transferred in the arc is

completely covered with slag. This prevents any reaction with the shielding gas.

Fig. 15 shows a metal droplet completely covered

with slag at the end of the FCAW wire. Thus there is

no carburisation or burn-off of elements with an oxy-

gen affinity, such as chromium, which would be unac-

ceptable for corrosion reasons.

The cost benefits for the user result on one hand from the lower gas costs and also from the lower gas

consumption which follows on from the shorter welding time.

2.2 Reliable and consistent weld quality

The basic requirement for proper performance of welding work is the use of suitably trained welding

staff. In many cases a requirement is made for certified welders for the production of welded compo-

nents and in certain regulations this requirement is mandatory. On the European market the proce-

dure for testing welders is specified in standard EN 287. There is reference to the individual welding

processes, such as metal active gas (MAG) welding using flux-cored wires.

Fig. 14: Welded joints produced on 2 mm thick metal sheets using flux-

cored wire 0.9 mm

Butt weld Fillet weld

Complete covering of the Partially peeled slag

droplet with rutile slag after cooling off

Lap joint Corner joint

Fig. 15: Metal droplet on a flux-cored electrode

10

Training, testing and maintaining the validity of test certificates for the welding staff represents a con-

siderable amount of time and money for the welding shop. Welding processes that allow the training

time to be shortened and that reduce possible weld defects therefore represent a cost reduction factor

from the quality management point of view.

Easy to operate and reliable in processing

Flux-cored wires ensure a very wide range of

possible setting parameters. This makes the sel-

ection of optimum welding data significantly

easier see Fig. 16.

The welding behaviour remains constant through-

out broad ranges of current intensity and volta-

ge. The large parameter box tolerates uninten-

tional changes to the operating point by the wel -

der without loss of quality. Welding with a

smooth, non-spatter spray arc is possible as low

as 150 Amps, 25 Volts and 6.5 m/min wire feed

with 1.2 mm FCAW wires and 0.9 mm wires

operate in the spray arc transfer already at 110 A, 26 V and 9.5 m/min. By comparison solid wire only

tolerates a very narrow operating range. This requires a high level of concentration from the welder

regarding correct torch positioning especially since relatively small deviations lead to impairment of the

welding behaviour.

The greater independence of parameter setting and the lower risk of welding defects compared with

welding using solid wires speak for the reliability of flux-cored wires.

Fig. 17 illustrates the characteristic penetration profiles of the wires mentioned. Using the flux-cored

wire provides more even penetration with excellent side wall fusion and a good weld profile due prima-

rily to the wider arc. The solid wire on the other hand exhibits very deep penetration in the middle but

in this case it is possible to see poor fusion of the lower side wall due to torch manipulation being a little

too flat. In practical application the problems caused by lack of fusion continue to give rise to diffi-

culties even when working with the most vigilant and experienced solid wire welders.

Flux-cored wire 1.2 mm

Gas: Argon + 18 % CO2

Excellent penetration

Good bead appearance

Solid wire 1.2 mm

Gas: Argon + 2.5 % CO2

Deep penetration at the

bead centre, however,

the lower plate is hardly

penetrated

Fig. 16: Possible parameter ranges in the spray transfer

for flux-cored and solid wires

Formation of spatters

Solid wire1.2 mm

Solid wire1.0 mm

FCAW wire 1.2 mm

Poor bead appearance

38

36

34

32

30

28

26

24

22

150 200 250 300

Amperage (A)

Fig. 17: Comparison of penetration profiles of solid wire and flux-cored wires

11

2.3 Product quality and constancy

Years ago there was some scepticism regarding the use of flux-cored wires. This was due to the fact

that the flux core was sometimes variable in quality or possibly even missing. Today this scepticism is

no longer appropriate since flux-cored wires from well-known companies are manufactured in modern

production plants. They consist of high-alloy austenitic precision steel strips and a filling of various

mineral and metallic components exhibiting a special composition depending on the type of alloy. At

Bhler Welding the infills are agglomerated prior to filling to ensure uniform filling and to prevent

decomposition of the different raw materials during filling due to their different specific weights.

A specially installed control system using up-to-date monitoring technology constantly and efficiently

checks the consistance of filling. The whole production process satisfies the criteria of EN ISO 9001.

At Bhler Welding every production lot is checked for the welding characteristics, feed properties and

chemical composition of the weld metal during quality assurance.

Increased precautions when storing partly used spools

and spools removed from their original packaging are

particularly important for today's users. As is the case

with high-alloyed rutile-coated stick electrodes, all rutile

slag-forming flux-cored wires must also be protected

from atmospheric moisture and the formation of con-

densation on the wire surface if the dew point falls.

They are more sensitive to the formation of worm-holes

than solid wires. The reason for this is that an excess

of hydrogen of humid wires is unable to effuse in time

prior to solidification of the weld pool due to the slag

protection of the weld on one hand and the high travel

speeds and simultaneously lower heat input on the

other too. Therefore care must always be taken to

store partly used spools correctly and always to use

wires which have acclimatized. Wires which have

become humid can be rebaked at 150C.

Today thousands of tons of high-alloyed flux-cored wires are successfully used for production welding

throughout the world. The wires have proven and established themselves in the construction of

chemical and petrochemical plants, offshore engineering, tanker construction, the paper and pulp indu-

stry, plant construction in the food, drinks or textile industries up to the welding of highly corrosion-

resistant flue gas desulphurisation plants.

12

Conveyer screw from AISI 316 Ti for the pulp industry welded with

Bhler EAS 4 M-FD

Pressure vessel with heating coil from AISI 316L welded with

Bhler EAS 4 M-FD

Pipe segment from duplex steel UNS S 31803 for the offshore

industry welded with Bhler CN 22/9 PW-FD

Part segment of a scrubber & separator made of

UNS S 31803 welded with Bhler CN 22/9 N-FD

Dissimilar joint weld, 3G,

welded with Bhler CN 23/12 Mo PW-FD

13

High-alloyed flux-cored wires are available for the most commonly used stainless CrNi and CrNiMo

steels as well as for dissimilar joints or weld cladding and are standardised in the European standard

EN 12073 and the American standard AWS 5.22 respectively.

3. SUMMARY

The present report investigates in depth the basic factors such as productivity, processability and qua-

lity in the selection of welding processes. The significant advantages of using flux-cored wires for wel-

ding stainless steels become perfectly apparent. Despite the higher product price of flux-cored wires,

there are remarkable time savings, productivity gains and potential cost savings to be made if all the

cost factors relevant to fabrication are taken into consideration.

Users who already have extensive practical experience of production welding using high-alloyed flux-

cored wires have given the following factors as reasons for changing over:

High deposition rate and increased productivity

Easy to operate

Smooth welding characterisitcs & weld finish

Radiographically sound weld deposit

Lower costs for the shielding gas

Simple and more cost effective post weld cleaning

Less repair work

Decreased overall fabrication costs

14

RANGE OF PRODUCTS

For flat and horizontal welding positions

* size 0.9 mm can be operated in all welding positions

For positional welding

If you have special questions or if you need expert consultation and

competent advice, please feel free to contact us.

A team of Bhler welding experts with special knowledge

in every sphere of welding engineering is at your disposal.

DESIGNATION EN 12073 AWS A 5.22

BHLER EAS 2 PW-FD T 19 9 LPM (C) 1 E 308 LT 1-4 (1) 1.2

BHLER EAS 4 PW-FD T 19 12 3 LPM (C) 1 E 316 LT 1-4 (1) 1.2

BHLER CN 22/9 PW-FD T 22 9 3 NL PM (C) 1 E 2209 T 1-4 (1) 1.2

BHLER CN 23/12 PW-FD T 23 12 LPM (C) 1 E 309 LT 1-4 (1) 1.2

BHLER CN 23/12 Mo PW-FD T 23 12 2 LPM (C) 1 E 309 L Mo T 1-4 (1) 1.2

BHLER E 308 H PW-FD TZ 19 9 HPM (C) 1 E 308 HT 1-4 (1) 1.2

size

in mm

size

in mm

DESIGNATION EN 12073 AWS A 5.22

BHLER EAS 2-FD T 19 9 LRM (C) 3 E 308 LT 0-4 (1) 0.9* 1.2 1.6

BHLER SAS 2-FD T 19 9 Nb RM (C) 3 E 347 T 0-4 (1) - 1.2 -

BHLER EAS 4M-FD T 19 12 3 LRM (C) 3 E 316 LT 0-4 (1) 0.9* 1.2 1.6

BHLER E 317 L-FD TZ 19 13 4 LRM (C) 3 E 317 LT 0-4 - 1.2 -

BHLER CN 22/9 N-FD T 22 9 3 NL RM (C) 3 E 2209 T 0-4 (1) - 1.2 -

BHLER CN 23/12-FD T 23 12 LRM (C) 3 E 309 LT 0-4 (1) 0.9* 1.2 1.6

BHLER CN 23/12 Mo-FD T 23 12 2 LRM (C) 3 E 309 L Mo T 0-4 (1) 0.9* 1.2 1.6

BHLER A 7-FD T 18 8 Mn RM (C) 3 E 307 T 0-G - 1.2 -

15

Bhler Schweit echnik

Aust r ia GmbH

Bhler Welding St. 1

A-8605 Kapfenberg

Tel.: ++43 (0) 3862-301-0

Fax: ++43 (0) 3862-301-95193

e-mail: postmaster.bsga@bsga.at

http://www.boehler-welding.com

Forwarded by:

Bhler Schweitechnik

Austria GmbH

Bhler-Welding-St. 1

8605 Kapfenberg / AUSTRIA

Tel.: ++43 (0) 3862-301-0

Fax: ++43 (0) 3862-301-95193

e-mail: postmaster.bsga@bsga.at

http://www.boehler-welding.com

Forwarded by:

B

S

G

A

0

3

/

2

0

0

1

E

2

5

0

0

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 8 - Chemical FloodingDocument76 pages8 - Chemical FloodingSyafrina Putri100% (3)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Corrosion Control in Refining IndustryDocument8 pagesCorrosion Control in Refining IndustryKmt_Ae0% (1)

- Chapter 7 - Casting ProcessDocument34 pagesChapter 7 - Casting ProcessIjal HaizalPas encore d'évaluation

- Repair of Rails On Site by Welding XA00127720Document20 pagesRepair of Rails On Site by Welding XA00127720wpsssamsungPas encore d'évaluation

- 09.soil LimingDocument25 pages09.soil LimingGAMUCHIRAI MUGADZAPas encore d'évaluation

- 24UTP Railway GBDocument8 pages24UTP Railway GBwpsssamsungPas encore d'évaluation

- Method Statement: Long Carbon EuropeDocument4 pagesMethod Statement: Long Carbon EuropewpsssamsungPas encore d'évaluation

- WPS TranslarailDocument2 pagesWPS TranslarailwpsssamsungPas encore d'évaluation

- EN 1090 White Paper17 119019 PDFDocument24 pagesEN 1090 White Paper17 119019 PDFZaza PokumbaPas encore d'évaluation

- CastingDocument48 pagesCastingwpsssamsungPas encore d'évaluation

- Xii Cbse 3Document1 pageXii Cbse 3pradishkrishna22Pas encore d'évaluation

- 08 Chapter 12Document26 pages08 Chapter 12M Zia DogarPas encore d'évaluation

- Filox RDocument6 pagesFilox RMahmudul HasanPas encore d'évaluation

- Chapter-12 - Aldehydes-Ketones-and-Carboxylic-Acids Important QuestionDocument13 pagesChapter-12 - Aldehydes-Ketones-and-Carboxylic-Acids Important QuestionPonuPas encore d'évaluation

- Testing-LimestoneDocument22 pagesTesting-LimestoneJaphet Charles Japhet MunnahPas encore d'évaluation

- Flame TestsDocument12 pagesFlame TestsBella TyPas encore d'évaluation

- This Study Resource Was: Engineering Chemistry LaboratoryDocument7 pagesThis Study Resource Was: Engineering Chemistry Laboratoryapple bottom jeansPas encore d'évaluation

- The Chemical Accidents (Emergency Planning, Preparedness and Response) RULES, 1996'Document26 pagesThe Chemical Accidents (Emergency Planning, Preparedness and Response) RULES, 1996'Hemant KuralkarPas encore d'évaluation

- ω-Transaminases for the Production of Optically Pure Amines and Unnatural Amino AcidsDocument9 pagesω-Transaminases for the Production of Optically Pure Amines and Unnatural Amino AcidsChamula K MasPas encore d'évaluation

- Raspberry Seed Oil - Virgin - Lot# 1680816300317040417Document1 pageRaspberry Seed Oil - Virgin - Lot# 1680816300317040417WootPas encore d'évaluation

- UV-4024 MSDS (英文版)Document4 pagesUV-4024 MSDS (英文版)urbaezPas encore d'évaluation

- AP X-Super Lube Cj-4Document1 pageAP X-Super Lube Cj-4Sami KahtaniPas encore d'évaluation

- Assessment 6 (Concentration of Solution)Document2 pagesAssessment 6 (Concentration of Solution)shaneeeePas encore d'évaluation

- ATD and DSC Analyses of Nickel SuperalloysDocument4 pagesATD and DSC Analyses of Nickel SuperalloysEnary SalernoPas encore d'évaluation

- Thermochemical Characteristics of Dimethyl Ether - Alternative FuelDocument13 pagesThermochemical Characteristics of Dimethyl Ether - Alternative FuelAlvaro BenattiPas encore d'évaluation

- Lecture 5-6-Grossman and Jominy HardenabilityDocument58 pagesLecture 5-6-Grossman and Jominy Hardenabilitychristofer kevinPas encore d'évaluation

- Hair OilDocument5 pagesHair OilSairam KogantiPas encore d'évaluation

- Clariant Exolit Flame Retardants For E-MobilityDocument17 pagesClariant Exolit Flame Retardants For E-MobilityomlPas encore d'évaluation

- Basics of Petroleum Geology and Formation Evaluation: Jack HorkowitzDocument37 pagesBasics of Petroleum Geology and Formation Evaluation: Jack HorkowitzMarcos SerrãoPas encore d'évaluation

- Chemistry Notes 6.4 - 6.9Document4 pagesChemistry Notes 6.4 - 6.9Grace LeePas encore d'évaluation

- Class Assessment Result For Grades 1-10 Learning Area: - (English/Filipino/Mtb/Ap/Esp)Document18 pagesClass Assessment Result For Grades 1-10 Learning Area: - (English/Filipino/Mtb/Ap/Esp)Joe TitularPas encore d'évaluation

- Hess's Law Bond Enthalpies 5.3 (22 Marks) : 1a. (1 Mark)Document6 pagesHess's Law Bond Enthalpies 5.3 (22 Marks) : 1a. (1 Mark)sennaPas encore d'évaluation

- PBC® Battery OverviewDocument2 pagesPBC® Battery OverviewNikša StanojevićPas encore d'évaluation

- Membrane Separations 3Document29 pagesMembrane Separations 3NandhanPas encore d'évaluation

- Us GHG Inventory 2020 Annex 2 Emissions Fossil Fuel CombustionDocument108 pagesUs GHG Inventory 2020 Annex 2 Emissions Fossil Fuel CombustionOscar SilvánPas encore d'évaluation

- r05311803 Heat Treatment TechnologyDocument8 pagesr05311803 Heat Treatment TechnologySrinivasa Rao GPas encore d'évaluation