Académique Documents

Professionnel Documents

Culture Documents

Sikadur 42 MP Normal PDF

Transféré par

Darwin Syahputra0 évaluation0% ont trouvé ce document utile (0 vote)

93 vues5 pagesSikadur-42 MP Normal is a three-component, solvent-free epoxy grouting system used for high-strength grouting and fixing of anchors, fasteners, and base plates. It has high early strength, is moisture tolerant, non-shrink, corrosion and impact resistant. The document provides technical data on packaging, storage, characteristics, mechanical properties, substrate preparation and application instructions for the epoxy grout.

Description originale:

Titre original

Sikadur 42 MP Normal.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSikadur-42 MP Normal is a three-component, solvent-free epoxy grouting system used for high-strength grouting and fixing of anchors, fasteners, and base plates. It has high early strength, is moisture tolerant, non-shrink, corrosion and impact resistant. The document provides technical data on packaging, storage, characteristics, mechanical properties, substrate preparation and application instructions for the epoxy grout.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

93 vues5 pagesSikadur 42 MP Normal PDF

Transféré par

Darwin SyahputraSikadur-42 MP Normal is a three-component, solvent-free epoxy grouting system used for high-strength grouting and fixing of anchors, fasteners, and base plates. It has high early strength, is moisture tolerant, non-shrink, corrosion and impact resistant. The document provides technical data on packaging, storage, characteristics, mechanical properties, substrate preparation and application instructions for the epoxy grout.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

Technical Data Sheet

Edition 1, 2007

Identification no:

02 02 02 01 001 0 000021

Version no 0010

Sikadur

-42 MP Normal

Sikadur

-42 MP Normal 1/5 1

C

o

n

s

t

r

u

c

t

i

o

n

Si k adur

-42 MP Nor mal

3-part, multi purpose epoxy grouting system

Product

Description

Sikadur

-42 MP Normal is a three-component, multi purpose, solvent-free,

moisture tolerant, epoxy grouting system. For use at temperatures between

+10C and +30C.

Uses High-strength grouting and fixing of:

Starter bars

Anchors

Fasteners

Tie rods

Crash barrier posts

Fence and railing posts

Under-grouting and bedding of:

Base plates

Machine bases, seat base-plates for light and heavy machinery including

heavy Impact and vibratory machinery, reciprocating engines, compressors,

pumps, presses, etc.

Bridge bearings

Mechanical joints (i.e. road/bridge/deck types, etc.)

Sleeper-less, direct rail fixing:

Crane tracks

Light rail and permanent way in tunnels

Light rail and permanent way over bridges

Characteristics /

Advantages

High-strength High early strength

Ready-to-mix, pre-batched units

Moisture tolerant

Non-shrink

Corrosion and chemically resistant

Stress and impact resistant

High compressive strength

High vibration resistance

Low coefficient of thermal expansion

Product Data

Form

Appearance / Colour Concrete Grey

Packaging 12 kg (A+B+C): pre-batched unit, pallets of 252 kg (21 x 12 kg)

Bulk packaging (not pre-batched):

144 kg (A+B+C)

Component C (Sikadur

-514) bag for 24kg units, pallets of 960 kg (40 x 24 kg)

Storage

Storage Conditions/

Shelf-Life

24 months from date of production if stored properly in original and unopened,

sealed and undamaged packaging, in dry conditions at temperatures between +5C

and +30C. Protect from direct sun light.

Back

Table of Contents

Sikadur

-42 MP Normal 2/5 2

Technical Data

Chemical Base Epoxy resin.

Density 2130 kg/m

3

(A+B+C)

Layer Thickness M Minimum grout depth: 10 mm

Maximum grout depth: 150 mm

Change of Volume Creep:

4.14 N/mm

2

(600 psi) / 31500 N (+60C) 1.1% (According to ASTM C1181)

2.76 N/mm

2

(400 psi) / 21000 N (+60C) (According to ASTM C1181)

API requirements: 0.5% with 2.76 N/mm

2

load

Thermal Expansion

Coefficient

2.7 x 10

-5

mm/mm/C (Temp. range -20C - +60C) (According to EN 1770)

Water Absorption

Coefficient W

0.059% (7 days) (According to ASTM C413)

Thermal Stability Heat Deflection Temperature HDT:

HDT = +55C (7 days / +23C) (According to ISO 75)

Effecti ve Bearing Area > 90% (According to ASTM C-1339)

Mechanical / Physical

Properties

Compressi ve Strength (According to ASTM C-579)

Curing time +10C +23

1 day ~ 36 N/mm

2

~ 93 N/mm

2

3 days ~110 N/mm

2

~122 N/mm

2

7 days ~115 N/mm

2

~126 N/mm

2

28 days ~118 N/mm

2

~130 N/mm

2

Product cured and tested at temperatures indicated.

Test specimen size: 12.7 * 12.7 * 25.4mm

Flexural Strength ~ 32 N/mm

2

(According to ISO 196)

~ 39 N/mm

2

(According to EN 53452)

Tensile Strength ~ 14 N/mm

2

(According to ASTM C 307)

~ 16 N/mm

2

(According to ISO 527)

Bond Strength > XX N/mm

2

(concrete failure) (slant shear) (According to ASTM C882)

(According to According to ISO 4624, EN 1542 and EN 12188)

~ 9 N/mm

2

(on steel)

> 3.5 N/mm

2

(concrete failure)

E-Modulus ~ 16000 N/mm

2

(Flexural) (According to EN 53452

~ 18000 N/mm

2

(Compressive) (According to ASTM D695-96)

Elongation at Break 0.1 + 0.05% (7 days at +23C) (According to ISO 75)

Strength Development Confirm the strength development by producing cubes on site and testing them

for compressive and flexural strength.

Exoterm Peak 44C (at +23C) (According to ASTM D 2471)

System

Information

Application Details

Sikadur

-42 MP Normal 3/5 3

Substrate Quality

Mortar and concrete must be older than 28 days (dependent on minimum

strength requirements).

Verify the substrate strength (concrete, natural stone etc.).

The substrate surface (all types) must be clean, dry and free from contaminants

such as dirt, oil, grease, existing surface treatments and coatings etc.

Steel substrates must be de-rusted to a standard equivalent to Sa 2.5

The substrate must be sound and all loose particles must be removed.

Substrate must be dry or mat damp and free from any standing water, ice etc.

Substrate Preparation Concrete, mortar, stone:

Substrates must be sound, dry, clean and free from laitance, ice, standing water,

grease, oils, old surface treatments or coatings and all loose or friable particles

must be removed to achieve a laitance and contaminant free, open textured

surface.

Steel:

Must be cleaned and prepared thoroughly to an acceptable quality standard

equivalent to SA 2.5 i.e. by blastcleaning and vacuum. Avoid dew point

conditions.

Surface and base plate contact area must be clean and sound. For best results,

the substrate shall be dry. Remove dust, laitance, oils, grease, curing

compounds, impregnations, waxes, foreign particles, coatings, and disintegrated

materials by mechanical means, i.e. chipping with a chisel, blastcleaning etc.

All anchor pockets or sleeves must be free of water. Apply grout immediately to

prevent re-oxidizing / rust formation.

For optimum results:

When grouting areas or equipment that is sensitive to vibration, it is

recommended that the contact surfaces are prepared according to the latest

edition of the American Petroleum Institutes Recommended Practice 686

Machinery Installation and Installation Design, Chapter 5.

Application Conditions /

Limitations

Substrate Temperature +10C min. / +30C max.

Ambient Temperature +10C min. / +30C max.

Material Temperature

Sikadur

-42 MP Normal must be applied at temperatures between +10C and

+30C.

Condition the material by also storing at this temperature for 48 hours before

use.

Substrate Moisture

Content

4% pbw

Dew Point Substrate temperature during application must be at least 3C above dew point

to avoid condensation.

Application

Instructions

Mixing Part A : B : C = 5 : 1 : 30 by weight (Standard)

Solid / liquid = 5 : 1 by weight

Possibility to adjust the Mixing ratio, depending on Flowability:

Part A : B : C = 5 : 1 : (27-36) by weight

Solid / liquid = (4.5 6) : 1 by weight

Sikadur

-42 MP Normal 4/5 4

Mixing Time Pre-batched units:

Mix components A and B in the component A pail for 3

min with a paddle attached to a low speed drill (300-

450 rpm). Avoid aeration while mixing until the material

becomes uniformly blended in colour and viscosity.

Place the mixed epoxy into an appropriate mixing

vessel. Slowly add the contents of component C (to

keep air entrapment at a minimum) dependent on flow

requirements (observe the correct mixing ratio) and

mix until uniform and homogeneous. (approx. 5 min)

Mix only that quantity which can be used within its

potlife.

Bulk packing (not pre-batched):

First, stir each component thoroughly. Add the

components in the correct proportions into a suitable

mixing pail. Mix the components. Use an electric low

speed mixer, etc as above for the pre-batched units.

Never mix Component A and B without adding

component C (as the exothermic reaction between A

and B alone generates excess heat)

Leave Sikadur

-42 MP Normal to stand in the normal

mixing vessel until the majority of entrained air bubbles

have dispersed.

Application Method /

Tools

Forming:

The consistency of the Sikadur

-42 MP Normal epoxy grout system requires the

use of permanent or temporary forms to contain the material around base plates,

for example. In order to prevent leakage or seepage, all of these formers must be

sealed. Apply polyethylene film or wax to all forms to prevent adhesion of the

grout. Prepare the formwork to maintain more than 100 mm liquid head to

facilitate placement. A grout box equipped with an inclined trough attached to the

form will enhance the grout flow and minimize air encapsulation.

Pour the mixed grout into the prepared forms from one or two sides only, to

eliminate air entrapment. Maintain the liquid head to ensure intimate contact to

the base plate. Place sufficient epoxy grout in the forms to rise slightly above the

underside (3 mm) of the base plate. The minimum void depth beneath the

baseplate shall be 12 mm. Where the void beneath the base plate is greater than

150 mm, place the epoxy grout in successive 150 mm lifts or less, once the

preceding lift has cooled.

Once hardened check the adhesion by tapping with a hammer.

Cleaning of Tools Sweep excess grout into appropriate containers for disposal before it has

hardened. Dispose of in accordance with applicable local regulations. Uncured

material can be removed with Sika Colma Cleaner. Cured material can only be

removed mechanically.

Potlife (200g, adiabatic testing)

+10C +23C

5 : 1 : 30

130 minutes 75-80 minutes

The potlife begins when the resin and hardener are mixed. It is shorter at high

temperatures and longer at low temperatures. The greater the quantity mixed,

the shorter the potlife. To obtain longer workability at high temperatures, the

mixed adhesive may be divided into portions. Another method is to chill parts

A+B and C before mixing them (i.e. only when application temperatures are

above +20C).

Sikadur

-42 MP Normal 5/5 5

Notes on Application /

Limitations

Minimum substrate temperature: +10C. The material must be conditioned by

being stored in an area with an ambient temperature between +10and +30C for

a minimum of 48 h before using. Do not thin with solvents. Solvents will prevent

proper curing and change mechanical properties.

Sikadur

-42 MP Normal is a vapour barrier when cured.

Minimum grout depth: 10 mm.

Maximum grout depth: 150 mm per lift.

The last lift must be kept at 50 mm.

Component C must be kept dry. For specific bolt grouting applications please

refer to Sika Technical Services. For proper seating, allow the grout to rise above

the bottom (3 mm) of the base plate.

Avoid splitting prebatched units to mix. Mix complete units only. Cold ambient,

substrate or material temperatures will influence the curing and flow

characteristics of Sikadur

-42 MP Normal. Do not subject cured epoxy grout to

sudden temperature changes especially during early curing stages. Contact Sika

Technical Services for control joint spacing on large base plate grouting projects.

Value Base All technical data stated in this Product Data Sheet are based on laboratory

tests. Actual measured data may vary due to circumstances beyond our control.

Local Restrictions

Please note that as a result of specific local regulations the performance of this

product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the application fields.

Health and Safety

Information

For information and advice on the safe handling, storage and disposal of

chemical products, users shall refer to the most recent Material Safety Data

Sheet containing physical, ecological, toxicological and other safety-related data.

Legal Notes

The information, and, in particular, the recommendations relating to the application and end-use of Sika

products, are given in good faith based on Sikas current knowledge and experience of the product when

properly stored, handled and applied under normal conditions in accordances with Sikas

recommendations. In practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising

out of any legal relationship whatsoever, can be inferred either from this information, or from any written

recommendations, or from any other advice offered. The user of the product must test the products

suitability for the intended application and purpose. Sika reserves the right to change the properties of its

products. The proprietary rights of third parties must be observed. All orders are accepted subject to our

current terms of sale and delivery. Users must always refer to the most recent issue of the local Product

Data Sheet for the product concerned, copies of which will be supplied on request.

C

o

n

s

t

r

u

c

t

i

o

n

PT. Sika Indonesia

Jl. Raya Cibinong- Bekasi km. 20

Limusnunggal- Cileungsi

BOGOR 16820 - Indonesia

Tel. +62 21 8230025

Fax +62 21 8230025

Website : www.sika.co. id

e-mail: sikacare@id.sika.com

Branches

Surabaya :

Puri Niaga Blok G No. 29, Jl. Raya Rungkut Menanggal 11, Surabaya

Tel : 031-8690202 ; Fax : 031-8682123

Medan :

Kawasan Industrial " Medan Star ", Tanjung Morawa Km.19,2

Jl. Pelita Raya Blok R No.32, Deli Serdang 20362

Tel : 061-7941200 ; Fax : 061-7940822

Batam :

Jl. Laksamana Bintan,Komp. Bumi Riau Makmur Blok E No.3,

Sungai Panas, Batam

Tel : 0778-424928 ; Fax : 0778-450189

Vous aimerez peut-être aussi

- 3-part epoxy grouting systemDocument7 pages3-part epoxy grouting systemcharlessimoPas encore d'évaluation

- SIKA Sikadur 42 MP Normal HCDocument5 pagesSIKA Sikadur 42 MP Normal HCKang Mas WiralodraPas encore d'évaluation

- High-Strength Epoxy Grouting SystemDocument6 pagesHigh-Strength Epoxy Grouting SystemGihasAbdPas encore d'évaluation

- Sikadur - 42 HES (VP) : 3-Part, High Performance, Low Exothermic, Pourable Epoxy Grouting SystemDocument4 pagesSikadur - 42 HES (VP) : 3-Part, High Performance, Low Exothermic, Pourable Epoxy Grouting SystemAjay SastryPas encore d'évaluation

- Sikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesiveDocument6 pagesSikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesivevladodjuPas encore d'évaluation

- Sikadur 31 CF NormalDocument4 pagesSikadur 31 CF Normaldepi_rachmanPas encore d'évaluation

- Sikadur 31 CFDocument4 pagesSikadur 31 CFRonald MassoraPas encore d'évaluation

- 2 - Sikadur-42 PC - PDS - GCC - (05-2018) - 2 PDFDocument5 pages2 - Sikadur-42 PC - PDS - GCC - (05-2018) - 2 PDFAkhil VelayudhanPas encore d'évaluation

- Sikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDocument6 pagesSikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDarwin SyahputraPas encore d'évaluation

- Sikadur - 32 Normal: 2-Part Structural Epoxy Bonding AgentDocument4 pagesSikadur - 32 Normal: 2-Part Structural Epoxy Bonding AgentFarhanSyarifPas encore d'évaluation

- Sikadur 31 CF Normal PDS (CE)Document5 pagesSikadur 31 CF Normal PDS (CE)Satria AdityaPas encore d'évaluation

- Sikagard Wallcoat PdsDocument5 pagesSikagard Wallcoat PdscharlessimoPas encore d'évaluation

- Sikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing SystemDocument6 pagesSikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing Systemthe pilotPas encore d'évaluation

- Sikadur®-42 IN: Product Data SheetDocument4 pagesSikadur®-42 IN: Product Data SheetJackson OmindiPas encore d'évaluation

- Sikafloor - 381 N: 2-Part Self Smoothing Epoxy Coating, Highly Chemically and Mechanically ResistantDocument5 pagesSikafloor - 381 N: 2-Part Self Smoothing Epoxy Coating, Highly Chemically and Mechanically Resistantthe pilotPas encore d'évaluation

- Spray Applied Polyurea Membrane Technical Data SheetDocument4 pagesSpray Applied Polyurea Membrane Technical Data SheetcharlessimoPas encore d'évaluation

- SikaWrap Hex - 230CDocument3 pagesSikaWrap Hex - 230CHakiki SaputraPas encore d'évaluation

- Sikadur 31 CF Normal: 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur 31 CF Normal: 2-Part Thixotropic Epoxy Adhesiverahayu59Pas encore d'évaluation

- Sikadur - 53 Uf GroutDocument3 pagesSikadur - 53 Uf GroutJU SHUANGPas encore d'évaluation

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 pagesSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal Coatthe pilotPas encore d'évaluation

- Sikadur-31 2-part epoxy adhesiveDocument4 pagesSikadur-31 2-part epoxy adhesivecamelia_pirjan5776Pas encore d'évaluation

- Sikafloor - 381: 2-Part Highly Chemically and Mechanically Resistant Self Smoothing Epoxy CoatingDocument6 pagesSikafloor - 381: 2-Part Highly Chemically and Mechanically Resistant Self Smoothing Epoxy CoatingAnonymous v1blzDsEWAPas encore d'évaluation

- PPG PDS Amercoat 370Document7 pagesPPG PDS Amercoat 370sanguripPas encore d'évaluation

- Sikadur-31 CF Normal 2012-05 - 1 PDFDocument5 pagesSikadur-31 CF Normal 2012-05 - 1 PDFNyu123456Pas encore d'évaluation

- SikaWrap Hex - 430G - VPDocument3 pagesSikaWrap Hex - 430G - VPHakiki SaputraPas encore d'évaluation

- Sikadur - 42 MP inDocument4 pagesSikadur - 42 MP inJU SHUANGPas encore d'évaluation

- Sikadur - 31 SBA S-02 MYDocument4 pagesSikadur - 31 SBA S-02 MYsamitha505Pas encore d'évaluation

- Sikafloor - 2530 W: 2-Part Water Based Epoxy CoatingDocument5 pagesSikafloor - 2530 W: 2-Part Water Based Epoxy Coatingthe pilotPas encore d'évaluation

- Devcon Plastic Steel Putty (A) - TDSDocument3 pagesDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- Sika AnchorFix S Product Data SheetDocument6 pagesSika AnchorFix S Product Data SheetorgaPas encore d'évaluation

- Sikagard®-63 N: Product Data SheetDocument3 pagesSikagard®-63 N: Product Data SheetAMIT HALDERPas encore d'évaluation

- Ceramic Repair Paste TDSDocument3 pagesCeramic Repair Paste TDSAzril DahariPas encore d'évaluation

- 2-part epoxy primer, levelling mortar, intermediate layer and mortar screed product data sheetDocument6 pages2-part epoxy primer, levelling mortar, intermediate layer and mortar screed product data sheetAjit Singh RathorePas encore d'évaluation

- Sikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingDocument5 pagesSikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface Sealingthe pilotPas encore d'évaluation

- Sikadur 30Document3 pagesSikadur 30Hakiki SaputraPas encore d'évaluation

- Relative Air Humidity and Condensation RiskDocument6 pagesRelative Air Humidity and Condensation RiskAnonymous v1blzDsEWAPas encore d'évaluation

- Icosit KC 330-2MDocument4 pagesIcosit KC 330-2MNelu IvascuPas encore d'évaluation

- Sikadur 30 PDFDocument5 pagesSikadur 30 PDFDarwin SyahputraPas encore d'évaluation

- Sikadur®-42 LP: Product Data SheetDocument4 pagesSikadur®-42 LP: Product Data SheetMuhammad ShahidPas encore d'évaluation

- Sikafloor 326 PDSDocument10 pagesSikafloor 326 PDSLinsonlinsonPas encore d'évaluation

- Sikafloor 144Document8 pagesSikafloor 144Jessica CaldwellPas encore d'évaluation

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocument4 pagesSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadPas encore d'évaluation

- Sika Anchorfix - 1: Fast Curing Anchoring AdhesiveDocument6 pagesSika Anchorfix - 1: Fast Curing Anchoring Adhesiveeye4aneye1989Pas encore d'évaluation

- Pds CPD Sikadur42GroutPak UsDocument2 pagesPds CPD Sikadur42GroutPak UsAHPas encore d'évaluation

- 2-part water based epoxy sealer coatDocument5 pages2-part water based epoxy sealer coatazheminPas encore d'évaluation

- Sikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarDocument4 pagesSikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarAnonymous v1blzDsEWAPas encore d'évaluation

- Sikadur®-52 ZA: Product Data SheetDocument4 pagesSikadur®-52 ZA: Product Data SheetAmar Babu ChPas encore d'évaluation

- SikaTop Seal 107 PDS (CE) PDFDocument4 pagesSikaTop Seal 107 PDS (CE) PDFSed BeelzePas encore d'évaluation

- Attachment-4 Sikagard 63 N PDSDocument3 pagesAttachment-4 Sikagard 63 N PDSnoto.sugiartoPas encore d'évaluation

- Sikagard 63 N PDS enDocument3 pagesSikagard 63 N PDS ennoto.sugiartoPas encore d'évaluation

- Fisa Tehnica Ultra Series-Sapa Cu Polistiren - CT12F3D1.6Document1 pageFisa Tehnica Ultra Series-Sapa Cu Polistiren - CT12F3D1.6rovandabilPas encore d'évaluation

- Sikagard 720 EpoCemDocument6 pagesSikagard 720 EpoCemMohiuddin MuhinPas encore d'évaluation

- Sikagard 63n Pds enDocument3 pagesSikagard 63n Pds enariorasalahPas encore d'évaluation

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049Pas encore d'évaluation

- Sikafloor 220 W ConductiveDocument5 pagesSikafloor 220 W Conductivethe pilotPas encore d'évaluation

- Sikadur®-42 (Au) : Product Data SheetDocument3 pagesSikadur®-42 (Au) : Product Data SheetPramuditha SuraweeraPas encore d'évaluation

- Sikadur31 TdsDocument4 pagesSikadur31 TdsFrederick Linsangan CruzPas encore d'évaluation

- Sika - Waterbars: Flexible PVC WaterstopsDocument5 pagesSika - Waterbars: Flexible PVC WaterstopsRonald MassoraPas encore d'évaluation

- Sikagard 700 S ID PDFDocument2 pagesSikagard 700 S ID PDFDarwin SyahputraPas encore d'évaluation

- Sikadur 42 MP Normal PDFDocument5 pagesSikadur 42 MP Normal PDFDarwin SyahputraPas encore d'évaluation

- Sikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDocument6 pagesSikadur-330: 2-part epoxy impregnation resin for fabric reinforcementDarwin SyahputraPas encore d'évaluation

- SikaWrap-231 C PDFDocument3 pagesSikaWrap-231 C PDFDarwin SyahputraPas encore d'évaluation

- Sikadur 30 PDFDocument5 pagesSikadur 30 PDFDarwin SyahputraPas encore d'évaluation

- Plastiment VZ PDFDocument2 pagesPlastiment VZ PDFDarwin SyahputraPas encore d'évaluation

- Plastiment V105 PDFDocument2 pagesPlastiment V105 PDFDarwin SyahputraPas encore d'évaluation

- Sikacrete W: High - Performance Mineral Admixture For Underwater-Cast ConcreteDocument2 pagesSikacrete W: High - Performance Mineral Admixture For Underwater-Cast ConcreteDarwin SyahputraPas encore d'évaluation

- SikaTile Grout PDFDocument2 pagesSikaTile Grout PDFDarwin SyahputraPas encore d'évaluation

- Sikatop Armatec 110 EpoCem PDFDocument2 pagesSikatop Armatec 110 EpoCem PDFDarwin SyahputraPas encore d'évaluation

- Sockolet Gap Control Threaded Joints - PR - 0XXDocument14 pagesSockolet Gap Control Threaded Joints - PR - 0XXRAMAKRISHNAPas encore d'évaluation

- Triton RFET: Multi-Channel NDT System for Tube InspectionDocument2 pagesTriton RFET: Multi-Channel NDT System for Tube InspectionElyel GonzalezPas encore d'évaluation

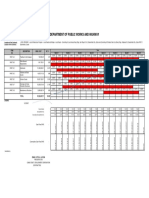

- Department of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractDocument1 pageDepartment of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractAdrian Louie Laganzo AquinoPas encore d'évaluation

- AD Case StudyDocument19 pagesAD Case StudySoham ShirgaokarPas encore d'évaluation

- Swissma: PAM Northern Chapter Half Day Seminar 20 May 2017Document117 pagesSwissma: PAM Northern Chapter Half Day Seminar 20 May 2017Shrimp HeadPas encore d'évaluation

- Construction Manual California PDFDocument956 pagesConstruction Manual California PDFAlexander Ponce VelardePas encore d'évaluation

- Triad Series: 3 Piece Ball ValvesDocument8 pagesTriad Series: 3 Piece Ball Valvesevilnemesis133Pas encore d'évaluation

- AWS blank welding formsDocument3 pagesAWS blank welding formsIvan Garzon100% (1)

- Lo+egis Rail EN Email PDFDocument164 pagesLo+egis Rail EN Email PDFChris MarkerPas encore d'évaluation

- Usa Submission PlanningDocument11 pagesUsa Submission PlanningRicky KhannaPas encore d'évaluation

- NSCP Chap4Document8 pagesNSCP Chap4BUILDING PERMITPas encore d'évaluation

- Assignment 3 PDFDocument14 pagesAssignment 3 PDFVishnu RajgopalPas encore d'évaluation

- Excel FileDocument6 pagesExcel FilePravin KenPas encore d'évaluation

- Sans 1200 MKDocument11 pagesSans 1200 MKannaselemelaPas encore d'évaluation

- Sheladia Sarva BrochureDocument10 pagesSheladia Sarva BrochureGohel MayurPas encore d'évaluation

- 03 Anchor and Plug System 3Document28 pages03 Anchor and Plug System 3Sunil YadavPas encore d'évaluation

- Spirax Sarco SV74 SeriesDocument2 pagesSpirax Sarco SV74 Series20040384iPas encore d'évaluation

- Cable Sizing Guide: Calculate Size for Ampacity, Voltage Drop & Short CircuitsDocument5 pagesCable Sizing Guide: Calculate Size for Ampacity, Voltage Drop & Short CircuitsDuong BuiPas encore d'évaluation

- Understanding Boat Design 101 PDFDocument1 pageUnderstanding Boat Design 101 PDFŁukasz ZygielPas encore d'évaluation

- Back AnalysisDocument7 pagesBack AnalysisBiren ShethPas encore d'évaluation

- Vastu Tips For A Perfect Staircase PDFDocument2 pagesVastu Tips For A Perfect Staircase PDFLandCraft Dev.Pas encore d'évaluation

- THESIS DOCTOR OF PHILOSOPHY GEORGE Jerin Mathew 2022Document187 pagesTHESIS DOCTOR OF PHILOSOPHY GEORGE Jerin Mathew 2022Amel RADJEFPas encore d'évaluation

- Spraying Tank-Hot Oil Heating (Massenza)Document2 pagesSpraying Tank-Hot Oil Heating (Massenza)jude tallyPas encore d'évaluation

- Conduits Electrical LatviaDocument13 pagesConduits Electrical LatviaÖmer Faruk GÜLPas encore d'évaluation

- Fastener glossary guideDocument32 pagesFastener glossary guideHugo RodriguezPas encore d'évaluation

- Data Sheet - Overhead TravellingDocument4 pagesData Sheet - Overhead TravellingSugiarto SaptomoPas encore d'évaluation

- Materials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersDocument10 pagesMaterials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersAkilesh Aravindakshan100% (1)

- No No - YesDocument3 pagesNo No - YesYedda M IlaganPas encore d'évaluation

- POMCUS System - Type II Forward Storage Site Facilities - Volume 1Document611 pagesPOMCUS System - Type II Forward Storage Site Facilities - Volume 1CptCavPas encore d'évaluation

- Hapag-Lloyd Container Specifications GuideDocument48 pagesHapag-Lloyd Container Specifications GuideRobertLouisNoyaPas encore d'évaluation