Académique Documents

Professionnel Documents

Culture Documents

Internship Report

Transféré par

SuVir SaHa0 évaluation0% ont trouvé ce document utile (0 vote)

381 vues41 pagesvbvcvbn

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentvbvcvbn

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

381 vues41 pagesInternship Report

Transféré par

SuVir SaHavbvcvbn

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 41

Internship report bd

Internship report bd is a document sharing education site, where Assignment, Research,

Project, Term paper, Presentation, Articl e, and Analysis Report are available.

Home

About

Download Report

Privacy Pol icy

Contact Us

Log In

Free avai l abl e report

Assignments

Internship Reports

Monograph

Project Papers

Research Paper

Sample Acknowledgement

Sample Certificate

Sample Dedicated

Sample Executive Summery

Sample Letter

Sample Recognition

Sample submission letter

Term Papers

Downl oad free fi el dwork report

Social work, Social science and Anthropology Fieldwork Research Paper Sample

An Internship Report on Marketing Activities of Garment Industries A Study

on RS Knit Wears Pvt. Ltd.

Labels: Internship Reports

ACCEPTANCE LETTER

This is to certify that .......................................... a student of MBA (Stream-a) year 2003-04,

Department of Marketing, .....................University, bearing roll no. ............... has completed

internship program in RS KNIT WEARS Pvt. Ltd. titled on Marketing Activities of RS KNIT

WEARS Pvt. Ltd.

He is directed to submit the report for evaluation.

(...............................)

Professor

Department of Marketing

....................University

To whom it may concern

This is to certify that................... a student (Roll No. ..............) of MBA Program carried on an

internship started from 10.05.2010 to 31.05.2010 at our RS Knit Wears (pvt) Ltd.

We wish him a prospective career and all success in life.

Signature

..............................

General Manager

RS knit Wears (Pvt) Ltd.

ACKNOWLEDGEMENT

At the very beginning, I acknowledge the infinite blessing and profound kindness of "Almighty Allah"-

the supreme authority of the universe. I also acknowledge the loving support of my teachers,

parents, and friends. I express my honest and sincerest gratitude to the Managing Director of RS

Knit Wears Pvt. Ltd, MOHAMMAD SOHEL, who assisted me a lot by giving an opportunity for eye

opening in this particular sector and extended an all-out support in all respect for writing this report in

the most comprehensive manner within the specified time frame.

I convey my deepest thanks to my institutional supervisor ................... for his precious time.

I was bound in my theoretical knowledge. It is my first experience to acquire knowledge in the

practical field. So, it is natural that there might have some mistakes. For these reasons, I am really

sorry and I beg pardon.

Finally, numerous thanks and gratitude to the Almighty Allah for paving my way to successfully finish

my report making.

Sincerely

.........................................

M.B.A (Stream-A) 2

nd

Semester

Bearing Roll: ............. Session: 2003-04

Department of Marketing

....................University

DEDICATED

To

My Beloved

Parents

Contents

CHAPTER-1

1.0 Introduction

1.1 Objectives of the study

1.2 Limitation of the study

CHAPTER-2

2.0 RS Knit Wears Pvt. Ltd

2.1 Historical Background

2.2 Description of the company

2.3 Employee safety, health & hygiene system

2.4 Objectives and Mission

2.4 Organizational Goals

2.5 Principal Objectives

2.6 Strategic View

2.7 Products

2.7 Sister concern

2.8 List of Companies Machineries

CHAPTER-3

3.0 Markets of Garments industries of Bangladesh

3.1 Problems and Present Situation of Readymade Garments

3.2 Non-Trade problems of garment sectors

3.3 Merchandising or marketing activities in garments factory

3.4 Steps of Readymade Garments Exporting

3.5 Business activities in RS Knit Wears Pvt. Ltd

CHAPTER-4

4.0 Strength of RS KNIT WEARS PVT. LTD

4.1 Weaknesses of RS KNIT WEARS PVT. LTD

4.2 Opportunities of RS KNIT WEARS PVT. LTD

4.3 Threats of RS KNIT WEARS PVT. LTD

4.4 Recommendation for marketing problems

4.5 Conclusion

CHAPTER-1

1.0 Introduction

The garment industry is by far the countrys most important manufacturer, earning around $5 billion

annually and accounting for about two thirds of all exports. Today the apparel export sector is a

multi-billion-dollar manufacturing and export industry in the country. The overall impact of the

readymade garment exports is certainly one of the most significant social and economic

developments in contemporary Bangladesh. With over one and over 10 million workers employed in

semi-skilled and skilled jobs producing clothing for exports, the development of the apparel export

industry has had far-reaching implications for the society and economy ofBangladesh.

Bangladesh has about 4,500 garment factories with up to 10 million livelihoods dependent on it

directly or indirectly. About 80 per cent of garment workers are women. The Ready Made Garments

sector has more potential than any other sector to contribute to the reduction of poverty.Two non-

market "have led to an important role in the confirmation of the head of the industry continued

success, these factors are (a) quotas under Multi-Fibre Arrangement1 (MFA) in the North American

market, and (b) special market European markets. The whole procedure is strongly related with the

trend of relocation of production. It has been reveals that the tendency of low labor charges is the

key reason for the transfer of garment manufacturing in Bangladesh. Bangladesh Garment Sector

and Global Chain the cause of this transfer can be clarified by the salary structure in the garment

industry, all over the world. Apparel labor charge per hour (wages and fringe benefits, US$)

in USA is 10.12 but it is only 0.30 inBangladesh. This difference accelerated the world apparel

exports from $3 billion in 1965, with developing nations making up just 14 percent of the total, to

$119 billion in 1991, with developing nations contributing 59 percent. In 1991 the number of workers

in the ready-made garment industry of Bangladesh was 582,000 and it grew up to 1,404,000 in

1998. InUSA, however, 1991-figure showed 1,106.0 thousand workers in the apparel sector and in

1998 it turned down to 765.8 thousand.

The tremendous success of readymade garment exports from Bangladeshover the last two decades

has surpassed the most optimistic expectations.

1.1 Objectives of the study:

The specific objectives of the study

are:

o To identify the marketing activities of RS Knit Wears Pvt. Ltd.

o To Find out the strengths, weaknesses, opportunities and threats of RS Knit Wears Pvt. Ltd.

o To pinpoint the problems of RS Knit Wears Pvt. Ltd. and possible recommendations.

1.2 Limitation of the study:

Garment industry of Bangladesh still now is not that much developed. I faced many difficulties in

writing this report. Some of this are- I found so many difficulties in searching information, in garment

factory most of the employee doesnt have any educational background. Due to the lack of enough

time I could not collect all necessary information to prepare a full and better report on this subject

matter. So I was not able to conduct with all functions within the reputed time.

CHAPTER-2

Introduction of the Company

2.0 RS Knit Wears Pvt. Ltd.

In the business world today no major player in apparel industry can ignore capability

of Bangladesh in offering qualitative and valuable products. RS Knit Wears Pvt. Ltd. has the

capability of providing a bridge between overseas customers / buyers and local manufacturers

in Bangladesh to ensure quality, services, timely deliveries and adherence to buyer's quality

standards. In today's world the key to success of any buyer is to identify- the country to source the

right product at right price. This is where the company - is step in to cater the buyer needs regarding

communication, quality and most of all timely delivery.

2.1 Historical Background

RS Knit Wears Pvt. Ltd. is a large company in Nrayanganj BSCIC hosiery industrial area and it has a

very good reputation. RS Knit Wears Pvt. Ltd. started its journey in garment industry in 1998 with the

apparel business. RS Knit Wears Pvt. Ltd. is a 100% export oriented composite garments industry.

The company is constantly providing customers across the world with garment sourcing solution,

with manufacturing facilities. Bangladeshentered in readymade garments business in early 1980s. At

that time there were very few local entrepreneurs who knew the business. Mainly the foreign

entrepreneurs directly operated their business for the cheap labor. But during late 1980s and early

1990s the scenario of Garment Sector of Bangladesh started changing. Local expert and

entrepreneurs started experiencing the knowledge of the business.

The company is committed to growth and improvement of all aspects of its operation and willing to

be a leader in the industry.

2.2 Description of the company

NUMBER OF EMPLOYEE: TOTAL 425 PERSON

a) PROFESSIONAL ADMINISTRATIVE OFFICER : 20 PERSON

b) CLINICAL SALE'S&RELATED OFFICER : 15 PERSON

c) FACTORY EMPLOYEE- CUTTING SECTON : 20 PERSON

d) SEWING SECTION :230 PERSON

e) CHECKING SECTION : 70 PERSON

f) FINISHING SECTI : 70 PERSON

2.3 Employee safety, health & hygiene system

Strictly maintaining safety, health and hygiene provisions as per ILO's andBangladesh labor law's

rules and regulation, the following facilities are available for employee safety, health and hygiene.

v Free medical service

v Proper first aid box

v Enough fire extinguisher

v Trained fire fighting team

v Training program for fire fighting

v Healthy toilets and urinals etc.

2.4 Objectives and Mission

RS KNIT WEARS PVT. LTD. realizes the need to stake out a competitive segment in the changing

global market of today through technological excellence and human expertise. The company is

committed to transpose its local success to the world scene.

Company Objectives:

v To establish as a one stop source for the Global Knit Apparel market.

v To satisfy and meet customer's expectation by developing and providing products and service

on time, which offer value in terms of Quality, Price, Safety & Environmental impact.

v To assure complete compliance with the international quality standards.

v To provide the employees internationally acceptable working condition/standards.

v To promote the development and best use of human talent & equal opportunity employment.

v To procure the most advanced & sophisticated technology suitable for producing desired

product.

v To attain highest level of competence through continuous development of the professional

management system and to ensure complete transparency in all aspects of business.

Corporate mission:

v Put the customer first always.

v Be flexible to the customer's needs.

v Adhere to the highest quality standards.

v Think innovatively but make informed business decisions.

v Deliver results

2.4 Organizational Goals

v To employ resources as incendiary for the growth of RMG sector.

v To provide service for the parties involved and invention of the necessary new service dimension.

v To search for new buyers for investment and help to develop products to suit such needs.

2.5 Principal Objectives:

v Profit maximization

v To provide quality product.

2.6 Strategic View:

v A truly international outlook for exporting.

v A long-term commitment for exporting

v A strategic approach to the development of new export market

v Credibility and close and long-term relationship in export market

v An international reputation for quality

v Resources available for export support

2.7 Products

company is manufacturer and exporter of readymade garments like T-SHIRT, POLO-SHIRT, TANK

TOP , ROUND NECK, INTER LOCK, 1X1. RIB, 2 X 2 RIB , DROP NEEDLE, LYCRA BODY

ETC, Dyeing and finishing fabric of 100% cotton, blends and 100% polyester. Knitting of fabrics in

100% cotton, blends and 100% polyester Different types of printing like Pigment, Rubber, Flock, Foil,

Sugar, Discos, Deactive, Embross, Plastic sole, Glitter, Hidensi, Transper, Gel, Stone print. Besides,

the company has very strong marketing division for all kinds of ready-made garments to expand

market to Europe, U.S.A, Canada and all over the world.

2.7 Sister concern:

AL AMIN EXPORT LTD.

MANUFACTURER & EXPORTER OR QUALITY SWEATER

Manufacturing of all kinds of sweaters, Pullovers, Cardigans etc.

01. Production

Capacity

3gg = 1350 dzs/ Month (Basic)

5gg = 1450 dzs/ Month (Basic)

7gg = 900 dzs/ Month (Basic)

Total=3,700 dzs/ month

02. Total Floor Space 24,500 Sq Ft (04 storyed building complex)

03. Office & Factory

Address

Plot # A-105 & 96, BSCIC Hosiery Industrial

Estate, Shasongaon, fatullah, Narayanganj

Phone : 7601605, 7602380

Fax : 7602379

E-mail: alaminex@hrcworks.com

2.8 List of Companies Machineries:

THE LIST OF CIRCULAR KNITTING MACHINE:-

BRAND/MODEL MACHINE TYPE

TYPE OF

DIA

OTY

01. KUKUHAMA

TAIWAN

S/JERSEY 17 01 SETS

02. KUKUHAMA

TAIWAN

S/JERSEY 18 01 SETS

03. KUKUHAMA

TAIWAN

S/JERSEY 19 01 SETS

04. KUKUHAMA

TAIWAN

S/JERSEY 20 01 SETS

05. KUKUHAMA

TAIWAN

S/JERSEY 21 01 SETS

06. LIEN YUEN

TAIWN

S/JERSEY 22 01 SETS

07. FUKUHAMA

TAIWAN

S/JERSEY 23 01 SETS

08. LIEN

YUENTAIWAN

S/JERSEY 24 01 SETS

09. LIEN

YUENTAIWAN

S/JERSEY 28 01 SETS

10. LIEN

YUENTAIWAN

RIB 30 01 SETS

11. FUKUHAMA

TAIWAN

RIB 36 01 SETS

Dyeing machines:

Rs knit wears (pvt) ltd. Is an export oriented knit composite factory. The main object of this company

is to produce world class knit dyed fabrics for the export oriented factories of Bangladesh. Dyeing

capacity of this factory is around 5 (five) tons a day. The factory has installed world class brand

machine to dye and finish various type of factories including single jersey , interlock, pique polo and

rib. In addition we are able to dye more sophisticated fabrics like viscose/lacra, nylon, 100%

polyester and offer enzyme washing. Our dyes/chemicals are of European origin including dyester,

bezema and CIBA from switzerland.

The lab is equipped with all necessary machines (including lab dyeing machine, photo

Spectrometers, auto solution preparation tools etc.) we have an experienced R & D department. The

water used in the dyeing process in very important and to achieve balanced ph content, our water is

processed through a state of the art, water softening treatment plant. The water we use has been

tested in European laboratories and has been certified as high quality with an excellent ph value.

This process has added to the quality of fabrics we produce.

The most fascinating part of this factory is the Water Treatment Plant. It has the Shillholko water

filter, which is the best of its category. So it does not secrete any waste water which hazardous for

our environment. The Waukesha USA Gas-Generator is capable to provide adequate power supply.

Our Finishing Dept. has a range at European and U.S. machinery, which allows us to offer high

quality, finished Knit fabrics.

Sewing Machines:

OVER LOCK

MACHINE :

50 SET (COUNTRY LOF

ORIGIN-JAPAN BRAND

(PEGASUS)

FLAT LOCK MACHINE

:

15 SET ( COUNTRY OFORIGIN-

JAPAN BRAND-(PEGASUS)

BACK TAPE

MACHINE :

05 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-

(PEGASUS)

PLAIN MACHINE :

02 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-(JUKI)

BACK TAPE CUTTING

:

02 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-

(PEGASUS)

CLOTH CUTTING

MACHINE :

O4 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-(KM)

THE MODULAR MANUFACTURING System (MMS) is Adopted for the flexibility and

shorter production cycle. Specially equipment include Automatic thread cutter and dust

CONTROLLER. Snapping machine, AUTOMATIC button stitch machines. Automatic

pocket setters, Automatic collar tuners and high-speed tape sewing machines are also

installed in the plant.

BUTTON HOLE :

01 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-

(BROTHER)

BUTTON STITCH :

01 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-

(BROTHER)

FEED OF THE ARM :

04 SET ( COUNTRY OF

ORIGIN-JAPAN BRAND-(JUKI)

CHAPTER-3

3.0 Markets of Garments industries of Bangladesh:

The ready-made garment industry in Bangladesh is not the outgrowth of traditional economic

activities but emerged from economic opportunities perceived by the private sector in the late 1970s.

Frustrated by quotas imposed by importing nations, such as the United States, entrepreneurs and

managers from other Asian countries set up factories in Bangladesh, benefiting from even lower

labor costs than in their home countries, which offset the additional costs of importing all materials

to Bangladesh.Bangladesh-origin products met quality standards of customers in North America

and Western Europe, and prices were satisfactory. Business flourished right from the start; many

owners made back their entire capital investment within a year or two and thereafter continued to

realize great profits. Some 85 percent of Bangladeshi production was sold to North American

customers, and virtually overnight Bangladesh became become the sixth largest supplier to the

North American market.

After foreign businesses began building a ready-made garment industry, Bangladeshi capitalists

appeared, and a veritable rush of them began to organize companies in Dhaka, Chittagong, and

smaller towns, where basic garments--men's and boys' cotton shirts, women's and girls' blouses,

shorts, and baby clothes--were cut and assembled, packed, and shipped to customers overseas

(mostly in the United States). With virtually nogovernment regulation, the number of firms

proliferated; no definitive count was available, but there were probably more than 400 firms by 1985,

when the boom was peaking.

After just a few years, the ready-made garment industry employed more than 200,000 people.

According to some estimates, about 80 percent were women, never previously in the industrial work

force. Many of them were woefully underpaid and worked under harsh conditions. The net benefit to

the Bangladeshi economy was only a fraction of export receipts, since virtually all materials used in

garment manufacture were imported; practically all the value added in Bangladesh was from labor.

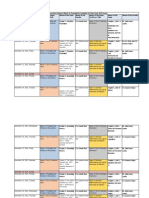

Export Promotion Bureau, Bangladesh

Export performance for the Month of July-May 2009-2010

Overall position Mn. US $

Produc

ts

Export

performan

ce for

2008-

2009

Export

target

for

2009-

2010

Strateg

ic

export

target

for

July-

May.

2009-

2010

Export

performan

ce for

July-May.

2009-

2010

%

Change

of export

performan

ce over

export

target

Export

performan

ce for

July-May.

2008-09

%

Change

of export

performan

ce

July-May.

2009-

2010

Over

July-May.

2008-09

Knitwe

ar 6429.26

7297.

21

6545.6

0

5755.36 -12.07 5809.60 -0.93

Woven

garmen

ts 5918.51

6687.

92

5999.0

6

5391.00 -10.14

5395.89

-0.09

Home

textile

313.51 351.1

3

314.96 263.38 -16.38 290.36 -9.29

Textile

fabrics

76.32 87.77 78.73 57.30 -27.22

69.65

-17.73

Main apparel items Exported over the last Five fiscal years value in million US$:

YEAR SHIRTS TROUSERS JACKETS T-SHIRT SWEATER

2004-2005 1053.34 1667.72 430.28 1349.71 893.12

2005-2006 1056.69 2165.25 389.52 1781.51 1044.01

2006-2007 943.44 2201.32 1005.06 2208.9 1248.09

2007-2008 915.3 2512.24 118152 2765.56 1474.09

2008-

2009(First

quarter)

305.18 774.25 286.66 689.60 741.87

Export Earnings over last five fiscal years value in million US$:

YEAR WOVEN KNIT TOTAL GROWTH%

2004-2005 3598.20 2819.47 6417.67 12.87

2005-2006 4083.82 3816.98 7900.80 23.11

2006-2007 4657.63 4553.60 9211.23 16.59

2007-2008 5167.28 5532.52 10699.80 16.16

2008-

2009(First

quarter)

1525.28 1831.08 3356.36 44.66

3.1 Problems and Present Situation of Readymade Garments:

Projecting a decline in Bangladeshs GDP growth to 5.5 per cent in the current fiscal from 5.9 per

cent of the last fiscal (2009-09), Asian Development Bank on Tuesday said this will happen because

of late-unfolding effects of the global economic recession. The slowdown in growth will be partly due

to lagged effects of depressed external demand forBangladeshs mainly low-end garment exports, it

said.

Addressing a press conference at the multilateral donor agencys Dhaka office marking release of

ADB quarterly Economic Outlook, the officials said growth will likely improve in the coming fiscal

(2010-11) as the worldwide economic recovery strengthens.

Laying special emphasis on resolving power and gas shortage, they said industries and other

sectors are suffering a lot that impedes the overall growth of the country.

Failure to address power and gas shortage as well as the unexpected surge in commodity prices

have been predicted to be the biggest risk for the economy, the ADB officials said.

They, however, noted that significant improvement in power and gas supply situation is unlikely in

near future as it needs huge time to set up large base-load power plants.

Expressing concern about the overseas employment, the ADB said it has declined by 42.2 per cent

up to February with many workers returning home although remittance has marked a 19.2 per cent

growth up to that time. ADB country director Paul J Heytens addressed the press conference while

M Zahid Hossain made the presentation on economic outlook. ADB energy expert Rahman Murshed

also spoke on the occasion.

The ADB said that the countrys economy was affected a little late by the global recession. But now

the global economy is recovering andBangladesh economy will also take a positive look in the

coming days.

It said that industrial growth will slow down to 5.6 per cent in the current fiscal as against 5.9 per cent

in the last fiscal. Similarly, the services sector growth will slow down to 5.9 per cent from 6.3 per

cent.

But at the same time, ADB expressed hope for the coming fiscal that the industrial sector will grow

robustly at 7.5 per cent with recovery in global demand and improved domestic business confidence

that will increase construction and investment.

Similarly, domestic support such as financial support to small and medium enterprises should also

boost industrial output in the coming year.

Appreciating the growth in the revenue collection, the ADB said the revenue growth rose 16.2 per

cent in last 7 months from 9.5 per cent in the first quarter of the current fiscal.

With the current pace, revenue targets for the fiscal 2009-10 are expected to be attained, revealed

the ADB outlook.

The ADB said that inflation is predicted at 7.5 per cent in the current fiscal and 7.8 per cent in the

next fiscal.

Garment sectors in Bangladesh have some problems for which productivity is lower than other

countries need. Some of these exiting problems are as follows:

Present obstacles:

Market Diversification: Bangladeshi RMG products are mainly destined to the US and EU. Back in 1996-

97, Bangladesh was the 7th and 5th largest apparel exporter to the USA and European Union

respectively. The industry was successful in exploring the opportunities in markets away from EU

and US. A recent WTO review points out thatBangladesh has not been able to exploit fully the duty

free access to EU that it enjoys.

2. Product Diversification: The growth pattern of RMG exports can be categorized into two distinct

phases. During the initial phase it was the woven category, which contributed the most. Second

phase is the emergence of knitwear products. In the global economy and ever-changing fashion

world, product diversification is the key to continuous business success. Starting with a few items,

the entrepreneurs of the RMG sector have also been able to diversify the product base ranging from

ordinary shirts, T-shirts, trousers, shorts, pajamas, ladies and childrens wear to sophisticated high

value items like quality suits, branded jeans, jackets, sweaters, embroidered wear etc. But the fact is

that its needs more diversification in the RMG products to capture the international market.

3. Low productivity: During last 10 years, Labor productivity rate in Bangladesh RMG is not

satisfactory but the lobar productivity ofMexico; Hong-Kong, Taiwan is high. The Bangladesh RMG,

workers take much longer time to complete stitching so the workers productivity is lower. All people

working at the spinning mills, weaning mills and fabric processing units are not improved in

productivity. Our managerial efficiency in not efficient so our total productivity is not increasing.

4. Lack of Forward Linkage: Forward linkage includes transportation packaging shipping and other

activities. After production we need the support of forward linkage to send the product to the

customer. ButBangladesh has no sufficient rail, truck facility. Lack of availability of

ship, Bangladesh is not able to send product in due time.

5. Inadequate Backward Linkage: Although the RMG industry is already 30 years old, on attempt

has so far been made to build up backward linkages textile industry to feed the RMG industry. The

RMG industry is highly dependent on important raw materials becauseBangladesh does not have

the capacity to produce export quality fabric. Orders are placed by the buyers on a cutting, making

and trim (CMT) basis. Bangladesh import 90 % of woven fabric and 40 % of the knit fabric. Shortage

of capital for backward linkage industries is the major weakness. There are two types of countries

involved in Backward Linkage. One type consists with backward linkage industries such

asChina, India, Korea, Hong-Kong etc. Another types which export clothing but depends on imported

textile for manufacturing such asBangladesh. So Bangladesh will face difficulty in lead-time.

6. Longest Lead-Time: Lead-time for order placed in Bangladesh need 90+ days from the date of

order. The lead-time in Singapore seaport is 6 hours and Sri-Lanka it is 8 to 9 hour but the lead-time

for Chittagongport is at least 6 days.

7. Underdeveloped Infrastructure Facility: The RMG sector has grown at a fast in Bangladesh. But

the port facilities have not expanded at that rate. After orders are placed it takes about 20-25 days

for transshipment of the import fabric to reach Chittagong port. The lead-time in Singapore seaport

is 6 hours and Sri-Lanka it is 8 to 9 hours, but the lead-time for Chittagong port in at least 6 days, we

need deep-sea pant, which can reach Chittagong port in 8-12 days. Also alternative port at Mongla

port needs to be developed. Private sector participation in port development is not satisfactory.

There is a need to have additional road and rail route for power distribution.

8. Complete Control of the Buyer: The buyer control Quota free world market. They observe whether

the organizations are maintaining labor law. In this sector, owner should conscious and they should

also know international labor law. Buyers will emphasize on minimum salary, child labor rights,

working condition and working environment.

9. Narrow Product Line: The narrow base of RMG exports is a matter of great concern and about 45

percent of its export will be vulnerable to competition after 2005. Bangladesh has very little access

to Japan.China and India markets for RMG export. Duty free access for RMG may be sought for

accessing to these countries on a bilateral basis.

10. Research and Training: The country has not dedicated research institute related to the apparel

sector. RMG is highly fashion oriented and constant market research is necessary to become

successful in the business. BGMEA has already established an institute which offers bachelors

degree in fashion designing and BKMEA is planning on setting up a research and training institute.

These and related initiatives need encouragement possibly intermediated by donor-assisted

technology and knowledge transfer. A facilitating public sector role can be very relevant here.

11. Political Unrest: Hartal, Strike, and Obstruction etc. political activities not only hamper production

but also shipment. For this we lost buyer and market. Bangladesh is a democratic country but

opposition parties often call Hartal. For this many foreign entrepreneurs do not investment in our

country.

12. Supportive Government Policy: In contrast to the public sector-led import-substituting

industrialization strategy pursued during the first few years after independence, the industrialization

philosophy of the government changed rather dramatically from the late 1970s when the emphasis

was on export-oriented growth to be spearheaded by the private sector. Towards this end, various

policy reforms were implemented in the 1980s and 1990s. Some of these reformed policies

contributed considerably to the growth of the RMG industry inBangladesh.

During the 1980s, a number of incentives were introduced to encourage export activities. Some of

them were new like the Bonded Warehouse Facility (BWF), while others like the Export Performance

License (XPL) Scheme 37 were already in operation and were improved upon. Also, rebates were

given on import duties and indirect taxes, there were tax reductions on export income, and export

financing was arranged. Not only the export has been limited to a small number but also the

products are not diversified. Bangladesh exports few RMG products such as Shirts, Jackets,

Trousers and Sweaters. As mentioned earlier as these are products for the low end of the

market.Bangladesh can expand its production for the low end of the market where it has a

competitive advantage as well as move upward to high priced fashion clothing.

3.2 Non-Trade problems of garment sectors:

There are some variables that are not directly related to trade but influence global trade.

These are sometime called non-trade issues. Some of them are discussed in the context

of Bangladesh.

Child Labor:

Child labor is one of the non-trade issues. It deprives the working children of early education.

It is harmful for normal physical and mantel development during childhood. Children would go to

school rather than work. When children are depriving of fundamental right it is a violation of human

rights. For this reason it has been made illegal in most countries. In spite of this, child labor

continues due to poverty. Although in most countries it is illegal to employ children. An ILO survey

indicates that more than 73 million of the worlds under aged children are employed for earning their

livelihood, in Asia, Africa and poor countries. Many of them are very risky. Bangladesh also suffers

from the child labor problem. A 1995 study revealed that children in Bangladesh were active in more

than 300 different kinds of jobs. There are many poor countries like Bangladesh where many

children do not go to school. Because they need financial support for their family, Most of families

are forced to their children to work. These children do not have any choice but selling their labor at

lower price. The wages are very low because the supply of child worker is much higher than the

demand. There are some families; the opportunity cost of sending their children to school is very

high. In case of unemployment, these children do not get food. There are some poor families of their

fundamental right. Child labor ideology is very good in a rich country. It may not be good in a poor

country without making alternative arrangement for the childrens education.

Exploitation of the Female Workers:

Though, this is a non-trade issue like child labor. There are many countries

including Bangladesh, female workers are exploited. Two studies completed by Bangladesh Institute

of development studies, are in 1990 and the after in 1997. Female workers are paid lower wages

than male workers. Female worker earned an average of the TK. 698 per month in the garments

industry. While a male worker earned TK. 1404 by 1997.The earning of female workers increased by

36% but male worker income incased by 69%, In the E.P.Z, average monthly wages were TK. 1521

for the female workers and TK. 2299 for the male workers. The wage gap between EPZ and Non

EPZ was found to be only 2% for man but 16% for woman, about 32.9% of the female workers and

12.8% of the male workers earned less than the minimum wage fixed by the government. This

discrimination is not the only problem. The RMG workers are also over worked but they do not get

money as per labor. In Bangladesh many female workers were burnt to death. But they did not get

compensation.

Labor Standards:

Labor standard means the terms and conditions under which labors agree to work in a

factory. These conditions may include hourly wages, paid leave, overtime, health care service, right

to form association etc. These are non-trade issues. The powerful retailers make buying decisions

on the basis of compliance or international bodies like ILO. The Uruguayrecognized the need for

standardized labor conditions on the ground of human rights. It is very difficult in Bangladesh. Rich

industrialized countries insist that the wages, working conditions, health and safety standards. If we

compare Bangladesh with rich countries and then Bangladesh will certainly be in a disadvantaged

position. Bangladesh like other developing counties, have established export-processing zones. The

average wages and other working conditions are better in these EPZ. The question of low wages is

debatable. Cheap labor is a natural factor in Bangladesh. Per capital income and average living

standard in Bangladesh is low. It is neither necessary to pay an hourly wages 5 Dollar

in Bangladesh. If we pay high wages, Bangladesh will not be able to compete in the market.

Environmental Standards:

A committee on trade and environment has been set up as a part of the world trade

organization. WT.O requires the developing counties to improve environmental standards for

accessing to the rich country markets.

People in the rich industrial world are interested in making working environmental standards.

Third world factories are trying to improve it. It is difficult to find a solution acceptable to all. The

developed country concept about environment is different from the poor countries. Bangladesh is not

only economically and technically poor but also in socially, culturally.

Eco-Labeling:

Industrialized importing countries consumers make their decisions not only on the price and

quality basis but also on the basis of environmental attributes. They consider the effect before,

during and after production. In many cases, fabrics contain chemical compounds that are harmful to

users. This certification is known as eco-labeling. Eco-labeling is designed to help environment

friendly products. Manufacturers design the products, packages and process to make them

environmentally acceptable.

The Security Concern:

The past 9/11 events and security measures taken by major importing countries at

deferent airports, particularly USA, have created special security. Muslim majority countries

like Bangladesh both at the port of exit and entry. Such inspection has nothing to do with the

traditional inspection of quality, quantity, specification or packaging. Those security measures in the

form of special inspection will be for the purpose of preventing terrorism.

Readymade Garments Industry holds a key position in the economy of Bangladesh in terms

of foreign exchange earnings, employment generation and poverty alleviation. Right now RMG

Sector is the highest foreign currency earner in Bangladesh.

RMG Industry has become the largest source of employment generation. Now 15-18 lacks

people are involved, of whom 90% are women in the RMG Industry of Bangladesh. Failure of the

RMG Industry will significantly reduce the export earning which will affect the domestic economic

activities

On January 1, 2005 quota facilities was ended. For this Bangladeshhas faced challenges at

home and abroad. So the garment industries should undertake some strategies to face the

difficulties. If RMG can take proper strategy to face the difficulty of post M.F.A then this sector

remain bright. These strategies are:

Cost Reduction Strategies:

Bangladesh has great opportunity in international markets if we can drop the price. To

increase its market share in both USA and EU markets as well as into new

markets Bangladesh should apply cost reduction method. Bangladesh faces competitive pressure

created by Mexico and CBI countries. They are selling RMG products in USA market during the past

several years. China has been reducing its prices. Chinese drop of prices is much cheaper. Chinese

price is cheaper than other suppliers. So the Bangladeshi exporters prices have gone down.

Since Bangladesh cannot control the prices in the USA market. The cost reduction strategies refer to

the cost-cutting measures that reduce the cost of producing RMG. The cut, make and trim

operations depending on whether the fabric is imported or not. Cost reduction strategies should be

applied in cut, make and trim operations.

There are some sub- strategies in the cost reduction strategies. These sub-strategies are

suggested below:

Development of Backward Linkage:

Back ward linkage development is necessary for the RMG industry to survive in the post

MFA era. If backward linkage is developed then it will ensure timely supply of raw materials which

will reduce cost. To complete an order, shorten lead time is necessary. Rules of origin it will make

easier for Bangladesh. Garments exporters buy fabrics against back-to-back LC.

Bangladesh pay high interest for 120 day back to back LC, Interest, charge, back

commissions and service fees are also paid by Bangladeshi exporters. All the charge increases the

RMG product of Bangladesh. IfBangladesh can supply local fabrics the total cost of domestic

product will be decrease. If Bangladesh can efficiently do vertical integration then it will increase

capabilities and get some benefits. It should be able to reduce lead-time.

Improving Labor Productivity:

Productivity in RMG sector has improved during the last 10 years. But the productivity

of Mexico, Hong Kong, Taiwan, and Malaysia is higher than Bangladesh. The Bangladeshi RMG

workers take much time to complete stitching a shirt than the workers in those countries.

SoBangladesh needs to improve labor productivity. To improve labor productivity Bangladesh should

train the workers. This is necessary step forBangladesh. There are some large factories which have

regular on the job training programs. But this program is not at the national level. Government

should do well-equipped training institutes. The supervisors and factory managers should also go

appropriate training. They can also increase productivity. The workers productivity cannot be highest

if the working condition is not good. If the workers are motivated then work efficiency will be

increased. If the worker suffers from insecurity, threat of jobs, do not get wages regularly then they

will be dissatisfied. Dissatisfied workers cannot give highest productivity.

If RMG wants to increase productivity it must improve the backward linkage. All the people

who working at the spinning mills, weaving mills and fabric processing must have proper training to

minimize the costs of production. It is also necessary to arrange training for managers, which will

increase total productivity.

Market Diversification:

Bangladesh depends on mainly two countries named the USA and EU. 96% apparels are

shipped to these two markets. This madeBangladesh vulnerable. The vulnerability can be reduced

by diversify markets. Market diversification is more important than product diversification. Without

market diversification backward diversification will fall in danger. The final product must be exported

at competitive prices.Bangladesh must develop forward linkages for competitive prices. The

development of forward linkages demand will increase. The present foreign buyers dominate the

marketing activities. Marketing intermediaries take more profits as their commission. Bangladeshi

entrepreneurs earn small margin. To increase their profit they need to build up marketing

capabilities. Innovative methods are needed for market diversification. E-marketing is one of

this. Bangladesh can negotiate the designs, shipment schedules. Prices etc. with the retailers in

the USA or EU or other countries. This will dominate companies. They can also have warehouses to

ensure quick supply of the finished goods. Market research including research on fashion design

facilitates diversification of products and markets. Marketing research identify changes in the

customers taste and preferences. Quick response increase market share.

Trade Diversion from the USA to the EU:

Bangladesh has traditional markets. Price and delivery system made more competitive

.If Bangladesh adds high priced items where competition is not very strong. The RMG industry

of Bangladesh is uncertain .To reduces the degree of uncertainty, the best way to explore new

markets. Between USA and EU, The EU is the large market.Bangladesh should expand its markets

wider and deeper in the EU. It is difficult for Bangladesh to compete with other countries. Product

differentiation can solve the problem. Recent statistics indicate that the exports from Bangladesh to

EU have been increasing. The Eastern European countries may create competitive pressure

for Bangladesh. Because of their geographical proximity and lower cost of production.

Both Bangladesh and most of the Eastern countries enjoy duty free status in the EU market it is the

price difference, quality of product and quality of delivery services that will matter. Bangladesh has

one advantage (low wage) and one disadvantage (low productivity and geographical distance).

IfBangladesh can increase its productivity then two disadvantages can cover by this.

Capacity Building:

Capacity building does not merely mean an increase in the production capacity due to

increase in the number of RMG factories and further development of backward linkages. It calls for

many other activities. It includes not only increasing production capacity (increasing spinning,

weaving, dyeing and processing facilities as backward linkages, and CMT operations) but also

acquiring capacity for design development, strengthening market research capability has been done

in India, Turkey and many other countries, gaining market promotion capability and relationships

management capability that contributes to image building. Also, improved quality of delivery services

is a major component of supply capacity. In addition, gaining the capacity of quick response is

essential. Maintaining long-term relationships for reliable transactions between the buyer and sellers.

The objectives are to improve the competitive position of the manufacturer and improve the retailer

profitability through increased inventory productivity and more efficient operation.

Attracting Foreign Direct Investment:

The discussions of product differentiation, product diversification and market diversification

have made references to the formation of strategic alliances with foreign buyer. Strategic alliance in

most cases call for FDI in the form of joint venture. It will be necessary to attract FDI to the RMG

sub-sector. If the inflow of FDI does not increase it will be difficult to face the challenges in the post

MFA era. To succeed in this case, government must improve the investment environment.

Ensuring Good Governance:

To succeed in its efforts to retain a leading position in the world apparel

market, Bangladesh must diversify market and products, develop backward linkage industries in a

balanced way. It must improve its productivity with a view to reduce its prices and improve its

delivery services. Price adjustment must be done in response from competitive pressure. Before

NAFTA was implemented the prices of Mexican apparels of the same categories were much higher,

about 12% than the prices of apparels exported from Bangladesh. So the Bangladeshi exporters

were comfortable in the US market. But after NAFTA was implemented, Mexican apparels enter

the US market duty-free. Before the preferential status was granted, Bangladesh had a minimum of

10% advantage over the prices of the CBI countries. The situation has now

reversed. Bangladesh prices are higher by almost 8%. It is therefore absolutely essential to find the

effective cost cutting measures. If cost of production and marketing can be reduced by some 10%,

then only Bangladesh can survive in future. Many experts believe that such reduction is possible by

improving management ofChittagong port, by supplying gas at a reduced price to the RMG factory

owners to generate power, by providing funds for training of the workers and supervisors to increase

productivity, providing equity fund at reasonable rates to develop backward linkage industry and

improving computerized communication technology. Beside, the buyer must believe that the cost of

doing business in Bangladesh is as low as it is in other countries. To reduce cost of doing

business, Bangladesh must improve the law and order situation and reduce the level of corruption.

One way to addressing the problem of good governance is to ensure effective application of

e-governance. It is a system under which the government and the people, the exporter-importers,

interact with the help of computers and ICT with each other with a view to achieving certain output

and minimizing the turn around time of the cargo vessels at Chittagong port. E-governance can

ensure accountability, transparency and work as a deterrent to corrupt practices.

None of the above measure scan is made effective in the absence of good governance.

Necessary political, legal, administrative, financial and other reforms must be implemented to make

the government machinery real functional. In addition, the government needs to encourage the

process of business advocacy and develop the official negotiating skills. Good governance is also

linked with prudent economic/business diplomacy.

Making available Financial Support:

Though Finance is available from local bank but the foreign bank does not contribute to the

RMG sector or in other way the local investors does not try to avail loan from foreign bank that refers

to shortage of capital that also mean that the owners can not establish proper and modern

technology to take the opportunity of competitive advantage.

Reducing the complexity of Financing by Commercial Bank:

The main constraints of establishing new garments or to improve the current production

facility through effective technology is availability of loan from our local bank that require a lengthy

and complex procedure. That abstaining from further investment both the present and prospect

investors either the local or foreign.

Providing available cash Incentives from Government:

Though the Bangladesh government provides cash incentive (5%) but our one of the main

competitor India provides (13%) that also decrease the competitiveness of our garment sector.

3.3 Merchandising or marketing activities in garments factory:

There is two type of merchandising in Garment Company:

o Commercial

o Official

Commercial:

They manage the export related document and ensure that the buyer LC is accurate. After

production they also manage the document of shipment.

Official:

They manage the production process and see whether the product is produced regarding the

requirement of the buyer and delivery the produced good within the shipment date.

Overall marketing/merchandising activities of readymade garments:

Export garments

To try to get garments order inquiry from buyer through various sources.

To study the order inquiry properly & to decide if it is workable for factory.

To find out the consumption of fabrics & accessories.

To collect the price of the fabrics & accessories this will be required for the inquiry order.

To assess the productivity of the item for the factory & also to Asses the cm charge as per market

rate.

To consider the other points if there is any.

To make costing on the garments inquiry.

To quote price to the buyer on the inquiry.

To finalize the price of the garments& to confirm the order with buyer through bargaining.

To check the master L/C, garments order sheet & the other necessary documents received from

buyer.

To make the material estimate sheet for fabrics & accessories for the confirm order.

To get price of the fabrics & accessories from the suppliers to confirm the rate through bargaining.

To get samples of the fabrics & accessories from the suppliers to get approval of them from buyer.

To confirm the approval of the quality of the fabrics & accessories to the suppliers.

To place booking of the fabrics & accessories with the suppliers.

To receive proforma invoice from the suppliers for each of the item, to check them for all details& if

all are ok then to give it to the commercial with proper note for opening of back to back L/C.

To keep communication with the suppliers for timely production & shipment of the goods against

booking.

To check the inventory report for all the items against the garments order & if there is any

discrepancy, then to take necessary steps immediately so that production & shipment of do not

hamper.

To get all the necessary samples for the garments approved from buyer before going for bulk

production.

To get the trim cards ready & to get it approved from buyer before going production.

To get the production file ready with all the necessary documents & to deliver same to the

concerned people before going for production.

To making planning of garments production so that buyers garments delivery date can be meet.

To stat the production of garments order timely.

To check that all details are being properly maintained in the garments production as per buyers

instruction.

To ensure that garments quality is being maintained as per buyers standard.

To make the inspection schedule & keep informed to the buyers representative so that inspection

of goods can be done timely.

To inform commercial department for probable date of inspection & shipments of goods so that

they can make the shipment documents timely.

To give booking with the shipping/air lines for the space for shipment of the garments.

To ensure that after inspection of goods by buyers representative, production department has

packed the goods properly has made it ready for shipment.

To ensure that the packed goods have been handed over to the shipping agencies for shipment

after proper formalities of customs.

To inform buyer for the shipped garments details with vessel schedules.

To fax/e-mail the shipment documents to buyer as soon as they are received.

To check that commercial has sent the shipment documents properly to the buyers bank as per

L/C details.

To check with commercial that payment of the shipped garments has been received from buyer

dully.

To keep the essential documents & samples reserved for some time after shipment of goods so

that for any claim, if there is any, from buyer, the actual status can be understood.

3.4 Steps of Readymade Garments Exporting:

Readymade garments exporting are involve in five phases. Marketing executives of the garments is

closely involved with these phases. The phases of garments marketing are the following:

1. Getting orders:

The main task of garments factory is to collect order from foreign buyer for maintain the business of

garments. Factories can collect order by the direct communication with the foreign buyer or by the

buying house or agent. Some garments factory owners himself perform this task. In others

marketing executives perform the same task. Marketing executives express their eagerness to get

order by direct communication with the buyer & buying house or by phone/fax/e-mail etc. Most of

the times the buyer or buying house also express eagerness to give order in the garments factory. At

first garments factory get inquiry of the order. After that garments factory doing costing on that

inquiry and submit the price quote to the buyers or buying house. At last garments order confirmed

by the price bargaining with the buyers on the basis of that price quotation.

Buying house: Buying house is the middleman between the buyer and RMG factory. It is quite

difficult to arrange buyer for RMG factory because most of the buyer come from foreign. And RMG

factories website is not that much effective thats why a class of broker grow in this gap between

buyer and the manufacturer. As they always maintain correspondence with the buyer they have

better understanding of buyers requirement. They act as a helping hand for us.

At first buyer request sample from the garments factory with all the necessary information regarding

to their product and then we match our capability with the buyers requirement. If capability matched

then we submitted a fare costing of that product to the buyer.

Costing: For costing of garment we have consider so many things such as following:

v Fabric consumption cost

v Accessories cost

v Fabric GSM

v Colour

v Washing, printing, embroidery cost

v CM (cutting & making) charge

v Commercial and additional expenses

v Buying house or agent commission

v Freight cost.

Order: If costing is in satisfactory level than the buyer will send the order sheet to the factory and will

request to send sample of the ordered garments for approval. Here I present some copy of order

sheet

2. Acquiring raw material:

When the garments order are confirmed with the buyer the garments factory start to collect

raw material quickly. Necessary steps for collecting raw material are the following:

v To make the list of necessary goods for performing order.

v To inform about the raw materials from more than one qualified suppliers.

v Suppliers price, sample, delivery time are properly examined & finalize the ultimate supplier by

bargaining for supplying various raw material.

v To give the accurate booking list to the suppliers & give the necessary information for taking

proforma invoice.

v Suppliers give proforma invoice against booking.

v To give supplier invoice to the commercial division & request to open a L/C against this.

v When the supplier sent the raw material to the factory destination then the factory examine the raw

material whether it is right quantity or any defect.

3. PRODUCTION OF GARMENTS:

When the raw material is available in factory then the probable date is determined for the production.

For that reason following subject matter are considered:

Factory space will keep ready for start garments production timely.

Production is complete before the shipment of minimum 3 days.

To fix daily production target on the basis of necessary machine & labor.

To make sample before the start of production the buyer approves that.

Merchandiser will make 5 files with related necessary papers & information of the order of

production.

To must have inline inspection on the primary produced product.

Production division are comply the suggestion from first line inspection.

2

nd

line inspection are performed by the buyers representative in mid time of production.

To give prior notice to the buyers representative for final inspection on which date.

After the final inspection cartoon are packed according to the packing list for shipment.

4. Consignment of garments:

When the products are produced then the merchandising division plan to shipment the

products with communicate the production division. Following subject matter are considered for the

shipment of garments:

To determine the mode of shipment-air/sea.

To fix the shipping agent whether it is nominated by buyers or the choice of factory.

To must have know from the L/C whether the product is sent on the basis of FOB or CNF.

To must give booking the shipping line & to take probable vessel schedule knowing the full

statement of products & probable date.

Necessary export documents are prepared against this exportable product.

To must give the copy of export document related to delivery date & other necessary information to

the CNF Agent.

CNF agent performs his duty till the products elevate to the vessel.

Merchandising division inform the buyers by fax/ e-mail of the commercial invoice, entire

packing list & left the vessel time of the shipment products.

5. Receiving of payment for garments:

After the export of products commercial division prepare all necessary papers & sent original copy to

the bank. A copy of bank document must send the buyers address by courier. If there is no objection

then the buyers bank sent the Bangladesh bank giving necessary direction for the matter of

payment. After that factory are informed payment received by the related bank.

3.5 Business activities in RS Knit Wears Pvt. Ltd.:

All the functions of RS KNIT WEARS PVT. LTD. are operated under seven major departments:

1. Merchandising department.

2. Sampling Department.

3. Commercial department.

4. Accessory supply department.

5. Production department.

6. Distribution department.

7. Accounts Department

1. Merchandising Department:

This department of RS KNIT WEARS PVT. LTD. is responsible for the following activities:

Searching buyers: The task of this department started with the searches of buyers, who want to

import garment products from our country, to get the order of the garment product manufacturing.

Introduce letter: After finding suitable buyers this dept. issues an introducing letter to the respective

buyers which describes RS KNIT WEARS PVT. LTD.'s experiences, its parameter of total activities,

efficiency and effectiveness and relationship with existing buyers.

CM: CM is another important activity that stands for Cost of Making. Here the merchandiser of this

dept. determines what are the things are required to make a unit or dozen of an order. Then he

makes calculation' of per unit cost on the basis of accessories consumption, fabric consumption,

labor cost and other relevant costs.

Price negotiation: When this department has the clear idea about the cost involved in the desired

transaction they start price negotiation to determine a final price that the buyer agrees to pay.

Select supplier: Merchandising department recognizes the effectiveness, of their commitment to

buyers. The bases of efficiency include supplier's adequate administrative setup to prepare all

necessary documents for exports, supplier's financial status and adequate capacities etc.

2. Sampling Department:

It starts its activities after receiving the original sample or sketch sample from the buyer with an,

intention to testify the capability of RS KNIT WEARS PVT.LTD. to meet the desired standard of the

products. Two people contribute toward the efficiency of sampling dept. They are sampling man and

pattern master of RS KNIT WEARS PVT. LTD.

3. Commercial Department:

The commercial department of RS KNIT WEARS PVT.LTD. prepares pro-forma invoice for the

respective buyer. The invoice includes the quantity of the buyer's order, its unit price and total price.

The commercial department also transfer master L/C on the name of selected supplier.

This department also maintains all clerical activities such as maintaining the accounts of daily

transaction, maintaining payroll, keeping the accounts of daily expenditures etc.

4. Accessory supply department:

For a smooth manufacturing, the assurance of on time delivery of fabric and accessories is must.

The responsibility of supplying accessories to the suppliers landed on the ground of this department.

5. Production Department:

Although named as production department, this service department rather follows up production

dividing its activities into following sections of responsibilities:

Quality monitor and control: This dept. supervises the manufacturing process to maintain the quality

and scheduled progress of the manufacturing in behalf of RS KNIT WEARS PVT. LTD.

Final Inspection: For its reputation, buyers usually delegate the responsibility of final inspection on

the shoulder of quality to the inspector of RS KNIT WEARS PVT. LTD. The efficient inspection is

the responsibility of the quality inspector of RS KNIT WEARS PVT. LTD.

6. Distribution Department:

As the name mentions the task of Distribution department of RS KNIT WEARS PVT. LTD. starts

from -receipt of final goods from the supplier factory after the final inspection and ends-with loading

of the goods bound for supplier. This department also prepares the supporting documents for export

such as bill of exchange, bill of lading, commercial invoice, certificate of origin, packing list etc.

7. Accounts Department:

Accounts Department do the all accounting related activities and maintain all the important

documents accordingly.

CHAPTER-4

SWOT Analysis of RS KNIT WEARS PVT. LTD.

The main objective of any business institution is to earn profit and top survive in the market with a

better competitive position. RS KNIT WEARS PVT. LTD. is not an exception. The main objective of

this company is also earning profit.

It is known that, Profit = Revenue Expense. With the changing business environment profit,

revenue and expense also change. There are many factors which force to change the profit, revenue

and expenses.

4.0 Strength of RS KNIT WEARS PVT. LTD.:

There are many factors that help in increasing or decreasing the profit of the company. When the

profit increases, it is treated as the strength of the company.

Skilled workforce:

From its beginning RS KNIT WEARS PVT. LTD. looks into the combination of effectiveness and

efficiency regarding its objectives. As a result within a few days it got the higher regard from its

buyers.

Market Reputation:

RS KNIT WEARS PVT. LTD. is one of the major Mills in Bangladesh that's why they have little bit

reputation in local market and having trust from investors.

Collaboration with suppliers:

To provide higher value in their value delivery process RS KNIT WEARS PVT. LTD. has built the

long-term relationship with some competent suppliers. This collaboration makes this organization

honest to its commitment of quality and scheduled delivery to its buyers.

Permanent Buyers:

For its reputation' of committed organization it has built a marketing network with some prominent

buyers. These buyers are not easily vulnerable to other factories, as they are satisfied with RS KNIT

WEARS PVT. LTD. for its efficiency and effectiveness.

Collaboration with backward linkage industry:

To be ever successful in their commitment to their buyers they always assure the on time delivery of

the accessories needed in the manufacturing process. Merchandizing dept. has taken the

responsibility of supplying these accessories to the manufacturing process for its assured supply.

For the convenience of this responsibility they have built long term relationship with the suppliers of

accessories that they don't manufacture and done necessary paper work with strong term and

conditions with those accessory suppliers.

Long-term relationship with buyers:

RS KNIT WEARS PVT. LTD. honors the long-term relationship with their buyers. So the buyers

remain loyal to the company. This is the reason long-term relationship with their buyers is strength of

the company.

4.1 Weaknesses of RS KNIT WEARS PVT. LTD.:

There are many factors that help in increasing or decreasing the profit of the company. When the

profit decreases, it is treated as the weakness of the company.

Fail to attract big Buyers:

Despite effectiveness and efficiency one of the weakness of RS KNIT WEARS PVT. LTD. is its short

capacity. For its low level capacity RS KNIT WEARS PVT. LTD. it's deprived from potential growth

resulting from its present reputation, which could be achieved otherwise.

Not International standard certified:

RS KNIT WEARS PVT. LTD. is not ISO certified organization. Not to say that, being as a proof of

quality, ISO certificate is very much essential for the spreading of its market.

No updated web site:

Though RS KNIT WEARS PVT. LTD. has a website named www.rsknit.com, the web site is not

updated for about 7-8 years. It would be more communicative if it had an updated web site. Much of

the business correspondence executed on online. Buyers would feel more convenience if RS KNIT

WEARS PVT. LTD. had an updated web.

Lack of warehousing:

There is no proper placing for final products to place them safely and at the time of their dispatch

there is possibility of mistake.

Communication Gap:

There are a little bit gaps in communication between the departments. May be these confirm each

and every thing from each other but still they make mistakes and blame each others to safe them.

HR Department:

HR Department is almost useless and only performing two activities. These activities are making

salaries and attendance of the employees and workers. They are not working to train the employees

and making appraisals to evaluate them.

4.2 Opportunities of RS KNIT WEARS PVT. LTD.:

There are many factors that help in increasing or decreasing the revenue and expense of the

company. When the revenue increases and the expense decreases, it is treated as the opportunity

of the company.

Cheap labor :

The labor cost in Bangladesh is very cheap. So it is an opportunity for RS KNIT WEARS PVT. LTD.

Motivating the employees:

HR department can prove and show them they are here for employees by motivating the employees

performing their best. They can find the motivation level of their employees and give them incentives

to motivate them.

Advertising:

RS KNIT WEARS PVT. LTD. has the opportunity to advertise about their selves to promote their

textile products.

They can advertise in international magazines about their selves . RS KNIT WEARS PVT. LTD. can

publish its own local business magazine to promote their selves. Can be advertised over the internet

(electronic Marketing)

RS KNIT WEARS PVT. LTD.'s own Shops:

RS KNIT WEARS PVT. LTD. can open its own shops in local market where they can display their

garments products and Apparels as well as curtains. The big advantage would be that advertising

would be done automatically and your textile products would also be sold to local market.

Online Shopping Store:

RS KNIT WEARS PVT. LTD. can open its online store where they can show their garments variety

and apparels. The advantage of this step would be

^ Online Marketing

^ Capturing the market over internet internationally

^ Capturing the market over internet locally

^ The material can be sold out at online shop.

Technology:

The technology has been improved for the textile industry and these technologies are being acquired

by the international competitors as well as by local competitors so they are producing good quality

garments products and increasing the efficiency as well as decreasing the cost of production. RS

KNIT WEARS PVT. LTD. has the opportunity to invest for the new technology. By acquiring the

latest technology, they can increase the production quality, efficiency and can decrease the cost of

production.

4.3 Threats of RS KNIT WEARS PVT. LTD.:

There are many factors which are harmful for the company and may cause potential minimizing of

the revenue and maximizing the expenses of the company. This are known as the threats.

Shortage of electricity:

The government of Bangladesh is still unable to provide the required quantity of electricity, the usage

of electricity has been increased. The companies who have their own electricity plants are save but

those who don't have are facing a major problem of shortage of electricity.

The threat of new entrants:

As the buying industry in our country is in the stream of growth the industry provides a good feed to

new entrants. So in this industry RS KNIT WEARS PVT. LTD. as a RS Knit Wears Pvt. Ltd. needs

high strategic stakes to survive.

The bargaining power of the firm's suppliers:

In this industry as garment manufacturers are numerous and their forward integration systems are

not strong for their illiteracy or inability to convince the foreign buyers. Therefore RS KNIT WEARS

PVT. LTD. enjoys little bargaining tendency of garment manufacturers.

The bargaining power of the firm's customers:

In our country RS Knit Wears Pvt. Ltd. industry faces a little bargain over the negotiation as a boon

of quota system. As a result the bargaining power of RS KNIT WEARS PVT. LTD.. is very little.

The threat of substitute products:

In this industry this aspect is not considered because there is no perfect substitute for their provided

service.

Local competitors:

Bangladesh is a lucrative domain for foreign buyers of garment products. As a result the garment

industry itself is very lucrative to the local entrepreneurs.

Political unrest:

In our country political instability often hampers the effectiveness and efficiency of business

organization. Thereby political unrest is a notable threat to the smooth function of RS KNIT WEARS

PVT. LTD.

4.4 Recommendation for marketing problems:

RS Knit Wears Pvt. Ltd. should be more careful and attentive in monitoring the production. So

that production goes on schedule and any unwanted occurrence such as short shipment may not

occur due to late delivery.

In the findings have mentioned that buyers do riot want to negotiate on quality. So, maintaining

product quality for RS Knit Wears Pvt. Ltd. is very important. To maintain appropriate quality, RS

Knit Wears Pvt. Ltd. should take necessary steps such as training course for their quality controller

or inspector etc.

The total industry should keep in mind that they need a truly international outlook for exporting

to attract buyers as well as long-term commitment with both of their buyers and suppliers.

The total industry must achieve an international reputation for quality to challenge the quota

free environment.

They should ensure that they have all the resources for garment export.

They should start marketing through trade fair.

They can advertise in international magazines about their selves.

RS KNIT WEARS PVT. LTD. can publish its own local business magazine to promote their selves.

Can be advertised over the internet (electronic Marketing)

By holding the seminars on textile industry and offer to attend the seminars to their customers

International business seminars in multiple countries and offer their products to already existence

and new customers.

Make a documentary as a business story about RS KNIT WEARS PVT. LTD. and offer it to show

out through such channels which can accept this offer for example National Geographic Channel

which shows such programs on different companies in the world.

Monthly Budget, by making monthly budgets for each department especially for the commercial

department, the late shipments and late purchasing of yarn can be vanished.

Organize fashion shows in foreign countries as well as in local markets.

4.5 Conclusion

Garments export contributes major foreign exchange to our economy. However the exuberance of

foreign currency through garment export is very much dependent on the effectiveness and efficiency

of this industry. So removing all its inefficiencies and ineffectiveness this industry should move

ahead with a vision to support the garment "export of our country especially to face the challenges of

quota free environment after 2005. But there haven't any quota system we can earn a lot of foreign

currency and participating in the healthy economy. Among the major obstacles causalities such as

natural calamities, strike, hartal or political instability are affecting the export marketing of garment

products severely. Bangladesh is a lucrative domain for foreign buyers of garment products. As a

result the RS Knit Wears Pvt. Ltd. industry itself is very lucrative to the local entrepreneurs. To be

ever successful in their commitment to their buyers they always assure the on time delivery of the

accessories needed in the manufacturing process. To ensure a rich flourish it needs a channel,

which will bridge between buyers and manufactures of garments a win-win relationship. No doubt,

role of RMG RS Knit Wears Pvt. Ltd. Industry, marketing to distribution, is very important to establish

this bridge. For the convenience of both buyers and suppliers, the RS Knit Wears Pvt. Ltd. industry

today has developed enormously with a vision to perform marketing and distribution task of garment

industry. Also government and RS Knit Wears Pvt. Ltd. should remove major error and digitalized

this department.

Newer PostOlder PostHome

Free report Archi ve

2012 (47)

o December (3)

o November (15)

o October (10)

An Internship Report on Marketing Activities of Ga...

Contact Us

Studies on Excipients Commonly used in Different D...

Marketing Efficiency of Agriculture Marketing-Type...

Internship Report on USHA SILK Industry Sapura Raj...