Académique Documents

Professionnel Documents

Culture Documents

Pipeline Transportation Systems for Liquids

Transféré par

Krystle Flowers0 évaluation0% ont trouvé ce document utile (0 vote)

37 vues3 pagesThis document provides guidelines for pipeline transportation systems that carry liquid hydrocarbons and other liquids. It includes details on optional and required welds for different types of openings and branches in pipelines. It specifies minimum and maximum dimensions for welds depending on the thickness of the pipe and reinforcement materials. Reinforcement requirements vary based on the size of the branch opening relative to the header diameter and design hoop stress levels. Complete encirclement reinforcement is specified if a localized reinforcement would extend around more than half the circumference.

Description originale:

Titre original

Pipeline

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides guidelines for pipeline transportation systems that carry liquid hydrocarbons and other liquids. It includes details on optional and required welds for different types of openings and branches in pipelines. It specifies minimum and maximum dimensions for welds depending on the thickness of the pipe and reinforcement materials. Reinforcement requirements vary based on the size of the branch opening relative to the header diameter and design hoop stress levels. Complete encirclement reinforcement is specified if a localized reinforcement would extend around more than half the circumference.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

37 vues3 pagesPipeline Transportation Systems for Liquids

Transféré par

Krystle FlowersThis document provides guidelines for pipeline transportation systems that carry liquid hydrocarbons and other liquids. It includes details on optional and required welds for different types of openings and branches in pipelines. It specifies minimum and maximum dimensions for welds depending on the thickness of the pipe and reinforcement materials. Reinforcement requirements vary based on the size of the branch opening relative to the header diameter and design hoop stress levels. Complete encirclement reinforcement is specified if a localized reinforcement would extend around more than half the circumference.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

ASM E B31.

4-2006 PIPELlNE TRANSPO RTATlO N SYSTEM S FO R

LlQ UID HYDRO CARBO NS AND O THER lIQ UIDS

Qptionat weld

'""'"

Option.t weld

,

1I

11

1I

1I

11 ,1

11

11

'1

"

I1

I

'

r-=

J

, --,1

11

I1

,1

"

,1

'

1

11

'1 "

1, 1,

1,

11

1,

1

'1

1,

,'I J

I

1;-1 -"

:

I

These longitudinal

:

I

I

:

weldl may be I

J

I

located anywhere 11

1I 8round circumference 1,

It I

1

11 r

JI

l'

///MW//////"""'//H'#'''/H#H'N'W/#HH''/'- "N/////hW/////////////////////NNN/////NHN///

GENERAL NO TE: Since fluid pressure is exerted

on both sides of pipe metal under tee, the pipe

metal does not provide reinforcement.

GENERAL NO TE: Provide hole in reinforcement to

revealleakage in buried welds and to provide

venting during welding and heat treatment Isee

para. 404.3.1(d)(B)). Not required for tee type.

SI..v. Typ.

T.. Typ.

Qptional weld

/

1

I

1 '

I

1

1

I

=--=-~ ~ -=- -=- ~

=

-=,

I I

I I

,

1

,

1

1

1

Qptionel weld

\

I

1

1

1

: 1

I ,

I I

1- - - - - - - -=J

, --- 1

1

I

I

'

I I

1 1

I

1

Saddle .nd SI.n. Type

s.dd.. Type

GENERAL NO TE: If the encircling m em ber fer tee, sleeve, or saddle type is thicker than the header and its ends

are to be welded to the header, the ends shall be cham fered (at approxim ately 45 deg) down to a thickness not

in excess of the header thickness.

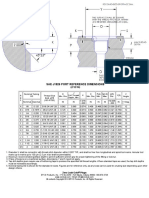

Fig. 404.3.1(C)(1) Welding Details lor Openings With Complete Enelrclement Types 01 Reinlorcement

16

Cop(ng",ASMElmem;lloonal

PfOYIdedbyIHSunder~...e_A.SME

NcreptOduct,,:.,ornetwor1ongpe...unedWlthol.Clo::enseffornIHS

Ucerwee"lec!Hrot.aI5938621100,u.er:CEIN,CEIN

NoIIofResale, 111'301.2OOS Cl83752 M ST

PIPElINE TRANSPORTATlONSYSTEM S FO R

lIQ UID HYDRO CARBO NS AND O THER lIQ UIDS

ASM E B31.4.2006

o.

Hueler

Header

Pod

Branch

BrBnch IW,

'-

,

",~~.

+

'

i

.

/:-~'

.. ..~

...'"

'"

~- - '

-- --

Same as Fig. 404.3.1(c)(3)

o.

H88der

Header

S8ddl.

"'b -

"'h-

N -

M - namln.1 wall thlcknen 01 piel reinforcement

member

nomln.1 WlII thlcknes. 01 sadelle Bt bnmch enel

nominal WlII thicknes. 01 saddle .t heleler enel

1/16 in. (1.5 mm) IminJ.1/8 In. 13 mm) {max.l(unleu

back welded or backing .trip l. usecU

Tb - nominal waU thlcknes, of branch

Th .

W, (min.) -

W2

(max.)

-

W2

(m in.) -

W3 (max.)

-

W3

(min.) ,.

W4 {min.! ,.

nominal wall thlckneu of header

the .maller 01 Tb .M.or 3/8 in. (10 mm)

approx. T

h

thesmellerof 0.7

Th'

0.7 M, or 1/2 in. (13 mm)

approx.

Th

the ,maller 010.7

Th'

0.7 Mh. or 1/2 in. 113 mm)

the ,meller of TI).

Mb'

or 3/8 in. (10 mm)

GENERAL NO TES:

(a)

AU welds are to have equalleg dimensions and a minimum throat equal to 0.707 x leg dimension.

(b) If the reinforcing member is thicker at its edge than the header, the edge shall be chamfered (at approximately 45 deg)

down to a thickness such that leg dimensions of the fillet weld shall be within the minimum and maximum dimensions

specified above.

(c) A hole shall be provided in reinforcement to revealleakage in buried welds and to provide venting during welding and

heat treatment [see para. 404.3.1 (d)(8)].

Fig. 404.3.1(c)(2) Welding Details for Openings With Localized Type Reinforcement

17

Copyflllh\ASMElntemlltlO>'I81

Pro'JIdedby IHSurde< 1Ice.-.e>M(lOASME

NoreptOducltOnOfne!'M)lkingpe...,."ned\lttttloutlicemefromIHS

U<:en8e'~'nI.aI5938621100.U8er-CEIN.CEIN

NotIorRen'e,111301'2OO5063752MST

M ore than 25%

25% or less Through 50% M ore Than 50%

(4) (4) (4)(5)

(2)(3) (2) (1)

(2)(3) (2) (1)

ASM E B31.4-2006 PIPEUNE TRANSPO RTATIO N SYSTEM S FO R

UQ UID HYO RO CARBO NS ANO O THER UQ UIDS

'

Header

nominal wall thickneh of header

nominal waU thickneh of branch

the smaller of

Th'

Tb or 3/8 in. (10 mm)

1/16 in. (1.5 mm) (min.), lIB in. (3 mm) (max.)

unleu back welded or backing strip is used

GENERALNO TE: W hen a welding saddle is used, it sha!l be inserted over this type of connection. See Fig. 404.3.I(c)(2).

Th -

T. -

W1

(minJ

-

N -

Fig. 404.3.1(C)(3) Welding Oetails for Openings Without Reinforeement Other Than That in Header and

Branch Walls

Table 404.3.1(c) Oesign Criteria for Welded Branch Conneclions

Ratio of O iam eter of Hole Cut for Branch Connection to Nom inal

Header Diam eter

Ratio of Design Hoop

Stress to Specfied

M in. Yield Strength

of the Header

20% or less

M ore than 20%

through 50%

M ore than 50%

be welded to the header, the ends shall be chamfered

(at approximately 45 deg) down to a thickness not in

excess of the header thickness, and continuous fillet

welds shall be made. Pads, partial saddles, or other types

of localized reinforcements are prohibited.

(2) The reinforcement member may be of the com-

plete encirclement type [see Fig. 404.3.I(c)(I)], pad or

saddle type [see Fig. 404.3.I(c)(2)], or welding outlet

fitting type. Where attached to the header by fillet weld-

ing, the edges of the reinforcem ent m em ber shall be

cham fered (at approxim ately 45 deg) down to a thick-

ness not in excess of the header thickness. The diam eter

of the hole cut in the header pipe for a branch connection

shall not exceed the outside diam eter of the branch con-

nection by m ore than ~ in. (6 m m ).

(3) Reinforcem ent for branch connections with hole

cut NPS 2 or smaller is not required [see Fig. 404.3.I(c)(3)

for typical detailsJ; however, care shall be taken to pro-

vide suitable protection against vibrations and other

CO!>Y"CInI ASME Intem21D<V1

1'>t000000byIHSunderhce, rIt1ASME

Noreproductlonorne\WOt!ungpe<mtttedlNllllO\.ll",*-fromIHS

external forees to which these small branch connections

are frequently subjected.

(4) Reinforcement of opening is not mandatory;

however, reinforcement m ay be required for cases

involving pressure over 100 psi (7 bar), thin wall pipe,

or severe externalloads.

(5) If a reinforcement member is required, and the

branch diameter is such that a localized type of reinforee-

ment member would extend around more than half the

circurnference of the header, then a complete encircle-

ment type of reinforcement rnember shall be used,

regardless of the design hoop stress, or a smoothly con-

toured wrought steel tee or cross of proven design or

extruded header may be used.

(6) The reinforcement shall be designed in accor-

dance with para. 404.3.I(d).

(d) Reinforcement of Single Openings

(1) When welded branch connections are made to

pipe in the form of a single connection, or in a header

18

l.JcenMe"'le<:hlnt.ar:;s306621100.U8et=CEIN,CEIN

NotIotReule,1113012OO6063752MST

Vous aimerez peut-être aussi

- BS EN 1993-1-8:2005 Fillet Weld DesignDocument5 pagesBS EN 1993-1-8:2005 Fillet Weld Designmn4webPas encore d'évaluation

- Sec-I 128Document1 pageSec-I 128Panchal ShaileshPas encore d'évaluation

- Anchor Bolt DesignDocument26 pagesAnchor Bolt Designdwicahyo_as100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Steel Structures Fasteners GuideDocument34 pagesSteel Structures Fasteners GuideEmrePas encore d'évaluation

- Connections and Tension Member DesignDocument9 pagesConnections and Tension Member DesignVigneshwari MahamuniPas encore d'évaluation

- Cylindrical Compression Helix Springs For Suspension SystemsD'EverandCylindrical Compression Helix Springs For Suspension SystemsPas encore d'évaluation

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingPas encore d'évaluation

- Pressure Vessel and Stacks Field Repair ManualD'EverandPressure Vessel and Stacks Field Repair ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978Pas encore d'évaluation

- Riveted Joints ASME IDocument7 pagesRiveted Joints ASME ICastoriadisPas encore d'évaluation

- 4.0 Reinforcing DeailingDocument16 pages4.0 Reinforcing DeailingRupesh Chaudhary EsRan TharuwaPas encore d'évaluation

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideD'EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuidePas encore d'évaluation

- Bearing Column Splices PDFDocument6 pagesBearing Column Splices PDFBobaru MariusPas encore d'évaluation

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Casing and TubingDocument13 pagesCasing and TubingHany AhmedPas encore d'évaluation

- Connection Design - Its Role in Steel DetailingDocument9 pagesConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.Pas encore d'évaluation

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsD'EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsPas encore d'évaluation

- Machine Design Lec3Document75 pagesMachine Design Lec3sam0415Pas encore d'évaluation

- An Introduction to Metal-Working (Illustrated)D'EverandAn Introduction to Metal-Working (Illustrated)Évaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717Pas encore d'évaluation

- Structural steel design module on welded connectionsDocument9 pagesStructural steel design module on welded connectionsdash1991Pas encore d'évaluation

- Me331-Design of Machine Elements Unit Iii Design of Fasteners and JointsDocument21 pagesMe331-Design of Machine Elements Unit Iii Design of Fasteners and JointsMuthuvel MPas encore d'évaluation

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyD'EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyPas encore d'évaluation

- AN BoltsDocument8 pagesAN BoltsAnthony McfayPas encore d'évaluation

- Ci3503crsi - Column Tie ConfigurationsDocument7 pagesCi3503crsi - Column Tie ConfigurationsNono_geotecPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Shell Horizontal Butt-Weld Minimum RequirementsDocument16 pagesShell Horizontal Butt-Weld Minimum RequirementsBTEPas encore d'évaluation

- Aa 036322 001Document1 pageAa 036322 001petronashscribdidPas encore d'évaluation

- SDM Chapter E - 0708Document6 pagesSDM Chapter E - 0708Janice FernandezPas encore d'évaluation

- NDT AcceptanceDocument62 pagesNDT Acceptancebommakanti srinivasPas encore d'évaluation

- Chapter 6 ConnectionDocument30 pagesChapter 6 ConnectionIvy SeahPas encore d'évaluation

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshPas encore d'évaluation

- Bolted ConnectionsDocument59 pagesBolted ConnectionsTusharRanjan100% (5)

- Guide to Joist Girder Connections (40Document36 pagesGuide to Joist Girder Connections (40Jesus Rafael Curiel PensoPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationtpchoPas encore d'évaluation

- Design of Riveted JointDocument12 pagesDesign of Riveted JointYogesh DandekarPas encore d'évaluation

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaPas encore d'évaluation

- V-Machine Design 1Document37 pagesV-Machine Design 1roamer10Pas encore d'évaluation

- RCC Member Design TipsDocument8 pagesRCC Member Design TipsAbhishek ChaudhariPas encore d'évaluation

- Anchor bolt design calculation for piperack foundationDocument10 pagesAnchor bolt design calculation for piperack foundationArivoli JayaramanPas encore d'évaluation

- ASME STS-1 Steel Stacks (Partial) - Edition 2000Document6 pagesASME STS-1 Steel Stacks (Partial) - Edition 2000Bui Chi TamPas encore d'évaluation

- Predilla Assignment Module 3Document15 pagesPredilla Assignment Module 3Justine PredillaPas encore d'évaluation

- Unit 3 Tension Members: StructureDocument28 pagesUnit 3 Tension Members: StructureRaj BakhtaniPas encore d'évaluation

- Hilok Hitigue InstallationDocument16 pagesHilok Hitigue Installationtbiris0% (1)

- ECDocument40 pagesECJosé CarlosPas encore d'évaluation

- Piping Tie-Rod Design Made SimpleDocument3 pagesPiping Tie-Rod Design Made SimpleSeungmin PaekPas encore d'évaluation

- Analysis and Design of Members For TensionDocument84 pagesAnalysis and Design of Members For TensionicpertacortaPas encore d'évaluation

- Perhitungan Pressure Vessel LengkapDocument70 pagesPerhitungan Pressure Vessel LengkapReo Aditya MahesaPas encore d'évaluation

- 49 CFR 178.61 Cylinder Specification RequirementsDocument7 pages49 CFR 178.61 Cylinder Specification RequirementsFarhan AliPas encore d'évaluation

- Catalogo Die Cast DMEDocument24 pagesCatalogo Die Cast DMEkontacPas encore d'évaluation

- Rad 34GX Imperial-46gx Metric NPW-200Document5 pagesRad 34GX Imperial-46gx Metric NPW-200patrick segoviaPas encore d'évaluation

- WABO Welder Qualification StandardDocument77 pagesWABO Welder Qualification StandardJuan Martinez100% (1)

- General Mechanical Questionnaire Without AnswersDocument7 pagesGeneral Mechanical Questionnaire Without AnswersDaniel Jimenez MerayoPas encore d'évaluation

- TSB1503G 9 P 1 PDFDocument18 pagesTSB1503G 9 P 1 PDFHatada Felipe100% (1)

- MCQ WeldingDocument3 pagesMCQ WeldingMostafaRock100% (2)

- 10 Common Chrome Plating DefectsDocument3 pages10 Common Chrome Plating DefectsRicardo GaringPas encore d'évaluation

- Astm 182Document15 pagesAstm 182ISABELPas encore d'évaluation

- Versa MilDocument45 pagesVersa MilmichaelguzziPas encore d'évaluation

- Sae J1926 Port Reference DimensionsDocument1 pageSae J1926 Port Reference DimensionsSanjeeb MohapatraPas encore d'évaluation

- Sr. Corre Out Question A B C D No. ct of 1Document17 pagesSr. Corre Out Question A B C D No. ct of 1Sandip AwaghadePas encore d'évaluation

- Grip Systems Catalog Inch 2012Document389 pagesGrip Systems Catalog Inch 2012Casey100% (1)

- Types of Screwdriver and Their Uses (With Pictures)Document7 pagesTypes of Screwdriver and Their Uses (With Pictures)Iman SadeghiPas encore d'évaluation

- History of Metal CastingDocument17 pagesHistory of Metal CastingMobaraz KhokharPas encore d'évaluation

- Die Casting PDFDocument16 pagesDie Casting PDFGokul PrabuPas encore d'évaluation

- Sand Casting Guide: Gating Systems & RisersDocument31 pagesSand Casting Guide: Gating Systems & RisersAmruta Rane100% (1)

- Wave Cyber 4 Inch MPV Spare Parts List (300 PSI&450PSI)Document11 pagesWave Cyber 4 Inch MPV Spare Parts List (300 PSI&450PSI)Leni YusnidaPas encore d'évaluation

- SSB 40 F Super - 50 F Super VT: Column Drill PressesDocument2 pagesSSB 40 F Super - 50 F Super VT: Column Drill PressesJosé SermeñoPas encore d'évaluation

- Types of Extrusion and Advantages of Extrusion - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsDocument4 pagesTypes of Extrusion and Advantages of Extrusion - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New Trendsl8o8r8d8s8i8v8Pas encore d'évaluation

- Everything about high-speed steelDocument2 pagesEverything about high-speed steeljerfmosPas encore d'évaluation

- NANN STANDARD CLAMPING TOOLS CATALOGDocument80 pagesNANN STANDARD CLAMPING TOOLS CATALOGEdwin RodriguezPas encore d'évaluation

- Tubular Non Tubular AWS D1 1 PDFDocument56 pagesTubular Non Tubular AWS D1 1 PDFRudy JakfPas encore d'évaluation

- Special Steels 3Document100 pagesSpecial Steels 3ramanamurtytv7176Pas encore d'évaluation

- Details - Aspx Coating Details: The Following Is A List of The Various Coating PropertiesDocument6 pagesDetails - Aspx Coating Details: The Following Is A List of The Various Coating PropertiesToolgripPas encore d'évaluation

- AIQSA Filtros PVCDocument1 pageAIQSA Filtros PVCJose Maria Clerigues AlepuzPas encore d'évaluation

- Form Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)siva100% (2)

- 34 Jigs and Fixtures For Machine ShopDocument12 pages34 Jigs and Fixtures For Machine ShopPRASAD326100% (8)

- 16-Nut & WasherDocument1 page16-Nut & Washerhesham alhelaleePas encore d'évaluation

- Din Handbook 402Document4 pagesDin Handbook 402fivehours5Pas encore d'évaluation

- Composite Materials and Technology: Chapter - 3 Fabrication of CompositesDocument25 pagesComposite Materials and Technology: Chapter - 3 Fabrication of CompositespincoPas encore d'évaluation