Académique Documents

Professionnel Documents

Culture Documents

Art 17 PDF

Transféré par

ChristianChávezRodríguez0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues13 pagesResults of analyses of cocoa pulp from the Ivory coast, Nigeria and Malaysia are reported. Cocoa fermentation is essential for the formation of chocolate flavour precursors. The defined cocoa pulp medium supported the growth of yeasts, lactic acid bacteria and acetic acid bacteria.

Description originale:

Titre original

art_17.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentResults of analyses of cocoa pulp from the Ivory coast, Nigeria and Malaysia are reported. Cocoa fermentation is essential for the formation of chocolate flavour precursors. The defined cocoa pulp medium supported the growth of yeasts, lactic acid bacteria and acetic acid bacteria.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues13 pagesArt 17 PDF

Transféré par

ChristianChávezRodríguezResults of analyses of cocoa pulp from the Ivory coast, Nigeria and Malaysia are reported. Cocoa fermentation is essential for the formation of chocolate flavour precursors. The defined cocoa pulp medium supported the growth of yeasts, lactic acid bacteria and acetic acid bacteria.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 13

J. Sci. Food Agric.

1986, 37, 297-309

Analysis of Cocoa Pulp and the Formulation of

a Standardised Artificial Cocoa Pulp Medium

Graham L. Pettipher

Cadbury Schweppes PLC, Group Research, The Lord Zuckerman Research Centre,

The University, Whiteknights, Reading RG6 2 LA

(Manuscript received 4 June 1985)

Results of analyses of cocoa pulp from the Ivory Coast, Nigeria and Malaysia are

reported. These include pH, viscosity and a, measurements and concentration of

soluble sugars, vitamins and anions. Pulp from Malaysian cocoa pods had a higher

water content, lower citrate, hemicellulose, lignin and pectin concentration and a

higher pH than Ivorian or Nigerian cocoa pods. The composition of a defined

cocoa pulp medium which has the same overall composition, pH, a, and viscosity

as cocoa pulp is described. The defined cocoa pulp medium supported the growth

of yeasts, lactic acid bacteria and acetic acid bacteria.

Keywords: Cocoa pulp; analysis; cocoa pulp medium.

1. Introduction

Cocoa fermentation is essential for the formation of chocolate flavour precursors. True chocolate

flavour is only developed during roasting. Cocoa fermentation is a natural complex process

involving a mixture of external microbiological processes occurring in the pulp surrounding the

bean and internal structural changes and enzymic reactions. A succession of microorganisms, in

particular yeasts, lactic acid bacteria and acetic acid bacteria, grow in the pulp producing ethanol,

lactic acid and acetic acid as metabolic products.'

The exothermic formation of acetic acid causes the temperature of the fermenting mass to rise,

often to >45"C. Bean death is caused by the ingress of acids and the increased temperature.

These factors prevent germination and cause structural changes which remove the compartmen-

talation of enzymes and substrates, thereby permitting the activity of enzymes such as

glycosidases and proteases.* During the subsequent aerobic conditions polyphenol oxidase

activity gives rise to the characteristic brown coloration of well-fermented cocoa.

I n view of the fact that both the initial colonisation and subsequent microbial activity essential

to the fermentation of cocoa is largely dependent upon the composition of the pulp surrounding

the bean, it is surprising that no detailed analysis of cocoa pulp has been reported. Published

results state that cocoa pulp contains 8&90% water, 1&13% simple sugars, ca 1% pectin,

>0.2% non-volatile acids and, more recently, up to 2% citric acid.s6 The concentration of

glucose, fructose and sucrose is known to vary with the age of the pod.' The amino acids,

aspartic acid, glutamic acid and asparagine, have been reported to account for the nitrogen

content of the pulp.'

The formulation of a defined cocoa pulp medium will facilitate both microbiological and

biochemical laboratory studies on cocoa bean fermentation. A detailed analysis of cocoa pulp has

been completed and the results used to formulate a defined cocoa pulp medium. The results of

the analyses and the formulation of the medium are given in this report.

291

298

G. L. Pettipher

2. Materials and methods

2.1. Samples of cocoa pulp

Amelonado cocoa pods (three to five) were obtained from the Ivory Coast and Nigeria, and

hybrid cocoa pods from Malaysia, usually within 5 days of harvesting. Disease-free pods were

opened and samples of cocoa pulp taken using the following methods:

1. Cocoa pulp was removed from the beans by scraping with a sharp scalpel.

2. Cocoa beans surrounded with pulp were deep frozen and then freeze-dried using an

Edwards DO1 freeze drier (Edwards, Crawley, UK) at a shelf temperature of 20C. After drying

the pulp was easily removed as a powder from the outside of the beans by scraping with a scalpel.

Freeze-dried samples were kept in a desiccator and both types of samples of cocoa pulp were

stored deep frozen until required for analysis.

2.2. Analyses

2.2.1. Measurement of p H

Samples of fresh cocoa pulp were suspended in distilled water as a 1 in 10 dilution and the pH

measured using an EIL 704S/46 pH meter and 1180 series pH electrode (Kent Industrial

Measurements, Chertsey, UK).

2.2.2. Measurement of water content

Weighed samples of fresh cocoa pulp were dried to constant weight at 80C on pre-weighed

planchets and the percentage water content was calculated.

2.2.3. Measurement of water activity (a,)

The a, of fresh Amelonado cocoa pulp and the defined cocoa pulp medium was measured by

hydrometry using a Humiditat TH2 (Novasina AG, Zurich) at 25C.

2.2.4. Measurement of viscosity

The viscosity of decimal dilutions (w/v) of fresh and freeze-dried Amelonado cocoa pulp and

defined cocoa pulp medium prepared with low or high viscosity carboxymethyl cellulose was

measured by means of a U-tube viscometer (Poulton, Selfe and Lee Ltd, Wickford, Essex-BS/

U size A) at 25C.

2.2.5. Mono- and disaccharide analyses

A weighed quantity of fresh pulp (ca 1 g) was ground in a pestle and mortar with a small quantity

of distilled water and then made up to 10ml total volume. One millilitre of the suspension was

added to 4ml acetonitrile. After shaking, the mixture was centrifuged at 15OOXg for 20 min and

then the supernatant was analysed using a Waters HPLC system (model 720 system controller,

model 730 data module, M6000A pump, U6K injector and an R401 differential refractometer;

Waters Associates, Cheshire, UK). Supernatants were filtered through a 0.45pm pore size

membrane filter before injecting 1Spl on to the column. Separation of the sugars was achieved

on a Waters carbohydrate analysis column using acetonitri1e:water (80:20, v/v) at a flow rate of

2mlmin-'. The concentration of each sugar in the samples was determined after calibration of

the instrument with standard solutions of known concentrations. Samples were analysed in

duplicate.

2.2.6. Hemicellulose, cellulose, lignin and pectin analyses

The hemicellulose, cellulose and lignin content of pulp was measured using the methods

described by McAllan and Smith.' Freeze-dried material was hydrolysed in O.SMH~SO~ for 4h at

100C which releases mannose, galactose, arabinose and xylose from hemicellulose. These sugars

were then quantified by high pressure anion-exchange chromatography of their borate-

complexes. The amount of these sugars was taken as a measure of the hemicellulose content in

the sample.

Analysis of cocoa pulp 299

Cellulose -was estimated by automated enzymic analysis of glucose after more stringent acid

hydrolysis of the residue from the first acid hydrolysis.

A crude measure of lignin content was obtained by weight loss following overnight incineration

at 550C of the residue from the cellulose hydrolysis.

The extraction of pectic substances from freeze-dried cocoa pulp, divided into two groups on

the basis of their solubility in water and sodium hydroxide, followed the procedure of Atkins and

Rouse. lo The estimation of pectic substances was determined by the colorimetric method of

Dische" as applied to citrus juices by Dietz and Rouse."

2.2.7. Organic acid and ethanol analyses

A 1 in 10 dilution of fresh cocoa pulp was prepared by grinding a weighed amount of material in

a pestle and mortar with the appropriate volume of distilled water. The suspension was

centrifuged for 20 min at 15OOxg and the supernatant filtered through a 0.45pm pore size

membrane filter. The samples were then analysed for organic acids by replicate injections on to

an h.p.1.c. column.

The h.p.1.c. system consisted of an Altex model llOA HPLC pump, an Altex sample valve

(5Opl) and a Waters differential refractometer. Organic acids were separated on an Aminex

HPX-87H column (Bio Rad Laboratories) fitted with an Aminex HPX-85H guard column using

0. 004~H~SO~ as the eluent at a flow rate of 0.6mlmin-'. The concentrations of individual

organic acids and ethanol were determined from linear calibration graphs obtained from

analysing levels of each (0.5-1.5 mgg-l) in the presence of the internal standard (propionic acid).

2.2.8. Measurement of total nitrogen

The total nitrogen content of freeeze-dried samples of cocoa pulp was determined by

conventional Kjeldahl digestion using a copper catalyst. The ammonia was distilled and collected

into a solution of boric acid which was then titrated with standard acid.

2.2.9. Free and total amino acid analyses

Free amino acids were determined in freeze-dried pulp by making a 100 mg ml-' suspension in

0.2 mM lithium citrate buffer (pH 2.0) and adding 1 ml norleucine (10 mM) as internal standard.

The suspension was mixed in a blender for 5 min. The blended mixture, plus the lithium citrate

rinses used to remove solid material adhering to the blades of the blender, was centrifuged for 30

min at 20OOxg and the supernatant containing the free amino acids was removed. The solid pellet

was resuspended twice more in lithium citrate buffer and the centrifuge procedure repeated until

4C50 ml of supernatant had been collected. The supernatant was then deproteinised with

5-sulphosalicyclic acid (20 mg ml-' supernatant) and left to stand overnight at 4C. The

supernatant was then centrifuged to remove any precipitated protein and the clear supernatant

adjusted to pH 2.0 using 6 N lithium hydroxide. Samples were filtered through 0.45pm pore size

membrane filters before being analysed by an automatic Biotronik LC 2000 amino acid analyser

(Biotronik, Frankfurt). The concentration of each amino acid in the sample was determined after

calibration of the instrument with a solution containing known concentrations of individual

amino acids.

Total amino acids in freeze-dried pulp were estimated by oxidising with performic acid before

acid hydrolysis to give stable analogues of methionine and cystine. l 3 This procedure gives good

recovery of all amino acids except tyrosine and tryptophan. Values obtained for tyrosine and

tryptophan are likely to be underestimates of the true concentration.

2.2.10. Measurement of fat

A weighed quantity of freeze-dried pulp was placed in a Soxhlet thimble. The thimble was then

placed in a Soxhlet apparatus, above a pre-weighed flask containing 40/60 petroleum ether (by vol)

on a water bath, with a water condenser in the top. The apparatus was left syphoning overnight and

then the petroleum ether was evaporated off. The flask was dried to constant weight in an oven and

the fat content of the freeze-dried pulp was calculated.

300 G. L. Pettipher

2.2.11. Trace metal analyses

Sample preparation and analyses were carried out using the methods described by Anon.14 A

weighed quantity of freeze-dried cocoa pulp (ca 1 g) was dry ashed. The ash was dissolved in HC1

and made up to 10ml with distilled water. Appropriate dilutions were made for each trace metal.

Sodium and potassium were analysed by flame photometry and other trace metals by atomic

absorption.

2.2.12. Vitamin analyses

The concentration of individual vitamins in freeze-dried cocoa pulp was estimated by microbiolo-

gical assay using known strains of vitamin-requiring microorganisms. Due to the limited amount

of sample available, only a composite of Ivorian and Nigerian cocoa pulp was analysed.

2.2.13. Ani on analysis

Fresh cocoa pulp was diluted 1 in 5 with distilled water and the anion content was estimated by

h.p.1.c. after filtration through a 0.45pm pore size membrane filter. Samples were injected on to

an ionosphere column (25 cmX4.6 mm; Chrompck, London) using sodium salicylate (25 mM, pH 5)

at 1 mlmin-' as eluent. Anions were detected by changes in refractive index.

2.3. Formulation of a defined cocoa pulp medium

The results of the analyses of I vorian, Nigerian and Malaysian cocoa pulp were used as a basis

for devising the formulation of a defined cocoa pulp medium. The formulation was selected to

give similar overall concentrations of individual components and to have a similar viscosity, a,

and pH as cocoa pulp.

2.3.1. Preparation of a cocoa pul p medi um

The polymeric materials, carboxymethyl cellulose, locust bean gum and pectin, were best

dispersed by adding to 500ml warm distilled water and blending in a Waring blender for 2 min.

To this suspension most of the remaining water and a11of the sugars, casein, casein hydrolysate,

glycerol monostearate, salts and mineral solution were added and then the medium was stirred

until the contents dissolved. The pH of the medium was adjusted to 3.6. The medium was then

made up to volume and autoclaved. To prevent caramelisation of the sugars an autoclave

temperature of 115C was used. Before use, the vitamin mixture and ascorbic acid solution were

added aseptically to the cooled medium.

2.4. Microbiological studies

The ability of the defined cocoa pulp medium to support the growth of microorganisms important in

the fermentation of cocoa was assessed by incubating with pure cultures of yeasts, lactic acid bacteria

and acetic acid bacteria and examining for an increase in the plate colony count after static

incubation for 2 days at 30C. The cultures used were Saccharomyces chevulieri C26 isolated from

fermenting cocoa, Lactobacillusplantarum C22, L. mali C34 (NCI B 10560) and Acetobacter aceti C3

(NCI B 8941).

3. Results

3.1. Analytical results

A summary of the results for the analysis of cocoa pulp from Ivorian, Nigerian and Malaysian

cocoa pods is given in Table 1. Detailed results for individual components are given in Tables

2-8. Due to the limited number of cocoa pods available some analyses were not made on pulps

from all three origins. Using averaged results for missing values, recoveries of 99.4, 100.2 and

100.2% were obtained.

3.1.1. p H

The pH values of I vorian, Nigerian and Malaysian cocoa pulp were 3.3, 3.6 and 3.9, respectively.

Analysis of coeoa pulp 30 1

3.1.2. Water content

The water content of the West African cocoa pulps were similar, ca83%, whilst that of the

Malaysian cocoa pulp was ca 86% (Table 1).

3.1.3. Water activity

The a , of Amelonado cocoa pulp and the defined cocoa pulp medium was 0.97 and 0.98,

respectively.

3. 1. 4. Viscosity

The viscosity of decimal dilutions of fresh and freeze-dried Amelonado cocoa pulp and defined

cocoa pulp medium made using low or high viscosity carboxymethyl cellulose is given in Table 10.

The reason why the viscosity of the fresh pulp was lower than that of the freeze-dried pulp

was probably due to the method of sample preparation. Both samples were centrifuged to

remove insoluble material but, in the case of fresh pulp, this was insufficient and filtration

through a 0.45pm pore size membrane filter was also used.

Table 1. Composition of Ivorian, Nigerian and Malaysian cocoa pulp

Ivorian Nigerian Malaysian

g1OOg-' fresh weight pulp

Water

Mono- and disaccharides

Plant cell wall polymers

Citrate

Protein, peptides, amino acids

Fat

Metals

Vitamins (composite sample)

Ethanol

82.60 82.50

11.15 13.05

2.81 ND

1.31 0.79

0.74 0.64

0.45 0.75

0.24 0.22

0.05

0 0.1

Recovery (%) 99.4 98.1

Recovery (70) with average - 100.2

results for missing values)

ND. not determined.

85.90

11.06

1.48

0.29

0.65

0.35

ND

ND

0.2

99.9

100.2

Table 2. Concentration of mono- and disaccharides in fresh Ivorian,

Nigerian and Malaysian cocoa pulp

Ivorian Nigerian Malaysian

g 100g-' fresh weight

Sucrose 4.35 1.92 1.35

Glucose 3.00 5.06 4.90

Fructose 3.80 6.07 5.35

Total 11.15 13.05 11.60

Analyses were made in duplicate, coefficient of variation ca 5%.

Table 3. Concentration of cellulose, hemicellulose, pectin and lignin

in freeze-dried Ivorian, Nigerian and Malaysian cocoa pulp

lvorian Nigerian Malaysian

g kg-' dry weight

Cellulose 51.8 ND 47.3

Hemicellulose 28.5 ND 15.8

Pectin 66.1 59.1 37.5

Lignin 15.0 ND 5.0

Total 161.4 105.6

302 G. L. Pettipher

The viscosity of the defined cocoa pulp medium can be varied over a wide range by using

different proportions of low and high viscosity carboxymethyl cellulose. It should be noted that

excessive blending of the polymeric constituents during the preparation of the media leads to a

reduction in the final viscosity.

3.1.5. Mono- and disaccharides

While the total amounts of mono- and disaccharides in pulps of different origins were similar,

ranging from 11 to 13% (Table l), the concentrations of the individual sugars, sucrose, glucose

and fructose, varied considerably, from 3 to 6% (Table 2) . The ratio of disaccharides to

monosaccharides was highest in the Ivorian pulp. As this ratio is known to decrease with

increasing age of the pod, it is likely that the pods from Nigeria and Malaysia were older than the

Ivorian pods.

Table 4. Concentration of total nitrogen, amino acids, protein,

peptides, and ammonia in Ivorian. Nigerian and Malaysian cocoa

Pulp"

lvorian Nigerian Malaysian

g1OOg-I fresh weight

Total nitrogen 0.11 0.11 ND

Free amino acids 0.15 0.11 0.21

Proteidpeptides 0.57 0.51 0.43

Ammonia 0.02 0.02 0.01

"Analyses made in duplicate on freeze-dried material, results

calculated as percentage fresh weight

Table 5. Concentration of free amino acids and free ammonia in freeze-

dried Ivorian, Nigerian and Malaysian cocoa pulp

Ivorian Nigerian Malaysian

Amino acid mgg-l dry weight

~_... . ~

Aspartic acid 1.06 0.73 1.56

Threonine 0.16 0.11 0.20

Serine 0.23 0.14 0.36

Asparagine 1.29 0.67 2.84

Glutamic acid 1.29 0.73 1.89

Glutamine 2.19 1.56 5.40

Proline 0.22 0.16 0.23

Glycine 0.03 0.02 0.07

Alanine 0.13 0.09 0.50

Valine 0.08 0.06 0.14

Cystine 0.01 ND ND

Methionine 0.01 0.04 0.01

Isoleucine 0.03 0.02 0.02

Leucinc 0.04 0.02 0.25

Tyrosine 0.12 0.07 0.02

Phenylalanine 0.06 0.05 0.05

Lysine 0.24 0.31 0.10

Histidine 0.14 0.11 0.06

Arginine 0.42 0.34 0.12

Hydroxyproline ND ND ND

a-Amino adipic acid ND ND ND

y-Amino butyric acid 0.44 0.63 0.62

Citrulline 0.09 0.03 0.01

Ornithine 0.17 0.07 0.10

Ammonium ions 0.12 0.17 0.09

Total 8.57 6.13 14.64

ND, not determined.

Analysis of cocoa pulp 303

3.1.6. Hemicellulose, cellulose, lignin and pectin

Only the Ivorian and Malaysian cocoa pulps were analysed for hemicellulose, cellulose, lignin

and pectin. Of these, the Ivorian pulp contained ca two times more hemicellulose, 1.8 times

more pectin and three times more lignin than the Malaysian pulp; the cellulose content of the

two pulps was similar (Table 3). The pectin content of the Nigerian pulp was higher than that of

the Malaysian pulp and similar to that of the Ivorian pulp. The ratios of water-soluble to

alkali-soluble pectin for the Ivorian, Nigerian and Malaysian pulps were 1.6, 1.4 and 1.1,

respectively.

The starch content of the Ivorian and Malaysian pulp was very low, as the starch plus glucose

fraction after the acid hydrolysis of hemicellulose could be accounted for by the free glucose plus

the glucose present as sucrose as determined by h.p.1.c.

3.1.7. Organic acids

Citrate was the major organic acid in the cocoa pulps from all three origins. Ivorian pulp

contained ca 4.5 times more citrate than Malaysian pulp and ca 1.7 times more than Nigerian

pulp (Table 1). The citrate concentration in the cocoa pulps was inversely and linearly related to

the pH. Other non-volatile organic acids, such as malic, tartaric and oxalic, occurred in

concentrations of (0.1%.

Ethanol was present in Malaysian pulp at a level of ~ ~ 0 . 2 % and in Nigerian pulp at caO.l%.

Ethanol was not detected in the Ivorian cocoa pulp.

3.1.8. Nitrogen

The total nitrogen content of Ivorian and Malaysian cocoa pulp was the same (Table 4). The

Table 6. Concentration of total amino acids and ammonia in freeze-dried

Ivorian, Nigerian and Malaysian cocoa pulp

Amino acid

Ivorian Nigerian Malaysian

mgg-' dry weight

Aspartic acid

Threonine

Serine

Asparagine

Glutamic acid

Glutamine

Proline

Glycine

Alanine

Valine

Cystine

Met hionine

Isoleucine

Leucine

Tyrosine

Phenylalanine

Lysine

Histidine

Arginine

Hydroxyproline

a-Amino adipic acid

y-Amino butyric acid

Citrulline

Ornithine

Ammonium ions

Total

ND. not determined.

8.22

1.54

2.06

ND

8.65

ND

2.02

1.63

3.12

1.15

1.35

0.71

0.92

2.46

0.51

1.62

2.92

0.66

2.09

ND

ND

ND

ND

ND

1.41

43.04

3.52

2.13

1.97

ND

6.76

ND

2.02

1.89

1.61

1.21

1.51

0.48

0.90

2.31

1.08

1.67

2.57

0.90

1.62

0.78

ND

0.39

ND

0.09

0.96

36.37

8.21

1.51

1 .IS

ND

11.46

ND

1.50

2.39

2.55

1.31

1.60

0.96

0.96

2.57

1.04

1.60

2.70

0.82

1.53

ND

ND

0.89

ND

0.11

0.95

46.41

21

304 G. L. Pettipher

total concentration of amino acids, either free or incorporated into peptides and proteins, in

Ivorian, Nigerian and Malaysian cocoa pulp was 0.72, 0.62 and 0.64glOOg-' fresh weight,

respectively. More than 90% of the nitrogen content of the pulps could be accounted for by

amino acids, Using a factor of 6.25 to convert nitrogen into crude protein. the total nitrogen

measured is equivalent to 0.69g protein 1OOg-' fresh pulp. All three types of cocoa pulp

contained only a low concentration of ammonium ions. Samples were not analysed for nitrate

content.

Of the individual free amino acids determined, glutamate, asparagine, glutamic acid and

aspartic acid occurred in high concentrations in Ivorian, Nigerian and Malaysian pulps (Table 5) .

Of the individual total amino acids determined, glutamic acid and aspartic acid were present in

high concentrations (Table 6).

3. I . 9. Fat

The concentration of fat in Ivorian, Nigerian and Malaysian pulp was 2.6, 4.3 and 2.6glOOg-'

freeze-dried pulp, respectively. This is equivalent to less than 0.8 g 100 g-' fresh weight (Table 1).

The concentration of fat in Nigerian pulp was 2.1 times more than in Malaysian pulp and 1.7

times more than in Ivorian pulp.

3.1.10. Trace metals

The trace metal content of West African cocoa pulp was 0.22-0.24% (Table 1). Potassium

accounted for the majority of the trace metals detected in both Ivorian and Nigerian pulp,

forming 87 and 89% respectively (Table 7). Magnesium, calcium and iron were present in higher

Table 7. Concentration of metal ions in freeze-

dried Ivorian and Nigerian cocoa pulp

Metal

Ivorian Nigerian

mg kg-l dry weight

Potassium

Sodium

Copper

Calcium

Iron

Magnesium

Zinc

Manganese

Nickel

Total

12000

40

6

730

230

800

15

5

L

13828

11000

60

12

460

80

730

3.5

5

3

12385

Table 8. Concentration of vitamins in a

composite sample of freeze-dried Ivorian

and Nigerian cocoa pulp

Vitamin M 100g-I

Thiamine (B, )

Riboflavin (B,)

Pyridoxine (B,)

Cyanocobalamin (BIZ)

Niacin

Pantothenate

Folie acid

Biotin

Ascorbic acid (C)

Total

220

250

30

4.0X16

2.6~10'

2.3 x 10'

95

63

3.0X1@

3.1X1@

Analysis of cocoa pulp 305

concentrations than sodium, copper, zinc, magnesium or nickel. The iron content of the Ivorian

pulp was ca three times that of the Nigerian pulp.

3.1. I I. Vitamins

Ascorbic acid (vitamin C) accounted for nearly 97% of the vitamins included in the analysis of a

composite sample of freeze-dried lvorian and Nigerian cocoa pulp (Table 8). All the vitamins

Table 9. Composition of a defined cocoa pulp medium

Fructose 50 g

Glucose 40 g

Sucrose 25 g

Locust bean gum (Sigma GO783) 5g

Casein, vitamin free (Difco 0579-17-2)

5.5 g

Casein hydrolysate, vitamin free (Difco 0646-15-3) 1.5g

Glycerol monostearate (BDH 26105) 5g

Carboxymethyl cellulose (high viscosity; BDH 27929)

Carboxymethyl cellulose (low viscosity; BDH 27649)

Pectin (Sigma P9135) 10.9g

1.35g

7.65g

Salts

Potassium dihydrogen citrate

Magnesium citrate .I 4 H20

Citric acid .1 H2 0

Ferric citrate .5 H20

Calcium citrate .4 H2 0

Calcium sulphate

Mineral solution

Distilled water added to give a final volume of 980 ml pH adjusted to 3.6 with H2SOn

Added after autoclaving:

Vitamin mixture

Ascorbic acid solution

Mineral solution

Disodium hydrogen phosphate

Sodium chloride

Zinc sulphate 0.7H20

Copper sulphate 0.5 H20

Manganese sulphate 0.4H20

Nickel chloride 0.6 HzO

Distilled water added to give a final.-volume of 1 litre

Vitamin mixture

Thiamine (B,)

Riboflavin (B2)

Pyridoxine (B,)

Cyanocobalamin (Bi2)

Niacin

Pantothenic acid

Folk acid

Biotin

Distilled water added to give a final volume of 1 litre, filter sterilised

Ascorbi c acid solution

Ascorbic acid

11.8g

1.44g

1.9g

0.16g

0.8Bg

0.09g

lOml

10 ml

lOml

1.4g

1.2g

1.2g

0.55 g

0.4 g

0.2g

39 mg

44 mg

700 mg

5 mg

455 mg

403 mg

17 rng

11 mg

0.53 g

Distilled water added to give a final volume of 10ml. filter sterilised

306 G. L. Pettipher

analysed for were present. Vitamins B6, niacin and pantothenate were present in higher

concentrations than vitamins B1, B2, BI2, folic acid and biotin.

3.1.12. Anions

The h.p.1.c. system used enabled the quantitation of nitrate and sulphate; phosphate and chloride

co-eluted. The quantity of these anions in Ivorian and Nigerian pulp averaged 0.05%. Of this,

sulphate comprised ca 88% and chloride plus phosphate ca 12%.

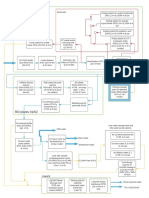

3.2. Formulation of a defined cocoa pulp medium

The composition of the defined cocoa pulp medium given in Table 9 has the same overall

concentrations of sugars, plant ceil wall polymers, citrate, protein, amino acids, fat, trace metals

and vitamins as those found in cocoa pulp. The medium does not contain lignin as this material is

not readily available commercially. The viscosity of the medium can be varied between 1.07 and

2.37cSt by using either low or high carboxymethyl cellulose (Table 10). Different ratios of the

two polymers can be used to obtain intermediate values. The a, of the medium is 0.98, which is

similar to that measured for cocoa pulp, namely 0.97. The pH of the medium is ca3.8 but it can

be adjusted to the required value by the addition of acid. Like cocoa pulp, the medium has a

higher concentration of sulphate than chloride or phosphate.

3.3. Microbiological studies

The defined cocoa pulp medium was able to support the growth of yeast, lactic acid bacteria and

Table 10. The viscosity of decimal dilutions of fresh and freeze-dried

Amelonado cocoa pulp and defined cocoa pulp medium prepared with high

or low viscosity carboxymethyl cellulose (CMC)

Viscosity (cst)

Fresh pulp 1.18

Freeze-dried pulp 1.29

Cocoa pulp medium with low viscosity CMC 1.07

Cocoa DUID medium with high viscositv CMC 2.37

Table 11. Growth of yeast, lactic acid bacteria and acetic acid bacteria in a defined

cocoa pulp medium as assessed by the plate colony count

Plate colony countlmY

After 2 days

pH of incubation

Organism medium Initial at 30C

Saccharomyces chevalieri C26 3.6 LOX 103 1. 5~10~

Lactobacillus plantarum C22 3.6 8.2Xl P 7. 8~10~

4.0 73x10 4.2X10

5.0 7.5~10 7. 7~10~

Lactobacillus mali C34 3.6 1. 4~10~ 1. 4~10~

4.0 1.8X105 1.1 x lo4

5.0 1. 4~10~ 2.5~10

Acetobacter aceti C3 3.6 2. 0~10~ 4.4x 106

Plate colony count methods:

Yeast-pour plates using Malt Extract Agar (Oxoid)

Lactobacilli-pour plates using MRS Agar (Oxoid), incubated anaerobically

Acetobacter-spread plates using WL Agar (Oxoid).

All plates were incubated for 2 days at 30C before counting colonies.

Analysis of coeoa pulp 307

acetic acid bacteria (Table 11). The increase in the plate colony count during the 2 days

incubation involved in the test was >2 log cycles for the yeast, lactic acid bacteria and acetic acid

bacteria.

The yeast, S. chevalieri, grew well and gassing of the medium was observed. The two species of

lactobacilli showed different growth responses. Whereas L. plantarum could grow in the

medium at pH4.0, L. mali could only grow if the pH was increased to 5.0 or higher. Neither

organism grew in cocoa pulp medium at pH3.6.

Preliminary results have shown that the cocoa pulp medium can be used as an isolation

medium if it is first solidified with 1.5% agar. The solid medium supports the growth of yeast and

acetic acid bacteria.

4. Discussion

4.1. Composition of Ivorian, Nigerian and Malaysian cocoa pulp

The analyses of the cocoa pulps from three origins gave similar results for water content, soluble

sugars, pectin and citrate concentrations to those reported previously.s6 The analyses provided

useful data on the cellulose, hemicellulose, lignin, amino acid, trace metal, vitamin and anion

concentrations of cocoa pulp, information which is lacking in the literature. In general, higher

recoveries of monosaccharides, disaccharides and organic acids were obtained from fresh as

opposed to freeze-dried samples of cocoa pulp. This may have been due to difficulties in

rehydrating the freeze-dried material. It is therefore recommended that when required for

analysis fresh cocoa pulp is preserved by freezing rather than by freeze-drying.

Major differences between the Ivorian, Nigerian and Malaysian cocoa pulp samples were the

pH and citrate levels. The Ivorian pulp which was probably obtained from the youngest pods, as

indicated by the high disaccharide:monosaccharide ratio, had the lowest pH and highest citrate

content. The Malaysian pulp had the lowest citrate content and the highest pH. Nigerian pulp

was intermediate in both pH and citrate level. Both the presence of citrate as the major organic

acid in unfermented cocoa pulp and the inverse and linear relationship between citrate content

and pH, suggests that the concentration of citrate is mainly responsible for the pH of the

unfermented pulp. The presence of ethanol in the Malaysian and Nigerian pulps suggests that

fermentation may have commenced, either in the pod or during sample preparation. It would

therefore be advisable to obtain further samples of Malaysian cocoa pods to establish whether or

not the differences between Malaysian and West African pulp pH and citrate levels are

significant.

The cocoa pods obtained from the Ivory Coast, Nigeria and Malaysia were received within 3-5

days of harvesting, although the exact time ,interval was unknown. Dehydration of the pulp

occurs progressively after harvesting and the extent of this will inevitably affect the water content

and hence the absolute concentrations of all the other pulp components. When the pods from the

different origins were received their pulps appeared visually similar. The sample of Malaysian

cocoa pulp contained more water and less of certain plant cell wall polymers than the samples of

West African cocoa pulps. The water content of the Malaysian pulp was >3% higher and,

although the cellulose levels were similar, Malaysian pulp contained only 53% of the

hemicellulose/pectin/lignin content of the Ivorian pulp. In addition to the increased pulp to bean

ratio of Malaysian cocoa beans,15 a higher water content and lower concentration of plant

cell-wall polymers could affect the cocoa fermentation by excluding air, thereby creating more

anaerobic conditions than those attained with Amelonado cocoa beans. This may partially

account for the higher levels of lactate observed in Malaysian beans compared with West African

beans. Lactic acid bacteria grow better anaerobically or in the presence of increased CO2

concentrations. l6

Although the levels of total amino acids in all three types of pulp were similar, the free amino

acid:peptide plus protein amino acid ratio in Malaysian cocoa pulp was approximately twice that

of the West African pulps. This may have been partially due to age differences between the pods

308 G. L. Pettipher

of different origins. Aspartic acid, glutamic acid and asparagine were present in cocoa pulp at

high levels compared with other amino acids but they do not, as Forsyth8 suggests, account for

the total nitrogen content of the pulp.

The concentration of trace metals in Ivorian and Nigerian cocoa pulp was similar and

approximately 50% of that reported by Ni ~hol l s.~ Potassium accounted for the majority of the

metal ions in both pulps. Other than citrate, sulphate comprised the major anion, with lower

levels of chloride andlor phosphate.

The composite sample of Ivorian and Nigerian cocoa pulp contained all of the vitamins

included in the analysis. These vitamins were at levels suitable for microbial growth, with the

possible exception of strains requiring high levels of vitamins. Vitamin C accounted for ca 97% of

the total vitamin content of the pulp. The quantification of the vitamins may be an underestimate

as the effect of freeze drying on the stability of vitamins in cocoa pulp is unknown.

4.2. Defined cocoa pulp medium

The defined cocoa pulp medium has the same overall composition, pH, a, and viscosity as cocoa

pulp. The limited microbiological studies undertaken indicate that the defined cocoa pulp

medium is capable of supporting the growth of the micro-organisms important in cocoa

fermentations, namely yeasts, lactic acid bacteria and acetic acid bacteria. The composition of

the medium may need minor modifications to obtain good growth of some species. e.g. an

increased pH for certain lactobacilli. Improved growth of some species especially lactobacilli may be

expected if anaerobic or enriched C02 atmospheres are used.

The cocoa pulp medium contains some insoluble components, such as the locust bean gum and

glycerol monostearate. If the medium is not shaken continuously these ingredients form a bottom

and surface layer respectively. It is likely that these components could be omitted from the

medium to improve handling without having a detrimental effect on the growth of micro-

organisms. For detailed microbiological studies on nitrogen metabolism, it would be advisable to

replace the casein hydrolysate content of the medium with a defined mixture of amino acids

based on the analytical results obtained.

The formulation of the cocoa pulp medium given in Table 9 is based on the analysis of

unfermented cocoa pulp. It can be considered as the starting point for model systems for studying

the microbiological and biochemical aspects of cocoa fermentation. Microbiological studies may

for example, include the effect of temperature and oxygen on the growth of microorganisms,

competition experiments, succession of microorganisms, and the utilisation of fermentation

products. By varying the composition of the medium to mimic the pulp at various stages of cocoa

fermentation, e.g. reducing the concentration of sugars and citrate and adding lactic acid and

ethanol, the different stages of cocoa fermentation can be modelled. Biochemical studies may

entail the incubation of fresh cocoa beans in the cocoa pulp medium which, by means of a

fermenter type system, is progressively altered in composition to mimic the pulp at different

stages of fermentation. During this incubation the diffusion of the fermentation products into the

bean, changes in enzyme levels and activities and the development of chocolate flavour

precursors could be monitored. The development of the defined cocoa pulp medium described in

this report should facilitate both microbiological and biochemical laboratory studies of cocoa

fermentation.

Acknowledgements

The author wishes to acknowledge the help of the following: M. D. Conisbee for skilled technical

assistance; Cadbury Schweppes: Cocoa Buying Department, Bournville, for arranging the supply

of cocoa pods; Technical Services, Dollis Hill, for trace metal analyses; Carbohydrates

Department, Group Research, for mono- and disaccharide analyses; Biochemistry Department,

Group Research, for pectin analyses; Flavour Chemistry Department, Group Research, for

organic acid and anion analyses; Lipids Department, Group Research, for fat analyses. National

Analysis of cocoa pulp 309

Institute for Research in Dairying: Basic Ruminant Nutrition Department for carbohydrate and

amino acid analyses; Analytical Services for total nitrogen analyses. Harry Pritchard Laborator-

ies, Birkenhead, for vitamin analyses.

References

1.

2.

3.

4.

5 .

6.

7.

8.

9.

10.

11.

12

13

14.

15

16

Lehrian, D. W.; Patterson, G. R. Biotechnology Vol. 5 (Reed, G.. Ed.), Verlag Chemie GmhH, Weinheim, 1983, pp.

52g575.

Biehl, B.; Adomako, D. Fermentation of cocoa (control, acidification, proteolysis) Lebensmittelchem. Gerichtl. Chem.

1983, 37, 57-63.

Nicholls, L. The Fermentarion of Cocoa (Smith, H. H. , Ed.), Bale Sons and Danielsson Ltd, London, 1983, pp. 230.

Knapp, A. W. Cocoa Fermentation. A Critical Survey of it5 Scientific Aspects. Bale Sons and Cornow Ltd, London,

1937.

Quesnel, V. C. Cocoa curing. J. Agric. SOC. Trinidad and Tobago 1967, 67, 41-50.

Quesnel, V. C. Fermentation and drying of cocoa. 1. Agric. SOC. Trinidad and Tobago 1967, 67, 527-545.

Pakiyasothy, E. V.; J ansz, E. R.; Senanayake, U. M.; Wijesundara, R. C.; Wickremasinghe, P. Effect of maturity on

some chemical components of cocoa. J. Sci. Food Agric. 1981, 32, 873-876.

Forsyth, W. G. C. A method for studying the chemistry of cocoa fermentation. Nature, Lond. 1949, 164, 25-26.

McAllan, A. B.; Smith, R. H. Carbohydrate metabolism in the ruminant. Bacterial carbohydrates formed in the rumen

and their contribution to digesta entering the rumen. Br. J. Nutr. 1974, 31, 77-88.

Atkins, C. D.; Rouse, A. H. The effect of different methods of juicc extraction on the pectic content of Valecian

orange juice. Proc. Floridu Stare Horric. SOC. 1953, pp. 289.

Dische, Z. A new specific colour reaction of hexuronic acids. J . Biol. Chem. 1947, 167, 189.

Dietz, J . H.; Rouse, A. H. A rapid method for estimating pectic substances in citrus juices. Food Re5. 1953, 18, 169.

Mason, U. S. ; Bcch-Andersen, S. ; Rudemo, M. Hydrolysate preparation for amino acid determinations in feed

constituents, 8. Studies of oxidation conditions for streamlined procedures. Z . Tierphysiol. 1980, 43, 146-164.

Anon. Analytical Methods Manual. Leatherhead Food RA, 1984.

Carr, J . C.; Davies, P. A,; Dougan, J . Cocoa fermentation in Ghana and Malaysia. Part 1. Res. Rep. Univ. Bristol Res.

Star. Long Ashton, Bristol, 1979.

Sharpe, M. E. The prokaryates. A Handbook on Habitats, Isolation and Identification of Bacteria (Starr, M. P.; Stolp,

H.; Truper, H. G.; Balows, A,; Schlegel, H., Eds.), Springer-Verlag, Berlin, 1981, pp. 1653-1679.

Vous aimerez peut-être aussi

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Classic Lux ManualDocument17 pagesClassic Lux ManualChristianChávezRodríguezPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Personal para Tamizaje en Módulos H1, H2 y H3.3Document2 pagesPersonal para Tamizaje en Módulos H1, H2 y H3.3ChristianChávezRodríguezPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Ranchos Frios LiviguiDocument1 pageRanchos Frios LiviguiChristianChávezRodríguezPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Personal para Movilizar Al Hito 5.4Document4 pagesPersonal para Movilizar Al Hito 5.4ChristianChávezRodríguezPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- For Feedback or Requests DM Me On Twitter @litteeenDocument43 pagesFor Feedback or Requests DM Me On Twitter @litteeenChristianChávezRodríguezPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Sensors AN2 Methane and Carbon Dioxide Sensing For Anaerobic Digestion and Biogas ApplicationsDocument2 pagesSensors AN2 Methane and Carbon Dioxide Sensing For Anaerobic Digestion and Biogas ApplicationsChristianChávezRodríguezPas encore d'évaluation

- Pulse of Profession 2015Document28 pagesPulse of Profession 2015Gilbert ArguetaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Anaerobic Digesters DesignDocument13 pagesAnaerobic Digesters DesignChristianChávezRodríguezPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- UfroDocument1 pageUfroChristianChávezRodríguezPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Plantilla para Cortar La Sim Card A Nanosim o Microsim PDFDocument1 pagePlantilla para Cortar La Sim Card A Nanosim o Microsim PDFJuniorBasquezPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Prácticas IAESTE en AustraliaDocument1 pagePrácticas IAESTE en AustraliaChristianChávezRodríguezPas encore d'évaluation

- Announcement OAS Kookmin KGEB ProgramDocument6 pagesAnnouncement OAS Kookmin KGEB ProgramChristianChávezRodríguezPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Https WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFDocument1 pageHttps WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFZainab KhatoonPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Wi Cswip 3.1 Part 13Document7 pagesWi Cswip 3.1 Part 13Ramakrishnan AmbiSubbiahPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Daikin RXS-K - Technical DataDocument21 pagesDaikin RXS-K - Technical DataPrestoneKPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Maintenance Checklist: Macan/S/GTS/Turbo (2015-On)Document2 pagesMaintenance Checklist: Macan/S/GTS/Turbo (2015-On)edk34100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- 11.numerical DifferentiationDocument20 pages11.numerical DifferentiationAbdulselam AbdurahmanPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- NCERT: Why Is Steel More Elastic Than Rubber?Document7 pagesNCERT: Why Is Steel More Elastic Than Rubber?Satyam RaiPas encore d'évaluation

- TDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemDocument12 pagesTDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemKermess McPas encore d'évaluation

- Alkali MetalsDocument12 pagesAlkali MetalsSaki Sultana LizaPas encore d'évaluation

- Hospital Managemen T System: Oose LAB FileDocument62 pagesHospital Managemen T System: Oose LAB FileAASHPas encore d'évaluation

- General Physics1 Q2 W8 Module8 ThermodynamicsDocument23 pagesGeneral Physics1 Q2 W8 Module8 ThermodynamicsRegine Ann ViloriaPas encore d'évaluation

- AC axial compact fan technical specificationsDocument5 pagesAC axial compact fan technical specificationsdhanasekhar27Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- CC5291-Design For Manufacture Assembly and Environments QBDocument11 pagesCC5291-Design For Manufacture Assembly and Environments QBYuvaraj Yuvi0% (1)

- Virtual Retinal DisplayDocument17 pagesVirtual Retinal Displaysaket_mnPas encore d'évaluation

- Treatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationDocument8 pagesTreatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationAnonymous ZAr1RKPas encore d'évaluation

- SQL SlidesDocument65 pagesSQL SlidescopsamostoPas encore d'évaluation

- Smart Card/Proximity Based Vehicle Identification & Access Control SystemDocument4 pagesSmart Card/Proximity Based Vehicle Identification & Access Control SystemkarunamoorthiPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Acids and Bases NotesDocument17 pagesAcids and Bases NotesNap DoPas encore d'évaluation

- B. Solving Quadratic EquationsDocument23 pagesB. Solving Quadratic EquationsHasnain -GamerPas encore d'évaluation

- Cylindrical Plug Gage DesignsDocument3 pagesCylindrical Plug Gage DesignskkphadnisPas encore d'évaluation

- A Git Cheat Sheet (Git Command Reference) - A Git Cheat Sheet and Command ReferenceDocument14 pagesA Git Cheat Sheet (Git Command Reference) - A Git Cheat Sheet and Command ReferenceMohd AzahariPas encore d'évaluation

- List of Practical Cs With SolutionDocument57 pagesList of Practical Cs With SolutionArjun KalaPas encore d'évaluation

- IJETR032052Document6 pagesIJETR032052erpublicationPas encore d'évaluation

- Homework1 PDFDocument3 pagesHomework1 PDFYuanhao LiuPas encore d'évaluation

- Oracle Coherence Admin GuideDocument156 pagesOracle Coherence Admin Guidegisharoy100% (1)

- Lubricants For Cement ProductionDocument21 pagesLubricants For Cement Productiongrameshkreddy2013100% (1)

- LEARNING GUIDE-spreadsheet (Repaired)Document53 pagesLEARNING GUIDE-spreadsheet (Repaired)Abel ZegeyePas encore d'évaluation

- Arm Assembly Language ProgrammingDocument170 pagesArm Assembly Language ProgrammingAnup Kumar Yadav100% (4)

- Visual Studio Add-Ins SuccinctlyDocument124 pagesVisual Studio Add-Ins SuccinctlyJosias GonzálezPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Methodology of Event StudiesDocument4 pagesMethodology of Event Studieshaichellam5577Pas encore d'évaluation

- Is 14416 1996Document20 pagesIs 14416 1996kaustavPas encore d'évaluation